Pressure Vessel Design: Methanator Analysis Table of Contents

advertisement

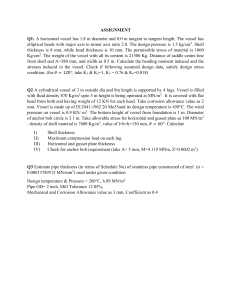

TABLE OF CONTENTS

S. NO

TITLE

PAGE

NO

1.

INTRODUCTION TO PRESSURE VESSELS

4

1.1.

BASIC TERMINOLOGIES USED

1.2

CYLINDERS AND SPHERS

2.

5

19

ANALYTICAL DESIGN OF METHANATOR

26

2.1

GIVEN DATA

28

2.2

REQUIRED DIMENTIONS OF METHANATOR

29

2.3

METHANATOR AS A THIN CYLINDER

2.4

THICKNESS OF SHELL

30

32

2.5

THICKNESS OF 2:1 ELLIPSOIDAL HEAD

34

2.6

OPENING IN THE PRESSURE VESSELS

35

2.7

SELECTION OF FLANGES

37

2.8

THICKNESS OF SKIRT OR DESIGN OF SUPPORTS

39

2.9

LOADINGS

44

2.10

STRESSES IN RESPONSE TO DIFFERENT LOADS

45

a) INTERNAL PRESSURE

45

1

b) WEIGHT

46

c) WIND LOAD

49

d) SEISMIC LOAD

54

2.11

COMBINATION OF STRESSES

57

2.12

COMPARISION

58

2.13

DESIGN OF ANCHOR BOLTS

58

2.14

WELDING OF PRESSURE VESSELS

62

3.

ANALYSIS BY ANSYS

67

3.1

ANSYS

68

3.2

ANSYS INPUT METHODS

69

3.3

SHELL 51

70

3.4

ANALYSIS OF METHANATOR UNDER INTERNAL PRESSURE

USING SHELL 51

71

3.5

ANALYSIS OF METHANATOR TO COMMAND WINDOW

72

3.6

ANALYSIS OF METHANATOR THROUGH GUI

72

3.7

TO FIND THE HOOP AND LONGITUDINAL STRESS ON ANSYS

88

3.8

DISPLACEMENTS OF NODES

91

4.

COMARISION AND CONCLUSION

92

4.1

MEMBRENE STRESSE IN METHANATOR

93

4.2

COMARISION OF ANSYS AND ANALYTICAL SOLUTION

94

4.3

CONCLUSION

96

REFERENCES------------------------------------------------------------

2

TABLES --------------------------------------------------------------------

3

INTRODUCTION

TO

PRESSUREVESSEL

S

4

1.1

BASIC TERIMINOLOGIES USED

VESSEL:

A container or structural envelope in which materials are processed,

treated, or stored; for example, pressure vessel, reactor vessel, agitator

vessel, and storage vessels (tanks).

PRESSURE VESSEL:

A metal container generally cylindrical or spheroid, capable or

withstanding various loadings.

STRAIN:

Any forced change in the dimensions of a body. A stretch is a tensile

strain; a shortening is a compressive strain; an angular distortion is a shear

strain. The word strain is commonly used to connote unit strain.

STRESS:

Internal force exerted by either of two adjacent parts of a body upon

the other across an imagined plane of separation. When the forces are

parallel to the plane, the stress is called shear stress; when the forces are

normal to the plane the stress is called normal stress; when the normal stress

is directed toward the part on which it acts is called compressive stress;

when it is directed away from the part on which it acts it is called tensile

stress.

5

STRESSES IN PRESSURE VESSEL:

• Longitudinal S1 stress.

• Circumferential (hoop) S2 stress.

S1 and S2 called membrane (diaphragm) stress

For vessel having a figure of revolution

Bending stress

Shear stress

Discontinuity stress at an abrupt change in thickness or

Shape of the vessel

TENSILE STRENGTH:

The maximum stress a material subjected to a stretching load can

withstand without tearing.

TENSILE STRESS:

Stress developed by a material bearing tensile load.

TEST PRESSURE:

The requirements for determining the test pressure based on

calculations are out lined in UG-99(c) for the hydrostatic test and UG-100(b)

for the pneumatic test. The basis for calculated test pressure in either of

these paragraphs is the highest permissible internal pressure as determined

by the design formulas, for each element of the vessel using nominal

thickness with corrosion allowances included and using the allowable stress

values for the temperature of the test. (Code UA-60)

6

THERMAL STRESS:

A self-balancing stress produced by a non uniform distribution of

temperature or by differing thermal coefficients of expansion. Thermal stress

developed in a solid body whenever a volume of material is prevented from

assuming the size and shape that it normally should under a change in

temperature.

THICKNESS OF VESSEL WALL:

1. The “required thickness” is that computed by the formulas in this

division, before corrosion allowance is added.

2. The “design thickness” is the sum of the required thickness and the

corrosion allowance.

3. The “nominal thickness” is the thickness selected as commercially

available, and as supplied to the manufacturer; it may exceed the

design thickness.

UNIT STRAIN:

Unit tensile strain is the elongation per unit length; unit compressive

strain is the shortening per unit length; unit shear strain is the change in

angle (radians) between two lines originally at right angles to each other.

UNIT STRESS:

The amount of stress per unit of area.

WELD METAL:

The metal resulting from the fusion of base metal and the filler metal.

7

WELDING:

The metal joining process in making welds.

In the construction of vessels the welding process is restricted by the

code (UW-27) as follows;

1. Shielded metal arc, submerged arc, gas metal arc, gas tungsten arc,

atomic hydrogen metal arc, oxy fuel gas welding, electroslag, and

electron beam.

2. Pressure welding process: flash, induction, resistance, pressure

Thermit, and pressure gas.

YIELD POINT:

The lowest stress at which strain increases without increase in stress.

For some purpose it is important to distinguish between the upper yield

point, which is the stress at which stress-stain curve first become horizontal,

and the lower yield point, which is the somewhat lower and almost constant

stress under which the metal continues to deform. Only a few materials

exhibit a true yield point; for some materials the term is sometimes used as

synonymous with yield strength.

SPECIFIC GRAVITY:

The ratio of the density of a material to the density of some standard

material, such as water at a specified temperature, for example, 4°C or 60°F.

Or (for gases) air at standard conditions of pressure and temperature.

8

STABILITY OF VESSEL:

(Elastic stability) The strength of the vessel to resist buckling or

wrinkling due to axial compressive stress. The stability of a vessel is

severely affected by out of roundness.

SHELL:

Structural element made to enclose some space. Most of the shells are

generated by the revolution of plane curve.

SHEAR STRESS:

The component of the stress tangent to the plane of reference.

RADIUS OF GYRATION:

The radius of gyration of an area with respect to given axis is the

square root of the quantity obtained by dividing the moment of inertia of the

area with respect to that axis by the area.

RESIDUAL STRESS:

Stress remaining in a structure or member as a result of thermal or

mechanical treatment, or both.

RESISTANCE WELDING:

A pressure welding process wherein the heat is produced by the

resistance to the flow of an electric current.

9

SECONDARY STRESS:

A normal stress or a shear stress developed by the constraint of

adjacent parts or by self-constraint of a structure. The basic characteristic of

a secondary stress is that it is self-limiting. Local yielding and minor

distortions can satisfy the conditions which cause the stress to occur and

failure from one application of the stress is not to be expected. Examples of

secondary stress are: general thermal stress; bending stress at a gross

structural discontinuity.

POISSONS’RATIO:

The ratio of lateral unit strain to longitudinal unit strain, under the

conditions of uniform and uniaxial longitudinal stress within the

proportional limit.

POSTWELD HEAT TREATMENT:

Heating a vessel to a sufficient temperature to relieve the residual

stresses which are the result of mechanical treatment and welding.

Pressure vessels and parts shall be post weld heat treated.

PREHEATING:

Heat applied to base metal prior to welding operations.

PRESSURE RELIEF VALVE:

A valve which relieves pressure beyond a specified limit and recluses

upon return to normal operating conditions.

10

PRESSURE WELDING:

A group of welding processes wherein the weld is completed by use

of pressure.

PRIMARY STRESS:

A normal or shear stress developed by the imposed loading which is

necessary to satisfy the simple laws of equilibrium of external and internal

forces and moments. The basic characteristic of a primary stress is that it is

not self-limiting. Primary stresses which considerably exceed the yield

strength will result in failure or at least, in gross distortion. A thermal stress

is not classified as primary stress. Primary membrane stress is divided into

local and general categories. A general primary membrane stress is one

which is so disturbed in the structure no redistribution of load occurs as a

result of yielding. Examples of primary stress are: general membrane in a

circular cylindrical or a spherical shell due to internal pressure or to

distributed live load; bending stress in the central portion of a flat head due

to pressure.

OPERATING PRESSURE:

The pressure at the top of a vessel at which it normally operates. It

shall not exceed the maximum allowable working pressure and it is usually

kept at a suitable level below the setting of the pressure relieving devices to

prevent their frequent opening. (Code UA-60)

OPERATING TEMPERATURE:

The temperature that will be maintained in the metal of the part of the

vessel being considered for the specified operation of the vessel. (Code UA60)

11

NEUTRAL AXIS:

The line of zero fiber stress in any given section of a member subject

to bending; it is the line formed by the intersection of the neutral surface and

the section.

MOMENT OF INERTIA OF AN AREA (SECOND MOMENT OF AN

AREA)

The moment of inertia of an area with respect to an axis is the sum of

the products obtained by multiplying each element of the area by the square

of its distance from the axis. The moment of inertia (I) for thin walled

cylinder about its transverse axis; I = Π r3 t

Where

r = mean radius of cylinder

t = wall thickness

MODULUS OF ELASTICITY (YOUNG’S MODULUS):

The rate of change of unit tensile or compressive stress with respect

to unit tensile or compressive strain for the condition of uniaxial stress

within the proportional limit. For most, but not all materials, the modulus of

elasticity is same for tension and compression. For nonisotropic materials

12

such as wood, it is necessary to distinguish moduli of elasticity in different

directions.

MODULUS OF RIGIDITY:

The rate of change of unit shear stress with respect to unit shear strain,

for the condition of pure shear within the proportional limit.

MAXIMUM ALLOWABLE STRESS VALUE:

The maximum unit stress permissible for any specific material that

may be used in the design formulas given in the code. (UG-23)

MAXIMUM ALLOWABLE WORKING PRESSURE:

The maximum gage pressure permissible at the top of a completed

vessel in its operating position for a designed temperature. This pressure is

based on the weakest element of the vessel using nominal thickness

exclusives of allowances for corrosion and thickness required for loading

other than pressure. (Code UA-60)

MEMBRANE STRESS:

The component of normal stress which is uniform ally distributed and

equal to the average value of stress across the thickness of the section under

consideration.

ISOTROPIC:

Having same properties in all directions. In discussion pertaining to

strength of materials, isotropic usually means having the same strength and

elastic properties.

13

JOINT EFFICIENCY:

A numerical value expressed as the ratio of the strength of a riveted,

welded, or braze joint to the strength of the parent metal.

LOADING:

Loading (loads) are the results of various forces. The loadings to be

considered in designing a vessel : internal or external pressure, impact loads,

weight of the vessel, wind and earthquake, superimposed loads, local load,

effect of temperature gradients.(Code UG-22).

LOW-ALLOY STEEL:

A harden able carbon steel generally containing not more than about

1% carbon and one or more of the following components; ‹ (less than) 2%

manganese, ‹ 4%nickel, ‹ 2%chromium, 0.6% molybdenum, and

‹ 0.2%vanadium.

HEAT TREATMENT:

Heat treating operation performed either to produce changes in

mechanical properties of the material or to restore its maximum corrosion

resistance. There are three principle types of heat treatment; annealing,

normalizing, and post weld heat treatment

.

HYDROSTATIC TEST:

The completed vessel filled with water shall be subjected to test

pressure which is equal to 1 ½ times the maximum allowable working

14

pressure to be marked on the vessel or 1 ½ the design pressure by

agreement between the user and the manufacturer. (Code UG-99)

IMPACT STRESS:

Force per unit area imposed to a material by a suddenly applied force.

IMPACT TEST:

Determination of the degree of resistance of a material to breaking by

impact, under bending, tensile and torsion loads, the energy absorbed is

measured by breaking the material by a single blow.

GAGE PRESSURE:

The amount by which the total absolute pressure exceeds the ambient

atmospheric pressure.

FILLER METAL:

Material to be added in making a weld.

FIBER STRESS:

A term used for convenience to denote the longitudinal tensile or

compressive stress in a beam or other member subject to bending. It is

sometimes used to denote this stress at the point or points most remote from

the neutral axis, but the term stress in extreme fiber is preferable for this

purpose. Also, for convenience, the longitudinal elements or filaments of

which a beam may be imagined as composed are called fibers.

15

FACTOR OF SAFETY:

The ratio of the load that would cuse a failure of a member or

structure, to the load that is imposed upon it in service.

FATIGUE:

Tendency of materials to fracture under many repetitions of a stress

considerably less than the ultimate static strength.

ECENTRICITY:

A load or component of a load normal to a given cross section of a

member is eccentric with respect to that section if it does not act through

centroid.The perpendicular distance from the line of action of the load to

either of principle central axis is the eccentricity with respect to that axis.

EFFICIENCY OF A WELDED JOINT:

The efficiency of the welded joint is expressed as a numerical quantity

and is used in the design of a joint as a multiplier of the appropriate

allowable stress value. (Code UA-60)

ELASTIC:

Capable of sustaining stress without permanent deformation; the term

is also used to denote conformity to the law stress-strain proportionality. An

elastic stress or elastic strain is a stress or strain within the elastic limit.

16

ELASTIC LIMIT:

The least stress that will cause permanent set.

DESIGN PRESSURE:

The pressure used in determining the minimum permissible thickness

or physical characteristics of the different parts of the vessel. (Code UG-60)

DESIGN TEMPERATURE:

The mean metal temperature (through the thickness) expected under

operating conditions for the part considered. (Code UG-20)

CREEP:

Continuous increase in deformation under constant or decreasing

stress. The term is usually with reference to the behavior of metal under

tension at elevated temperatures. The similar yielding of a material under

compressive stress is usually called plastic flow or flow.

CORROSION:

Chemical erosion by motionless or moving agents. Gradual

destruction of a metal or alloy due to chemical process such as oxidation or

action of a chemical agent.

CLAD VESSEL:

A vessel made from plate having a corrosion resistant material

integrally bonded to a base of a less resistant material. (Code UA-60)

17

ALLOY:

Any of a large no. of substances having metallic properties consisting

of two or more elements; with few exceptions, the components are usually

metallic elements.

18

1.2

CYLINDERS AND SPHERES:

Vessels such as steam boilers, air compressors, storage tanks,

accumulators and large pipes are subjected to internal fluid pressure which is

uniformly distributed. All the above mentioned vessels are classified as

cylinders or spheres.

THIN CYLINDER:

If the ratio of the thickness to the internal diameter i.e. t/d is less than

about 1/20, the cylinder is assumed to be thin cylinder.

THICK CYLINDER:

If the ratio of thickness to the internal diameter i.e. t/d is greater than

1/20, the cylinder is assumed to be thick cylinder.

STRESSES IN CYLINDERS:

The following stresses are illustrated in fig. (1) and fig. (2)

CIRCUMFERENTIAL OR HOOP STRESS:

The stress which acts tangent to the circumference and perpendicular

to the axis of the cylinder is called circumferential or hoop stress. It is

denoted by fh.

19

LONGITUDINAL STRESS:

The stress which acts normal to circumference and parallel to the axis

of the cylinder is called longitudinal stress. It is denoted by fl.

RADIAL STRESS:

The stress which acts in a direction perpendicular to the internal

surface is called radial stress. It is denoted by fr. Radial stress is very small

as compared to fl and fh in case of thin cylinder and is therefore ignored.

20

ANALYSIS OF THIN CYLINDER:

Consider the equilibrium of half cylinder of length ‘L’ sectioned

through a diameteral plane as shown in fig, (3)

Let the internal diameter be‘d’ and the thickness ‘t’; ‘p’ is the applied

internal pressure, fh the hoop stress and fl the longitudinal stress.

HOOP STRESS:

Consider the elemental ring of the cylinder subtending an angle δθ.

Let ds = arc length of elemental ring = r.

Force acting on elemental ring = p *area

= prδθL

Vertical component of this force = prδθL Sinθ

Total vertical force =prL 0∫180Sinθδθ

= -prl (cos 180 – Cos 0) = 2prL

= pdL

eq.(1)

But

dL = horizontal projected area.

21

So

Total vertical force = pdL = intensity of pressure * horizontal

projected area.

This force tries to burst the cylinder into two halves and is called

‘bursting force’.

Bursting force

= F = pdL

Resisting force

= stress * resisting area

And

= fh * 2tL

For equilibrium of cylinder

Bursting force = Resisting force

pdL

fh

= fh*2tL

= pd/2t

eq.(A)

LONGTUDINAL STRESS:

Cross sectional area =Π /4 d2

Total force at the end of cylinder = p* Π/4 d2

This force tries to burst the cylinder at the ends of cylinder and is

called ‘bursting force’.

Bursting force = F = p* Π/4 d2

Resisting force

= stress * resisting area

= fl* Πdt

for equilibrium of cylinder

Bursting force = resisting force

P* Π/4 d2 = fl* Πdt

22

Fl = pd/4t

eq. (B)

Comparing (A) and (B)

Fl =1/2 fh

THIN SPHERICAL SHELL:

In case of spherical shell also, the radial stress will be neglected and

the circumferential or hoop stress will be assumed to be constant.

As shown in the fig. the two stresses are equal to due to symmetry. i.e.

fh = f l = f

Cross-sectional area = Π /4d2

Bursting force

= p* Π /4d2

Resisting force

= stress * resisting area

= f * dt

For equilibrium of shell

Bursting force = resisting force

P * Π /4d2 = f * dt

f

= pd/4t

23

CYLINDERICAL SHELL WITH HEMISPHERICAL ENDS:

As shown in the fig. let t1 be the thickness of the cylinder and t2 be the

thickness of the hemisphere, the internal diameter being assumed the same

for both.

STRESSES IN THE CYLINDERICAL PORTION:

If the shell is subjected to an internal pressure p, stresses in the

cylinder will be;

Hoop stress, fh = pd/2t1

And

Longitudinal stress, fl =pd/4t1

Hoop strain,Єh = fh/E – ν fl/E = 1/E (fh – ν fl)

=1/E (pd/2t1 - pd/4t1) = 1/E ((2pd - pd/4t1))

Єh

= pd/4t1E (2 - ν)

Longitudinal strain, Єl = fl/E - fh/E = pd/4t1E - pd/2t1

Єl

= pd/4t1E (1 – 2ν)

24

STRESSES IN THE SPHRICAL PORTION:

For the hemispherical ends having thickness t2, we have

fh΄ = fl΄ = f = pd/4t2

Therefore, hoop stress, fh = pd/4t2

And

Longitudinal stress, fl = pd/4t2

Then

Hoop strain, Єh΄ = fh/E – fl/E = pd/4t2E – pd/4t2E

Єh΄ = pd/4t2E (1 -ν)

Longitudinal strain,Є l΄ = fl΄/E - ν fh΄/E = pd/4t2E - νpd/4t2E

Єl ΄ = pd/4t2E (1 -ν)

Therefore for spherical portion

Єh΄ = Єl΄

At the junction of cylindrical and spherical portion

Єh = Єh΄

Pd/4t1E (2 -ν) = pd/4t2E (1 -ν)

t2/t1 = (1 -ν )/(2 -ν )

for steel,= 0.3

Therefore,

t2/t1 = 7/17

The maximum hoop stress will then occur in the ends, i.e.

f = pd/4t2 = (17/7) (pd/4t1)

Which is greater than the hoop stress fh in the cylinder. For equal maximum

stress t2 should equal to 0.5.

25

ANALYTICAL DESIGN

OF METHANATOR

26

2.1 GIVEN DATA

PARAMETETS:27

Working temperature = 364 °C

Design temperature = 454 °C

Working pressure = 380 Psi.g

Design pressure = 435 Psi.g

DIMENSIONS:Inside diameter = 102" = 2590.8 mm

Tangent to tangent length = 150" = 3810mm

Type of dished ends = 2:1 semi ellipsoidal

Hydrostatic test pressure = 806 Psi.g

Welded joint efficiency = 100 %

Corrosion allowance = 1.6 mm

MATERIAL:ASTM

A387 G11

CODE RECOMMENDED

ASME

Section 8 division 1

28

2.2 REQUIRED DIMENSIONS OF

METHANATOR

The quantities or dimensions that are to be determined for designing are

listed below

I

Thickness of shell

(according to UG -27(c))

II

Thickness of 2:1 semi ellipsoidal head (according to UG-32(d))

III

Openings in the pressure vessel as per requirement (according to

UG-36 (b) (1) (2))

IV

Selection of flanges (according to UG-44 & UG-11 (a) (2))

V

Thickness of skirt or design of supports.(according to UG-54 &

appendix G)

VI

VII

VIII

IX

X

XI

XII

XIII

Specify different kinds of loads (UG-22)

Find stresses in response to different loads.

Combination of stresses.

Comparison of stresses with allowable stress of material.

Openings in skirt

Design of anchor bolts

Design of base ring.

Welding specification for Methanator

29

2.3 METHANATOR AS A THIN

CYLINDER

As we know that if the ratio of thickness to internal diameter i.e. t/d is less

than about 1/20 (0.05), the cylinder is assumed to be thin cylinder otherwise

it would be thick.

For methanator this ratio will be

t/d = 1.438/102 = 0.014

< 0.05

So we treat methanator as thin cylinder

So incase of methanator the radial stresses can be neglected. And there will

be only circumferential or hoop stress & longitudinal stress in the

methanator. Further the governing stress will be the greater of the two & we

base our design on it.

30

31

2.4 THICKNESS OF SHELL

According to specifications in UG-27 (c) which deals with the thickness of

shells under internal pressure and clause “c” with the cylindrical shells,

gives formulae for the thickness based on either longitudinal joint or

circumferential joint.

a) CIRCUMFERNTIAL STRESS (LONGITUDINAL JOINTS)

It means that the governing stress will be the

circumferential stress (hoop stress) in the long seam. For this it has to satisfy

that P does not exceed 0.385SE .In which case we shall use the following

formulae for thickness of shell

t=

PR/ (SE -0.6P)

b) LONGITUDINAL STRESS (CIRUMFERENTIAL JOINTS)

It means that the governing stress will be the longitudinal

stress in the circumferential joint. For this it has to satisfy that P does not

exceed 1.25SE. OR if the circumferential joint efficiency is less than than ½

the longitudinal joint efficiency. In which case we use the formula for

thickness is

t = PR/ (2SE +.4P)

As for methanator

P < 0.385SE

32

435 < 0.385(16394.966) (1.0)

435 < 6312.06

Satisfied

therefore hoop stress will be governing therefore design is based on the

longitudinal joint & we find the thickness as follows

t = PR / (SE – 0.6P)

Where

t = min. required thickness of shell, in

P = internal design pressure, psi

R = inside radius of shell, in

S = max. Allowable stress, psi

E = joint efficiency (min)

Putting the values in the above equation for methanator.

Allowable stress for the material to be used is also given (16394.966 psi)

t = (435) (51) / ((16394.966) (1.0) – (0.6) (435))

t = 1.375"

t = 1.375" + corrosion allowance

t = 34.9 + 1.6

mm

t = 36.5 mm

t = 1.4387"

we shall take a plate of 1 ½" for safety

33

2.5 THICKNESS OF 2:1

ELLIPSOIDAL HEAD

It will be found by UG-32 (d) which states

The required thickness of a dished head of semi ellipsoidal form, in

which half the minor axis (inside depth of the head minus the skirt)equals

one-forth of the inside diameter of the head skirt, shall be determined by

t = PD / (2SE – 0.2P)

An acceptable approximation of a 2: 1 Ellipsoidal head is one with a knuckle

radius of 0.17D and a spherical radius of 0.90D.

For methanator

t = (435) (102) / (2(16394.966) (1.0) – (0.2) (435))

t = 1.3567" + corrosion allowance

t = 1.3567" + (1.6 * 0.394")

t = 1.4197"

34

Knuckle radius = 0.17D = 17.34"

Spherical radius = 0.90D = 91.8"

Where

D = internal diameter in inches

2.6 OPENINGS IN A PRESSURE VESSEL

The clause of the code concerning with the design of openings is UG-36(a)

(b)

a) shape of openings

1) Openings in cylindrical or conical portions of vessels, or in formed

heads, shall preferably be circular, elliptical or round opening exceeds twice

the short dimensions, the reinforcement across the short dimensions shall be

increased as necessary to provide against excessive distortion due to twisting

moment.(The opening made by a pipe or a circular nozzle, the axis of which

is not perpendicular to the vessel wall or head, may be considered as

elliptical opening of design purposes)

35

2) Openings may be of other shapes than those given in (1) above, and all

corners shall be provided with a suitable radius. When the openings are of

such proportions that their strength cannot be computed with assurance of

accuracy, or when doubt exists as to the safety of a vessel with such

openings, the part of the vessel affected shall be subjected to a proof

hydrostatic test as prescribed in UG-101.

b) size of openings

1) Properly reinforced openings in cylindrical shells are not limited as to

size except with the following provisions for design. The rules in UG-36

through UG-43 apply to openings not exceeding the following: for vessels

60 in. in diameter and less, one half vessel diameter, but not to exceed 20

in.; for vessel over 60 in. in diameter, one third the vessel diameter, but not

to exceed 40 in. For openings exceeding these limits, supplement rules of 17 shall be satisfied in addition to UG-36 through UG-43.

2) Properly reinforced openings in formed heads and spherical shells are

not limited in size. For an opening in end closure, which is larger than one

half of inside diameter of the shell, various alternatives to reinforcement

may also be used.

FOR METHANATOR

As we know that openings in a vessel are made as per requirement, but the

the factor to be considered in is its size, which will require various degrees

of reinforcements as stated above.

36

As there are five openings in the methanator all of them are in its heads.

Two of them are elliptical & three are circular.

As for methanator there is the maximum opening is of size 24" &

24 < 1/3(102)

24 < 34 to40

So we use UG-36 for opening.

2.7 SELECTION OF FLANGES

We know that openings of size 2.5" or larger shall be flanged & we shall use

flanges with raised face.

For methanator , all the flanges would be of rating 600lb which are selected

from the pressure-temperature rating (ANSI B16.5-1981) For design

pressure of 435 psi.g & design temperature of 806°F, which will be rounded

off to 850F & 535psi.g table attached.

Other specification of the flanges according to their pipe sizes are given

(high lighted) for 600lb flanges in the table attached.

37

LENGTH OF STUD BOLTS

38

2.8 THICKNESS OF SKIRT OR DESIGN OF

SUPPORTS

A skirt is the most frequently used and the most satisfactory support for

vertical vessels. It is attached by continuous welding to the head and usually

the required size of this welding determines the thickness of the skirt.

39

Figures A and B show the most common type of skirt to head attachment. In

calculations of the required weld size, the values of the joint efficiency given

by the Code (UW 12) may be used.(UG-54 &APPENDIX G)

t = 12 MT / R2* Π *SE + W / DΠSE

Where

D = Outside diameter of skirt, in

E = efficiency of skirt to head joint.

(0.6 for butt weld, fig A, 0.45 for lap weld, fig. B)

MT = moment at skirt to head joint, ft. lb

R = outside radius of skirt, in

S = stress value of the head or skirt material whichever is

smaller, psi

t = required thickness of skirt, in

W = weight of tower above the skirt to head joint, in

operating condition. lb

NOTE:-

40

Using extremely high skirt, the stresses at the base may govern. To calculate

the required thickness of skirt, in this case the above formula can be used.

The moment and weight shall be taken into consideration at the base and

joint efficiency will be taken as 1.0.

For methanator the weight of the vessel used is as approximated later. And

we are taking into account the moments due to two forces firstly due to

earthquake

And secondly due to wind. Whichever is greater should be used.

As the moment at the skirt to head joint due to seismic load is greater as

indicated by the calculations later. so we shall use M due to earthquake

FOR METHANATOR

D = 104.875"

E = 0.6

MT= 76059.58 lbft

R = 52.438"

S = 16394.966 lbft

t =?

W = 41877.676 lb

So minimum thickness of skirt

t = 12*76059.58 / 52.4382*3.14*16394.966*.6

} earthquake

+

41877.676 / 104.875*3.14*16394.966*0.6

} weight

t = 0.01074 + 0.01292

t = 0.02366"

41

The above calculations are from the “Pressure vessel hand book by

Megyesy”

To verify our calculations we also used the formula from another book of

“Dennis R. Moss”these calculations are as under

THICKNESS REQUIRED AT OPENING OF SKIRT

There are five openings in the methanator skirt but the biggest opening is of

24" in dia. Therefore the design is based on this opening

G = width of opening in inches = 24"

D = width of skirt = 104.875"

Mb= moment at base, in-lb = 79327.3986 lbft (earthquake)

Wb=weight of vessel at base, lb = 41877.676lb

Fy = minimum specific yield strength, psi = 34988.435psi

fb = bending stress, psi = ?

fb = 1 / (ΠD-3G) * [48Mb/D + Wb]

Now after putting the values in above formula & solving we get the value of

bending stress as follows

fb = 1852.9475 psi

Now the thickness of skirt can be found by two formulae the greater of the

two values must be taken

42

tsk = fb/ 8*Fy = 1852.9475 / 8*34988.435

tsk = 6.6E-6

OR

tsk = (fb / 4640,000)1/2

tsk = 0.019"

The greater value should be taken.(0.019)

Which nearly equal to the thickness found earlier

DETERMINE ALLOWABLE LONGITUDANAL STRESSES:TENSION,

St = lesser of 0.6Fy or 1.33S

St = 0.6Fy

St

or

St = 1.33S

= 0.6*34988.435

= 1.33* 16394.966

= 20993.06

= 21805.304

COMPRESSION,

Sc = 0.333Fy

= 0.333*34988.435

or

= 1.33S (whichever is less)

or

= 21805.304

S = 11651.148

THICKNESS REQUIRED AT BASE DUE TO Mb:43

LONGITUDINAL FORCES

Flt = [48*Mb / Π*D2] – [Wb / Π* D]

Flt = 1323.037 – 127.168

Flt = 1195.868 lb/in

Flc = (-) {Flt}

Flc = - 1450.205 lb/in

Therefore skirt thickness req. at base

t sk = Flt/ St

OR

= Flc / Sc

= 1195.868 / 20993.06

OR

= 1450.205 / 11651.148

= 0.056"

OR

= 0.12"

The greater of the two values is taken i.e. 0.12"

2.9 METHANATOR IS TO BE SUBJECTED TO THE

FOLOWING KINDS OF LOADINGS

From the list of the loadings on a pressure vessel given in UG-22,

methanator is liable to be subjected to the following loads.

Internal pressure

44

Weight of the vessel and normal contents under operating or test

conditions(this includes additional pressure due to static head of

liquids)

Weights of various attachments

Wind & seismic reactions

2.10 STRESSES IN RESPONSE TO DIFFERENT LOADS

a) DUE TO INTERNAL PRESSURE

As we are treating methanator as a thin cylinder so the values of hoop

stress & longitudinal stress are calculated as under

Therefore radial stresses are ignored (very small) so we consider the

following primary membrane stresses.

Hoop Stresses

Longitudinal Stresses

HOOP STRESSES (S 1)

Fh = Pd /2t

= (435) (102) / 2(1.4381)

= 15426.6 lb/in2

LONGITUDINAL STRESS (S 2)

45

Fl

= Pd / 4t

= (435) (102) / 4(1.4381)

= 7713.302 lb / in2

As hoop stress is greater so design is based on hoop stress.

b) STRESS DUE TO WEIGHT OF VESSEL &

ATTACHMENTS

It is assumed that weight of the vessel and its attachments results in

compressive stress only & eccentricity doesn’t exists and the resulting force

coincides with the axis of the vessel.

The weight shall be calculated for the various conditions of the tower as

follows.

A. Erection weight

B. Operating weight

C. Test weight

The compressive stress due to the weight is given by

S = W / ct

--------------------------------------------- (a)

Where

S = unit stress, psi

W = weight of vessel above the section under consideration, lb

c = circumference of shell or skirt on the mean diameter, in

t = thickness of shell or skirt, in

The weights of different vessel elements are given in the tables attached.

WEIGHT OF METHANATOR

46

A) ERECTION WEIGHT

1) SHELL=1588*12.5(TTL) =19850 lb

2) SEMI ELLIPSOIDAL HEADS = 5553*2 =11106 lb

3) FLANGES (6) = F# (SIZE) = wt. of weld neck +wt. of slip on

+studs

• A (24") = 977 + 876 + 365

• Aa (12") = 226 (W N)

• AT & BT (2") = 4(10) + 2(4.5)

{W.N + STUDS}

• B (12") = 226 (WN)

• C (6") = 73+86+30

TOTAL WEIGHT OF 6 FLANGES = 2908 lb

4) PIPES (assuming SCH. 160)

Elbow (12") =450lb

2 pipes (1½") = 2*4.9 lb/ft * 16'

Pipe (2")

Pipe

= 7.5 lb/ft * (9/12)'

(6") = 45.3 * (105/12)'

TOTAL WEIGHT DUE TO PIPES & ELBOW = 1008.775 lb

5) PLATES

(There are 4 plates in the methanator upper manhole & which

are 4" wide & ½" thick & also 3' long)

Weight of one plate = 6.80*3

Weight of 4 plates = 20.4*4 = 81.6 lb.

47

6) INSULATION

(We shall use an insulation of mineral wool of thickness 2½".

The weight of insulation given in the table is in pounds per cubic feet so in

order to get the weight of insulation we will have to calculate the volume of

insulation to be used on methanator. For that we will 1st have to find the

circumference of the vessel based on external diameter.

Volume of insulation on shell = TTL + circumference + thickness

=

12.5' + Π * Do + 0.2083'

=

12.5 + 27.44 +0.2083

=

71.4469.ft3

Volume of insulation on the heads = 1.09 * D2 *thickness *2

= 1.09 * 8.739^2*0.2083*2

= 34.6838 ft3

TOTAL VOLUME OF INSULATION TO BE USED ON THE

METHANATOR = 106.1307’ ~ 110 ft3

Therefore

TOTAL WEGHT OF INSULATION (MINERAL WHOOL) = 80lb/ft3

*110

= 880 lb.

Adding all the above weights = 35834.375 lb

For over weights of plates & welding weights add 6% of the above weights

to total weight.

Total weight = 35834.375

48

6% of total weight = 2150.0625

Therefore, the erection weight =37984.437lb

B) OPERATING WEIGHT

ERECTION WEIGHT = 37984.437 lb

WEIGHT FOR OPERATING LIQUID = 5% OF THE ERECTION

WEIGHT

= 1899.22 lb

TOTAL OPERATING WEIGHT OF METHANATOR

=41877.676 lb

STRESS DUE TO WEGHT OF METHANATOR

Putting values in the formula (a)

Where,

c = Π * D mean = 3.14 (103.438) =324.79 in

t = 1.438

Sw = 41877.676 / 324.676*1.438 =89.88 psi (compressive)---------(1)

c) STRESS DUE TO WIND LOAD:

Towers under wind pressure are considered as uniformly loaded cantilever

beams. The computation of wind is based on standard ANSI A58.1-1982.

Where terrain features and local records indicate that 50 years at standard

49

height are higher than those shown in the map, those higher values shall be

the minimum basic wind speed.

The minimum basic wind speed for determining design wind pressure shall

be taken from the map of wind speed.

Design wind pressure shall be determined by the following formula:P = qs*Ce *Cq

Where,

P= Design wind pressure, psf

q s = Wind stagnation pressure at the standard height of 30 feet as

tabulated:

Basic wind speed, mph.

Pressure q(s), psf

70

13

80

17

90

21

100

26

110

31

120

37

130

44

C q = Pressure coefficient (shape factor):

Round or elliptical towers----------------------------0.8

C e = Combined height, exposure and gust factor coefficient as tabulated:

Coefficient C(e)

Height above ground,

Exposure C

Exposure B

ft.

0-20

20-40

40-60

60-100

100-150

150-200

1.2

1.3

1.5

1.6

1.8

1.9

0.7

0.8

1.0

1.1

1.3

1.4

Exposure C---------------------The most severe exposure

50

Exposure B ---------------------Intermediate exposure

For the methanator we will take a wind speed of 130 mph, so the value of

qs =44psf

Ce = 0.8-------------------------For circular vessel

Cq = 0.8 ------------------------Intermediate exposure & vessel height of

28ft

There fore the value of wind pressure using the above formula will be;

P = 28.16 psf

We will take the wind pressure 30 psf.

QUANTITIES

Shear

FORMULAS

V= Pw*D1*H1

Moment at base

M=Pw*D1*H1*h1

Moment at height h(t)

Stress

Mt = M- ht{V-0.5PwD1ht}

S= 12Mt / R2*Π*t

Where,

D1= width of the vessel with insulation, ft = 9.15 ft

51

E = Efficiency of the welded joints = 1.0

h1= lever arm, ft = H / 2 = 12.66'

ht = distance from base to section under consideration, ft = 12.8

H = length of vessel section, ft =25.33'

M = Maximum moment (at the base), ft-lb

Mt= Moment at height h t, lbft

Pw= Wind pressure, lb. / ft2 = 30'

R = Mean radius of vessel, in =51.7"

S = Stress due to wind, psi =?

V = Total shear, lb

t=

Thickness of shell excluding corrosion, in = 1.435"

The values of shear, moment at base & moment at skirt joint are calculated

as under and then the stress developed in response to the moment M(t) using

the formulae listed in the table above. By putting the values of the

parameters listed above for methanator

52

Shear = V = 30*9.15*25.33

V = 6953.085 lb

Moment (at base) M = 30*9.15*25.33*12.66

=88026.0561 lbft

Moment at head to skirt joint

Mt = M – 12.833{V – 0.5*30*9.15*12.833}

Mt = 21400.25465 lbft

Stress due to wind = 12*Mt / (51.7)2*Π*1.435

S (wind) = 21.32 psi

d) STRESS DUE TO SEISMIC LOAD

a) PERIOD OF VIBRATION

As a result of wind tall towers develop vibration. The period

of vibration should be limited, since large natural periods of vibration can

lead to fatigue failure. The allowable period has been computed from the

maximum permissible deflection.

53

QUANTITIES

FORMULAS

Period of vibration,T sec

Maximum allowable period of

T=0.0000265(H / D)2*(wD /t)^½

Ta=0.80(WH /Vg) ½s

vibration,Ta sec

Where,

D = Outside diameter of vessel, ft. =8.75lb

H = Length of vessel including skirt, ft. = 27.4166 ft

G = 32.2 ft. / sec2 acceleration

T = Thickness of skirt at the base, in. =0.001"

V = Total shear, lb., = 3203.64 lb (calculated ahead)

W= Weight of tower, lb. = 41877.676 lb

w= weight of tower per foot of height, lb. = 1588lb (from table)

Putting values to get period of vibration for methanator

T = 0.0000265(27.4166 / 8.75) 2*(1588*8.75/.001) ½

T = 0.96 sec

Now allowable period of vibration

Ta = 0.80 {w*H / V*g} ½

Ta = 2.668 sec

As ‘T’ is less than ‘Ta’ hence the condition is satisfied

STRESS DUE TO EARTHQUAKE

54

The loading condition of the tower under seismic forces is similar to that

of the cantilever beam when the load increases uniformly towards the

free end

FORMULAS

Shear

V=ZIKCSW

Moment

M=[FtH+(V-Ft)(2H /3)]

Mx= M(x/H)

Where

C= Numerical coefficient

= 1/15(T) ½ = 0.067/ (T) ½

=0.068(should not be more than 0.12)

E = Efficiency of welded joints = 1.0

Ft = Total horizontal seismic force at the top of the vessel, lb

= 0.07TV (Ft shall not exceed 0.25V)

=

H=

0, for T < 0.7

Length of vessel including skirt, ft = 27.4166'

I = Occupancy importance coefficient (use 1.0 for vessels)

K = Horizontal force factor (use 2.0 for vessels)

M = Maximum moment at the base, lbft

Mx= Moment at distance x, ft-lb

S = Numerical coefficient for site structure resonance

= 1.5 if T < 2.5

The product CS shall not exceed 0.14

W = Weight of the vessel, lb

Z = Seismic factor

= 0.375 for methanator

55

Shear = 0.375*1*2*0.068*1.5*41877.676

V = 3203.64lb

Ft = 0.07*T*V =215.284

0.25V = 800.91

As condition is that Ft should not exceed 0.25V so it is satisfied for

methanator

Therefore,

Moment

M = [215.28*27.4166+(3203.64-215.28)*(2*27.4166/3)

M = 162493.4962lbft

Moment at skirt to head joint

Mt = M(x/H)

where x=12.833

Mt = 76059.58748 lbft

56

Therefore stress due to earthquake

Seq = 12* Mt / R2 *Π* t

= 12*76059.58 / (51.7)2*3.14*1.435

Seq = 75.74 psi

2.11 COMBINATION OF STRESSES

The stresses induced by the previously described loadings shall be

investigated in combination to establish the governing stresses.

It is assumed that wind and earthquake loads do not occur simultaneously

Thus the tower should be designed for either wind or earthquake load

Whichever is greater?

In case of methanator the stress due to internal pressure is the hoop stress

(membrane stresses), the stress due to earthquake (greater) & stress due to

weight (compressive) is considered

57

Combination of stresses will be as follows

+stress due to earthquake

+stress due to internal pressure

-stress due to weight

From the previous calculations putting the values of stresses

+15426.6 lb/in2

+75.74 psi

-89.99 psi

Combined stress at the head to skirt joint on the vessel in operating

conditions =

15412.46 psi

2.12 COMPARISON

The governing stress will be tensile as shown by the positive sign, which is

lesser than allowable stress of the given material at that particular

temperature

Therefore the design is safe.

2.13 DESIGN OF ANCHOR BOLTS

Vertical vessels, must be fastened to the concrete foundation, skid or other

structural frame by means of anchor bolts and the base (bearing) ring.

THE NUMBER OF ANCHOR BOLTS

The anchor bolts must be in multiple of 4 and for tall towers it is

preferred

58

to use minimum 8 bolts.

SPACING OF ANCHOR BOLTS

The strength of too closely spaced anchor bolts is not fully developed in

concrete foundations. it is advisable to set the anchor bolts not closure than

about 18" .to hold this minimum spacing, in the case of small diameter

vessel the enlarging of the bolt circle may be necessary by using conical

skirt or wider base ring with gussets.

DIAMETER OF ANCHOR BOLTS

Computing the required size of bolts the area within the root of the

threads only can be taken into consideration. The root areas of the bolts are

shown below in table A. for corrosion allowance 1/8 of an inch should be

added to the calculated diameter of anchor bolts.

For anchor bolts and base design is described for methanator

1) An approximate method which may be satisfactory in a number of cases.

2) A method which offers closer investigation when the loading conditions

and other circumstances make it necessary.

59

* Source

Pressure Vessel Hand Book by

We will use the approximate method

The design of anchor bolts is to assume the bolts replaced by a

continuous ring whose diameter is equal to the bolt circle.

The required area of the bolts shall be calculated for empty condition

of tower.

FORMULAS

Maximum tension lb. /lin. In. T

Required area of one bolt Sq.-in. Ba

T=12M/Ab-W/Cb

Ba=TCb/SbN

60

Stress in Anchor Bolt psi.

Sb

Sb=TCb/BaN

Where,

Ab = area within the bolt circle, sq. - in.

Cb = Circumference of bolt circle in.

M = Moment at the base due to wind or earthquake, ft. – lb.

N =Number of anchor volts

Sb = maximum allowable stress value of bolt material psi.

W= Weight of the vessel during erection, lb.

Diameter of bolt circle = 102 + 2(1.438) +2(l (2))

Let us assume l (2)

= 3.375

Diameter of bolt circle = 102+2*1.438+2*3.375

= 111.62"

From table B

minimum no. of bolts=16

maximum no. of bolts=20

bolt size = 2 ¾"

bolt root area = 4.618 sq. in

From table C

specimen no.=SA 193B7

max. allowable stress = 16,000 psi

For checking stress in anchor bolts

61

Given,

Bolt circle dia. = 111.62"

Area with in the bolt circle = Ab = Π r2 =9780.33 sq.in

Circumference of bolt circle = Π D = 350.6"

Moment at base due to earthquake =162493.4962lbft

Weight during errection=W = 41877.676 lb

Max. allowable stress= Sb = 16,000 psi

N =16

Area within one bolt = 4.618 sq.in

Maximum tension

T = 12*162493.4962/9780.33 - 41877.676/350.6

T = 199.3726-119.425

T=79.94 ~ 80 lb/in

Stress in anchor bolts

S(b) = 80 * 350.6 / 4.618 *16

S(b) = 379.60 psi

Which is less than the allowable stress so it is satisfied

2.14 WELDING OF PRESSURE VESSELS :

There are several methods to make welded joints. In a particular case

the choice of a type from the numerous alternatives depend on:

1. The circumstances of welding.

2. The requirements of the code.

3. The aspect of economy.

• THE CIRCUMSTANCES OF WELDING:

62

In many cases the accessibility of the joint determines the type of

welding. In a small diameter vessel (under 18-24 inches) from the inside,

no manual welding can be applied. Using backing strip it must remain in

plate. In larger diameter vessels if a man way is not used, the last (closing)

joint can be welded from outside only. The type of welding may be

determined also by the equipment of the manufacturer.

• CODE REQUIREMENTS:

Regarding the type of joint the Code establishes requirements based on

service, material and location of the welding. The welding processes that

may be used in the construction of vessels are also restricted by the Code.

The Code-regulations are tabulated on the following pages under the

titles:

(a). TYPES OF WELDED JOINTS:

(Joints permitted by the code, their efficiency and limitations of their

applications.) Table UW-12

(b). DESIGN OF WELDED JOINTS:

(Types of joints to be used for vessels in various services and under

certain design conditions.) UW-2, UW-3

(c).JOINT EFICIENCIES AND STRESS REDUCTIONS:

(Efficiencies of joints at certain locations and reduced allowable stress

to be used in calculations of vessel components.)

The data of the table are based on the following Code regulations:

Full, spot, partial radiographic examination or no radiography of A, B, and C

joints. UW-11

63

For longitudinal stress calculation the efficiency of partially radio

graphed joints is the same as for spot radio graphed joints.

Seamless vessel sections and heads with Category B,C or D butt joints

that are spot radio graphed shall be designed for circumferential stress using

a stress value equal to 85% of the allowable stress value of the material;

UW-12(b)

When the joints are not radio graphed and for joint efficiency, E the

value in column of table “Types of welded joints” are used, in all other

design calculation, a stress value equal to 80% of the allowable stress value

of material shall be used except for unstayed flat heads, etc. UW-12(c)

• THE ECONOMY OF WELDING:

If the two preceding factors allow free choice, then the aspect of

economy must be the deciding factor.

Some consideration concerning the economy of welding:

V-edge preparation, which can be made by torch cutting, is always

more economical than the use of J or U preparation.

Double V preparation requires only half the deposited weld metal

required for single V preparation.

Increasing the size of a fillet weld, its strength increases in direct

proportion, while the deposited weld metal increases with the square of its

size.

Lower quality welding makes necessary the use of thicker plate for

the vessel. Whether using stronger welding and thinner plate or the

64

opposite is more economical, depends on the size of vessel, welding

equipment, etc. this must be decided in each particular case.

WELDING ON METHANATOR:

To the joints under certain conditions special requirements apply.

These special requirements which are based on service, material, thickness.

According to the designed conditions, service environment, material, and

design thickness it is recommended to use a double V-type butt joint. This

double V-type butt joint can be applied with out a backing strip, thus

reducing the cost of material. The joint efficiency of each every joint in the

vessel should be one according to radiography. A double V-type butt joint is

shown in the fig. below.

There will be a circumferential joint at each shell head junction.

There will be another circumferential joint in the middle having a

longitudinal seam on each side. As evident from the fig.

65

66

ANALYSIS

BY

ANSYS

67

3.1 ANSYS

ANSYS is software of FEA (Finite Element Analysis) which gives you a

way to test your model before manufacturing. you can calculate stress,

strain, displacement, thermal stresses, resonance, also optimum design

parameters, points where our model becomes unstable and much more. Any

of seven analysis types offered in ANSYS:

• STATIC

• MODAL

• HARMONIC

• TRANSIENT

• SPECTRUM

• EIGENVALUE BUCKLING

• SUBSTRUCTURING

• CFD (COMPUTATIONAL FLUID DYNAMICS)

All of these analysis types help us in design optimization to a great

extent. Whether the problem is linear or non-linear i.e. isotropic or

orthotropic, we can solve it with the help of this software. Design

optimization also helps you in finding suitable design parameters of a

failed structure. So, in short, ANSYS is a complete analysis tool which

can give you all what you want.

68

3.2 ANSYS INPUT METHODS

• GUI (Graphical user interface)

• COMMAND WINDOW

• INPUT(Data) FILE

69

3.3

70

3.4 ANALYSIS OF METHANATOR UNDER

INTERNAL PRESSURE USING “SHELL 51”

71

3.5 ANALYSIS OF METHANATOR THROUGH COMMAND

WINDOW

/PREP7

/TITLE, METHANATOR

ANTYPE,STATIC

ET,1,SHELL51

R,1,1.438

MP,EX,1,30E6

MP,NUXY,1,.3

N,1,51

N,2,51,10

E,1,2

CP,1,UX,1,2

! COUPLE RADIAL DIRECTION

D,1,UY,,,,,UZ,ROTZ

D,2,ROTZ

F,2,FY,3554507.8

! CAP FORCE

SFE,1,1,PRES,,435 ! INTERNAL PRESSURE

FINISH

/SOLU

OUTPR,ALL,1

SOLVE

FINISH

/POST1

ETABLE,STRS_HOOP,NMISC,6----------(Z DIR)

ETABLE,STRS_LONGI,NMISC,7---------(Y DIR)

3.6 ANALYSIS OF METHANATOR THROUGH GUI

Since the material of methanator is same throughout therefore we will use

istroptropic material for structural analysis. The units specified in BIN

(BTU) .

72

MAIN MENUE > PREFERENCES > STRUCTURAL

In order to give title to our modal.

FILE>CHANGE TITLE>METHANATOR

73

MAIN MENU >SOLUTION > NEW ANALYSIS > STATIC

DEFINIG THE ELEMENT TYPE

As we are using “Shell 51” for the analysis of methanator therefore, define

thhe element type as follows,

MAIN MENU>PREPROCESSOR>ELEMENT TYPE >ADD/EDIT/DELETE>SHELL51

74

DEFINING REAL CONSTANTS

In “shell 51” we will only take two nodes of the vessel material . as it is a a

2DOF case therefore the thickness of the vessel could be entered in the real

constants. Since the shell is of uniform thickness and the dished ends are of

comparatively less thicker than the shell (as calculated in analytical design),

to compensate for the increase in strength due to bending. Therefore, the

thickness remains the same throughout the vessel.i.e. 1.438 in.

75

MAIN

MENU>PREPRCESSOR>REALCONSTANTS>1.438"

DEFINIG MATERIAL PROPERTIES

For isotropic materials, the properties remains the same in every direction.

Here we have entered the young’s modulus (30e6), the density of material is

(0.28), the posion’s ratio (0.3). all of these values are given in the table of

material for the methanator.

MAIN MENU>PREPRCEESOR>MATERIAL PROP>CONSTANT-ISOTROPIC

76

The two nodes are plotted at a distance of 51 inches from the origin which is

infact, the radius of methanator. Thr height of element is taken at 10 inches.

Main menu>preferences>create>nodes>In active CS

77

CREATING ELEMENT

MAIN MENU>PREFERENCES>CREATE>ELEMENTS>THRU

NODES

78

APPLYING CONSTRAINTS

MAIN MENU>SOLUTION>APPLY>DISPLACEMENT

79

80

APPLYING LOADS

81

In order to see the effect of longitudinal component of pressure which causes

the longityudinal stress in the shell membrane, longitudinal force is applied

as caculated earlier in addition to the internal pressure which is 435 psi.

MAIN MENU>SOLUTION>APPLY>FORCE/MOMENT>FY

82

83

after creating element of the methanator material. And after applying the

boundary conditions & loads . The element is ready for the solution. As

shown on the previous page.

solve the element as shown below.

MAIN MENU>SOLUTION>SOLVE-CURRENT LS

84

POSTPROCESSING

It is the environment where the results of the analysis can be listed or ploted.

For our case the resuts are ploted as follows. As we are interested in the

stress therefore we have listed or plotted the equivalent stress or von mises.

MAIN MENU> GENERAL POSTPROCESSOR>LIST

RESULTS>NODAL SOLU>STRESS-COMPONENTS

RESULTS

85

MAIN MENU>GENERAL POST PROCESSOR>LIST

RESULTS>NODAL SOLU>STRESS-PRINCIPALS

RESULTS

86

MAIN MENU>GENERAL POSTPROCESSOR>PLOT

RESULTS>NODAL SOLU>STRESS-VON MISES

87

3.7 TO FIND THE HOOP AND LONGITUDINAL STRESS

Hoop stress will be along the z-axis & longitudinal stress will be along y_axis.

Starting from mainmenu the following path is followed to see the hoop and

longitudinal stresses.

GEN. POSTPROC>ELEM. TABLE>DEFINE TABLE>STRESS-HOOP-NMISC,6

------------------------------------ >STRESS_LONG-NMISC-7

88

TO SEE THE STRESSES (HOOP &LONG)

GEN.POSTPROC>LIST RESULTS>ELEM. SOLN>BY SEQUENCE-NMISC,6

BY DOING THIS HOOP STRESS IS OBTAINED.

89

TO SEE THE LONGITUDINAL STRESS

---------------------------------------------->BY SEQUENCE-NMISC,7

THE LONGITUDINAL STRESS IS OBTAINED.

90

3.8 DISPLACEMENTS OF THE 4 DOF’s

91

COMPARISON

&

CONCLUSION

92

4.1 MEMBRANE STRESSES IN

METHANATOR

The membrane stresses i.e hoop & longitudinal stresses ploted are in pound

per square inch.

93

4.2 COMPARISON OF ANSYS & ANALYTICAL

SOLUTION

As it is evident from the chart that our longitudinal stress is exactly the same

but the circumferential stress varies slightly owing to rounding off data.

CONCLUSION

For analytical design we have used the

ASME SECTION-8

division 1 which gives the ultimate design calculations. As we

have got the same values from the software therefore ANSYS is

a reliable software.

94

REFERENCES

SECTION VIII

VESSELS

RULES FOR CONSTRUCTION OF PRESSURE

DIVISION 1

PRESSURE VESSEL HANDBOOK (Seventh Edition) by

EUGENE F. MEGYESY

PRESSURE VESSEL DESIGN MANUAL

by DENNIS R. MOSS

95

96

97

98

99

100

101

102

103

104

105

106