MSc IN LOGISTICS AND SUPPLY CHAIN

MANAGEMENT

SCHOOL OF ECONOMICS

Dissertation Project

Assessing the Impacts of Supply Chain 4.0

Solutions on Supply Chain Operations

Ntanatsas Christos

Supervisor: Dr. Michael Madas

ABSTRACT

The digitalization - digital transformation of the firms does not focus only

on the creation and adoption of the new technologies. It can also consist an

important tool for the redesign of a company in the way by which it can

connect its data, its people, and its processes both in the internal and the

external environment of the company. As its point of reference, the fourth

industrial revolution has the combination of knowledge and training of

machines, data science (Data Science) and technical intelligence (Artificial

Intelligent), which both can and do create an innovative, useful, and

competitive environment for companies (MIT Forbes 2019). Most companies

focus on the digital formation of their supply chains (digital supply chain).

In order for the companies to become competitors and increase their profits,

they must invest in the digitization of supply chains. Thus, their main

priority is the training of staff in the latest technological innovations.

Nowadays, the rate of digitization has improved considerably due to the

possibilities that companies now have. The creation of new applications

resulted in many improvements in areas such as transactional activities,

the planning and organization of the entire supply chain, the management

and coordination of the warehouses, the forecast of the demand and, finally,

the acceleration of analysis in decision - making. By applying digitization

and new technologies, the new innovations that offered various benefits to

supply chains and logistics services were Augmented Reality (AR), Big Data

(BD), Cloud Computing (CC), Robotics (R), Internet of Things (IoT), SelfDriving Vehicles (SDV), and 3D Printing (3DP). Another part of the

digitalization are the customers. When the customers are at the center of

the digital ground, the influence of digitalization is more effective. In short,

digitization focuses on new technologies for the purposes of improving

service levels, flexibility, costs, leadership, forecasting, inventories, as well

as for the purposes of properly implementing the processes and

organizational changes that will occur, in order to achieve the goals that

businesses aim for. Although innovations and digital transformations have

had a serious impact on supply chains, especially on the digital supply

chain, they were presented with many challenges. The present thesis

examines the impact supply chain 4.0 technologies have on supply chain

operations. It utilizes the Scor model, including functions, metrics and Kpis.

The purpose of the present thesis is to analytically present each individual

technology and critically evaluate their effects. The method that is used to

evaluate the impact supply chain 4.0 technologies have on supply chain

operations is the House of Quality. The key findings of the thesis are, all

operations in the supply chain are interconnected with no clear borders

among them. Thus, some technologies can result in either positive or

negative effects. Despite the challenges, it is concluded that the supply

chain will become smarter, more transparent and efficient at every stage,

through digital transformation and the use of intelligent technologies.

1

Table of Contents

ABSTRACT ..................................................................................................... 1

CHAPTER 1 .................................................................................................... 7

Introduction .................................................................................................... 7

1.1 Overview ................................................................................................ 8

1.2 Supply Chain 4.0 ................................................................................. 9

1.3 The reasons to evaluate SC 4.0 technologies on SC operations. ....... 10

1.4 Aim and objectives .............................................................................. 12

1.5 Outline of the thesis ............................................................................ 13

CHAPTER 2: METHODOLOGY.................................................................. 15

SYSTEMATIC LETERATURE REVIEW .................................................... 15

2.1 SYSTEMATIC LETERATURE REVIEW .......................................... 16

2.2 Systematic literature review justification. ........................................ 17

2.3 Systematic literature review steps ..................................................... 18

2.3.1. Mapping score research ............................................................... 18

2.3.2. Define Research Scope ................................................................. 19

2.3.3. Identify the keywords and the literature sources. ..................... 20

2.3.4. Search strings ............................................................................. 20

2.3.5. Define the search criteria. ........................................................... 21

2.3.6. Data extraction ........................................................................... 22

2.3.7. Analyze and synthesize the data. ............................................... 23

2.3.8. Writing Up ................................................................................... 23

CHAPTER 3 .................................................................................................. 24

DESCRIPTIVE ANALYSIS ......................................................................... 24

3.1 Chronological Analysis ....................................................................... 25

3.2 Geographical Analysis ........................................................................ 25

3.3 Quantitative and qualitative approach .............................................. 27

3.4 Overview of existing SC 4.0 Technologies. ......................................... 28

CHAPTER 4 .................................................................................................. 37

Supply chain 4.0 Technologies ..................................................................... 37

Internet of Things: IoT.............................................................................. 38

Big Data..................................................................................................... 39

Cyber-physical System.............................................................................. 40

Intelligent Transportation System ........................................................... 42

2

3D-printing ................................................................................................ 43

Cloud Computing ...................................................................................... 44

Drones........................................................................................................ 46

Artificial Intelligence ................................................................................ 46

Blockchain ................................................................................................. 48

Internet of Services ................................................................................... 50

Deep Learning ........................................................................................... 52

RFID (Radio Frequency Identification).................................................... 53

Data mining............................................................................................... 55

Augmented Reality ................................................................................... 57

Robotics ..................................................................................................... 59

Smart Sensors ........................................................................................... 61

Automatic guide vehicles (AGV) ............................................................... 62

Real Time Locating System ...................................................................... 64

Autonomous mobile robots (AMRs) - Warehouse Robots ........................ 65

Machine 2 Machine ................................................................................... 68

Self-driving Vehicles ................................................................................. 70

CHAPTER 5 .................................................................................................. 72

SUPPLY CHAIN OPERATIONS REFERENCE (SCOR) ........................... 72

MODEL ......................................................................................................... 72

5.1 Introduction ......................................................................................... 73

5.2 SCOR Model ........................................................................................ 74

5.2.1 Process ........................................................................................... 75

5.2.2 Metrics and performance attributes ............................................ 78

Performance attribute ........................................................................... 79

Metrics .................................................................................................... 80

CHAPTER 6 .................................................................................................. 83

Impact Assessment ....................................................................................... 83

6.1 Introduction ......................................................................................... 84

6.2 The combination of SCOR model and Technologies with HoQ ......... 85

6.3 The reasons to use QFD-HOQ. ........................................................... 86

6.4 Quality Function Deployment (QFD) ................................................. 87

6.5 House of Quality Chart (HOQ) ........................................................... 88

6.6 Previous Relevant Research. .............................................................. 90

3

6.7 Assessment of Supply Chain 4.0 Solutions on supply chain

operations. ................................................................................................. 91

6.8 Results ................................................................................................. 95

6.8.1 The profile of the experts .............................................................. 97

6.8.2. Discussion of results .................................................................... 97

CHAPTER 7 ................................................................................................ 101

Challenges and Barriers ............................................................................ 101

7.1 CHALLENGES AND BARRIERS ....................................................... 102

7.1.1. Political challenges .................................................................... 102

7.2.2. Environmental Challenges and Organizational Challenges .... 103

7.3.3. Technical Challenges ................................................................. 104

7.2 CONCLUSIONS- FUTURE RESEARCH ........................................... 105

REFERENCE ............................................................................................. 107

4

List Of Figures

FIGURE 1.1: TRADITIONAL SUPPLY CHAIN ..................................................................... 11

FIGURE 1.2: SUPPLY CHAIN ECOSYSTEM ......................................................................... 11

FIGURE 1.3: OUTLINE OF THE THESIS ............................................................................. 13

FIGURE 2.1:SYSTEMATIC LITERATURE REVIEW ............................................................. 17

FIGURE 2.2: RESEARCH SCOPE ........................................................................................ 19

FIGURE 2.3: PROCESS OF DATA EXTRACTION ................................................................. 22

FIGURE 3.1: YEAR OF PUBLICATIONS .............................................................................. 25

FIGURE 3.2: CONTINENT DISTRIBUTION OF ARTICLES .................................................. 26

FIGURE 3.3: COUNTRY DISTRIBUTION OF ARTICLES ..................................................... 27

FIGURE 3.4: STUDY METHOD DISTRIBUTION ................................................................. 28

FIGURE 4.1: REPRESENTS THE ARCHITECTURE OF IOT ................................................. 39

FIGURE 4.2: REPRESENTS THE ARCHITECTURE OF BIG DATA ....................................... 40

FIGURE 4.3: REPRESENTS THE ARCHITECTURE OF CPS ................................................. 42

FIGURE 4.4: REPRESENTS THE ARCHITECTURE OF ITS .................................................. 43

FIGURE 4.5: THE ROLE OF 3D-PRINTING TO SUPPLY CHAIN .......................................... 44

FIGURE 4.6: THE OVERVIEW STRUCTURE OF CLOUD COMPUTING .............................. 45

FIGURE 4.7: PRESENTS THE ROLE OF DRONE IN A LARGE WAREHOUSE ........................ 46

FIGURE 4.8: THE ARTIFICIAL INTELLIGENCE IN THE WAREHOUSE .............................. 48

FIGURE 4.9: THE BLOCKCHAIN TECHNOLOGY .............................................................. 50

FIGURE 4.10:THE INTERNET OF SERVICES ..................................................................... 51

FIGURE 4.11: PRESENTS THE ARCHITECTURE OF DEEP LEARNING ................................ 53

FIGURE 4.12:THE ARCHITECTURE OF RFID SYSTEM ..................................................... 55

FIGURE 4.13:PRESENTS THE ARCHITECTURE OF DATA MINING .................................... 57

FIGURE 4.14:THE AUGMENT REALITY SYSTEM .............................................................. 59

FIGURE 4.15:THE ROBOTS AND DRONES IN THE WAREHOUSE...................................... 60

FIGURE 4.16:PRINCIPAL COMPONENTS OF THE ARCHITECTURE OF SMART SENSORS .. 62

FIGURE 4.17:EXAMPLES OF AVG IN THE WAREHOUSE ................................................. 64

FIGURE 4.18:ARCHITECTURE OF RTLS .......................................................................... 65

FIGURE 4.19:EXAMPLE OF THE AMR IN THE WAREHOUSES ......................................... 66

FIGURE 4.20:EXAMPLE OF WAREHOUSE ROBOTS........................................................... 68

FIGURE 4.21:PRESENTS THE ARCHITECTURE OF MACHINE 2 MACHINE ...................... 69

FIGURE 4.22:THE SELF-DRIVING VEHICLE, ROBOT AND THE DRONE ............................ 71

FIGURE 5.1:SCOR MODEL .............................................................................................. 74

FIGURE 5.2:SCOR MODEL'S LEVELS ............................................................................... 76

FIGURE 6.1: THE STEPS FOR THE OVERALL RESEARCH METHODOLOGY ...................... 86

FIGURE 6.2: HOQ CHART ................................................................................................ 89

5

List Of Tables

TABLE 1: THE DATABASES USED FOR THE RESEARCH .................................................... 20

TABLE 2: SEARCH STRINGS .............................................................................................. 21

TABLE 3: FINAL ACCOUNT OF DATA ............................................................................... 23

TABLE 4: KEYWORDS FREQUENCY ................................................................................. 30

TABLE 5: LITERATURE REVIEW TABLE ........................................................................... 31

TABLE 6: SCOR MODEL PROCESS ................................................................................... 76

TABLE 7: SCOR MODEL ATTRIBUTES ............................................................................. 80

EXPERT PANEL SURVEY ........................................................................................... 94

MASTER EXPERT PANEL .......................................................................................... 96

6

CHAPTER 1

Introduction

The first chapter is the introductory chapter of the present thesis. The

structure of this chapter is explained by the following figure:

7

1.1 Overview

According to the Council of Supply Chain Management (CSCM), supply

chain includes many activities and methods for the best coordination

between the suppliers and the final customers. In other words, supply chain

is the key for the original suppliers, partners, companies, and stakeholders

to share, use and produce information, services, and products with others

or among them (Schrauf & Berttram, 2016). The rapid changes and growth

that occur in the technological and financial aspects have an impact on the

supply chains development (MacCarthy et al., 2016). In order for the

companies to achieve their main goals, to “stay” competitive and capable of

maximizing their revenue and minimizing their risks, they must

incorporate the new technologies in their operating environment (Kaprova,

2017). Nowadays, technology is a necessary factor in the supply chain of all

firms, which try to adapt to these changes as rapidly as possiblein order to

operate better (Sehgal, 2011). In this new digital era, the influence of the

fourth industrial revolution (Industry 4.0), such as the Information and

Communication, Internet of Things (IoT) etc., based on the cyber-physical

system (CPS) for the logistics services and the supply chain applications,

leads to digitalization (digital transformation). The digitalization can be

considered as a digital transformation in logistics, which improves the ways

of communication and the exchange of information through the supply

chain. For example, the communication between the supply chain

managers, logistics service providers and final customers can be performed

under an online network. Because of the applications and technologies of

Industry 4.0, the digitalization in the supply chain has made the companies

and many industries to direct their attention in these transformations.

(Büyüközkan & Göçer, 2017). With the influence of industry 4.0, terms such

as ''Supply Chain 4.0'', ''Digital Supply Chain'' DSC, ''Digital Logistics'', we

can now be seen in the field of industries and companies. These terms

illustrate the application of the digital technologies in the process of

manufacturing, trading and logistics, which are connected by a network in

order for the final products or services to arrive at the final consumers.

Specifically, in the modern era, supply chain 4.0, or digital supply chain

(DSC), can be defined as a sum of interconnected processes that associate

with the coordination, planning and controlling of services or products

between the suppliers and customers. (Büyüközkan & Göçer, 2017).

Moreover, the manufacturing process is constantly evolving by a large scale

and therefore affects all the different parts of the supply chain. The aim is

to educate the big firms on how to improve their revenues, by effectively

using the new digital technologies in their organization.

8

1.2 Supply Chain 4.0

As was referred before, the term “supply chain 4.0” can be considered as the

sum of activities of the supply chain, such as design, planning, consumption,

production, distribution and reverse logistics with the use of the digital

technologies, that were developed in the fourth industrial revolution,

“Industry 4.0'”. Particularly, in the modern day, Supply chain 4.0 can be

defined as a number of interconnected processes that associate with the

coordination, planning and controlling of services or products between the

suppliers and customers. (Büyüközkan & Göçer, 2017). Moreover, the

manufacturing process is constantly evolving by a large scale and therefore

affects all the different parts of the supply chain. The firms should adopt

the new technologies rapidly and become aware of how supply chain 4.0 will

help them coordinate their business more effectively. The objective is the

creation of new methods in order to improve communication and

collaboration for consumers and suppliers, manufacturing, forecasting,

acquisition, distribution, sales and marketing, as well as other activities

that happen in the process of supply chain (Chan, 2003). Finally, the most

important aim is for firms to improve their revenue and become more

competitive against other firms (Büyüközkan & Göçer, 2017, Tjahjono et al.,

2017). Supply Chain 4.0 has six characteristics (Wu et al. 2016).

1. Instrumented: The systems with sensors, RFID tags and other meters

that are useful to gather all of the information - data for better decision making.

2. Interconnected: All the supply chain's members are connected, for

example the IT systems (Information Technology), the products, their

assets, and many other objects.

3. Intelligent: Smart systems that are collecting and analyzing a high

number of data, in order to improve decision - making and maximize the

performance.

4. Automated: Automated activities that have the objective of replacing the

resources with the lowest efficiency.

5. Integrated: Integrated activities that are useful among the members for

decision - making, collaboration, communications and using the common

systems.

6. Innovative: The capacity for developing new values after receiving the

most efficient solution for a problem.

In summary, the digital supply chain is a very useful process to gain new

forms of revenue and to develop new technological approaches for the firms.

Supply chain 4.0 is about the way processes are managed under a new

variety of innovative technologies, not about digital goods or services.

9

1.3 The reasons to evaluate SC 4.0 technologies on SC operations.

At first, supply chains link the suppliers with the customers in a linear

manner, in order to deliver the products. In fact, every firm has sourcing

inputs from suppliers and, in turn, delivers the products or services to

consumers. The firms in “simple supply chains” (figure 1.1 provides the

steps of traditional supply chains), or “traditional supply chains”, use

regular methods for the communication between their suppliers and

customers, such as telephone, fax, e-mail or sometimes the negotiations

were performed face to face. These tools were used many years ago and,

even in our days, they form the main means of communication for a lot of

supply chains. However, such means result are neither time, nor cost

effective. Another problem that firms used to have is the difference between

the supply and the demand. This happened, because the process of every

supply chain was to link the customers to the suppliers, with each firm

delivering the products or services to consumers. The aim was for every firm

to successfully deliver the products in the best time and with least

percentage of failure. The planning process was designed to guarantee that

the deliveries and the supplier’s delivery activities were organized in

accordance with the customers’ activities. With the passage of time and the

evolution of technology, various new technologies were applied in the

functions of the supply chain. The purpose was to solve all the above

problems, but also to upgrade the functions of the supply chain in all of its

parts. However, with the application of new technologies, there were

various effects on the logistics. For example, some companies made use of a

new technology, but without knowing the effects it would have on other

functions of the chain. The use of a technology will certainly have different

implications for certain logistics functions. Obviously, the effects for some

functions will be positive and for some negative. Another possibility is that

some of the functions are not affected at all. Moreover, some technologies

did not offer what was necessary in logistics and had a high cost, as they

created disadvantages in several cases. Finally, after considering all of

these problems, SC 4.0 technologies can be applied to supply chain

operations to improve an integrated supply chain ecosystem. The flow of

information is directed in every part of the firm correctly and efficiently and

the response takes place in real time. In order to rapidly respond to the

changes in customer demand and to track and trace them effectively, supply

chains have enabled new sensing technologies, that are called internet of

things (IoT), including radio frequency identification (RFID), Bluetooth,

and GSM (global system for mobile communication), as well as many others.

With these digital transformations, the firms can watch the changes in

customers’ demand and respond rapidly and effectively to them. Thus, with

a good supply chain coordination, the firm can ultimately achieve a

competitive advantage. In conclusion, the need to evaluate all SC 4.0

technologies in logistics functions is very important.

10

Figure 1.1: Traditional supply chain

Figure 1.2: Supply chain ecosystem

Source: Michael J. Ferrantino, Emine Elcin Koten

11

1.4 Aim and objectives

Nowadays, the digitalization and the digital transformation of the supply

chain is a topic that one needs to pay attention to. With the rapid

improvement of the industry revolution, the firms adopt all these new

technologies and innovations, in order to become more competitive in the

economic world of the market. The present thesis focused on published

academic journals, articles and books. The present literature review focuses

on the property and characteristics of each technology 4.0 separately, as

well as on the impact they have and the way they are used in the operations

of the supply chain. Additionally, the present literature review tackles the

challenges and barriers posed by digitization. In conclusion, the present

thesis will focus on the review of published academic work on the impact of

SC 4.0 technologies on supply chain operations and, more specifically, on

the analysis of the digital integration of the levels of the SCOR model. The

current thesis examines two main objectives:

Objective 1. To review the impacts of Supply Chain 4.0 technologies on

supply chain operations.

Research Question: What is the impact of SC 4.0 technologies on

supply chain operations?

Objective 2. To present the challenges and barriers.

Research Question: What are the challenges and barriers of digital

transformation?

Keywords: Supply Chain 4.0, Supply Chain operations

12

1.5 Outline of the thesis

Figure1.3: Outline of the thesis

Chapter 1

Introduction

Introduce the topic.

Identification of

thesis objectives and

research scope.

Chapter 4

Supply Chain 4.0

Techologies

Chapter 2

Methodology

Define the SLR

methodology

Defines the SLR

process of the

thesis

Chapter 3

Descriptive analysis

Presentetion of the

descriptive results

Analyze and discuss

the findings

Chapter 5

Chapter 6

SCOR model

Impact Assessment

Presentation of SC

4.0

Define the SCOR

model

Define the HOQ

analysis

Define the use of

tecnhologies and

their characteristics

Discussion about the

supply chain

operations and

metrics.

Presentation and

discuss the

thematical results

13

Chapter 7

Challenges-Barriers,

Conclusions and Future

research

Presentations and

define the challenges

and barriers

Summarize the findings.

Identification of future

research opportunities

The systematic literature review technique will be outlined in further detail

in Chapter 2. The SLR model's procedures will be outlined and,

furthermore, a comparison will be made between the traditional research

technique used and the unique research method that the present thesis

utilizes. Additionally, the extent of the research will be analyzed, as well as

the steps that will be taken. More information on how to extract transparent

findings will be provided. The descriptive findings of the investigation,

which will be documented using tables, schemes, and diagrams, will be

presented and discussed in chapter 3. In chapter 4, the SC 4.0 technologies

will be presented and analyzed, along with their use characteristics. In

chapter 5, the SCOR model, metrics, and operations will be presented in

detail. The present thesis’ findings will then be provided and debated in

chapter 6. Barriers and challenges are evaluated and discussed in chapter

7. Finally, in chapter 8, the major findings and conclusions will be

summarized, as well as future research potential will be explored.

14

CHAPTER 2: METHODOLOGY

SYSTEMATIC LETERATURE REVIEW

Overview

The systematic literature review (SLR) is the method that is being used for

the present thesis. The SLR is a method that guarantees safe results

through an analysis of published academic journals and articles. The

process is to gather information (articles or journals) that is related to the

research questions. The results must cover all of the topics and questions

and must be characterized by transparency. There are many steps that

must be followed in order to complete this method. The objective of

systematic literature review is to find, evaluate and concentrate the results

in order to provide ''sincere'' findings. The second chapter mostly presents

the method used in the current thesis, specifically, the SLR (systematic

literature review) method and its basic procedures. The following figure

represents the structure of chapter two:

15

2.1 SYSTEMATIC LETERATURE REVIEW

The method that will be used in the current analysis is not something “new”.

The technique called systematic literature review started to develop in the

field of health sciences, mainly in the United Kingdom, as well as in other

fields of research. Transparency, replicability, and objectivity define the

SLR process. The focus of the systematic literature review is to extract the

best outcomes in each study area. The idea of best outcomes implies safer

assumptions and specific results for the subject of each analysis. In

addition, the aim of this approach is to ensure that there are no cases of

errors or prejudices by processes over personal study. Moreover, with the

tactic of Ray Moynihan and Melissa Sweet, an analysis was used in

healthcare issues in order to achieve as few gaps in the research subject as

possible, as well as a clear image - conclusion for the thesis on the existing

problem (Sweet and Moynihan, et. al. 2007). Repetitive literature tackles

and presents a particular challenge - problem, fills literature gaps and

heads to a conclusion, providing a solution for potential problems

(Baumeister & Leary, et. al. 1997). Therefore, this literature review method

includes a general picture of the facts. It is not an ongoing method that

encompasses all the information - knowledge of a specific the specific

category that it deals with. However, the subjectivity that scholars use for

sampling these papers and journals should be taken into notice, as well as

the fact that conclusions extracted in such a way may not be an object of

reliance in supporting future studies (Weyinmi Demeyin, et. al. 2016). The

following figure (2.1) shows the process of the systematic literature review.

Also, a detailed methodological approach is useful as a part of a systematic

literature review. There are three kinds of literature reviews. The first one

is the theoretical background, which is the most common. It focuses on the

theoretical foundations and on the context of the research and it helps to

bring the questions of the topic into focus. The second one is called literature

review as a chapter of a graduate thesis, also called as thesis literature

review. The last one is the stand-alone literature review. The purpose of

this review is to check a topic in a field, without having collected or analyzed

any primary data. Finally, the SLR method consists of many steps, that

researchers must follow, in order to completely extract the final results.

16

Figure 2.1: Systematic Literature Review

Source: Kitchenham, Brereton,2013

2.2 Systematic literature review justification.

The method that is used is the systematic literature review (SLR). There

are many advantages for conducting this method. First of all, this method

is distinguished by its scope, purpose of the research and by its strictness.

For the researchers, it constitutes a referenced work tool that they can use,

when conducting new research, as it helps them to create a first clear

outline of the literature review. This method has a main purpose and

extracts specific conclusions, that are related with the research. The

existing bibliography is analyzed and can be considered as objective as

possible. Finally, after summarizing the conclusions, it can also be used to

highlight gaps in the current research and provides a framework for future

researchers. On the other hand, there are many disadvantages in

systematic literature review method. The first one is, that there are many

situations in which limited studies are available, because they might not

represent the best knowledge available. Also, a systematic literature review

method is inappropriate, when the questions of the research are too vague

17

or too wide. In such a case, it would yield a lot of different studies. On the

other hand, if the question is too narrow, it would yield very few studies.

Finally, another consideration is whether the researcher has enough time

and energy. For example, in the case that the volume of the bibliography,

which must be analyzed is very large, the question arises whether the

researcher can consume all the amount of his time and energy for

conducting the systematic literature review. After considering all of the

above, the systematic literature review (SLR) method is selected for the

present thesis.

2.3 Systematic literature review steps

2.3.1. Mapping score research (identify the purpose of the research)

This step can also be called the purpose of the research. It is the first step

of the process of the systematic literature review method and it is a very

important part, because it is used to guide the author at aiming and

creating specific questions at the specific field. The choice of questions that

the author develops, moves the entire literature review process

(Kitchenham and Charters 2007). Thus, the choice of academic studies,

books, journals etc. to be included in the review, the method for data

extraction, the criteria the author uses for the selection of studies and

synthesis, should all be orientated towards answering the research

questions. Α very common mistake is to select a question which will guide

to a big amount of data, resulting in the literature review becoming hard to

limit and control. For this reason, it is suggested that researchers use a

prereview mapping to help the subtopics within a research question

(Brereton et al. 2007). After reviewing the literature on the research

question, the researchers have the opportunity to develop a fast-mapping

procedure to identify the methods of the research, which relate to the

research question. Finally, the mapping helps the researchers to decide if

the range of materials should be limited to a specific research question or

to check most of it.

The present thesis focuses on two research questions:

1. To review the impacts of SC 4.0 technologies on SC operations.

2. To present the challenges, barriers, and drivers.

18

2.3.2. Define Research Scope

Before reviewing the ways by which the research will take place, it is

important to define the field of the research. The concept of digital supply

chain is something new for the supply chain managers and for the

researchers (Gülçin Büyüközkan & Fethullah Göçer, 2017). Moreover, it

proved difficult for all companies to adopt the digitization of all processes.

Some of them responded quickly and the results were efficiency and

improvement in all of their areas. On the other hand, there were companies

that found it quite difficult to move forward in this new era. Thus, in this

research, the entire existing bibliography will be reviewed, with its focus

being on digital conversions in the supply chain 4.0. Additionally, the effects

digital transformations have on the supply chain operations will be

examined, as well as which are these specific effects. Finally, the challenges

created for all companies to implement the digitization will be presented.

The next figure (2.2) shows the main areas and the scope of the research.

The main areas of the research are Supply Chain 4.0 and Supply Chain

Operations, the common point of which is the field of the research.

The following figure (2.2) describes the relationship between the two

keywords and the research area between them:

Figure 2.2: Research Scope

Supply

Chain

operations

Supply

Chain 4.0

The research area of the thesis

19

Supply Chain operations: Warehousing, Transportation, Order Fulfillment, Manufacturing,

Procurement, Demand planning, Forecasting, Distribution process, Outsourcing process,

Safety stock planning, Supply network planning, Customer collaboration, Supplier

collaboration, Purchase order, Receipt confirmation, Invoice verification, Production

planning, Manufacturing execution, Inbound and outbound process, Cross docking,

Warehousing and Storage, Physical inventory, Sales order, Billing process, Freight cost

process, Lifecycle planning, Promotion planning.

2.3.3. Identify the keywords and the literature sources.

The second step is to identify the keywords, which will be used in the

present thesis, as well as the literature sources (Table 1) for developing the

entire systematic literature review. The second step, in which the author

needs to identify the keywords is crucial for the process of the systematic

literature review. First, they relate with the objectives of the research, so

the author must identify the keywords with close attention, because they

must relate with the topic and its aims. Moreover, the keywords must

“connect” with the scope of the research, which is very important and one of

the first parts of the research that requires careful attention. Thus, the

objective of the present thesis is reviewing the published research on the

digital transformation on the supply chain 4.0. The keywords for the present

thesis are the following:

Keywords: Supply Chain 4.0, Supply Chain Operations.

Table 1: The databases used for the research

Databases

Description

Scopus

Scopus is a top library database that includes summaries and citations

for academic journal articles. After all these years, it is one of the

databases of first choice, as it covers nearly 21,000 titles from 5,000

publishers, of which 20,000 are peer-reviewed journals in many areas.

The owner of Scopus is Elsevier.

Web of Science is a library of many databases. It is a database itself that

provides many articles and journals for academic use. It is also

considered as one of the top open databases.

IEEE Xplore is one of many research databases. It provides access to

many journals and articles, that relate to different study areas, like

computer science, electrical engineering etc. IEEE Xplore provides 5

million documents, related to the different research areas.

Web of

Science

IEEE Xplore

2.3.4. Search strings

In the systematic literature review, the search method is called Boolean

search (“AND”, “NOT”, “OR”). The combinations of the terms “AND”, “NOT”

and “OR” are used for literature search. The literature search focuses on

different academic articles, books, and journals from different countries of

the world, which were published mainly between 2015 and 2020. The terms

20

''AND'', ''OR'' and “NOT” are used in the literature search with the following

ways:

The term ''OR'' is used in the present thesis and will be included before, or

after, of one or of the two keywords. The term ''NOT'' is not used in the

research. It is used when there is a chance that one of the keywords will

change the results. Finally, the term ''AND'' is used in the research and

explains that the terms before and after the term ''AND'', are both used at

the same time for the search.

Table 2: Search strings

Combination Search strings

(“Supply Chain 4.0”) AND (“Logistics” OR “Warehousing” OR

“Transportations” OR “Order Fulfillment” OR” Manufacturing” OR

“Procurement” OR “Demand planning” OR “Forecasting” OR “Distribution

process” OR “Outsourcing process” OR “Safety stock planning” OR “Supply

String 1+2 network planning” OR “Customer collaboration” OR “Supplier collaboration”

OR “Purchase order” OR “Receipt confirmation” OR “Invoice verification”

OR “Production planning” OR “Manufacturing execution” OR “Inbound and

outbound process” OR “Cross docking” OR “Warehousing and Storage” OR

“Physical inventory” OR “Sales order” OR “Billing process” OR “Freight cost

process” OR “Lifecycle planning” OR “Promotion planning”)

2.3.5. Define the search criteria.

After completing all the previous parts and research in the databases,

identification and selection of the criteria must be performed. As was

referred before, the aim of the present thesis is to provide a complete

overview in the field, that focuses on issues that concern digital

transformations. In order to improve the search results, the next part of the

systematic literature review method is to define the exclusion and inclusion

criteria. Exclusion criteria are the criteria that are used by the author to

limit the academic studies, journals, articles etc. Inclusion criteria are the

opposite, as they are used for the last part of the process.

Inclusion criteria:

1. The review related to the Field (digital transformation) and on the

question of the research.

2. The publication year of the studies are between 2010 and 2020.

3. Must be written in the English.

4. The articles and journals must come from trusted sources.

21

Exclusion criteria

1. Studies that are not related to the field are rejected.

2. Papers with publication year before 2010 are rejected.

3. Not written in English.

4. Not academic types of studies.

The following figure 2.3 represents the process of the data extraction of the

articles, by using the combination search string (1+2) to the three

databases. These articles were filtered by the exclusion and inclusion

criteria according to following table. After being filtered through the

exclusion and inclusion criteria, the overall number of articles that will be

evaluated are 381.

Figure 2.3: Process of data extraction

©

Search string

combination (1+2)

Total articles

18.018

Total articles

Not written in

English

27.653

270

Not academic

types of studies

Total articles

27.383

9365

Before 2010

Total articles

7.735

10.283

Studies not related

to the area

9.902

Total articles

381

2.3.6. Data extraction

Using the above string, an amount of articles was found from the three

databases. After taking into account the inclusion and exclusion criteria,

according with the previous table, the total initial count of the remaining

articles was 381. Thus, the final total sum of articles that will be reviewed

22

after this process is 63. The following table 3 represents the process of the

data extraction in detail.

Table 3: Final account of data

Databases

Without criteria

Initial count

(after criteria)

Final count

Scopus

15.498

Web of Science IEEE Xplore

11.542

613

Count

27.653

205

123

53

381

31

20

12

63

2.3.7. Analyze and synthesize the data.

After the data extraction, the review of the remaining papers starts at the

present stage. There are three critical parts. The first part is the projection

of abstracts and names, the second part is the projection of the text as a

whole and the third part is the calculation of the paper’s quality

(qualitative, quantitative and mixed). In this step, all the articles were

synthesized and organized according with their quality.

2.3.8. Writing Up

It is the last step of the process. After all of the previous steps are over, the

last level is to write up the findings from the research.

23

CHAPTER 3

DESCRIPTIVE ANALYSIS

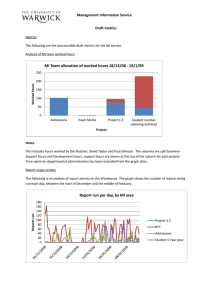

Overview

In the present chapter the amount of selected articles is being evaluated,

based on the characteristics (keywords, year of publication etc.) and

organized on tables, schemes, and figures. Specifically, the papers will be

classified based on the year of publication, the geographical distribution,

the keywords, and the research methods. Moreover, in the present chapter

the keywords’ frequency, the technologies and the operations will be

presented, according with the literature review. The following figure

presents the structure of chapter three.

24

3.1 Chronological Analysis

The chronological analysis is the presentation of the publication year of the

articles that were selected from the databases (Chapter 2, SLR), after

filtering them though the criteria limitation (Chapter 2), that were used for

the selection of the literature review. As it was mentioned before, one of the

criteria was the publication year of the articles. Specifically, the articles

that were published before the year 2010 were rejected. On the other hand,

the selected articles were published between the years 2010 and 2020. The

interest on the digitalization of the supply chain operation is growing, due

to the development of the technologies over the last years. For that reason,

most of the selected articles were published between 2016 and 2020, so that

all the new technologies and impacts to the supply chain can be presented.

The following Figure (3.1) provides the distribution of the 63 articles:

Figure 3.1: Year Of Publication

number of articles

16

14

12

10

8

6

4

2

0

2010

2011

2012

2013

2014

2015

2016

number of articles

2017

2018

2019

2020

As it was presented in the above figure, the number of the most articles

were published in the year 2019. From the year 2016 to the year 2020, the

digitalization of the technologies and innovations has changed and

improved dramatically. Finally, over the last 4 years, new technologies have

appeared, that also play an important role in the supply chain.

3.2 Geographical Analysis

The geographical analysis confirms that the selected articles were

published in different countries, specifically in 12 different countries. Most

of the selected articles were published in European countries (46%), with

articles published in North/South American countries being the second

highest in quantity (36%). The remaining selected articles were published

in Asian (16%) and African countries (2%). The following figure (3.2)

describes the percentage of the geographical distribution of published

articles, by continent.

25

Figure 3.2: Continent distribution of articles

Distribution Of articles

2%

Europe

36%

46%

Asia

North/South America

Africa

16%

From the above figure (3.2), it can be observed that the biggest percentage

of published articles come from Europe (46%), North/South America (36 %)

and Asia (16%). In Europe, many international companies pay attention in

the new technologies. The same holds true for companies in North/South

America, with the United States of America being the main point of

developing the digitalization. In Asia, countries like China, South Korea,

and Taiwan, play an important role in the field of global digitalization.

Those are the reasons why most of the selected articles were published in

the above three continents.

The following figure (3.3) describes analytically the origins of the literature

review from different countries of the world.

26

Figure 3.3: Country Distribution of articles

Articles

LITHUANIA

GREECE

FRANCE

UKRAINE

CHINA

CALIFORNIA

THAILAND

ENGLAND

SOUTH AFRICA

AUSTRIA

SRI LANKA (COLOMBO)

UNITED ARAB EMIRATES

GERMANY

HAWAI

CANADA-(TORONDO)

INDIA

IRELAND

SPAIN

USA

TURKEY

LATVIA

BRAZIL

NORWAY

RUSSIA

POLAND

SWITZERLAND

1

1

1

1

3

2

1

3

1

2

1

1

5

1

2

5

1

2

14

3

1

5

1

2

2

1

0

2

4

6

Articles

8

10

12

14

3.3 Quantitative and qualitative approach

In the literature review, it is clear that two research methods were used.

These research methods are the quantitative analysis and the qualitative

analysis. The articles, that were selected, followed the qualitative analysis,

as they explain the significance of digitalization, the Supply Chain analytics

and the definition Supply Chain 4.0, which must be understood. For

example, Gülçin Büyüközkan’s and Fethullah Göçer’s article on the digital

supply chain and the impact of digital technologies like blockchain, IoT, Big

data, automation, and robotics, follow a qualitative literature review

analysis (Büyüközkan, Göçer,2017). On the other hand, the rest of the

articles followed the quantitative approach and explain the main points

through mathematical and statistical approaches. For example, the article

by Mariusz Kostrzewski, Monika Kosacka-Olejnik, Karolina WernerLewandowska 2019 (Assessment of innovativeness level for chosen

solutions related to Logistics 4.0), used a statistical and mathematical

approach, in order to analyze which solutions, that are related to Logistics

4.0, are really innovative and which are not. The above article followed the

27

16

quantitative analysis. The following table (3.4) presents the percentage of

articles that followed the quantitative, mixed, and qualitative approach.

Figure 3.4: Study method distribution

Study Distribution

23%

Qualitative

59%

18%

Quatintative

Mixed

3.4 Overview of existing SC 4.0 Technologies.

In the selected articles, many topics are analyzed and a lot of them are

focused on Supply Chain 4.0 technologies. In order to analyze the

digitalization of the supply chain, it was necessary to present all the

technologies that were developed these last 10 years. The main topics that

are analyzed in the selected articles are Augmented reality, Big Data, Cloud

computing, Internet of Things, Robotics, Sensor technology / smart sensors,

Self-driving vehicles, Drone, Cyber-physical systems, RFID, Intelligent

Transportation Systems, Machine 2 Machine sensors, Blockchain, Artificial

Intelligence, Deep learning, Automated Guided Vehicles (AGVs),

Autonomous Mobile Robot (AMR), Real-time locating systems (RTLS), Data

mining, and finally the Internet of Services. The following table 5 (literature

review Table) presents all of the 21 technologies that were found due to the

literature review and the selected articles that referenced them. The

following technologies will be analytically defined in the next chapter. The

importance of supply chain 4.0 technologies has been highlighted in recent

literature and numerous scholars have discussed their uses and

characteristics. The present thesis examines the current literature review

of supply chain 4.0 technologies and supply chain operations from an

28

academic, as well as from an industrial perspective. It is examined how

supply chain 4.0 technologies affect supply chain operations and thus

compile a list of new technologies, as well as which are the challenges barriers of these digital transformations. The research was conducted in

two phases. The first phase consisted of examining the supply chain

operation and metrics. Thus, a part of the literature review focused on the

terms of the operations, on the metrics and on the role they have on the

supply chain. For the description and presentation of the supply chain

operation and level metrics, the Scor model constitutes an important and

useful tool for the current research. For the evaluation of the impacts, the

level 1 metrics of the Scor model has been used. In the following chapters a

detailed description of the Scor model, of the functions and of the metricsKpis is presented. The Scor model was the main pillar of the present

research, because every function and every metric had to be examined and

presented to explain their role and the way the technologies could be used

in combination with them. However, the main part of the literature review

was based on the new Supply Chain 4.0 technologies, that were developed

and are still developing to this day. The roles and the characteristics of each

one of these technologies will be introduced on the next chapter “Supply

Chain 4.0 technologies (Thematical Analysis)”. In the next part of the

present thesis, the metrics (level 1 Scor model) and the new technologies

are necessary to develop the QFD analysis. The QFD (Quality Function

Deployment) or House of Quality (HOQ) is a method used in this research

to clarify and evaluate the impacts that the supply chain 4.0 technologies

have in supply chain operations. Concerning the HOQ, it is the central

nervous system that regulates the entire QFD operation. For new product

design, the HOQ is a well-known and commonly used method. It converts

customer expectations into a sufficient number of engineering goals to be

met by a new product design, based on marketing research and

benchmarking results. The review of academic journals, articles and books

follows a classification process, that explains how the literature is used as

a foundation for the conceptual and theoretical framework. The

classification - methodology used in the present literature, as well as the

introduction of the literature review was explained above. A comprehensive

search is used to acquire relevant academic publications with the goal of

collecting, organizing, and synthesizing existing knowledge. However,

because supply chain 4.0 is a new phenomenon that only developed recently,

the corresponding publication channels are still scattered. The research of

the present thesis focuses on major online databases such as Scopus, IEE

Xplore and Web of Science. Books, peer and non-peer reviewed articles,

industry reports and white papers, are among the literature sources

explored through scientific databases and conventional search engines. As

a result, the current study examines published academic publications and

books to determine the implications and trends of SC technologies in supply

29

chain operations. The research is performed based on the year of

publication, subject, and objective of the published articles.

From the databases (Chapter 2), the keywords for the selection of the

articles were defined. The following table presents the frequency of the

keywords that were used.

Table 4: Keywords Frequency

Keywords

Frequency

Supply Chain 4.0

8

Supply Chain Analytics

14

Digital Transformation

6

Digitalization

5

Technologies

8

Industry 4.0

15

Logistics

9

Challenges

4

Big Data

3

Robotics

1

Artificial Intelligent

5

Internet of Things

7

Cyber Physical System

1

Blockchain

4

Radio Frequency Identification

4

Automated Guided Vehicles

1

Autonomous Mobile Robot

1

Data mining

1

Deep Learning

3

Drones

1

Internet of services

2

Cloud Computing

2

Real Timing Location System

2

Smart Sensors

4

Self-Driving Cars

4

30

Table 5: Literature review Table

Description of articles

Objective

Abbreviations References

This article provides the limitations and benefits

from digital supply chain. The paper provides the

digital supply chain trends, and the knowledge gaps

are consolidated.

The paper analyzes the continuous development

and evolution of supply chains and their impacts in

the economic development. Also, the terms of

supply chain analytics (SC 4.0) and digital

transformation are provided.

The aim of this article is to present the influence

and the impacts of digital technologies in the supply

chain operations and the degree of these effects.

Also, it describes the threats and opportunities of

the digital transformation and industry 4.0.

The paper describes the characteristics and the use

of smart technologies- smarts sensors in the digital

supply chain. Finally, it presents the logistics

operations and the benefits from digital

transformation.

The paper presents the impacts and the

technologies like Big Data, Cloud Computing and

3Dprinting and explains the term of supply chain

4.0.

This paper provides the terms of the supply chain

4.0 and the influence of industry 4.0 in the global

supply chains, and presents the challenges from

digitalization.

Digital Supply Chain

DSC

Supply Chain 4.0

SC 4.0

Industry 4.0/

Digital Supply Chain

IN4.0/DSC

Sensor technology smart sensors

ST/SC

Big Data /

Cloud Computing /

3D Printing

BD/CC/

3DP

Industry 4.0

IN 4.0

The paper explores the opportunities of the

technologies Big Data, Artificial Intelligence and

Robotics, that change the conditions on the

efficiency and customer service levels.

Robotics / Big Data /

Artificial Intelligence

/

Augmented reality

R/BD/AI/

AR

This article presents the benefits and impacts of an

effective digital transformation to the supply chains

operations.

Digital Supply Chain

DSC

This article provides the term of industry 4.0 and

what influence it has on supply chains. Also, it

presents the impacts on the supply chains from

digitalization and the characteristics of internet of

things.

This paper provides the term of digital

transformation and digital strategy. Also, it

presents the determinants of digital transformation.

Internet of Things

IoT

Digital Supply Chain

DSC

The paper presents an overview of the terms

Logistics 4.0. It presents solutions and influences

concerning Industry 4.0 by developing a

mathematical model which evaluates the solutions

in the level of their innovations.

Industry 4.0

IN 4.0

31

Et. al. Gülçin

Büyüközkan,

Fethullah Göçer

[1]

Et. al. Michael J.

Ferrantino,

Emine Elcin Koten

[2]

Et. al. Yevhen

Krykavskyy,

Olena Pokhylchenko,

Nataliya Hayvanovych

[3]

Et. al. Vladimir

Scherbakov,

Galina Silkina,

Vladimir Scherbakov

[4]

Et. al. Zaza Nadja,

Dimitrios Makris,

Lee Hansen, Omera

Khan [5]

Et. al. Felipe Campos

Martins, Alexandre

Tadeu Simon, Renan

Stenico Campos

[6]

Et. al. Massimo

Merlino,

Ilze Sproģe

[7]

Et. al. Enis Gezgin,

Xin Huang, Prakash

Samal, lldefonso Silva

[8]

Et. al. B. Tjahjono, C.

Esplugues, E. Ares, G

Pelaez

[9]

Et. al. Bohnsack, R.

Hanelt, Marz D

Marante

[10]

Et. al. Mariusz

Kostrzewski, Monika

Kosacka-Olejnik,

Karolina WernerLewandowska[11]

This paper explains the growing of the new

technologies, through digital transformation and

clarifies the effect that industry 4.0 has on supply

chain.

The paper provides the influence of digitalization in

the global economy and the benefits and

characteristics of smart technologies.

Digital Supply Chain

DSC

Sensor technology smart sensors

ST

This paper presents the technology Internet of

things, the challenges in Logistics from the digital

transformations and the requirements to have an

effective transformation.

The aim of this paper is to present the solutions

which were recognized in the areas of organization

and technology innovations. These solutions are the

technologies Internet of things and Big Data. Also,

the impacts of these technologies on supply chains

operations are provided.

The aim of this paper is to present the criteria for

logistics center to adopt the effects of Industry 4.0.

Internet of Things

IoT

Internet of Things /

Big Data

IoT/

BD

Digital Supply Chain

/

Industry 4.0

DSC/

IN 4.0

The paper provides the benefits of technologies like

Cyber-Physical Systems (CPS), Internet of Things

(IoT), Internet of Services (IoS). One of Industry

4.0 key technologies is the Cyber-Physical Systems,

because it can be applied in many areas.

The article provides a literature review of Big Data

technology. Also, it describes the role of the

technology in the supply chain transformation.

Cyber Physical

System /

Internet of Services /

Internet of Things

CPS/

IoS/

IoT

Big Data

BD

In this paper the terms of digitalization, digitation

and digital transformation are explained. The

benefits and consequences to supply chain

operations by these three terms are also provided.

Digital Supply Chain

DSC

The main objective of the paper is to provide the

characteristics and benefits of the technologies

Artificial Intelligence, Real Time locating System

and Internet of things.

The paper evaluates the impacts on the supply

chain operations through the performance metrics.

Also, it presents how the application of artificial

intelligence combines with these metrics.

Internet of Things /

Artificial Intelligence

/ Real-time locating

systems

Artificial Intelligence

IoT/AI/

RTLS

The purpose of this article is discovering new

metrics through the SCOR model, that relate to

Industry 4.0, in order to understand and clarify the

digitalization on the operations of supply chain.

This article measures the supply chain operations

(SCOR model) and, with the performance

indicators, it analyzes the impacts of the new

technologies to supply chain.

Industry 4.0

IN 4.0

Digital Supply Chain

DSC

32

AI

Et. al. Senthil

Muthusami, Mohandas

Srinivsan

[12]

Et. al. MohamedIliasse Mahraz,

Loubna Benabbou,

Abdelaziz Berrado

[13]

Et. al. L. Barreto,

A. Amarala,

T. Pereira

[14]

Et. al. Krzysztof

Witkowski

[15]

Et. al. Volkan Yavasa,

Yesim Deniz OzkanOzen

[16]

Et. al. Gleison Matana,

Alexandre Simon,

Moacir Godinho Filho,

Andre Helleno

[17]

Et. al. Mondher Feki,

Imed Boughzala,

Samuel Fosso

Wamba[18]

Et. al. Alina

Bockshecker, Sarah

Hackstein, Ulrike

Baumöl

[19]

Et. al. Kersten,

Wolfgang, Blecker,

Thorsten, Ringle,

Christian M. [20]

Et. al. Francisco

Rodrigues LimaJunior, Luiz Cesar

Ribeiro Carpinetti

[21]

Et. al. Ertugrul

Ayyildiz, Alev Taskin

Gumus

[22]

Et. al. Sri Yogi

Kottala, Kotzab Herb

[23]

The paper presents the advantages and

characteristics of using Blockchain technology in

the supply chain. Also, it provides the

transformation on supply chain operation through

the block chain approach.

Blockchain

BC

The modeling and evaluating of the performance of

logistics processes is the main objective of this

article. Also, the influences of new technologies on

the warehouse and transportation activities are

provided.

The operations of supply chains are presented in

this article. Also, the challenges of digitalization to

the supply chain operations are referred.

Digital Supply Chain

DSC

Digital Supply Chain

DSC

The understanding of relationship between supplychain processes and supply chain performance are

important. In this article, the supply chain

performance and the influence of Industry 4.0 on

them is being presented and evaluated.

The impacts and challenges of digital supply chain

are presented. The new technologies and the

influence of industry 4.0 to every part of the supply

chain are provided.

Industry 4.0

IN 4.0

Digital Supply Chain

/ Industry 4.0

DSC/

IN 4.0

This paper refers to the development of the RFID

(Radio Frequency Identification) and the

Blockchain technology. The advantages and the

disadvantages of these two technologies are also

presented.

The main objective of this article is to determine the

new technologies that are used in logistics and

supply chain operations, as well as their impact on

them. Also, this article focuses on specific

technologies like AGVS, IDS and RFID.

The potential of Blockchain and the efficiency

influence that has on supply chain are presented in

this article.

RFID/ Blockchain

RFID /BC

Automated Guided

Vehicles / RFID

AGVS/ RFID

Et. al. Rajiv Bhandari,

Mumbai

[30]

Blockchain

BC

The paper presents issues related to design and

organization of warehouse processes. Also, it pays

attention on the modelling logistics process and the

way the technologies can improve the processes.

Intelligent

Transportation

Systems / Digital

Supply Chain

ITS/DSC

This paper introduces radio frequency

identification (RFID) technology and presents the

advantages and disadvantages of RFID in supply

chain operations.

This paper analyzes the way of the use of

autonomous mobile robots and the capabilitiesbenefits the supply chain gains from the application

of AMR.

RFID

RFID

Autonomous Mobile

Robot

AMR

Et. al. Pankaj Duttaa,

Tsan-Ming Choib,

Surabhi

Somanic,Richa Butalac

[31]

Et. al. Michał

Kłodawski,

Konrad Lewczuk,

Ilona Jacyna Gołda,

Jolanta Żak [32]

Et. al. Gary M.

Gaukler Ralf W.

Seifert

[33]

Et. al. Gerhard P.

Hancke

[34]

33

Et. al. Ilhaam A.

Omar, Raia

Jayaraman, Khaled

Salah, Mazin Debe,

Mohammed Omar

[24]

Et. al. E. Lepori.

D.Damand

B. Barth

[25]

Et. al. R.H.

Thilakarathna, M.N.

Dharmawardana,

Thashika Rupasinghe

[26]

Et. al. Archie

Lockamy,

Kevin McCormack

[27]

Et. al. Margarita

Stohler,

Tobias Rebs,

Marcus Brandenburg

[28]

Et. al. Feng Tian,

Vienna

[29]

In this paper the definition of the data mining

technology, its process, and characteristics are

presented.

This paper describes the use of artificial intelligence

and the deep learning technology. Also, it clarifies

the impacts and the influence on the supply chain.

The article provides an overview of deep learning

technology and its capabilities. The criteria for

using this technology are also referred.

The aim of this paper is to show the applications of

deep learning and artificial intelligent on supply

chain and on other areas.

In this study technologies like Robotics, Artificial

Intelligence, Autonomous Vehicles, Augment

reality, Blockchain, Drones are defined

(Characteristics, Capabilities, Disadvantages).

Data Mining

DM

Artificial Intelligence

/ Deep learning

AI/DL

Deep learning

DL

Deep learning /

Artificial Intelligence

DL/AI

Blockchain / Drone /

Artificial Intelligence

/

Cyber-physical

systems /

3D Printing /

Augmented reality

Internet of Things /

Internet of Services

BC/DR/AI/CPS

/ 3DP/AR

Et. al. Christopher S.

Tanga, Lucas P.

Veelenturf

[39]

IoT/IoS

This article presents the key challenges of cloud

computing. Also, this study describes the

relationships and the effects between cloud

computing and internet of services.

Cloud Computing /

Internet of Services

CC/IoS

This article explains the types of machine learning

systems- deep learning that are used in the supply

chain and analyzes the processes and tasks that

they aim to complete.

The definition of the real time locating system is

presented in this study. Also, its capabilities and

disadvantages are analytically presented.

Deep learning

DL

Et. al. Robert

Kleinfeld, Dr. Stephan

Steglich, Lukasz

Radziwonowicz,

Charalampos Doukas

[40]

Et. al. Rafael MorenoVozmediano, Rubén S.

Montero, Ignacio M.

Llorente

[41]

Et. al. Michael Veale

Irina Brass

[42]

Real-time locating

systems

RTLS

This article describes the results of the

implementation of the technologies real timing

located system and the internet of things.

Internet of Things /

Real-time locating

systems

IoT/RTLS

This paper presents the advantages and the

characteristics of the automated driving vehicles.

Automated Guided

Vehicles

AGVs

The influence and the benefits from self-driving

vehicles in transportations problems are described

in this article. Also, the characteristics and the way

of using them are defined.

This article explains the understanding of selfdriving vehicles (concepts, the way of using and

benefits).

Self-driving vehicles

SDV

Self-driving vehicles

SDV

In this study, concepts and the connection of

technologies that are called internet of thing and

internet of services are provided.

34

Et. al. N. Lakshmi,

G.H. Raghunandhan

[35]

Et. al. Tien Yin Wong,

Neil M. Bressler

[36]

Et. al. Li Deng, Dong

Yu

[37]

Et. al. Mario Coccia

[38]

Et. al. Witsarawat

Chantaweesomboon,

Charuwalee

Suwatthikul,

[43]

Et. al. You-Wei Lin.

Chi-Yi Lin

[44]

Et. al. David M.

Woisetschläger

[45]

Et. al. Danielle Dai,

Daniel Howard

[46]

Et. al. Brandon

Schoettle, Michael

Sivak.

[47]

The history of the self-driving vehicles and

automated vehicles system is described in this

article. Also, it explains the relationships of these

technologies with the supply chain operations.

Self-driving vehicles /

Automated Guided

Vehicles

SDV/AGVs

This paper analyzes the key technology of selfdriving cars and illuminates the state-of-art of the

self-driving cars.

Self-driving vehicles

SDV

This paper analyzes and describes all the types of

the warehouse robots, the way they work and also

the benefits that warehouses have from their

development.

In this article the roles of the robotics to

warehouses are described, as well as the robots’

architecture and characteristics.

This article explains how useful the robots are to

the warehouses, the role of every type of warehouse

robot, especially all the types of Autonomous guide

vehicles.

The key technology of a self-driving car is discussed

in this study. The four major technologies of selfdriving cars are discussed and surveyed in this

paper: car navigation system, path planning,

environment perception and car control.

This paper presents the internet of things and many

others technologies, as well as how they co-work

under the same circumstances in the supply chain.

Robotics

R

Robotics

R

Et. al. Ruthie Bowles

[51]

Automated Guided

Vehicles

AGVs

Automated Guided

Vehicles

AGVs

Internet of Services

IoS

The connection between the industry 4.0, the

internet of things and smart sensors are presented

in this study. The impact these technologies have on

the supply chain operations and the way they

improve the process of supply chain are also

presented.

This article presents the challenges and the concept

of digital transformations. It analyzes the new

technologies and describes the challenges of digital

transformations.

This study provides an overview of technologies,

industry 4.0 and digital transformation in the new

area.

This paper analyzes how to use the smart sensors

and when they are appropriate to use. Also, it

provides the advantages and benefits of their

application in other areas.

Sensor technology smart sensors /

Industry 4.0

ST/IN 4.0

Et. al. Lothar Schulze,

Sebastian Behling,

Stefan Buhrs

[52]

Et. al. Dimitrios

Bechtsis, Naoum

Tsolakis, Dimitrios

Vlachos, Eleftherios

Iakovou. [53]

Et. al. Jacqueline

Zonichenn Reis,

Rodrigo Franco

Gonçalves. [54]

Et. al. Martin Neuhold

[55]

Digital Supply Chain

DSC

Et. al. Westerman

[56]

Digital Supply Chain

/

Industry 4.0

Sensor technology smart sensors /

Industry 4.0

DSC/

IN 4.0

This study introduces the technologies internet of

things (IoT), Artificial Intelligence and RFID, and

the impact that was created with the development

of these three technologies on the warehouse

operation.

Internet of Things /

Artificial Intelligence

/

RFID

IoT/AI/ RFID

Et. al. Yogita Malik.

Arora