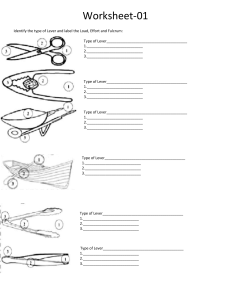

18.1A Use hand tools Topic One – Introduction INTRODUCTION TO HAND TOOLS General engineering hand tools are used in many different occupations Their design, general safety and general classifications are explained in this section. The methods of use are written for a right-handed person. Left-handed will have to change the various stances and positions. NOTE: It is important to carefully follow the instructions supplied by manufacturers of tools. If the tools are not used regularly, their instruction sheets must be kept for quick reference. Definitions Hand tools have been designed to apply one or more Principles of science of mechanics to make tasks easier. When you have used hand tools, you have used many of these principles even if you don not know the ideas behind them. The lever The lever makes use of mechanical advantage to produce a large force at one end by applying a relatively small effort at the other. It is used for pushing, pulling, lifting, lowering and praising. To do this, a point of support (fulcrum or pivot point, F) is needed somewhere along the lever. The illustrations show two types of lever: One with the fulcrum between the two forces acting on the lever and close to the load move. The other with the fulcrum at one end of the lever instead of between the two forces, but still close to the point where the shifting force is needed. The first type of lever is used to lift or to praise; the second, to push or pull. From the illustrations you can see that the closer the load is to the fulcrum and the longer the lever is on which you have to apply the effort, the easier it will before you to shift a big load. Also, the closer the load is to the fulcrum, the smaller the distance is over which you can shift the load in any one movement of the lever. This principle is called Leverage and is related to the length of the tool and the applied force. More leverage can be applied with a longer tool than can be applied with shorter tool. The unit for leverage is the Newton meter (Nm). THIESS Training Center 1 of 5 18.1A Use hand tools Topic One – Introduction The crank The crank is used for changing a force that acts along a straight line into a rotating force. Pedals on a bicycle are crank, and some hand tools operate as cranks. When a force acts to turn an object about its axis, the turning effect produced is called the ‘turning moment’ or Torque. The turning moment is equal to the applied force times the length of the lever. That is, torque (turning effect) is the result of the applied force times (multiplied by) the perpendicular distance between the applied force line and the pivot point. The unit for torque is the Newton meter (Nm). For example, if we apply a force of 100 Newton to a lever of 0.5 meter, the resultant torque will be: T=100X0.5=50Nm. Torque causes parts to twist around their axis or center point. When using a cranked tool you will get the maximum effect if you apply the force at right angles to the plane of the crank, since this will produce maximum torque. In the diagrams, a brace is shown turning about its axis for a quarter of a turn under the action of a force that acts vertically downwards. The distance from the axis decreases from maximum to zero. This causes the torque, or turning moment, exerted by the force to decrease also. THIESS Training Center 2 of 5 18.1A Use hand tools Topic One – Introduction Applied force Applied force is the degree of push or pull given to the tool by its operator. Applied force is measured in Newton (N). Pressure A force applied to a very small area will result in great pressure on that surface. A large mass that takes up a large surface area will produce far less pressure than when that same mass concentrated on a small area. Note how pressure is applied in the use of various hand tools. Chisels and other hand tools used to cut metal apply the principle of pressure by concentrating force on a very small area and that of wedging to cut and separate at the same time. The inclined plane It is easier to pull a load up over a ramp (inclined plane) than to pull it up vertically. Wedges and screws are useful small-scale applications of the principle of inclined plane. THIESS Training Center 3 of 5 18.1A Use hand tools Topic One – Introduction Tension Tension means stretching. That is, when a bolt is tensioned its length increases by a very small amount. Tightening Tightening is the result of applying a torque to a nut so that the thread angle can tension the bolt. NOTE: The applied torque will also twist the bolt. This can be removed by turning the nut slightly backwards. Many hand tools are simple machines. You apply the effort. They help you to do work because many simple mechanical principles are applied. Learning how hand tools cut will help you understand the cutting action use in machining metals. Learning to understand hand tools, as simple machines will help you understand more complex ones. Try to reason out why hand tools are designed as they are, what they are use for, and why certain materials are used in them. This will help you get better use from your hand tools. Hand tools classifications Generally hand tools classified as: Fastening tools, e.g. spanner and screwdriver Gripping and Clamping tools, e.g. pliers and grip Impact tools, e.g. hammer and punch Marking, Measuring and Gauging tools, e.g. steel rule and scriber Cutting tools, e.g. file and hacksaw Portable power tools, e.g. portable grind and portable drill In this module trainees will be introduced to the basic tools they will be required to use, and instructed in the proper use and maintenance of them. This module will explain about fastener and fastening tools, gripping and clamping tools, impact tools, and cutting tools, for a little about marking, measuring and gauging tools. More about marking, measuring and gauging tools will provide in next module. And for portable power tools will introduce and explain in use power tools module. More explain about classification in section two. THIESS Training Center 4 of 5 18.1A Use hand tools Topic One – Introduction Safety Always use proper personal protective equipment (PPE) when do our job. Give attention to care in the use of hand tools. Hand tools can cause incidents when an incorrect, improvised or defective tool is used. Also, when the correct tool is used carelessly, or not put away safely, injury may result. Make sure you select the proper type and size of tool for the job. Check the condition of any tools before use it. Do not use tools that are worn out or damaged. Maintain tools in good condition and remember that cutting tools need to sharp to be safe. Make sure you use each tool in the correct manner. Replace tools on shadow boards or in their correct place when you are not using them. Do not use hammer to assist the turning movement of a spanner. Do not extend spanners with a length of piping or other means to increase leverage. Do not strike a hardened surface (ball race, etc.) with a hammer, as one or both surfaces may chip and fly. Do not use spanners or any tools that coated with grease or oil. Do not carry screwdrivers, chisels or pointed tools in the pockets of overalls, etc. They are dangerous in the event of the fall. Do not use spanner as a hammer. Learn to use all the hand tools a correct and safe method for each tool is described in section two and three. THIESS Training Center 5 of 5