食品商务网-领先的网上食品贸易市场,食品行业门户网站(http://www.21food.cn)

32.2.05A

AOAC Official Method 996.11

Starch (Total) in Cereal Products

Amyloglucosidase–a-Amylase Method

First Action 1996

AOAC–AACC Method

(Applicable to determination of total starch in cereal products.)

See Table 996.11 for the results of the interlaboratory study supporting the acceptance of the method.

Caution: See Appendix B, safety notes. Glucose oxidaseperoxidase-aminoantipyrine buffer mixture, MOPS,

and acetate buffers contain sodium azide. Avoid contact with skin and eyes. In case of contact, immediately

flush contact surfaces with plenty of water. Disposal of

these reagents into sinks with copper or lead plumbing

should be followed immediately with large quantities

of water to prevent potential explosive hazards.

Dimethyl sulfoxide is a skin irritant and should be used

with caution.

A. Principle

Test samples are hydrated and starch is hydrolyzed to

maltodextrins with thermostable α-amylase at 95–100°C. Temperature and pH are adjusted and maltosaccharides are quantitatively hydrolyzed to glucose with highly purified amyloglucosidase. Glucose

is determined with high purity glucose oxidase–peroxidase reagent.

Products containing high-amylose starches or resistant starch are

pre-treated with dimethyl sulfoxide at 95°C before treatment with

α-amylase. Starch content is reported on “as is” basis.

B. Apparatus

(a) Grinding mill.—Centrifugal, with 12-tooth rotor and 0.5 mm

sieve, or similar device. Alternatively, cyclone mill can be used for

small quantities.

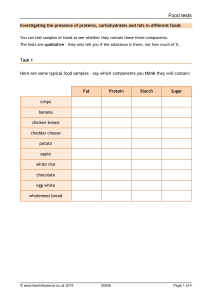

Table 996.11

(b) Bench centrifuge.—Holding 16 × 120 mm glass test tubes,

with rating of ca 1000 × g.

(c) Water bath.—Maintaining 50 ± 0.1°C.

(d) Boiling water bath.—Boiling H2O at 95–100°C (e.g., fryer

filled with H2O).

(e) Vortex mixer.

(f) pH Meter.

(g) Stopclock timer (digital).

(h) Top-loading balance.

(i) Analytical balance.

(j) Laboratory oven.—With forced-convection; maintaining

103 ± 1°C; used for determining dry weight of test sample.

(k) Spectrophotometer.—Operating at 510 nm.

(l) Pipets.—Delivering 100 and 200 µL; with disposable tips. Alternatively, motorized hand-held dispenser can be used.

(m) Positive displacement pipetter.—With 5.0 mL tips accurately delivering 100 and 200 µL; and 50 mL tips delivering 3.0 mL.

(n) Dispenser.—500 mL, to deliver 3.0 mL. Used for glucose

oxidase–peroxidase–aminoantipyrine buffer mixture.

(o) Glass test tubes.—16 × 120 mm, 17 mL, for centrifugation at

ca 1000 × g; and 18 × 150 mm.

(p) Test tube racks.—48 place, holding 16 × 120 and

18 × 150 mm tubes.

(q) Thermometer.—Reading 103 ± 1°C.

(r) Filter paper.—Fast, ashless.

C. Reagents

(a) 3-(N-morpholino)propanesulfonic acid (MOPS)

buffer.—pH 7.0. Contains 50 mM MOPS, 5 mM calcium chloride,

and 0.02% sodium azide. In 1 L volumetric flask dissolve 11.55 g

MOPS in 900 mL H2O and adjust pH to 7.0 with 1M HCl (ca 17 mL).

Add 0.74 g CaCl2.2H2O and 0.2 g sodium azide. Dilute to volume

with H2O. Buffer is stable at room temperature.

(b) Thermostable a-amylase solution.—10 mL; 3000 U/mL. Dilute 1 mL α-amylase solution (in 50% glycerol) to 30 mL with

MOPS buffer, (a). Thermostable a-amylase solution is stable up to

Interlaboratory study results for determination of total starch in processed cereal products by amyloglucosidase–

a-amylase method

Mean total

starcha, %

Moisture, %

No. of labs

sra

sRa

RSDr, %

RSDR, %

rb

Rc

Chicken feed pellets

44.9

11.4

32

1.4

2.1

3.1

4.7

3.9

5.9

White bread

60.9

10.6

32

1.6

3.0

2.6

4.9

4.5

8.4

Green pea

38.5

12.4

31

1.3

1.9

3.4

4.9

3.6

5.3

High amylose maize starch

74.8

13.4

26

2.2

3.6

2.9

4.8

6.2

White wheat flour

68.0

12.8

31

2.0

2.9

2.9

4.3

5.6

8.1

Wheat starch

85.3

12.2

26

2.8

3.3

3.3

3.9

7.8

9.2

Oat bran

38.5

8.8

31

1.5

1.9

3.9

4.9

4.2

5.3

Spaghetti

67.5

11.8

31

2.6

3.2

3.9

4.7

7.3

9.0

High amylose-maize starch

(DMSO method)

84.2

13.4

31

1.8

2.4

2.1

2.9

5.0

6.7

Wheat starch (DMSO method)

84.7

12.2

31

2.6

3.9

3.1

4.6

7.3

10.9

Sample

a

Calculated on “as is” basis.

b

r = 2.8 × sr.

c

R = 2.8× sR.

© 2000 AOAC INTERNATIONAL

3 years when frozen. (Note: One unit [U] of α-amylase activity is

amount of enzyme required to release 1 µmole p-nitrophenol from

“end-blocked” p-nitrophenyl maltoheptaoside in presence of saturating levels of α-glucosidase and amyloglucosidase [i.e., Ceralpha

α-amylase assay reagent] at 40°C and pH 6.0.) Thermostable α-amylase solution should be free of detectable levels of free glucose.

(c) Amyloglucosidase solution.—10 mL; 200 U/mL. Use directly

without dilution. Solution is viscous; for dispensing, use positive

displacement dispenser. Amyloglucosidase solution is stable up to

3 years at 4°C. (Note: One unit [U] of enzyme activity is amount of

enzyme required to release 1 µmole p-nitrophenol from

p-nitrophenyl β-maltoside in the presence of saturating levels of

β-glucosidase [i.e., amyloglucosidase assay reagent] at 40°C and

pH 4.5.) Amyloglucosidase solution should be free of detectable

levels of free glucose.

(d) Glucose oxidase–peroxidase–aminoantipyrine buffer mixture.—Mixture of glucose oxidase, 12000 U/L; peroxidase,

650 U/L; and 4-aminoantipyrine, 0.4 mM.

Prepare buffer concentrate by dissolving 13.6 g KH2PO4, 4.2 g

NaOH, and 3.0 g 4-hydroxybenzoic acid in 90 mL distilled H2O. Adjust to pH 7.4 with either 2M HCl (16.7 mL HCl/100 mL) or

2M NaOH (8.0 g NaOH/100 mL). Dilute solution to 100 mL, add

0.4 g sodium azide, and mix until dissolved. Buffer concentrate is

stable up to 3 years at 4°C.

To prepare glucose oxidase–peroxidase–aminoantipyrine buffer

mixture, dilute 50 mL buffer concentrate to 1.0 L. Use part of diluted

buffer to dissolve the entire contents of vial containing freeze-dried

glucose oxidase–peroxidase mixture. Transfer contents of vial to 1 L

volumetric flask containing diluted buffer. Reagent is stable

2–3 months at 4°C and 2–3 years at –20°C. Color formed with glucose is stable several hours. (Note: Glucose oxidase must not be contaminated with β- and/or α-glucosidase and chromogen color

complex must be stable at least 60 min.)

Check color formation and stability of glucose

oxidase–peroxidase–aminoantipyrine buffer mixture by incubating

(in duplicate) 3.0 mL glucose oxidase-peroxidase-aminoantipyrine

buffer mixture with glucose standard (100 µg dried crystalline glucose in 0.2 mL 0.2% sodium benzoate solution). After 15, 20, 30,

and 60 min incubation, read absorbance, A, of solution at 510 nm.

Maximum color formation should be achieved within 20 min, and

color should be stable at least 60 min at 50°C.

(e) Aqueous ethanol.—About 80% (v/v). Dilute 80 mL 95% ethanol (laboratory grade) to 95 mL with H2O.

(f) Sodium acetate buffer.—(1) 200 mM, pH 4.5.—Pipet 11.8 mL

glacial acetic acid (1.05 g/mL) to 900 mL H2O. Adjust pH to 4.5 with

1M NaOH solution (ca 60 mL is required). Add 0.2 g sodium azide

and dilute to 1 L with H2O. (Caution: Sodium azide should not be

added until pH is adjusted. Acidification of sodium azide releases

poisonous hydrazoic acid.) Buffer is stable 12 months at room temperature. (2) 50 mM, pH 4.5.—Dilute 200 mM acetate buffer 1 + 3

with H2O.

(g) Dimethyl sulfoxide (DMSO).—Laboratory grade.

(h) Glucose standard stock solution.—1 mg/mL. Before preparing solution, dry powdered crystalline glucose (purity ≥97%) 16 h at

60°C under vacuum. Dissolve 0.1 g dried glucose, weighed to nearest mg, in 100 mL distilled water.

(i) Corn starch.—Containing known content of starch (e.g., ca

98% dry weight).

Items (a)–(c), (h), and (i) are supplied in Total Starch Assay kit

available from Megazyme International Ireland Ltd, Bray Business

Park, Bray, Co. Wicklow, Ireland.

D. Preparation of Test Samples, Standards, and Reagent Blank

(a) Test sample.—Grind ca 50 g laboratory sample in grinding

mill to pass 0.5 mm sieve. Transfer all material into wide-mouthed

plastic jar and mix well by shaking and inversion.

(b) D-Glucose standard working solutions.—50 and 100 µg. Add

50 and 100 µL D-glucose standard stock solution, C(h), to separate

test tubes, and adjust volume in each tube to 100 µL with H2O. Prepare solutions immediately before use.

(c) Reagent blank.—Transfer 0.1 mL H2O into test tubes and proceed with total starch determination using standard assay procedure

starting from step E(a)(7).

E. Determination of Total Starch

(a) Standard procedure α-amylase/amyloglucosidase

(AA/AMG).—Run D-glucose working standard solutions (in quadruplicate), reagent blank (in duplicate), and corn starch with each

set of tests. Use reagent blank to zero spectrophotometer. (1) Accurately weigh 90–100 mg ground test portion directly into glass

test tube. Tap tube gently on laboratory bench to ensure that all particles drop to bottom of tube. (Note: When analyzing cereal products containing high levels of glucose [processed cereal products

{e.g., breakfast cereals} and all products of unknown or uncertain

composition {i.e., products containing free glucose or

maltodextrins}], pre-extract 90–100 mg of weighed, ground test

sample 2× with 10 mL 80% aqueous ethanol, C(e), at ca 80°C over

10 min/extraction. Centrifuge slurry at 1000 × g and discard

supernatant. Use sediment for analysis.) (2) Add 0.2 mL 80%

aqueous ethanol to tube and stir on Vortex mixer to ensure that test

portion is wet. Add 3.0 mL thermostable α-amylase, C(b), and mix

contents of tube on Vortex mixer to ensure complete dispersion.

(3) Immediately place tube in boiling water bath for 2 min, remove

from water bath, and mix vigorously on Vortex mixer. Return tube

to boiling water bath for additional 3 min and then mix contents

vigorously on Vortex mixer. (Note: Some solids will adhere to side

of test tube; however, this will not affect analysis since tube contents are treated with enzyme in this step.) (4) Place tubes in water

bath set at 50°C and let equilibrate 5 min. Add 4.0 mL 200 mM sodium acetate buffer, C(f)(1), and 0.1 mL amyloglucosidase solution, C(c), and vigorously mix contents on Vortex mixer. Cap tube

with marble and incubate 30 min at 50°C. (5) Quantitatively transfer the entire contents of test tube to 100 mL volumetric flask. Use

water wash bottle to rinse tube contents thoroughly. Dilute to 100

mL with H2O. (Note: If product contains <10% starch, adjust volume to 10.0 mL [instead of 100 mL]. Make appropriate adjustments

to calculations.) Thoroughly mix contents of flask. Centrifuge

aliquot of suspension 10 min at 1000 × g. Alternatively, filter

aliquot through filter paper. (6) Carefully and accurately transfer 0.1

mL aliquot of each supernatant (or filtrate) to bottoms of separate

test tubes; use 2 tubes/supernatant (or filtrate). (7) Add 3.0 mL glucose oxidase–peroxidase–aminoantipyrine buffer mixture, C(d), to

each tube (reaction solutions from test portion and corn starch, re© 2000 AOAC INTERNATIONAL

agent blank, and D-glucose standard working solutions), and incubate 20 min at 50°C. (8) Measure and record absorbance, A, of each

test solution at 510 nm against reagent blank. Average A values for

each test and use in Calculations, G.

(b) Modified procedure (DMSO/AA/AMG).—For products containing enzyme-resistant starch. (1) Accurately weigh 90–100 mg

ground test portions directly into glass test tube. Tap tube gently on

laboratory bench to ensure that all particles drop to bottom of tube.

(Note: When analyzing cereal products containing high levels of

glucose, pre-extract 90–100 mg weighed, ground test sample 2×

with 10 mL aqueous ethanol, C(e), at ca 80°C over 10 min/extraction. Centrifuge slurry at 1000 × g and discard supernatant. Use sediment for analysis.) (2) Add 0.2 mL 80% aqueous ethanol to tube and

stir on Vortex mixer to ensure that test portion is wet. (3) Immediately add 2 mL DMSO solution, C(g), and stir tube on Vortex mixer.

Place tube in vigorously boiling water bath and remove after 5 min.

Add 3.0 mL thermostable α-amylase solution, C(b), and mix contents on Vortex mixer to ensure complete dispersion. (4) Immediately proceed according to standard procedure (AA/AMG) starting

from step E(a)(3).

(2) Centrifuge reaction solution 10 min at 1000 × g and carefully

pour supernatant into 100 mL volumetric flask.

(3) Resuspend pellet in 5 mL 50 mM sodium acetate buffer,

C(f)(2), by vigorous stirring on Vortex mixer. Add additional 5 mL

50 mM sodium acetate buffer, mix, and centrifuge 10 min at

1000 × g.

(4) Combine supernatant with that from step (2), and dilute to

volume. Analyze for starch starting with step E(a)(6).

(5) To pellet from (3) add 2 mL DMSO and analyze for starch by

modified procedure E(b) starting from step E(b)(3) [proceed to procedure E(a) as stated].

(6) At step E(a)(5), adjust volume to 10 mL (instead of 100 mL).

(7) Proceed with standard procedure, E(a), starting from step

E(a)(6). Make appropriate adjustments to calculations.

G. Calculations

Calculate total starch content (percent, on as is basis) in test sample as follows:

Total starch, % = A × F ×1000 ×

=A×

F. Determination of Enzyme-Resistant Starch (Optional)

(Note: This part of method was not validated in collaborative study.)

Level of enzyme-resistant starch in products depends on nature of

original starch (e.g., high amylose) and on processing conditions.

This may vary from 0.1–30% total starch in product. Determine

level of enzyme resistant starch as follows:

(1) Analyze product according to standard procedure,

E(a)(1)–(4).

1

100 162

×

×

1000 W

180

F

× 90

W

where A = absorbance of reaction solutions read against reagent

blank; F = factor to convert absorbance values to µg glucose =

100 µg glucose/absorbance value for 100 µg glucose; 1000 = volume correction, i.e., 0.1 mL taken from 100 mL; 1/1000 = conversion from µg to mg; 100/W = conversion to 100 mg test portion;

162/180 = factor to convert from free glucose, as determined, to

anhydroglucose, as occurs in starch.

Reference: J. AOAC Int. 80, 571(1997).

Revised: March 1998

© 2000 AOAC INTERNATIONAL