PAGE 1 of 5

KENNE BELL

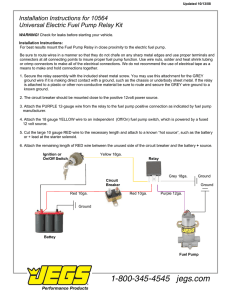

Hi Tech Performance Products

BOOST-A-PUMp™ WIRING INSTRUCTIONS

.nstallation of the KENNE BELL BOOST-A-PUMp™(BAP)

is simple and straightforward.

All you need to do is locate

the "HOT" (12 VOLT POSITIVE +) wire going to your pump and wire the BAP in series as shown in the following

diagrams. NOTE: The INPUT wire to the SAP is the fused red wire.

IMPORTANT! ON VEHICLES USING FEEDBACK

TO THE ENGINE COMPUTER TO TELL IT WHEN THE PUMP IS RUNNING - WIRE THE BAP

AFTER THE FEEDBACK WIRE OR THE CHECK ENGINE LIGHT MAY COME ON. WIRE THE BAP ONLY AS SHOWN IN THE FOLLOWING

DIAGRAMS OR DAMAGE MAY OCCUR AND WARRANTY WILL BE VOID ..

FROM FUEL PUMP

RELAY OR OTHER

PUMP SUPPLY

(manual switch,

pressure switch,

etc ...)

+

CD

POSITIVE WIRE---,.

LOCATE

.-------1~~

POSITIVE WIRE GOING TO PUMP

+1 1-

TO GROUND

p

U

M

P

STEP 1

FROM FUEL PUMP

RELAY OR OTHER

PUMP SUPPLY

+

POSITIVEWIRE

r-------1~

TO GROUND

(manual switch,

pressure switch,

etc ...)

p

®

CUT POSITIVE

U

M

WIRE GOING TO PUMP

p

STEP2

.r

';J4M'WI

FROM FUEL PUMP

RELAY OR OTHER

PUMP SUPPLY

+

POSITIVE WIRE

(manual switch,

pressure switch, etc ...)

RUN CABLE TO

INSIDE OF CAR

AND MOUNT

CONTROLLER

TO INTAKE (vacuum switch) or

SUPERCHARGER

or TURBO

..OUTLET

Vacuum I Pressure

MANIFOLD

Switch

(pressure I boost

switch)

STEP3

CAUTION! BOOST-A-PUMP

GROUND IMPORTANT!

Note: Double check ground. If

ground Is inadequate unit may be

damaged.

POSITIVEWIRE

OUT

RED

I

N

P

U

T

BLACK

GROUND

B

A

P

.-------1~

TO GROUND

+

RED

P

0

U

U

T

p

M

P

U

T

o

BLACKr::;'\

GROUND

TAKE THE END OF THE WIRE THAT YOU

CUT COMING FROM THE FUEL PUMP RELAY

OR SWITCH AND CONNECT IT TO THE

FUSED RED WIRE OF BAP. TAKE THE OTHER

END OF THE WIRE THAT YOU CUT GOING

ON TO THE PUMP AND CONNECT IT TO THE

OTHER RED WIRE. CONNECT BLACK WIRES

TO GOOD GROUND. YOUR PUMP WIRE NOW

"GOES THROUGH (IN AND OUT OF)" THE

BOOST-A-PUMP. RUN CABLE FOR SWITCH

AND CONTROLLER AS SHOWN.

r243/12219

KB-20

PAGE 2 of 5

KENNE BELL

PART# KBS9066 I KBS9067 20AMP

KBS906S I KBS9069 40AMP

BOOST·A·PUMp™ INSTALLATION INSTRUCTIONS

I. The Kenne Bell BOOST-A-PUMp™ (BAP) may be mounted anywhere as long as it is protected

water or extreme heat (above 300 F). Preferred mounting is under the seat or in the trunk.

from exposure to

0

2. Locate the 12 volt + wire going to the fuel pump from the fuel pump relay. It is important that you positively

determine the proper wire to splice into or the BAP will not function. If you do not see your vehicle listed on our

FUEL PUMP WIRE GUIDE. use your service manual or contact the dealer to determine the wire color and location.

NOTE: ON VEHICLES WITH COMPUTER CONTROL.THE

BAP SHOULD BEWIRED IN AFTER THE FEEDBACK

TO THE COMPUTER. NOT BEFORE.A CODE MAY BE SET IFTHE COMPUTER SEES HIGHER THAN NORMAL

VOLTAGE TO THE FUEL PUMP.

3. After you have located the fuel pump wire. trial fit the assembly first to insure the cables will reach their proper

installation points.

4. The Cockpit Controller must be located inside the vehicle to allow access to the adjustment knob. The cable has a

plug-in connector that can be routed through a small hole in the firewall or trunk depending on where the BAP

module is mounted. Make sure that the cable will reach the module as this cable CAN NOT be extended. Extendine

this cable will affect the operation of the BAP.

5. The other cable included in the kit goes from the BAP module to the activation switch (VACUUM for normally

aspirated and BOOST for supercharged / turbocharged applications). Route this cable through the firewall or trunk

from the switch location to the module. Make sure that the cable will reach the module because this cable CAN NOT

be extended. Extendine cable will affect operation of the BAP.

6. If the cable(s) will not reach the desired

extended up to ten-(IO) feet.Again. DO

AND/OR BLACK POWER WIRES may

power wires. Make sure all connections

location of the BAP module. the main # 10 AWG POWER WIRES may be

NOT EXTENDTHE MULTI-CONDUCTOR

CABLES. ONLYTHE RED

be extended. Use only # I 0 AWG copper stranded wire to extend the BAP

are solid and free from exposure to moisture.

7. Check to make sure you have the correct activation switch for your application. The VACUUM switch application has

two wires: RED and BLACK (RED from switch connects to the RED wire/ BLACK to BLACK).The SUPERCHARGED

/TURBOCHARGED

switch also has two wires: RED and BLACK.These simply connect to the BOOST switch.

Polarity has no effect.

8. Install the VACUUM switch with a short piece (no longer than 24") of 5/32" vacuum line from a good intake manifold

vacuum source. ON SUPERCHARGED /TURBOCHARGED

applications. install the BOOST switch with a short

piece (no longer than 24") of 5/32" vacuum line to the BLOWER SIDE ONLY of the intake manifold (the BAP will

not function if the line is on the inlet side of the supercharger / turbocharger).

9. Connect the fuel pump wires as shown in STEPS I - 3.The two BLACK ground wires on the BAP module may be

connected to the frame if desired. IMPORTANT:THIS MUST BE A GOOD CLEAN GROUND CONNECTION

FREE OF PAINT. RUST OR OTHER MATERIAL - DAMAGE TO THE UNIT CAN RESULT IF NOT GROUNDED

PROPERLY. (we recommend grounding the BLACK BAP wires to the battery NEGATIVE terminal or to the ground

wire going to the fuel pump).

10. Mount the BAP module with the four (4) included self tapping screws. The module does not need to be mounted to a

metal surface since the two black wires act as a ground.

II.

Plug in the Cockpit

Controller

and activation switch cables. The BAP is now ready for use.

r

117/24819

PAGE 3 of 5

BOOST·A·PUMp™ FUEL PUMP WIRE GUIDE

VEHICLE

YEAR

Mustang 5.0L

Mustang 5.0L

'86 - '90

Mustang

5.0Ll4.6L

'91 - '93/\

'94 - '98/\

*

Ford Trucks

WIRE COLOR

LOCATION

PINK wi BLACK STRIPE

Under driver's seat at relay

GREEN wi YELLOW STRIPE Under mass air meter

In trunk in harness

BROWN wi PINK STRIPE

GREEN wi YELLOW STRIPE Under power distribution box

under hood

Buick GN

'84 - '87

TAN wi WHITE STRIPE

In trunk (left side )+++

Syclone I Typh

'91 - '92

GRAY

Past bulkhead connector towards

pump (see diagram). Fuel pump

relay is located on the left side

firewall. There are 2 relays; one

for the AlC and the other for the

fuel pump (closest to engine).+++

" Includes Cobra

* All models and years from '91 up that we know of ...

+++ You must change the stock fuel pump fuse from 10 AMP to 20 AMP.

NOTE: DO NOT TIE INTO WIRE

AT RELAY - VOLTAGE WILL FEED

BACK TO INPUT OF BAP AND BLOW

FUSE.

Sorry, but we do not have the wire locations and colors for all vehicles, so please consult your service manual or dealer if you

do not see your vehicle listed above, OR you may be able to get info from Taylor Automotive Tech 1(800) 636-6414 or retrieve

information from the internet.

'JICK GN SWITCH PANELS - Note: If using a Kenne Bell KB82068 Fuel Pump / Anti Theft Switch, the switch MUST BE

'--.dYPASSED as the switch is not rated high enough to handle the increased load.

MAKE SURE THE TWO WIRES TOGETHER THAT GO TO THE PRESSURE

I VACUUM SWITCH HAVE VERY GOOD CONNECTIONS

TO

BOOST

A

PUMP

Vacuum I Pressure

Switch

NOTE: THIS CABLE CAN BE

SHORTENED

IF DESIRED

NOTE SOME VEHICLES

HAVE A BUILT·IN SAFETY SYSTEM (BELOW) WHERE THE ENGINE WILL NOT START UNTIL THE OIL PRESSURE

HAS BUILT UP ENOUGH TO ACTIVATE THE FUEL PUMP RELAY DO NOT WIRE THE BAP INTO THIS CIRCUIT

IF YOU ARE NOT SURE

WHETHER YOUR VEHICLE HAS THIS DEVICE LOCATE THE FUEL PUMP FIRST AND WIRE THE BAP CLOSEST TO THE PUMP

r------------------_

-:r---~

TO

FUEL

PUMP

WIRE IN

BOOST-A-PUMP

HERE

FUEL

PUMP

RELAY

Oil Pressure

Sender

1072607

PAGE 4 of 5

KENNE BELL

BOOST-A-PUMP

TECHNICAL INFORMATION AND INSTALLATION INSTRUCTIONS

OVERVIEW

The Kenne Bell BOOST-A-PUMP is designed to increase the output of any fuel pump from 1% up to 50%. It accomplishes this by increasing the

voltage approx. 5 volts (10% per volt). It will also maintain this pre-set voltage or output within 1% regardless of battery voltage (within 9 -17 volts).

A little known fact is that voltage to a fuel pump can vary 10% depending on the accessories that are on i.e. lights, stereo, AC, wipers, heater, brake

lights and even directional signals. The BOOST-A-PUMP immediately compensates for any subsequent voltage drop and fuel output reduction.

In fact, the BOOST-A-PUMP will maintain the +50% output as low as 9 volts! Yes, you can also use it on the ignition system to either increase or

maintain the desired voltage if bypassing or eliminating the charging system.

TECHNICAL

BACKGROUND

Kenne Bell has 37 years of background experience in hydraulic engineering. We know fuel systems. The Kenne Bell fuel flow bench is second to

none. We have documented the flow capacities of various fuel line types and sizes, tested all the currently available pumps (stand alone, inline

booster and in tank), regulators, fuel rails, mass air meters and filters. Countless dyno tests have been conducted on our in house dyno with a

variety of fuel system combinations. Fuel pressure and flow and air fuel ratio were measured with our computerized data logger system. The

BOOST-A-PUMP is the latest on the long list of Kenne Bell innovations.Read the following technical information. It will help you to better understand the dynamics offuel flow and pressure.

FLOWvs.

PRESSURE

First of all, pressure - not volume - is the most important indicator. A fuel injector with the proper pressure will flow the necessary fuel (volume). If it

doesn't have the correct pressure, only THEN do you become concerned about volume. Study the pump flow graph in our literature and you will

notice that as flow increases - pressure decreases. Conversely as flow (volume) decreases, pressure increases. Never forget that and it will help

you better understand the relationship between pumps, injectors, regulators, fuel lines, FMU/FMB's etc. EXAMPLE: (See Pump Flow Graph in

literature). Apump flows 88Lat40 psi. What is the flow at 50 psi? Answer: 78Lat50 psi. Whatis the flow at 30 psi? Answer: 97Lat 30 psi. You need

132Lat40 psi. Can't make it with the 88L.Add a Kenne Bell BOOST-A-PUMPto

the 88Lstock pump and you have it.

INSTALLATION

Installation is easy and straight forward. The BOOST-A-PUMP splices into the existing hot (+) fuel pump wire and increases the voltage to the

pump (see STEPS 1 - 3). Connect to the red wires as shown. The black wires are the grounds. There is a cable that connects to the Cockpit

Controller and a cable that connects to the Vacuum/Boost switch.

KB89066 VACUUM SWITCH ACTIVATION

(NORMALLY A SPIRA TED ONL Y)

For non-supercharged applications, the cable connects to a vacuum switch (normally aspirated) and activates at WOT (wide open throttle) and

low vacuum (approx. 4"). Depending on how efficient your intake system is (ideal vacuum gauge reading at WOT is 0") indicating "0" or no

restriction thru the filter, hoses, throttle body and intake manifold. 2", 3", 4", 6" etc. represent varying degrees of restriction, 6" being highly

restrictive. NOTE: The vacuum switch is adjustable. To alter setting tee in a vacuum gauge between the switch and an open hose. Suck on the

other end of the hose. You can typically register up to 10" of vacuum. Watch the gauge needle. You will hear the switch "click." The "click" is the

contacts closing that activate the BOOST-A-PUMP.

KB89067 PRESSURE SWITCH ACTIVATION (SUPERCHARGED

On supercharged or turbocharged applications,

(cost$10).

OR TURBOCHARGED

the pressure switch activates the BOOST-A-PUMP

ONL Y)

at approx. 3.5 psi. There is an optional 5 psi

FMU I FMBAPPLICATION

FMU/FMB (fuel mangagement units or boosters) are supplied with all Kenne Bell, Vortech, Paxton, ATI, Wheeler/SVO and B&M, BBK supercharger kits. These valves are installed in the fuel return line and merely restrict or shut off this line and increase fuel pressure thereby diverting

more fuel thru the injectors. NOTE: Our dyno testing has determined that these FMU/FMB devices increase fuel pressure as boost increases.

Example: Mustangs with stock intank pump and 241b injectors 48 psi with boost reference. An FMU raises the pressure to 55 psi "fixed." An inline

pump raises pressure to 90 psi "fixed" and the injectors go sonic and lock. Better approach would have been the stock pump and FMU at 55 psi.

BOOST-A-PUMP would allow pressure to be fully adjustable between 55 to 90 psi for ideal air fuel ratio and maximum horsepower. CAUTION:

Typically an FMU raises fuel pressure 10 psi for every 1 psi of boost IFthe pump has the capacity.

INLINE BOOSTER PUMPS (WITH FMU I FMB)

Therefore, we do not recommend inline "booster" pumps with any FMU/FMB system. 1.) They can increase fuel pressure to dangerous levels. 2.)

There is no pump flow adjustment. Fuel and pressure are FIXED and cannot be adjusted. 3.) Some injectors go "sonic" or "lock up" at higher

pressures negating control by the computer. 4.) "Inline" pumps are noisy. Inline stand alone high capacity pumps are acceptable but be careful of

big inline pumps with the FMU/FMB. Remember, the injectors must be capable of supplying or passing all this additional fuel volume into the

engine or the pressure will increase to alarming levels. Larger injectors (increases pump volume and decreases pressure) and or eliminating thaFMU/FMB (allows increased fuel volume thru the return line so lowers pressure) or a smaller pump with a Kenne Bell BOOST-A-PUMP will redu

and better control this pressure because of the adjustability.

<c;>

r

072607

PAGE 5 of 5

INLINE PUMPS (WITHOUT FMUlFMB)

Inline pumps that do not utilize an FMU are typically not a problem as most fuel regulators have the flow capacity to bypass the fuel not used by the

injectors back to the tank via the return line. Two (big) stand alone pumps may flow more fuel at idle than the regulator can bypass. An abnormally

high idle pressure that cannot be lowered with adjustment indicates this condition exists. Here again the preferred set up is one (1) big pump and

'BOOST-A-PUMP triggered by a switch that eliminates all that high volume at idle.

FUEL TEMPERATURE

There is one other consideration - fuel temperature. The more fuel the pump discharges the higher the fuel temperature. An inline booster pump

that is activated full time forces all the excess fuel flow thru the regulator and return line heating the fuel in the process. Yet another reason the

Kenne Bell BOOST-A-PU MP activated by a pressure switch is the preferred set up.

REGULATORS

Kenne Bell was the first to manufacture a true billet aluminum adjustable regulator. The SyclonelTyphoon,

Buick Turbo V6's and many other

vehicles do not use the FMUlFMB's. Standard equipmentforthese

vehicles is an adjustable pressure regulator. Set the idle with vacuum hose on.

Pressure will increase 8 psi at 0 vacuum and increase proportionally with boost. Example #1.30 psi idle, 38 psi at 0 vacuum and 48 psi at 10 psi

boost. Example#2. 40 psi idle, 48 psi atO and 58 psi at 10 psi boost- or68 psi at20 psi boost. These numbers are attainable only if the regulator is

boost referenced (vacuum line connected). If the vacuum line is not connected, expect 8 psi more at idle, the same at 0 vacuum and minus the

boost psi at

On naturally aspirated applications removing the vacuum line does not affect WOT fuel pressure - only idle pressure by 8 psi.

Turbocharged or supercharged engines can experiment with an airfuel ratio by varying WOT pressure with this vacuum line. 8 psi can result in up

to .6AF/R variances.

war.

FORD FUEL PRESSURE

DO IT WITH A CHIP

Ford pressure regulators work best at stock pressure (30 psi with vacuum line on). No, this is not a misprint. The EEC looks at both the idle and

WOT fuel tables to adjust fuel. Therefore increasing fuel pressure helps only temporarily - until the EEC sets WOT fuel based on idle pressure. It

begins adjusting both back to the pre set air fuel ratio programmed in the EEC orthe Kenne Bell SWITCH CHIP program. However, at some point,

as pressure is increased, the EEC is unable to "trim" back the rich mixture at idle and WOT. Then again, if idle remains at the stock 30 psi setting

WOT pressure can be increased and the mixture richened without the EEC trimming either. That is the principle behind the FMU/FMB on all

supercharger kits currenly available. Emissions are not affected as the richening only occurs at

The best approach is to control air fuel ratio

with a Kenne Bell SWITCH CHIP or a stand alone system, such as the OFI. The Kenne Bell SWITCH CHIP does not alter air fuel ratio at idle, part

tt,rottle etc. -onlyWOT.And NEVER try to "adjust out" idle up and down surge with the idle screw. The airfuel ratio at idle is OFF (excessively lean

tch) if the engine is "hunting." It's trying to adjust for a poorly calibrated idle mixture. Lower the pressure at idle to 30 psi and back off the idle

~rew

to the factory setting. Slight adjustments may be made without adverse effects.

war.

SPEED DENSITY

Speed Density System Ford cars and trucks use pre-mapped fuel tables in both open and closed loop so raising fuel pressure is sensitive as

compared to the Mass Air Systems which rely on air flow (mass) to calibrate fuel delivery. Therefore, the Kenne Bell BOOST-A-PUMP is an ideal

approach for both naturally aspirated and supercharged vehicles (with and without FMU/FMB). Because of it's less sophisticated computer, the

Syclone/T yphoon Speed Density System is not as sensitive to idle pressure.

EMISSIONS

Since the Kenne Bell BOOST-A-PUMP is only activated at WOT (open loop) fuel pressure at idle and part throttle cannot possibly be affected on

any vehicle. Even if activated full time at maximum 50% increase we have not seen evidence of elevated fuel pressure on any of the vehicles

we've tested. Nevertheless, 50 State Legal Status has been applied for.

FUEL PRESSURE

GAUGE

- GET ONE!

,

You can't determine engine RPM without a tach. You can't determine engine temperature without a temperature guage. You can't determine boost

without a boost gauge. And there is certainly no way you can determine fuel pressure without a fuel pressure gauge. GET ONE. One cannot tune

and trouble shoot a fuel injected car without a fuel pressure gauge.

TROUBLESHOOTING

BOOST·A·PUMP DOESN'T ACTIVATE

Check all wire connections

Check ground. MUST BE GOOD GROUND CONNECTION.

Faulty pressure switch. Bypass the switch by connecting the two wires together (short together - there is no voltage on this circuit)

DO NOT GROUND THESE WIRES. Now check the red OUTPUT + wire and GROUND with a VOM. Turn Cockpit Control to MAX.

Voltage should read at least 16 volts.

Check for blown fuse. See inlinefuse in red INPUT + wire (carry a spare with you at all times).

~OOST·A·PUMP CYCLES "ON" & "OFF"

'----'Built-in internal circuit breaker (separate from the fuse) in BOOST-A-PUMP

rating is 15amps (maximum peak20 amps, 40 amps for-2 Models).

module is being triggered because of overload. Operating

r 183118218

Hi Tech Performance

ALTERNATE

Products

INSTRUCTIONS

FOR RUNNING

BOOST.A·PUMp™

OLD FUEL

PUMP RELAY

1'"::8-=7-a------I

BATTERY

I

OLD WIRE TO

FUEL PUMP

(CUT AND USE TO

RUN COIL OF NEW

RELAY)

~

86

+

-

••

.

NEW

30 AMP

FUSE

{~EMOVEI

=-

~

INPUT

BAP

.,

TO

FUEL

PUMP

·"0

I

IOUTPUT

NEW FUEL

PUMP RELAY

(30AMP

MINIMUM)'

-

-

,

-

10743 Bell Ct. Rancho Cucamonga,

Orders (909) 941-6646 Tech (909) 941-0985

'\

I

30-87a

NEW

10 or 12

AWG WIRE

NEW WIRING

r

CA 91730

Fax (909) 944-4883

(

I

BOOST·A·PUMP Supplement for '03 Cobra

To be used with BAP instructions.

See general BAP instructions included with BAP for specific installation.

This page is meant as an overview explaining where to mount the BAP and exactly which wire to tap into.

BAP SETTING

Set BAP controller based on supercharger pulley size.

NOTE: If you have a larger crank pulley than stock, use the

pulley ratio or peak boost into engine.

PULLEY SIZE / BOOST / PULLEY RATIO

r.-&".~..,,·

I

I .. - .

o·

.

UI$V~"

"-:~~~.'~.'

0

Ratio

Boost

9

11

13

15

17

20%

4"

1.87

25%

3-314"

2.00

30%

35%

3-1/2"

40%

3"

2.14

2.3

2.51

L_ ~~~_.

3-1/4"

~:~~~;__

Fuel

pump

control

module.

.. ' .. ..

I;'_3 .._~~ J

.,, __

Fuel psi at wide open throttle should be 85 psi at 6500RPM.

1 . The BAP will be mounted in the trunk behind plastic/felt insulation, remove this to gain access for insulation.

Pay attention and don't drill through the fender when drilling hole for BAP.

2. There is a wire loom leading to fuel pump control module, slice, tape and pull back loom.

~

3. Locate brown wire with pink stripe coming from fuel pump control module, this is the wire leading directly

to the twin intake pumps. Cut this wire approximately 2-3 inches from connector.

4. Install heat shrink on red fused wire of BAP (input) splice to wire coming from fuel pump control

solder wires and heat shrink.

module,

5. Splice, solder, and heat shrink non-fused output wire from BAP to brown with pink wire leading to pump.

6. Install ground lug on black ground wire and attach chassisground location in fender well. Close to fuel pump

control module. Be sure to solder ground lug to insure against corrosion.

7. Run controller wire to desired location and mount control box. Shown installed in trunk, this is a nice place

to mount it. (no one can re-adjust your fuel by accident)

8. Run switch wire through car inside under plastic lower trim panel to engine compartment.

9. Hook switch wire to boost switch and tee into boost line leading to fuel pressure sensor from discharge

manifold.

1 O. Replace stock 20A fuse inn power distribution center (under hood) with 30A for fuel pump. Refer to owners

manual for correct fuse location.

"--- 11. Overall this makes for a very clean installation. Ziptie all loose wires. Re-Ioom fuel pump control module and

tape up with electrical tape.

12. Set BAP controller according to the table above.

Page 40 of 43

BOOST-A-PUMP Instructions for 199 and up Mustang GT

This page is meant as an overview explaining where to mount the BAP and exactly which wire to tap into.

FIGURE 1

FIGURE

2

NEVER EXCEED 75 PSI AT WIDE OPEN THROTTLE.

1. The BAP will be mounted in the trunk behind plastic/felt insulation, remove this to gain access for insulation.

Pay attention and don't drill through the fender when drilling hole for BAP. See figure I.

2. There is a wire loom leading to the roll over switch, slice and tape back.

3. Locate pink wire with black stripe coming from roll over switch. Cut this wire approximately

from connector. See figure 2.

2-3 inches

I

tfU-'tf' 'J'i/ "\ ~\\ovl

-::>

4. Install heat shrink on red fused wire of BAP (input) splice to wire coming from roll over switch, solder wires

and heat shrink.

5. Splice, solder, and heat shrink non-fused output wire from BAP to pink with black stripe wire.

6. Install ground lug on black ground wire and attach chassis ground location in fender well. Close to fuel pump

control module. Be sure to solder ground lug to insure against corrosion.

7. Run switch cabling (black/red wires) through car inside under plastic lower trim panel to engine

compartment.

8. Connect switch wires (black/red - polarity does not matter) to boost switch and tee into boost line leading

to Fuel Rail Pressure Sensor from discharge manifold.

TO FUEL RAIL PRESSURE

SENSOR BOOST

LINE.

(TAP INTO LINE

WITH TEE)

vacuu~~lrc~ssure

..-m{lP-------

TO BAP IN TRUNK

9. Overall this makes for a very clean installation. Ziptie all loose wires. Tape up with electrical tape.

Page 101 of 104

R072704

6E3-A-18

4.3L TURBO (VIN Z) DRIVEABILlTY,AND EMISSIONS

TO IGNITION

SWITCH

...I

~

FIPFUSE

o

o

~440rOcRN

ECM

4400R.~D

1

A

C201

~4~-----31TAN----~

~

A

GRNIWHT 465

t

FUELPUMP

RELAY

BLKlWHT 450

B+

RELAY DRIVE

~-~

BA11

BA12

FUEL PUMP RELAY

HARNESS

CONNECTOR

CHART A-S

Circu it Description:

FUEL PUMP RELAY CIRCUIT

4.3L TURBO (VIN Z) SYCLONE AND

TYPHOON (PORT)

When the ignition switch is turned "ON ,n the Electronic Control Module (ECM) will activate the fuel pump

relay and run the in-tank fuel pump. The fuel pump will operate as long as the engine is cranking or running

and the ECM is receiving ignition reference pulses.

If there are no reference pulses, the ECM will shut "OFF" the fuel pump within 2 seconds after key "ON."

Should the fuel pump relay or the 12V relay drive from the ECM fail, the fuel pump will be run through an .

oil pressure switch back-up circuit.

Test Description:

Numbers below refer to circled

numbers on the diagnostic chart.

1. This test will determine if the oil pressure switch

is closing and supplying voltage to the fuel pump

when the relay is not functioning.

2. This test will determine if the oil pressure switch

is stuck open.

Diagnostic Aids:

An inoperative fuel' pump relay can result in long

cranking times, particularly if the engine is cold or

engine oil pressure is low. The extended crank period

is caused by the time necessary for oil pressure to

build enough to close the oil pressure switch and turn

"ON" the fuel pump.

-,

Bussed Electrical

Fuse!

.Ampe

Center (BEe) (continued)

I

3-)

3;:>

10

10

FlAB

to

es

rlA7

15

NC clutch relay. Eme~

roessese s-r;ilCll. EV,&J>C/lfIISl9'

~err! ct'frtrol soIonoo. EGR ~SlM:. rroduIc. Heated oxygen

sensOtS lH02SI. Variab\Q VOl""! timing so;eooid. ~;eI 1..\ar.iI'Old

Runner Coolrd (UNlC) mod:.Ji<e,AlJtO-'flak "all~lssioo

(7{OO).

EVAPtantslerDlJf9llvu."'e

FlA9

F1.50

ts

AiCeMehrell!,

ts

High beam relay

Fl.SI

10

COl'lYert£!elCPraLserelay.c.cnv«tiblcl\lp~rre<ay

".52

sc

R6arwir.da ••••

dr;lr061re1a'J

Fl.~

I.

PCMI(""'-ollrelay

F1.t:6

20

Raoo(16S06)

swi1d:I,leItfror.tjHB6.Gl}

1=1.57

20

l..uggag( c(l",pattnlEnt~d

Cocwe,t:bIa top rais!l rel!y. Con'lrile

FI.SS

Fog lamp relay

F1.59

is

eo

FL61

20

Qgarfl(11l~

F1.6.:?

20

romparlmentle!l

inboard,

SlIb-

wooJerampli1ier,l\igyagecOO'Ipartrnenlr;glltoolOOaaJ

F1.6

t

ec

I

F1.i

n.s

!

<in

31

I ABScomroiomule(2C2lS'1

F1.9

1

!

1

3a

1 WIl1dShiek::~e~IOOIOr(17508)

I P::Jolief\'IIodowmolO1,leflr~r!233~i

1 P~r·.~owmo!ol'.t9l1fea:j2J39.41

I Saatlldjust' .•••

'iltho:lfive·lii;lerrott(uA7011,Lumbal8cju~

FUG

F1.I:

Fl.12

3i)

f1.13

FI.g

F,.sn

1.-fHI

3G

so

I

I

I

I

i

F't

ae

se

IS

cece

Clreuitsprolmed

Fl.45

I Sta:'\oeneisy(114SOj

I Po-ft.orwlO(lowmcr.oU~lthO(lt

1 Subwoofer ampl7>IGr.I~9::.ge

I

I

fl.'1~

Fl,«

I

3-)

Amp!

fanre/ay

I OIoWl:f meter rea

40

FL4

F"!I!

H:gh~Clfl9iru1mc1io;l!IorrJay,Low~~Cr.g~neCO'lii~

30

fl.2

rr.s

Cl01.~

"'CMpo-Nf.'·

Cln=1,lltspro~ed

fU

F1.3

-;

Pc...-erwniowlTlOlOi,ti1lIlla"1l

SutrNooIer ampfiliGr.lIJQgagecompartmonttight

'MlOferam~9r.luggagaC()mp.artm&ntt!lllou\boafll

:nXo3ld, Sub-

top 100.V9r(elay

SWwooIer amplifier, lei! Irool channel, Subwook!f tll1llif,er,

rl!;ht front ct\aMel

H!9h s.pe«l eoglr!e COOl~!an relay, LO\I,Ispeed enr;!ne cooling

lal'ltclay.l9f1itiootral!s.Iormet'~a,ct2(I8&1f),kJnitJon

transtol'T!lE!fcl\IXlCitor.lgniror,coiI{I2fl29},ccionr.!ugs

1S

Fualpumprolav

IS

ASS comroimocMe{2C21!:i).

McdJIe (PCM) {12A65OJ

PowfIrtr8ln Control

HOlnlelay

rel&ase rei6.y

$mar. ,It.n:tion Box {SJ6}

Smat: JIJ:\::;ion Box jSJB), D~r

dQof urkcl

rela~·.Ooot

1.1I'\.

Io:kretay,~kI-::tIQltty

1'1.63

i$JB)

'"

'eo"

~Wlrrx*ll(l~236}

Fl.65

Fl.67

eo

SmaJlJt«::fIOClBox(SJBI

Fl.5&

20

Igl'\ltlons'o'!1tth{11572)

FIJl4

FIJCl~do)rs.

Geoerato~

Smar1 JIKlt!IOO sex ISJ8j. kces.sory

1flay /'!illY

POto'eruatr. ConIrol ModiJe (PCM) (12A6SO). Radio (18&:>&,

&A2Jl

JlroCtioo

Box

ABSCQI11ro1m::OOte(2C.2191

\]REPLACE

IW/30AMP

2005-2006 MUSTANG GT BOOST-A-PUMp™

WIRING

•..,."

4.6L

2-4·2

..-

FUSE

~

'\;

L

a

J

I

RUNCABLETO

INSIDEOF CAR

AND MOUNT

CONTROLLER

TO INTAKE (vacuum switch) or

SUPERCHARGER

or TURBO

OUTLET

Vacuum I Pressure

MANIFOLD

Switch

(pressure / boost

switch)

-+-

N

P

U

T

....,

BLACK

GROUND

B

A

RED

r-----------------------------------------------,Powartr.lnC<:H

r

I

21

I

Cl.82

1nertIaFuol

Shutol1'(lFS)

RED

OUT~

±

't

II"""-

U

l\nllMOdllle

l~,~~(''

~,y=-=-=--=;iF=-=-=--=--=--=--_;_#==-=-=-*======,*_=;~-=-_J_~*~-=-;;f:~'Jb

l_iU;h(90;ul2)

Uf.f/J

IN

r r

3C~'~

FP"

FPC

GND

T

II:~=

t=----4-iFu.llankpr-s-~·

-~

--

---

:":::ACCe!emor

lur"tr~dueer

~lpo.Hlon

1,I\to(0H307)

st:nsor(9C~1

SIH'IMlf

15,.,$

15'·16

151."

24.2?~

p

GYlRO

PK'8Il

U

alS:~

T

==X:=

P

61~.~.1

i

"",

(nsln..mcn!

C"'.•.•

~

1J.56

I LCIVT

_=x:=

~~~~¥~r"

-'' '

51 c41j

_

__

~

__

3

1

_C4l3

•

281~i~~

_5300

'-i,,2'

I s".~

110-8

FuettJ.nkLmlt

lom07)

1S1-1}!

~

G4(1)

,,,,}':::o

.:» Si~-=---:""-=--------=--_ SiG"";:-I:::~=~~con.

1RTN I,,,,,,,,,,.•,,,,

L--~-----------__

6

t

C175n

lITN

~fS1.6

NOTICE

SOME BAPS ARE SHIPPED

WITH ONE GROUND WIRE,

SOME WITH TWO. SIMPLY

HOOK UP BOTH IF SO

EQUIPPED.

NOTICE

MUSTANGS

REQUIRE A NEW FUSE TO BE INSTALLED

IN THE FACTORY FUSE PANEL UNDER THE HOOD

(DRIVER

SIDE) • LOCATE THE FACTORY FUSE FOR

THE FUEL PUMP AND REPLACE IT WITH THE ENCLOSED

30 AMP FUSE. ALSO CHECK TO MAKE SURE THE

BAP FUSE IS 30 AMPS·

REPLACE

IF IT IS NOT, THEN

IT WITH THE ONE ENCLOSED. IF YOU DO

NOT INSURE BOTH FUSES ARE 30 AMPS, YOU MAY

BE STRANDED WITH A BLOWN FUSE.

NOTICE

KENNE BELL

27-7

LIGHTNING BOOST-A-PUMP WIRING (BEFORE)

ENGINE CONTROLS (5.4L SPORT)

1-----·-·

1

I

KENNE BELL

27-7

LIGHTNING BOOST-A-PUMP WIRING (AFTER)

ENGINE CONTROLS (5.4L SPORT)

R053107 CORELFILSIINSTRUCTIONSIBAPILIGHTNING

BAP.cdr

Page 1 of 1

~

r---~---, .....••

_[E]

. =.

: IIUM:III(Mw"'~ :~

r

•

1'I4U'

I

•

L

•

~

.AI

I

XI 10

I

&.

lelIA

---.,..

iliA

•••-

•.--..

I

---"

III

••

..-

PI(

0CIna:u' r

.

PI(

•

1

II

ION

IQH

1M

•

••

II(

~

22

7446

IN

7••••

7447

PI)

f¥'f

..

'.

'.

-------.-

.-----------------

L

-------------------

7447

IN

I

I

moa

Fuel Pump Flow Control

2010 Camaro

------.

KEMNE BELL BOOST.A.PUMPTM 2011 MUSTAN:G GT

.'.

.

.

.

.".

'.

.

,

'.,

WI'RINGSCHEMATIC

'.ffSEW en

HallI';_"'"

' f.

..,.,

··.

f

·

,.i •

. ,

, • INJf'WIIU

.

·

·

,-'.'•

"

f

:

:

CEa

,}.t ..... . ..

••fl3

(tSll

IN

\0

i=

i~

. ~.

.

r;-si

I.

J

"-'-

r[J'

=

. I: PR~URE

I:)

ff'Il ;

~11

d'32

Ij"

fPC·~g~-,~~"iti£_.ciM"

:

:Ii

-j:

,.

'1)0

:

: I; 8$

~

:

~

~ J:

np ~I'.

._-I G5

~'cae;

. ...• --..

FUSEI)'" i Cie6•••• -

,u

~

,..

' o+-C4G33

e4O'3J~'fioU: '~~El

Vf.!. ~

1

YE-oG

... ,.~"."" ... ".",!

lE230

•• 91.1

VEt22

vUi"

-

f

,_.3_t_~:u1'Nlll

t: .

_ a

~.~:~R£

f 'j"" 4il'lflSOll

, ;t

~£JIOtIE71:

r

." .

-~

._-

"21 t

-

s

ElECTRCMC

ENCI/ECONTIIQL&

RESTlWN1S

COIC1I\CI.

=:f

t;:":'.-::';';'1;

:r"(IIC1I)

····'H·

C4C3!qtn3

'tIE

as:

E

EHS.

8

""

••

QOI'A

t·EH&'

'

.~~~-.~.'.:.~.,~.'

Ii

!l

i5

1'";01,'111"

)I~.t;

!It,'"

!':tJJ

~..

•.•, >-

~II'CI

,-----

.

-. "$-----r"

1-----------.

-

~'.,~:~,.1f.~~~.~.~<'c~-::

Rffi.L!'J£I.1

:

:,

"I:

..~

:

4

:. ,"

j

::1

"..

.•

.:.

:I

'

J

•

r

•

1-.

,-

,

=.~r

~r

~

i.···-·I-~_lO

~

"

> .2

,C403S

:

II

CdS;!

.i

RYIS

t

u.

3

Vl411

CC!'ITRQ.

....

fPCClM)

III

Z5..'

1&:'

CEa

.....

"-:iI I

'~~-'-

..•

.";

,

I

.'.

J S1lS

.- ..

INPUT U~<::26:j'

_

!'I!,!I!!II.

BJI.MI

' I·

•

i1BAPoUTPUT!;-CUT:=

I t

Vl-GII'

21

!:

"'(K;

.-,FUEL

.,3mt

is

~

2

-I

. I CI~

-I:

fTPIW'

,1mEItf

.HI1ICTlOII

CIU.r

!I·t

,

:

.,

,

•

~RlIM\R

-;

. "SWITCH

:

'IIK~.~''.

!r~r~'

ti

I

r

9YfP

"

-

FONEIITRAII

ClClNJIIQ.'

=,lECPCIIJ

.'

l

:

::1"

'M37

M

z·:

'9Ha~JJ~"~~~~'--j