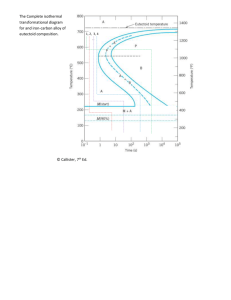

Lab Report Template Lab 1 ‐ Metallography 1. Summary Experiment Objective: The objective of this experiment was to conduct a comprehensive metallographic analysis of various metal samples, including pure metals, solid solution alloys, steels, and cast irons. Through precise sample preparation techniques involving mounting, grinding, polishing, and etching, we aimed to uncover and document the internal microstructure of these materials. By using metallographic microscopes, we examined the samples at both low and high magnifications, enabling the identification of different phases and the construction of each metal. Additionally, we sought to estimate grain sizes and examine the relationship between microstructure and material properties. Results and Conclusions: Our examination of the microstructures yielded valuable insights into the nature of the metal samples. We identified distinct phases within each material, such as ferrite and pearlite, depending on the sample type. This analysis allowed us to draw connections between microstructure and material properties. Notably, we observed that variations in composition and carbon content influenced the microstructure, which in turn affected properties like hardness, tensile strength, and ductility. Additionally, the successful identification of an unknown sample through microstructural analysis showcased the practical applications of metallography in materials science and engineering. 2. Results and Observations 2.1 Record the etching response time for each sample in the table provided Sample SAE 1020 SAE 1045 SAE 1080 Iron Ingot Etch Response Time (Seconds) 10-20s 10-20s 13s 25s 2.2 Attach the micrographs of the four samples in the space provided. Indicate the magnification and label all phases present. Record additional observation in the space provided (e.g., differences between the microstructure of these samples). 1 Sample #1 ‐ Ingot Cast Iron Micrograph Additional Observations In ferrite phase sine theres low carbon content No substantial black grains – impurities or low carbon Sample #2 ‐ SAE 1020 Steel Micrograph Additional Observations Both black and white grains. White grains are ferrite and black grains are pearlite. 2 Sample #3 – SAE 1045 Steel Micrograph Additional Observations Mostly pearlite in this section it seems. Ferrite phase grains are large. Sample #4 ‐ Unknown Sample Micrograph The SAE 1080 Additional Observations Mix between black cementite and white ferrite. All grains in pearlite phase 3 2.3 Calculate the grain size (grain diameter) of Sample #1 (the ingot cast iron). Take three measurements and show your grain size calculation in the space provided. (17.674 + 7.579 + 11.087)/3 = 12.11 μm 3. Provide answers to the questions given by the TA and attach them to the end of this template. Discuss what pearlite and ferrite looks like under the microstructure and list their properties. Pearlite and ferrite are two microstructural components commonly found in metals, especially in steel. Pearlite has a layered structure with alternating light (ferrite) and dark (cementite) bands, resulting from a eutectoid reaction during cooling. It is intermediate in hardness, contributes to strength, enhances ductility, provides toughness, and has moderate electrical conductivity. Ferrite, on the other hand, appears as a bright phase with a cubic crystal structure (body-centered cubic or BCC). It is relatively soft, highly ductile, ferromagnetic, and offers good electrical conductivity. Some stainless steel alloys contain ferrite for corrosion resistance. Discuss the effect of grain size on the strength and toughness of the material and explain why The grain size of a material significantly influences its mechanical properties. Smaller grain sizes lead to increased strength through grain boundary strengthening and the Hall-Petch relationship, as finer grains create more obstacles to dislocation motion. Conversely, larger grain sizes tend to enhance toughness and ductility, allowing for more plastic deformation and energy absorption during fracture, reducing the risk of brittle failure. The interaction between dislocations and grain boundaries explains these effects, with materials containing finer grains being stronger but potentially more brittle, while those with larger grains offer improved toughness and ductility. Compare carbon content vs microstructure, their relation, and discuss the effect of increasing carbon content in the material and how it affects the microstructure. The relationship between carbon content and microstructure in materials like steel significantly impacts their mechanical properties. Low-carbon steel (up to 0.3% carbon) is soft and ductile due to its ferritic microstructure. Medium-carbon steel (0.3% to 0.6% carbon) transitions to pearlite, offering a balance of strength and ductility. High-carbon steel (above 0.6%) becomes hard but brittle with cementite dominance, while very high carbon levels (above 0.8%) yield extremely hard but brittle martensite. Engineers choose materials based on this relationship, selecting low carbon for ductility and toughness, and high carbon for hardness and wear resistance, while considering trade-offs between these properties for specific applications. 4