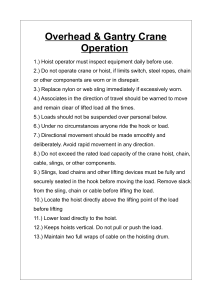

toaz.info-leea-academy-step-notes-lmp-mar-2017-v13-pr 02c8ab20f6b5052fba999ec4f15f6cc3

advertisement