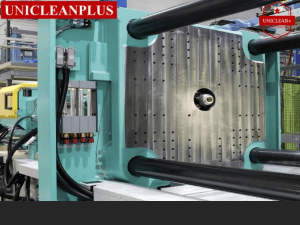

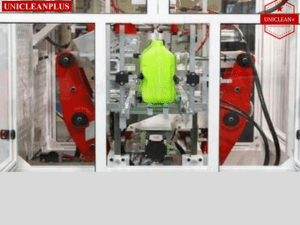

The Ultimate Guide to Purging Compound for Plastic In the world of plastic injection molding, efficiency is key. The process involves intricate machinery, precise temperatures, and a keen eye for detail. Yet, even the most wellmaintained equipment encounters challenges. This is where the Purging Compound comes into play, acting as the unsung heroes in the realm of plastic manufacturing. Understanding Purging Compounds Purging materials are cleaning agents used to eliminate residues and contaminants from the machinery involved in plastic injection molding. The Purging Compound for Plastic functions by melting, scrubbing, and removing residual plastic, colourants, or other contaminants that may have adhered to the equipment’s surfaces. The Role They Play Minimizing Downtime: The Injection Molding process demands precision, and any downtime for cleaning and maintenance can impact production schedules. Purging Compounds reduce this downtime by efficiently cleaning the equipment, ensuring a swift transition between different materials or colours. Enhancing Quality: Residual plastics or colourants can negatively affect the quality of molded products. Purging Compounds ensure a clean, uncontaminated transition between different materials, thereby maintaining the quality of the manufactured plastic parts. Cost-Efficiency: Efficient cleaning means less waste of raw materials and reduced scrap rates. This not only saves on material costs but also contributes to a more sustainable manufacturing process. Types of Purging Compounds Mechanical Purging Compounds: These compounds rely on mechanical action to clean the equipment. They work by scrubbing and dislodging the contaminants from the surfaces. Chemical Purging Compounds: Chemical Purging Compounds utilize a chemical reaction to break down and remove contaminants. They are effective for stubborn residues and when a more thorough cleaning is required. Hybrid Purging Compounds: A blend of mechanical and chemical properties, hybrid Purging Compounds offer a versatile solution, catering to various cleaning needs. Choosing the Right Purging Compound Selecting the appropriate Purging Compound depends on several factors: Material Compatibility: Ensure the compound is compatible with the materials used in the injection molding process. Cleaning Efficiency: Different compounds offer varying degrees of cleaning effectiveness. Consider the type and extent of contamination when choosing. Process Compatibility: Some compounds may require specific procedures or temperatures for optimal performance. Best Practices for Using Purging Compounds Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations regarding usage, dilution, and application of Purging Compounds. Regular Maintenance: Implement a proactive maintenance schedule, including Purging Compound usage, to prevent excessive build-up of contaminants. Trial Runs: Before full implementation, conduct trial runs to assess the compatibility and efficiency of the chosen Purging Compound with your equipment and materials. Purging Compounds might not be in the limelight of plastic injection molding, but they play an indispensable role. Purging Compound for Plastic from UNICLEANPLUS ensures a clean, efficient, and cost-effective production process, contributing significantly to the quality and consistency contributing significantly to the quality and consistency of manufactured plastic parts. Choosing the right Purging Compound and employing best practices can streamline operations, reducing downtime and enhancing overall productivity in the intricate world of plastic manufacturing. They offer free samples, which you can use to understand the process and select the ideal purging material. Call them at +91 9021232809 to place your order. To Read Our Published Blog: http://blogs.rediff.com/unicleanplus/2023/12/11/the-ultimate-guide-to-purging-compound-for-plastic/ Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com