foundation determination of the excavation volume counting

advertisement

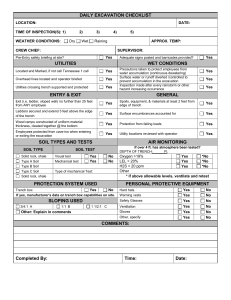

Пт, 22 декабря 2023 Construction and repair by own hands Construction and repair by own hands Determination of the excavation volume. Counting the volume of excavation work Lipetsk College of Construction, Architecture and Industry Technologies Practical work number 1 "Calculation of the volume of excavation work and the complexity of their implementation" On discipline: "Technology and organization of construction production" For specialty 270103 Construction and operation of buildings and structures Teacher N.I. Krygina Lipetsk - 2009 Objective: the purpose of doing practical work is to master the student's basics of designing soil development technology when excavating a pit for construction; In addition, the student should get acquainted with the methodology for developing the main document of the project for the production of works - the elements of the technological map for the excavation of the pit for the construction. a common part The volumes of ground masses are counted many times: in the design process - according to the drawings, while performing construction processes - by natural measurements. The excavation works usually include: vertical layout of sites; Vertical planning is carried out to equalize the natural relief of the sites allocated for the construction of various buildings and structures, as well as for the improvement of the territories. Excavation works on vertical planning include excavation of soil in some areas of the site, moving, piling and compacting it in other areas (in the embankment zone). Vertical layout of sites in the section of excavations is carried out before the devices in them are connected and foundations, and on the site of embankments - after the installation of these structures. The amount of work on the vertical planning of sites is measured by square meters of the surface. development of excavations and trenches; The calculation of the volume of the developed soil is reduced to determining the volumes of various geometric 몭gures that determine the shape of a particular earth structure. It is assumed that the volume of soil is limited to planes, and some unevenness does not a몭ect the accuracy of the calculation. The volume of soil is measured with cubic meters of a dense body. The volume of excavation is calculated by the formula: Vk = n / 6 ∙ [(2a + a1) ∙ b + (2a1 + a) ∙ b1], where H - pit depth, m; a, b - the length of the sides of the excavation at the base, m; a 1 , b 1 - the length of the sides of the pit on top ( a 1 = a + 2H m ; b 1 = b + 2Hm ); m Is the slope coe몭cient. Fig. 1 Geometrical scheme for determining the volume of the excavation With a passage of pits under free-standing foundations sometimes use the formula: Vк = н / 3 (Fn + Fв + √Fн + Fв), where F mr. and F at - respectively, the area of excavation on the bottom and top, m 2. When calculating the volumes of trenches and other linearly extended structures, their longitudinal pro몭les are divided into sections between points of fracture. For each such section, the trench volume is calculated separately, after which they are summed. Thus, the volume of the trench on the section between points 1 and 2: V1 - 2 = ∙ l1-2 V1 - 2 = ∙ l1-2 Fig. 2 Geometrical scheme for determining the volume of a trench Fig. 3 Sectional pit: С - construction, О - back몭lling back몭lling of soil; Specify the required sizes L - Total length of the trench or ditch. A - Width at the top. B - Bottom width. H - Depth of trench. The program will calculate the volume and surface area of the trench. If the width of the top and bottom of the trench are di몭erent, then a useful volume of slopes D. C and the volume Calculation of the trench volume For laying communications, heat pipes, sewerage or installing a strip foundation on your site, you may need to dig a trench. You can invite specialists for this, but you can do it yourself. But in either case, you will need to know some characteristics of the trench. Calculate them you will help our program. Based on the length, width and depth of the trench, it will determine its volume and surface area. In the event that the width of the top and bottom of the trench di몭er, a useful amount of slopes will also be calculated. Calculating the trench volume will help you not only to ease your work, but also to calculate the cost of land works, if you still decide to use the services of specialists. Trenching There are three ways to dig trenches. This is the digging of trenches by hand, with the help of a hand trencher or trench excavator. The 몭rst case is usually resorted to where there is no access to special equipment. This is a rather laborious way of digging trenches, which is heavily in몭uenced by the quality of the ground. Hand trenchers reduce the time of such work. It can be bought or rented. You can also order trench digging in a specialized company. Then it will be performed by a professional. The excavator is used wherever construction machinery can pass to the site, and also where there is a large amount of work. Before renting such an excavator, you need to 몭nd out the width of the bottom of the trench in order to pick up a car with the size of the bucket that matches it. If you decide to dig a trench yourself, 몭rst of all you should know that for a di몭erent type of work trenches of a certain depth are required. So, for example, for a cable laying, as a rule, trenches of about 70 cm depth are digging. And for a sewage system, deeper trenches are required. It is desirable that this depth is half a meter greater than the depth of freezing of the soil. The width of the trench is also a몭ected by the type of work being done. The smallest width of the trench is measured on the bottom and should correspond to the type and size of pipes laid in it. All types of soil development in trenches and trenches, including cutting of the vegetative layer of soil, development of soil in pits and trenches and cleaning of the bottom of the excavation are subject to volume calculation. Before calculating the volume of soil development, a decision is made as to how the excavation of trenches and excavations will be performed - with wall fastening or with slopes. Prior to the commencement of excavation work, excavation of the plant bed is performed in an area equal to the pit pit at the top + 10 m from each side. In order to 몭nd the value S - Cutting area of the vegetative layer of soil - it is necessary to perform the following actions: 1. Find the dimensions between the extreme axes of the building X and Y (Figure 11). For example, let us take X = 36, Y = 12, the depth of excavation H k = 2.825. Fig. 11. Scheme of the excavated pit horizontals: A - horizontal number 2. Then, from the blueprint of the foundation plan, f is the distance from the extreme axis to the outer edge of the basement (in this case, we set the foundation width to 1 m) and l 1 - the distance between the extreme edge of the foundation and the bottom line of the slope, which is taken in the interval 0.8 ... 1 m (Figure 12). 3. De몭ne the values a and b - respectively, the length and width of the boiler-basin along the bottom (Figures 12, 13) by formulas a= X+2 f+2l 1 , b= Y+2 f+2l 1 , where X and Y - the distances between the extreme axes of the building. Fig. 12. Determining the size of the excavation at the bottom Excavation works Fig. 13. De몭nition of the excavation parameters from= a+2mH to, d= b+2mH to, where H к - pit depth; m - the index of the slope of the excavation, is selected according to Table. 1 app. depending on the soil category. a= 36 + 2 (0.5 + 0.5) + 2⋅0.8 = 39.6 m; b= 12 + 2 (0.5 + 0.5) + 2⋅0.8 = 15.6 m; from= 39.6 + 2⋅0.5⋅2.825 = 42.425 m; d= 15.6 + 2⋅0.5⋅2.825 = 18.425 m. 5. Calculation of the cutting area of vegetative soil, m 2, is made by the formula S=( c+10⋅2)(d+10⋅2) , S=(42,425+10⋅2)(18,425+10⋅2)=2398,7. The cut-o몭 area is 2398.7m 2 . 3. Calculation of the volume of excavation excavation excavation 6. When the excavation is located in a zone of embankment with a complex relief of the area, its volume is determined by the method of transverse pro몭les (Fig. 14). Cat-lavan is divided into a number of sections by vertical planes. The volumes of simple 몭gures that make up the whole volume are counted, after which the total volume of the excavation is found by folding them according to the formula V k = V 1 + V 2 + V 3 +...+V n. 7. To enter the excavator in the pit, as well as the entry and exit of the car dumps at the end (with the lowest working marks), the trench is arranged with an entrance trench (Fig. 14). The slope of the trench is assumed to be 1: 8 ... 1: 12 depending on the type of soil. Fig. 14. Calculation scheme 8. When excavating an excavation for calculating the volume of excavation, the whole pit is divided into elementary 몭gures for simpli몭cation of calculations, as well as cross sections of no more than 20 m in length 1-1 , 2-2 , 3-3 ) (Figure 15). Fig. 15. Split the pit into sections 1-1, 2-2, 3-3 Excavation works 9. After the breakdown into sections, it is necessary to determine the black marks and the depth of the excavation at the intersection points with the base line of the trench from the excavation (Figures 1517). where F i and F i +1 - cross-sectional areas at the beginning and end of the section under consideration; L is the distance between sections. In this example F i - this F 1, a F i +1 is F 2 (see Figure 16). Fig. 17. Scheme of excavation with horizontals and found marks 10. The volume of the excavation trench is determined by: 3. Calculation of the volume of excavation excavation excavation where H к - pit depth; b tr - the width of the entrance trench on the bottom, is assumed to be 3.5 ... 7 m; m - slope coe몭cient; m t - slope of the entrance trench, m t = 1/8 = 0.125. 11. By the formula (1), substituting into it F 1 and F 2, we obtain the formula: V 1 = F 1 + 2 F 2 L, where L - length of the site, m; F 1 , F 2 - the area of the initial and 몭nal cross sections, m 2 (Figure 18). Fig. 18. Finding the area of the trapezium section F 1 and F 2 The area of the trapezoid is found from formula F=(b+ mH)H. Since the trapezium heights are not the same, we 몭nd their average value by the formula H cp = H 1 + 2 H 2 , where H cp is the average depth of the excavation in this section. Section 1-1 : F 1 = (15.6 + 0.5⋅3.75) 3.75 = 65.53m 2. Excavation works Section 2-2 : F 2 = (15.6 + 0.5⋅2.7) 2.7 = 45.76m 2. V 1 = (65,53+45,76) 20 = 1112.9 m 3. 2 Here L = 20 m (see 몭gure 15). Section 3-3 : F 3 = (15.6 + 0.5⋅1.9) 1.9 = 31.445m 2. Knowing the area of the second F 2 and the third F 3 trapezoids and distance L= 19.6 m (see Figure 15), determine the volume of the second 몭gure V 2: V 2 = (45,76+31,445) 19.6 = 756.61 m 3. 2 12. The volume of soil in the face slopes is determined by the formulas: 1) for angular rectangular pyramids (Figure 19): V pir = m 3 3 Hto 3; V 3 = 0,5 3 3 ⋅4,5 3 = 3.8 m 3. Here, 4.5 is the depth of excavation in Fig. 17; Fig. 19. Corner rectangular pyramid 3. Calculation of the volume of excavation excavation excavation 2) for triangular prisms (Figure 20): V prisms = mb 4 (H 1 2 + H 2 2); V4= 0,5 ⋅ 15,6 (4,5 2 +3 2) = 57,04 m 3 .4 Fig. 20. Triangular prism V 5 = 0,5 3 ⋅3 3 = 1.125 m 3. 3 V 6 = 0,5 3 ⋅1,3 3 = 0.091 m 3. 3 V7= 0,5 ⋅ 15,6 (2.5 2 +1.3 2) = 15.483 m 3 .4 V 8 = 0,5 3 ⋅2,5 3 = 0.65 m 3. 3 13. V k = V 1 + V 2 + V 3 + .... +V 8 = 1947.7 m 3. Volume of developed soil V k = 1947.7 m 3. The volume of work for the cleaning and compaction of the soil is equal to the area of the bottom of the boiler S = ab , where a and b - dimensions of the excavation along the bottom. The bottom area is 617.76 m 2. Excavation works 3.1. Selection of a leading machine for the development of trenches and trenches In order to correctly choose the excavator, you need to consider: The volume of earthworks; Dimensions of the excavation (width, depth, area); Geological conditions of the construction site (types of soils, availability of groundwater, etc.); To have data on how the soil will be unloaded (into transport vehicles or "skilful"). Excavator with a straight shovel develops soil I-II groups in a dry slaughter above the level of parking with loading in vehicles or "skill-met." The bucket capacity is from 0.15 to 5 m 3, the bottomhole height is 10 m. Backhoe excavator develops soil I-VI groups below the parking level. The bucket capacity is from 0.15 to 1.25 m 3, the depth of trench digging is up to 5.8 and the pits are up to 4 m. The backhoe excavator is recommended for the development of narrow trenches and small pits "pile-up" and with loading in means of transport. The main indicators, which determine the e몭ectiveness of the excavator, are as follows: 1) the size of the earthen prism tear o몭 by the excavator from one parking lot (step of moving L n) (Figure 21); 2) the angle of rotation of the excavator must be at least 70 ... 90 о and not more than Fig. 21. Options of the excavator 3. Calculation of the volume of excavation excavation excavation Here are the necessary characteristics of the excavator for the performance of the chicken operation: bucket capacity in k, m 3; group of the developed soil; digging depth H cop; digging radius R to n; distance from the axis of the boom to the axis of rotation r w; height of boom heel axis h w; distance from the axis of rotation to the support l o; distance from support to slope (minimum) l P; minimum step size of excavator movement L min. 2.1. Technological map for excavation. 2.1.1. Data for excavation works: 1. Ground - sandy loam, loam. 2. Pipes - steel GOST 10704-91 about 159x4,5 3. The length of the pipeline - l = 346 km. 4. Construction time - summer 5. District of construction - p. Yuzhny, Barnaul 6. Physical and mechanical properties of soil 1) Sandy loam, loam. 4) Group of soil for work: bulldozer - I; Excavator odnokovshovy - P; 2.1.2. Determination of the volume of excavation. 1. Calculation of volumes for trench development. a) Trench width at the bottom: a = Æ + 2a = 0.159 + 2x0.2 = 0.559 m. Due to the fact that the development of the trench is carried out by a multi-bucket rotary excavator with replacement equipment and a working width of 0.6 m, we accept the width of the trench at the bottom and at the top of 0.6 m. In places where it is necessary to lay slopes, vertical walls are fastened with special temporary fasteners, support posts. d) Trench volume: V tranche = (a + B cp) / 2 * h cp * l; where B is the width of the trench between the two pickets; h ср - the height of the trench is intermediate between two pickets; l is the length of the trench section between the two pickets. Calculation of the volume of excavation work on the development of the trench. Table 1 2) The volume of the pipeline: V pipes = (p * d 2 * l) / 4, V pipes (Æ 225Х12,8 mm) = 148,6 m 3. V pipes (Æ 110X6.3 mm) = 0.2 m3. V pipes (Æ 63X4.5 mm) = 0.25 m 3. V pipes commonly. = 149.05 m 3. 3) Soil volume under the pit: V pr = 0.05 * V tranche = 182.28 m 3. 4) Volume of soil by back몭ll: a) Sinning: V sub = V trumpet trumpet - V pipe = 948.1-149.05 = 799.05 m 3. width of the padding on the top: Bn = a cp + 2 * (d + 0.2) * m = 600 + 2 * 0.425 * 0 = 0.6 m; amount of trenching: V subtransfer = (d + 0.2) * L * (A + B under) / 2 = (0.6 + 0.6) / 2 * 0.425 * 1800 = 948.1 m 3. b) Back몭lling: V back몭ll. = V sum. Tranche - V pipes. - V sinus sinus = 3645.546 - 149.05 - 799.05 = 2697.446 m 3. V sum. tranche = V tranche + V pr = 3645.546 + 182.28 = 3827.826 m 3. 5) For the arrangement of cavaliers for back몭lling, the area of its cross-section is calculated by the formula: S кав = V кав /L=3237/3817=0.848, m 2. The volume of soil in the cavalry, taking into account its initial loosening V kav = V ct * K pr = 2697.446 4.2 = 3237, m 3 If the cross section of the cavalier is in the form of an isosceles triangle with a steepness of slopes of 1: 1.5, which corresponds to the steepness of the slopes of the bulk soil, then the height H and the base B in m of such cavalry are expressed by the formulas: Н = S кав /1.5=0.848/1.5=0.57, m; B = 3 * H = 3 * 0.0.57 = 1.7, m 6) Calculation of the scope of work for cutting the plant layer: F cp = A 1 * l = 9.025 * 3817 = 34448.425, m 2 A 1 = 1.7 + 1 + 0.6 + 1 + 0.225 + 1 + 3.5 = 9.025, m 2.1.3 Selection of dump trucks for the delivery of sand during the installation of the pipeline base: a) The volume of soil in a dense body in the bucket of an excavator: V gr. = (Vokov. * K on) / K pr = (0.12 * 0.8) / 1.2 = 0.08 m 3. where V kov is the received volume of the excavator bucket, m 3; K nap-coe몭cient of 몭lling the bucket, adopted: for a rotary excavator 0,8 ... 1; dragline 0.9 ... 1.15; b) Mass of soil in the bucket of the excavator: Q = V gr. * r = 0.08 * 1.7 = 0.136 t. where r - density of soil at natural occurrence, t / m 3. c) Number of buckets in the body of a dump truck: For the transportation distance of 3 km, we choose a Kraz-222 dump truck with a carrying capacity of 10 tons. n = P / Q = 10 / 0.136 = 74 Bucket d) The volume of sand in a dense body, loaded into the truck body: V = V gr. * n = 0.08 * 74 = 5.92 m 3. e) Duration of one cycle of the truck operation: Tc = t n + 60 * l / V r + t n + 60 * 1 / V n + t m = 7.6 + 60 * 3/19 + 2 + 60 * 3/30 +2 = 27.57 min. t n = V * H in p / 100 = 5,92 * 1,8 / 100 = 7,6 min- time of ground loading, min; N cp - the norm of computer time, taking into account the development of excavator 100m 3 of soil and loading into vehicles, mash.min, determined by pENiP2-1; Hpp = 1.8 L - ground transportation distance, km; V г - average speed of a dump truck, km / h, in a loaded state, determined from Table 7; V n = 25 ... 30 km / h - average speed of the dumper in the empty state; t p = 1 ... 2 min - unloading time; t m = 2 ... 3 min - maneuvering time before loading and unloading. e) Required number of dump trucks: N = T c / t n = 25.57 / 7.6 = 4 dump trucks. 2.1.4. Selection of sets of earth - moving vehicles. Technical and economic comparison of sets of machines. It is implemented taking into account the following indicators: 1. The cost of developing 1 m 3 of soil. C = (1.08 * SC Mash shift + 1.5 SZp) / P shift. Vyr. 1.08 - factor that takes into account overhead costs; With mash. shifts - the cost of the machine change included in the kit; P shifts. gt; - shifting of the excavator, taking into account the development of soil and loading into vehicles; SZp - the amount of wages not included in the cost of the machine change; 1.5 - coe몭cient of salary overhead. P shifts. gt; = (8 / H vp) * 100, m 3 / cm, where 8 is the number of hours of operation of the machine per shift; H vr - the norm of computer time, taking into account the development of excavator 100m 3 of soil and loading in vehicles, cars. hour, determined by EniR 2-1. 2. Determine the speci몭c capital investments for the development of 1 m 3 of soil. To ud. = 1.07 / П see * (S (С opt./T year.) 1,07 - the cost factor for the delivery of machines of the manufacturer to the base of mechanization; With opt. - inventory and estimated cost of machines included in the kit; T year. - the normative number of shifts in the work of machines per year. 3. The resulted expenses for development of 1 m 3 of a ground. П уд. = C + E * K ud. E is the normative coe몭cient of investment e몭ciency. 4. The complexity of developing 1 m 3 of soil. T = S T mash. cm / V lead. mache S T mash. cm - total complexity of the set of machines; V Ved. mash - the amount of soil development by the leading machine. We select sets of machines. table 2 I option Leading machine П option Leading machine Rotary Excavator ETR-161 Dragline E - 505 bucket capacity 0.12 m 3 bucket capacity 0.5 m 3 For cutting a plant layer Bulldozer DZ-18 (T-100M) Grader DZ - 14 (D - 395) back몭lling back몭lling Bulldozer DZ-18 (T-100M) Bulldozer DZ-18 (T-100M) IAM-4502 ramming IAM-4502 ramming Site layout Site layout Bulldozer DZ-18 (T-100M) Bulldozer DZ-18 (T-100M) The estimated cost of machinery and the cost of machine-shift mechanisms Table 3 We calculate the technical and economic indicators: For rotary excavator ETR - 161 with the development of soil in the dump. P shifts. gt; = 8 / 1.8 * 100 = 444.4 m 3 / cm C = (1.08 * (44.22 + 3 * 24.5)) / 444.4 = 0.28 rubles. To ud. = 1.07 / 444.4 * (23620/300 + 7210/300) = 0.25 П уд. = 0.28 + 0.15 * 0.25 = 0.607 The obtained data is reduced to a table and compared: Table 4 We accept for the production of works a set of machines and mechanisms of the 몭rst variant, since the parameters of this set are more pro몭table and more economical in comparison with the set of machines and mechanisms of the variant. 2.1.5. Guidelines for the production of earthworks. 1. Cutting the plant layer. The process of cutting the vegetation layer is made by the DZ - 18 bulldozer on the basis of the T - 100M tractor, with the hydraulic drive of the swinging dump. Set of soil is carried out in a rectangular way, to the depth of cutting 0.15 m. The scheme of the bulldozer movement is a strip near the strip. Scheme of soil set: Scheme of bulldozer movement: 2. Development of a trench. The development of the trench is made by a multi-bucket excavator of the ETR-161. The development is carried out in the dump on the frontal pattern, since the work is carried out in unrestricted conditions outside the buildings. Technical characteristics of the ETR - 161 excavator: 1) Bucket capacity - 0.12 m 3 2) Number of buckets - 10 pcs; 3) The greatest depth of digging - 2.4 m; 4) Development width - 0.61 m; 5) The highest discharge height is 5.6 m; 6) Power 86 (118) kWt (hp); 7) Weight - 13.1 tons; 8) Productivity 600m per shift Scheme of the excavator face: Manual re몭nement is done by a team of digging workers to remove excess soil that was not removed by the excavator from the trench and leveling the base. The harvested soil is stored in the cavalier on the edge of the trench. The trench base is constructed by the same brigade - excavators at a height of 15 cm from the bottom of the trench for laying pipes. Scheme of manual revision of the trench: Foundation of the trench. 5. Sinus 몭lling with compaction. Sinning is performed in order to secure the gas pipeline to the trench from shifts and displacements. The ground is taken from the cavalier. Soil compaction is carried out at a height of 20 cm from the top point of the gas pipeline. The soil is compacted by IE-4502 tampers by hand. The scheme of 몭lling the soil in a trench is similar to that of the base device. 5. Back몭lling. Back몭lling is done by bulldozer brand DZ -18 on the basis of the tractor T100M, with a hydraulic drive of the swivel blade, at an angle of 45 ° to the axis of the trench. The ground moves from the cavalier next to the trench. The back몭lling scheme of the trench: 6. Layout. The layout is made by bulldozer DZ-18 on the basis of the tractor T-100. Scheme of bulldozer movement - a strip next to the strip. Upon completion of the planning, soil cover is recultivated with sowing of grasses, which must be carried out no later than one year after the completion of the work. Tra몭c scheme: 2.1.6. Measures for the safety of earthmoving. 1.6.1. General safety requirements for earthmoving: 1. In order to avoid accidents and damage to machinery and equipment, maintenance personnel must know and strictly follow the safety rules. 2. The operator (machine operator) is allowed to operate the machine (equipment), who has received special training and received a certi몭cate for driving the machine. 3. The machine (equipment) must be kept in good order. It is not allowed to start work on a faulty machine (equipment). 4. The engine must be started by the senior in shift. Before starting, it should give a warning signal. 5. Before moving out of the way, the driver must make sure that there are no people in the danger zone and foreign objects. 7. Warehousing of materials, movement and installation of construction machinery and transport within the prism of collapse of the soil is prohibited. 1.6.2. Safety in the operation of a single bucket excavator. 1. When working, the excavator must stand on a horizontal platform that is previously leveled. 2. In the presence of people in a hazardous area, it is prohibited to start the work of an excavator 3. When the engine is running, it is forbidden to carry out the maintenance of the excavator. 1.6.3. Safety in the operation of the bulldozer. 1. When working the bulldozer, the following requirements must be observed: a) stop the car, if there is an obstacle before the cutting edge of the blade, which the bulldozer can not overcome; b) do not push the knife blade over the edge of the slope; c) lowering the heap to the ground when cleaning or repairing it; d) not to approach caterpillars to the edge of the freshly scattered mound closer than 1 m. 2. The machine left with the engine running must be safely braked. 4. The bulldozer is prohibited from: a) Start the movement of the bulldozer without giving a warning signal; b) Leave the bulldozer cab during its movement; c) Take on the chest. 2.1.7. Operational quality control. Operational control is performed in the course of production and after their completion. It is carried out by measuring method or by technical inspection. The results of monitoring are recorded in general and special work journals, journals of geotechnical control. Indicators of operational control in the development of excavations and devices natural grounds *. Table 6 Technical requirements Limit Deviation Scope of control 1. Deviation of the marks of the bottom of excavations from the design (except for excavations in boulders, rock and permafrost soils) during roughing: For excavators with a mechanical drive according to the types of working equipment: dragline +25 cm The measurement points are set randomly, the number of measurements should not be lower: single-bucket excavators equipped with buckets with teeth single-bucket excavators, equipped with a planning bucket, mopping equipment, excavators planners: bulldozers trench excavators scrapers 2. Deviation of the bottom marks of the excavations from the design during roughing in rocky soils and permafrost soils, except for planning Underweight direct digging + 10 cm back shovel + 15 cm for hydraulic excavators: 10 cm + 5 cm not allowed by the table. 5 SNIP 3.02.01-87 Underweight Not allowed 3. The same, without loosening of boulder and blocky soils: Underweight Crossings Not more than the maximum diameter of boulders (blocks) contained in the soil in an amount exceeding 15% by volume, but not more than 0.4 m If the number of measurements per site is at least 20 in the highest places established by visual inspection 4. The same, planning cuts: Underweight Crossings * Method of control - measuring. 13. Calculation of labor costs and wages . Table 7 Name The amount of work Justi몭cation Average time per hour Cutting of the vegetative layer DZ-18 (T- Pricing The cost of labor 100M) Development of a trench excavator backhoe, bucket 0.12 m 3 Foundation in the trench Saddle stitching by tampons IE-4502 Back몭lling with bulldozer DZ-18 (T- 100M) Planning with bulldozer DZ-18 (T100M) 2.1.9. Material and technical resources. Table 8 2.2 Technological map for the assembly of pipes into a thread and a butt joint. 2.2.1 Input data for the work: 2. Pipes - polyethylene (PE-80) Æ 225 X 12.8 mm, Æ 110 X 6.3 mm, Æ 63 X 4.5 mm. 3. Construction time - summer 2.2.2 Determining the scope of work. 1. The length of the pipe is 12 m. 2. The length of the pipeline is 3822 m. 2.2.3 Selection of load-lifting mechanisms by mounting parameters. For the assembly and butt joint of pipes on the edge of the trench, the thread used car cranes. Q = Pe + Sq basic, Р э - weight of the mounted element; Sq basic - The weight of the rigging (slings, traverses, etc.). Q = 102.6 + 27.3 = 129.9 kg. Mounting crane for the assembly of pipes into the thread on the edge of the trench: The installation crane is selected according to the actual weight of the drop pipe, which falls on the crane, with the corresponding boom outreach. R=B/2+a1+a2+a3+b/2 B - width of the trench at the top; b - width of the crane; and 2 - width of the place occupied by the link; and 3 - distance from the pipe to the axis of the crane (pipelayer). According to regulatory data, the weight of the pipes: Table 1 To perform these works, the KS-1561 crane is suitable with the following characteristics: 1) The estimated reach of the boom is -11 m; 2) Carrying capacity - 4 t; 3) The basic car - MAZ-200. Load-lifting device - soft towels PM-521. 2.2.4 Guidelines for the production of work. 1. Assemble pipes into a string. Assembling of pipes in a string is made on the edge of the trench. Pipes are brought by the ZIL-131 pipe carrier and are stored with subsequent assembly. The number of pipes brought by one tube carrier Æ 225 mm - 24 pieces. Pipes of smaller diameters are produced in bays. When assembling pipes into links, external centralizers are used for easy mounting of the type: CNE-8-15 for Æ 110-160 mm; TsNE-16-15 for Æ 160-225 mm. Scheme of work: 2. Butt joint of links. It is carried out by a brigade consisting of welders 5 and 3 digits. Butt welding with a heated tool. Welding of pipes is performed at an ambient temperature of -15 ° C to + 40 ° C. The place of welding protects against precipitation, dust and sand. When welding, the free end of the pipe is closed to prevent drafts inside the welded pipes. The connecting parts are welded to pipes or pipe sections in procurement department at an ambient temperature of at least -5 ° C. Butt welding of polyethylene pipes is performed by the welding machine "Vidos-4600 SPA" with a set of semirings d = 225 mm, the wall thickness is not less than 5 mm. The technological process of joining pipes and parts by butt welding includes: Preparation of pipes and parts for welding (cleaning, assembly, alignment, machining of the ends, checking the coincidence of the ends and gaps in the joint); Welding of the joint (fusion, heating of the ends, removal of the heated tool, joint deposit. Cooling of the joint). Sequence of the process of assembly and welding of pipes from polyethylene. a) Centering and 몭xing the ends of welded pipes in the welding machine clamps. b) Machining of the ends of pipes by means of an edge. c) Checking the accuracy of the coincidence of the ends by the clearance "C" == 0.5 mm for pipes Æ from 110 to 225 mm. d) Fusion and heating of welded surfaces with a heated tool e) Draft of the joint before the formation of the welded joint. Before assembling and welding pipes and 몭ttings, they carefully clean their cavities from soil, snow, ice, stones and other foreign objects. The ends of pipes and 몭ttings are cleaned of all contaminants at a distance of at least 50 mm from the ends. Clean the ends of pipes and parts from dust and sand produce dry or moistened ends (rags) with a subsequent wiping dry. If the ends of pipes or parts are contaminated with grease, oil or any fats, degrease them with alcohol, white spirit, acetone. The ends of the pipes, deformed or having deep (more than 4-5 mm) nicks, are cut o몭. The assembly of welded pipes and parts, including the installation, alignment and 몭xing of welded ends, produce in the clamps of the centralizer of the installation for welding. The ends of pipes and parts are centered on the outer surface in such a way that the maximum displacement of the outer edges does not exceed 10% of the nominal wall thickness of the pipes to be welded. Pipe alignment is performed by turning one or both pipes around their axis, installing supports under the pipes at some distance, using gaskets. With a di몭erence in the thickness of the walls of welded pipes or parts greater than 15% of the nominal wall thickness or more than 5 mm on a pipe (part) having a large thickness, make a bevel at an angle of 15 + 3 ° to the pipe axis to the thickness of the wall of the thin pipe (part). When welding the butt-end of the pipe ends from the clamps of the centralizers is 15-30 mm, and welded parts not less than 5 mm. The 몭xed and centered ends of pipes and parts before welding are subjected to machining-turning, in order to equalize the welded surfaces, directly in the welding plant. After mechanical treatment, surface contamination of the ends is not allowed. Removal of chips from inside the pipe or part is done with a brush, and removing the burrs from the sharp edges of the buttwith the help of a knife. After processing, once again check the alignment and the presence of a gap in the joint. Between the ends brought into contact there should be no gaps greater than: 0,5 mm - for pipes with diameter from 110 to 225 mm inclusive. The gap between the blade tip (GOST 882-75) with an error of 0.05 mm. Butt welding by a heated tool consists in heating the welded ends of pipes or parts to a viscous-몭owing state of polyethylene by direct contact with a heated tool and then joining the ends under the pressure of the deposit after removing the tool. In the process of digging, a pit is made with dimensions of 1.2X1.0X0.7 m. 2.2.5 Selection of vehicles for transporting pipes. Polyethylene pipes are not classi몭ed as dangerous goods GOST 19433, they are transported by any mode of transport in accordance with the rules for the carriage of goods. When packing pipes use the means in accordance with GOST 21650. Pipes delivered to the construction site in the segments are tied into packages fastening in at least three places. When packing pipes in coils and coils, the ends of the pipes must be rigidly 몭xed. Pipes secured in bags are transported by vehicles equipped with platforms and bodies; the distance between the bundles on the packages is not more than 3 m. Transportation on the lapwing trucks is not allowed. When transporting pipes by road, the length of the pipe ends or pipes that are hanging from the body of the machine or platform should not exceed 1.5 m, coils and coils are transported on auto sites. Pipeline nodes are delivered to construction sites in containers in which they are securely fastened. The inscription "DO NOT DROP" is placed on the containers. Pipes are transported on a 몭at surface of vehicles during transportation, protecting them from contact with sharp metal parts. Transportation, loading and unloading of pipes is performed at an ambient temperature of at least -20 ° C. Dropping pipes and 몭ttings from vehicles is not allowed. When loading and unloading works, it is not allowed to move the pipes by dragging. For transporting the pipes, a ZIL-131 cross-country vehicle with a trailer that carries pipes in packages is suitable, with the following technical characteristics: Number of pipes carried Æ 225 mm - 24 pieces; The base car is ZIL-131. 2.2.6 Safety measures in the course of work. 1. To protect the welder from electric shock, the insulation status of the handle of the electrode holder and all current-carrying parts and wires is systematically checked. 3. Cranes and other hoisting gear must be inspected and tested before commissioning. 4. When operating jib cranes, you must not allow people to stay in the zone of their operation; during the lowering of pipes, 몭ttings, 몭ttings and other parts in the trench and wells, workers must be withdrawn from them 2.2.7 Calculation of labor costs and wages . For all types of work is made the calculation of labor costs and wages. Table 7 Name The amount of work Justi몭cation Average time per hour Tube welding on the edge of the trench Butt Weld Butt Welding 9-2-7 T2 No. 2c 2.8. Material and technical resources. Need for operational materials: Pricing The cost of labor Table 3 2.3. Technological map of pipeline laying in a trench 2.3 Technological map laying of the pipeline in the trench. 2.3.1 Input data for the work: 1. Construction conditions - unrestricted. 2. Pipes - polyethylene (PE-80) 0 225 X 12.8 mm, 0 110 X 6.3 mm, 0 63 X 4.5 mm. 3. Construction time - summer 4. District construction - Pavlovsky district. 2.3.2 Determination of the scope of work. The length of the laid pipeline is 3822 m. 2.3.3 Selection of load-lifting mechanisms by mounting parameters. Selection of load-lifting mechanisms. According to regulatory data, the weight of the pipes: Table 1 Pipelayers T-614 are used for laying the pipeline in a trench, which are selected in the same way as the installation cranes. Characteristics of the pipelayer T - 614: 1) The estimated reach of the boom is 5.53 m; 2) Carrying capacity - 6,3 t; 3) The moment of stability - 16 tons * m; 4) Basic tractor - DT-75; 5) The speed of lifting the load, m / min - 8,3; 6) Lowering speed of cargo , 7) Travel speed, km / h: forward-3.05-6.5; back-2.6-3.25; m / min - 8,3; 8) Basic dimensions (with a vertically raised boom and counterweight attached), mm length - 4560; width - 3640; height-6000; 9) Weight, t-11.9. Load-handling device - traverses. 2.3.4 Guidelines for the production of packings. 1. Pipeline laying in the trench. Laying of the pipeline into the trench is made by the T-614 pipelayers with a payload capacity of 6.3 tonnes, the estimated reach of the boom is 5.53 m. As a load-handling device, traverses are used for laying. Scheme for laying the pipeline in a trench using traverse for both pipelayers: 2.3.5 Safety measures for the production of packings. 1. Lowering of pipes, various materials and parts into the trench is carried out mechanically using pipelayers. Dumping pipes and materials in a trench is prohibited. 2. Passports and individual numbers for which they are recorded in a special register of their technical condition must be entered into all machines and devices. 3. Pipelayers must be inspected and tested before commissioning. 4. When pipelayers work, one should not allow people to stay in the zone of their operation; during the lowering of pipes, 몭ttings, 몭ttings and other parts in the trench, workers must be withdrawn from them 2.3.6 Calculation of labor costs and wages. For all types of work is made the calculation of labor costs and wages. 2.3.7. Material and technical resources. Need for operational materials: Table 3 2.4 Technological map for pipeline testing. 2.4.1 Input data for the work: 1. Construction conditions - unrestricted. 2. Pipes - polyethylene (PE-80) Æ225 X 12.8 mm, Æ 110 X 6.3 mm, Æ 63 X 4.5 mm. 3. Construction time - summer 4. District construction - Pavlovsky district. 2.4.2 Determination of the scope of work. The length of the pipeline under test is 3822 m. 2.4.3 Selection of the compressor station. 1) Discharge pressure - 2.5 MPa; 2) Productivity - 12 m 3 / min; 3) The basic car - KRAZ-257; 4) Overall dimensions - 9.66 X 3.02 X 3.06 m; 5) Mass-21 tons. 2.4.4. Guidelines for the production of test works. The gas pipeline in the city is tested for strength and density. To clean the inner cavity of pipes from scales, moisture and contaminants before testing, blow. Purge is produced by air with a pressure of 7 * 133.3 Pa for which the temporary valves are installed. The gas pipeline is tested for strength by air during construction, with a test pressure of 4.5 * 10 5 Pa. The test time is 1 hour. At the same time, a visible pressure drop across the manometer is not allowed. Detected defects must be eliminated before the density test. The gas pipeline is tested for density by air with a test pressure of 3 * 10 5 Pa, the test duration is not less than 24 hours. The results of the density test are considered positive if the actual pressure drop does not exceed the design value determined for a gas pipeline of the same diameter by the formula: The gas pipeline, when tested for density, is kept under pressure for at least 30 minutes, after which, without lowering the pressure, an external inspection is performed and all welded, 몭anged and threaded joints are checked with a soap solution. In the absence of a visible drop in pressure on the manometer and leaks during saponi몭cation, the gas pipeline is considered to have passed the test. When testing the gas pipeline, in the course of production, inventory caps with rubber seals are installed. The work schedule is shown in the graphic part of the technological map. 2.4.5. Measures for safety in the manufacture of installation work. 1. Passports and individual numbers must be entered on all machines and devices, according to which they are recorded in a special register of their technical condition. 2. The compressor station must be inspected and tested before commissioning. 3. When testing the gas pipeline with air, all shut-o몭, safety and discharge devices must be checked in the most careful manner. 4. When raising the air pressure in the gas pipeline, it is forbidden to people near inventory dummies. 5. No work on liquidation of defects in a gas pipeline under pressure can be made. 6. At the ends of the tested gas pipeline there should be inventory plugs, as well as anchorages that absorb the forces that arise in the pipeline when the pressure rises. 7. During the test, the presence of people within the guard zone is prohibited. 2.4.6. Calculation of labor costs and wages. For all types of work is made the calculation of labor costs and wages. Table 1 2.4.7. Material and technical resources. Need for operational materials: table 2 2.5. Technological card for purging pipeline. 2.5.1. Original data for the work: 1. Terms of construction - unrestricted. 3. Pipes - polyethylene (PE-80) - Æ 225Х12,8 mm, Æ110Х6,3 mm, Æ 63X4.5 mm. 3. Construction time - summer 4. District construction - - Pavlovsk district. 2.5.2. Determination of the scope of work. The length of the blown pipeline is 3822 m. 2.5.3. Choice of compressor station. The compressor station is selected by performance, discharge pressure and mobility. The required parameters correspond to the compressor station SD 12/25, with technical characteristics: 1) Discharge pressure - 2.5 MPa; 2) Productivity - 12 m 3 / min; 3) The basic car - KRAZ-257; 4) Overall dimensions - 9.66 X 3.02 X 3.06 m; 5) Weight - 21 tons. 2.5.4. Guidelines for the production of blowdown operations. Purging the gas pipeline. The gas pipeline is purged in two stages: 1. Filling the receiver; 2. Purging the gas pipeline. At the 몭rst stage, one part of the pipeline is 몭lled with air to a pressure of 1 MPa. At the second stage, the remaining part is blown through the inventory blowdown unit. During the production process, the detected faults are eliminated. The scheme of production is presented in the graphic part of the technological map. 2.5.5. Measures for safety in the manufacture of blowdown operations. 8. Passports and individual numbers must be entered into all machines and devices, according to which they are recorded in a special register of their technical condition. 9. The compressor station must be inspected and tested before commissioning. 10. When testing the gas pipeline with air, all shut-o몭, safety and discharge devices must be checked in the most careful manner. 11. When raising the air pressure in the gas pipeline, it is forbidden to people near inventory stubs. 12. No work on liquidation of defects in a gas pipeline under pressure can be made. 13. At the ends of the gas pipeline under test, there should be inventory plugs, as well as anchorages that absorb the forces that arise in the pipeline when the pressure rises. 14. During the test, the presence of people within the guard zone is prohibited. 2.5.6. Calculation of labor costs and wages. For all types of work is made the calculation of labor costs and wages. Table 1 Justi몭cation Name The amount of work Average time per hour Pricing The cost of labor Purging the gas pipeline (몭lling the receiver) Purge gas pipeline (purge) 2.5.7. Material and technical resources. Need for operational materials: table 2 2.6. Technological map for the puncture. 2.6.1. Original data for the work: 1. Construction conditions - unrestricted. 2. Pipes - polyethylene (PE-80) - Æ 225Х12,8 mm, Æ110Х6,3 mm, Æ 63X4.5 mm. 3. Construction time - summer 4. District construction - Pavlovsky district; 1. Ground - loam; 2. Physical and mechanical properties of soil 1) Sandy loam, loam. 2) Average density in natural occurrence - r = 1,65 t / m 3, - r = 1,8 t / m 3 3) The coe몭cient of initial loosening is 20% (K pr = 1,2). 2.6.2. Determination of the scope of work. The length of the puncture is up to 90 m. 2.6.3. Selection of load-lifting mechanisms by mounting parameters. Selection of load-lifting mechanisms. For the installation and dismantling of equipment for puncturing, car cranes are used. The crane's load capacity is determined by: Q = P e + Σq basic. , P e is the weight of the mounted element; Σq basic - The weight of the rigging (slings, traverses, etc.). Q = 102.6 + 27.3 = 129.9 kg. The installation crane is selected according to the actual weight of the equipment being lowered, which falls on the crane, with the corresponding boom output. The calculated reach of the crane's boom (from the vertical axis of the crane's rotation to the trench's center) will be: R=B/2+a1+a2+a3+b/2 B - width of the trench at the top; b - width of the crane; a 1 - distance from the edge of the trench to the pipe; a 2 - width of the seat occupied by the link; a 3 - distance from the pipe to the axis of the crane (pipelayer). R = 0.6 / 2 + 1.0 + 0.225 + 2 + 3.6 / 1 = 5 m To perform these works, the KS-3561 crane is suitable with the following characteristics: 1) The estimated reach of the boom is 14.5 m; 2) Carrying capacity - 10 t; 3) The basic car - MAZ-200. Load-handling device - steel slings. 2.6.4. Directions for the production of works with horizontal extrusion. Puncturing is performed using a pipe provided with a tip that is pressed into the ground. In order to push the pipe shells into the ground during piercing, an installation consisting of two GD170/1150 jacks is used. Hydraulic jacks ГД-170/1150 are actuated by high-pressure pumps of grades Н-403 and Г-17. Transmission of the pushing forces of the pipe to be laid (the case) is carried out by clamping yokes (screw). Installations for piercing piercing pockets are mounted in working pits, 10-13 m long and 2.2 m wide and 2.5 m deep. The length of the receiving trench along the bottom is 1-1.5 m. Vertical guide frames for laying steel cases are made from wooden beams at the same time as the device fastening the front wall of the working pit. Horizontal frame guides are installed at the bottom of the working pit and are made of shortened sleepers and rails. The length of the guide frames is assumed to be 1-1.5 m less than the length of the links of the casing being laid; with the extension of the casing being laid with links of 6 m in length, the guide frames should be 4.5-5 m. To transfer the reactive piercing forces to the ground, I-type stop walls are used. To transfer the pressure forces from the hydraulic installation to the stop wall of the foundation pit, support packages are used from the sections of rails welded together. On the image. 1 shows the basic shoe of the Soyuzvodokanal project for pressing forces up to 980 kN 2-kerchief 4-rib of rigidity To transfer pressure to the ends of the pushers, pressure plugs are used, which are made from a piece of pipe, which is closed at both ends by shaped 몭anges. For the transfer of pressure from the jacks to the pressure plugs are pressure connections with 몭anges: the length of the link is 8 m, the outer diameter is 219 mm, To reduce the friction resistance when laying pipes and casings by piercing, use various tips with an external diameter, 20-50 mm larger than the diameter of the casing being laid. Use cone-shaped tips of welded construction. Horizontal extrusion is carried out by installing PU - 2 up to 100 m long from the worker into the receiving trench. After the puncture the equipment is dismantled. Schemes for the production of works are given in the graphic part of the project. Speci몭cations of hydraulic jack GD-170/1150: 1. The force developed by the rod, those in the course of: Straight-170; The reverse-88; 2. Working pressure of the liquid, MPa-29.4; 3. The stroke of the rod is 1150 mm; 4. The diameter of the cylinder is 273 mm; 5. The length of the jack is 1618 mm; 6. Weight - 547 kg. 2.6.5. Measures for safety in the manufacture of horizontal work extrusion. 1. During the whole period of the work on the device of transitions, surveillance should be carried out from the distance of the track and the line-operational services. 2. Installation of warning signs and posters is also carried out, which is checked by the responsible representative who issues a written permission for their installation. The boards indicate a maximum speed of 40 km / h. 3. The operation of mechanisms close to the inside of electri몭ed railroads is carried out in accordance with the requirements of GOST 12.1.013. "The safety rules for workers of railroads. Transport on electric lines 23/3288. 2.6.6. Calculation of labor costs and wages. For all types of work is made the calculation of labor costs and wages. Table 1 Justi몭cation Name The amount of work Average time per hour Pricing The cost of labor 9-2-10 T1 No.1 a The device of a wooden thrust wall Installation 9-2-10 T2 No.1 a of equipment 1 for installation horizontal extrusion 9-2-10 T2 No.2 a 1 installation Dismantling of equipment for horizontal extrusion 9-2-10 T3 No. 8 g Pressing of steel pipes with a hydraulic jack without soil development Trumpet trenching 2.6.7. Material and technical resources. The need for operational materials. ALSO ON THE TOPIC Aster terry perennial Houses made of round logs Pile for foundation pit, foundation pits strengthening Manufacturing of stamps and seals Forged gates with own hands FENCE Automatic for airing the greenhouse with their own hands Construction of a house made of foam blocks Roof end: types, purpose and assembly COMMUNICATIONS Counting the volume of excavation work Basic parameters of single bucket excavators Wooden facades, restoration or new decoration INTERIOR DECORATION OF THE HOUSE Calculation of materials for roo몭ng from bitumen shingles Miniature well - master class Principle of operation of the hydraulic cylinder BATHHOUSE Big football goal with your own hands Hydroplombs - sealing of water leakage through cracks and holes How to wait for a meeting with your soulmate FLOOR Flowers without seedlings Foam made of polystyrene "Elka" Types and methods of excavation works about the project Contacts Site Map © 2018 Construction and repair by own hands