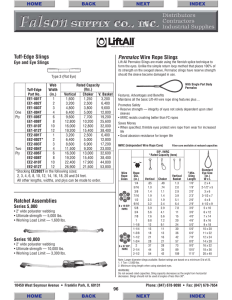

RIGGING CATALOG CharlestonsRigging.com CarolinasRigging.com CHARLESTON’S RIGGING AND MARINE HARDWARE 1304 MEETING STREET CHARLESTON, SC 29405 843-723-7145 843-723-5859 FAX 800-742-6703 sales@charlestonsrigging.com CAROLINA’S RIGGING 1219 BLUFF ROAD COLUMBIA, SC 29201 803-799-7702 803-799-7518 FAX 800-745-6627 columbiasales@carolinasrigging.com CAROLINA’S RIGGING AND CRANE INSPECTION DIVISION 2052 B GORDON HIGHWAY AUGUSTA, GA 30909 706-396-1700 706-396-1705 FAX 866-385-9346 augustasales@carolinasrigging.com IMPORTANT: READ WARNINGS BEFORE USING THIS PUBLICATION It is of utmost importance that anyone using this publication read and understand all warnings and other information listed below and/or adjacent to the product description. All products are sold with the express understanding that the purchaser is thoroughly familiar with the correct application and safe use. Use all products properly, in a safe manner and for the application for which they were intended. CHARLESTON’S/CAROLINA’S RIGGING assumes no responsibility for the use or misapplication of any product sold by this firm. Responsibility for design and use decisions rests with the user. IMPORTANT WARNINGS REMEMBER: ANY PRODUCT WILL BREAK IF ABUSED, MISUSED OR OVERUSED. Any well-designed and well-built product can become hazardous in the hands of a careless user. THEREFORE: 1. 2. 3. 4. 5. Never exceed the Work Load Limit. Match components properly. Keep out from under a raised load. Avoid shock loads. Inspect products regularly. risk, etc. When in doubt, inspect products prior to each use. Carefully check each item to be inspected for wear, deformation, cracks or elongation - a sure sign of imminent failure. Immediately withdraw such items from service. It would be impossible in the scope of this publication to list all possible dangers and misapplications associated with the use of all products contained herein. However, in order to promote safe rigging habits, the most common hazards associated with the use of these products are outlined. Rigging manuals or other, more specific, literature should be consulted for more detailed information and cautions. WORK LOAD LIMIT - Never exceed the Work Load Limit (WLL) or Rated Capacity. The Work Load Limit is the maximum load which should ever be applied to the product, even when the product is new and when the load is uniformly applied - straight line pull only. Avoid side loading. All catalog ratings are based upon usual environmental conditions, and consideration must be given to unusual conditions such as extreme high or low temperatures, chemical solutions or vapors, prolonged immersion in salt water, etc. Such conditions or high-risk applications may necessitate reducing the Work Load Limit. Work Load Limit will not apply if product has been welded or otherwise modified. MATCHING OF COMPONENTS - Components must match. Make certain that components such as hooks, links or shackles, etc. used with wire rope (or chain or cordage) are of suitable material and strength to provide adequate safety protection. Attachments must be properly installed and must have a Work Load Limit at least equal to the product with which they are used. REMEMBER: Any chain is only as strong as its weakest link. RAISED LOADS - Keep out from under a raised load. Take notice of the recommendation from the National Safety Council Accident Prevention Manual concerning all lifting operations: “All employees working at cranes or hoists or assisting in hooking or arranging a load should be instructed to keep out from under the load. From a safety standpoint, one factor is paramount: Conduct all lifting operations in such a manner that, if there were an equipment failure, no personnel would be injured. This means keep out from under a raised load and keep out of the line of force of any load.” SHOCK LOADS - Avoid impacting jerking or swinging of load - Work Load Limit will not apply. A shock load is generally significantly greater than the static load. AVOID SHOCK LOADS. REGULAR INSPECTIONS - Inspect products regularly for visible damage, cracks wear elongations, rust, etc. Protect all products from corrosion. The need for periodic inspections cannot be overemphasized. No product can keep operating at its rated capacity indefinitely. Periodic inspections help determine when to replace a product and reduce rigging hazards. Keep inspection records to help pinpoint problems and to ensure periodic inspection intervals. Rust damage is another potential hazard. When in doubt about the extent of corrosion or other damage, withdraw the items from service. Destroy, rather than discard, items that have been judged defective. They might be used again by someone not aware of the hazard of the defect. DEFINITIONS WORK LOAD LIMIT (WLL) - The Work Load Limit is the maximum load which should ever be applied to the product, even when the product is new and when the load is uniformly applied - straight line pull only. Avoid side loading. Never exceed the Working Load Limit. PROOF TEST LOAD (PROOF LOAD) - The term “Proof Test” designates a quality control test applied to the product for the sole purpose of detecting defects in material or manufacture. The Proof Test Load (usually twice the Work Load Limit ) is the load which the product withstood without deformation when new and under laboratory test conditions. A constantly increasing force is applied in direct line to the product at a uniform rate of speed on a standard pull testing machine. BREAKING STRENGHT/ULTIMATE STRENGTH - Do not use breaking strengths as criterion for service or design purpose. Refer to the Work Load Limit instead. Breaking strength is the average force at which the product, in the condition it would leave the factory, has been found by representative testing to break when a constantly increasing force is applied in direct line to the product at a uniform rate of speed on a standard pull testing machine. REMEMBER: Breaking strengths, when published, were obtained under controlled laboratory conditions that are almost always impossible to duplicate in actual use. DESIGN FACTOR - (sometimes referred to as safety factor) - An industry term denoting theoretical reserve capability. Usually computed by dividing the catalog Breaking Strength by the catalog Work Load Limit and generally expressed as a ratio. For example: 5 to 1. SHOCK LOAD - A load resulting from the rapid change of movement, such as impacting, jerking of swinging of a static load. Sudden release of tension is another form of shock loading. Shock loads are generally significantly greater than static loads. Any shock loading must be considered when selecting the item for use in a system. AVOID SHOCK LOADS. Due to the diversity of the products involved and uses to which they can be put, it would be counterproductive to make blanket recommendations for inspections procedures and frequency. Best results will be achieved when qualified personnel base their decisions on information from rigging and engineering manuals and on experience from actual use in the field. Frequency of inspection will depend on environmental conditions, application, storage or product prior to use, frequency of use, whether or not life, limb or valuable property are at Page 2 BE ON THE SAFE SIDE CRANE INSPECTION OSHA Certified Crane and Hoist Inspection • Certified Load Weight Testing Bridge Cranes • Monorails • Crawler • Hydraulic Cranes • Jib Cranes • OSHA Training HOIST REPAIR Certified Chain • Lever • Electric Hoist Repair and Testing PER ANSI B30. Specifications Manual • Electric • Air RENTALS Hoist/Manual & Electric • Air Tuggers • Winches Blocks up to 100 Ton, Load Cells • Heavy Haul Skates WIRE ROPE All Sizes 1/16” to 2” Diameter, 6 x 19 • 6 x 37 • 19 x 19• 35 x 7 • Constructex • Dyform IWRC and Fibercore • Galvanized and Stainless Steel Cable SLINGS & TIE DOWNS Wire Rope Chokers and Bridles • Boom Pendants • Synthetic Web Slings and Bridle Alloy Chain Slings and Bridles • Polyester Truck Tie Downs • Ratchet Assemblies CHAIN G8 Alloy • G7 Transport • G4 Hi-Test • G3 Proof Coil • Load Binders • Binder Chains ROPE/CORDAGE Nylon • Manila • Combo • Poly • Polyester & Nylon Double Braid Splicing Capabilities, 3 Strand and Double Braid • 6/8/12 Strand Ropes OIL SORBENTS Pads • Rolls • Socks • Particulate Booms • Skirted Booms • Turbidity Curtains HOIST/MONORAIL/BRIDGE CRANES Manual • Electric • Air Hoist • Chain Falls • Lever Hoist •Trolleys • Bridge Cranes & Monorails • Jib Cranes RIGGING HARDWARE Shackles • Turnbuckles • Clips • Hooks • Blocks • Snatch Blocks • Swivels • Sockets • Overhaul Balls Lifting Clamps • Trolleys • Winches • Ratchet Pullers • Lifting Eyes MARINE HARDWARE AND SUPPLIES Galvanized Bolts • Nuts • Washers • Tie Back Rods • All Thread Rods • Nails • Staples • Eye Bolts and Lags Pile Guides • Cleats • Fendering • Filtercloth • IPE Decking • S/S Screws & Guns • Barge Lights & Batteries SAFETY AND FALL PROTECTION 100% Tie Off Lanyards • Retractable Lanyards • Body Harnesses • Rope Grabs Life Lines • Anchors • Fall Protection • Horizontal & Vertical Lifeline Systems Page 3 SINGLE LEG SLINGS IWRC - IPS (EIPS capacity is approx. 15% higher) Rated capacities of basket hitches are based on a minimum diameter of curvature at the point of load contact 40 times the rope diameter for slings 1/4” thru 1” diameter and 25 times the rope diameter for slings 1 1/8” diameter and larger. TWO LEG BRIDLE SLINGS Rated Capacities in Tons (2000 lb) IWRC - IPS (EIPS capacity is approx. 15% higher) Page 4 Rated Capacities in Tons (2000 lb) IWRC - IPS (EIPS capacity is approx. 15% higher) THREE LEG BRIDLE SLINGS FOUR LEG BRIDLE SLINGS Rated Capacities in Tons (2000 lb) IWRC - IPS (EIPS capacity is approx. 15% higher) Page 5 CHOKER TYPES & CAPACITIES IWRC - IPS (EIPS capacity is approx. 15% higher) CHOKER HITCH RATED CAPACITY ADJUSTMENT Page 6 OPEN/CLOSED SWAGE SOCKETS (EIPS capacity is approx. 15% higher) IWRC - IPS Page 7 BRIGHT WIRE ROPE - 6 x 19 CLASS Page 8 BRIGHT WIRE ROPE - 6 x 36 CLASS Page 9 EFFECTS OF ANGLES ON SLING CAPACITIES Vertical sling angle 0˚ WIRE ROPE SLING REJECTION CRITERIA Page 10 SYNTHETIC WEB SLINGS - CARE CLEAN SLINGS ARE EASIER TO INSPECT, STRONGER AND LAST LONGER! (1-5 Using Code Letters - EE, EN - TCA etc.) See the following pages for descriptions and diagrams of Types 1-5 Page 11 SYNTHETIC WEB SLINGS 1 PLY TCS Vertical TTS *Steel hardware not available on 1 inch Choker Basket 1-901 1 inch 1,600 1,300 3,200 1-902 2 inch 3,200 2,600 6,400 1-903 3 inch 4,800 3,800 9,600 1-904 4 inch 1-906 6 inch 6,400 9,600 5,100 7,700 12,800 19,200 1-908 8 inch 12,800 10,200 25,600 1-910 10 inch 16,000 12,800 32,000 1-912 12 inch 19,200 15,400 38,400 **1 Ply with steel hardware available in Type 1-TCS only (3 & 4 Ply also available) EEF 2 PLY Vertical Choker EET Basket 2-901 1 inch 3,200 2,600 6,400 2-902 2 inch 6,400 5,100 12,800 2-903 3 inch 8,900 7,100 17,800 2-904 4 inch 2-906 6 inch 11,500 16,300 9,200 13,100 23,000 32,600 2-908 8 inch 20,500 16,400 41,000 2-910 10 inch 24,000 19,200 48,000 2-912 12 inch 26,900 21,500 53,700 ˚ (3 & 4 Ply also available) EN 1 PLY Vertical 1-901 1-902 1-903 1-904 1-906 1-908 1-910 1-912 1 inch 2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 3,200 6,400 9,600 12,800 19,200 25,600 32,000 38,400 2 PLY Choker 2,600 5,100 7,700 10,200 15,400 20,500 25,600 30,700 Basket Vertical 6,400 12,800 19,200 25,600 38,400 51,200 64,000 76,800 2-901 1 inch 2-902 2 inch 2-903 3 inch 2-904 4 inch 2-906 6 inch 2-908 8 inch 2-910 10 inch 2-912 12 inch Page 12 6,400 12,800 17,800 23,000 32,600 41,000 48,000 53,700 Choker 5,100 10,200 14,200 18,400 26,100 32,800 38,400 43,000 Basket 12,800 25,600 35,500 46,100 65,300 81,900 96,000 107,400 Gray Cordura and Nylon Wear Pads ENDLESS ROUND SLINGS SPECIFICATIONS AND RATED CAPACITY IN POUNDS Color Code Purple Green Yellow Tan Red White Blue Orange Orange Orange Orange Orange Orange Size 1 2 3 4 5 6 7 8 9 10 11 12 13 Approx. Body Diameter Inches 0.60 0.80 1.00 1.20 1.30 1.40 1.55 1.75 1.95 2.35 3.15 3.95 4.80 Vertical 2,600 5,300 8,400 10,600 13,200 16,800 21,200 25,000 31,000 40,000 53,000 66,000 90,000 Choker 2,100 4,200 6,700 8,500 10,600 13,400 17,000 20,000 14,800 32,000 42,400 52,800 72,000 Basket 5,200 10,200 16,800 21,200 26,400 33,600 42,400 50,000 62,000 80,000 106,000 132,000 180,000 60 Degree 4,500 9,200 14,500 18,400 22,900 29,100 36,700 43,300 53,700 69,300 91,800 114,300 155,900 45 Degree 3,700 7,500 11,900 15,000 18,700 23,800 30,000 35,400 43,900 56,600 74,900 93,300 127,300 Warning: Horizontal sling angles less than 30 degrees shall not be used. Page 13 ALLOY CHAIN SLINGS - GRADE 80 1. Determine the weight and configuration of the load(s) to be lifted. 2. Determine the type of chain sling required according to weight and configuration. 3. Determine the size of the body chain according to the working load limits* *. Be sure to take into consideration the effect of the required angle. 4. Determine the reach required to give the desired angle. The reach is measured from the upper bearing surface of the master link to the bearing surface of the lower attachment. * * Working load limit: The working load limit is the maximum load in pounds which should ever be applied to chain, even when chain is new, and when load is uniformly applied in direct tension to a straight length of chain. ** The life and strength of Grade 80 chain slings depend on proper inspection, maintenance and use. For additional information, refer to ANSI B30.9 and OSHA 1910.184. CARE Chain requires careful storage and regular maintenance. • Store chains on an A frame in a clean, dry place. • To avoid corrosion, oil chains before prolonged storage. • Do not heat Grade 80 chain; this will alter its thermal treatment. • Do not plate or change surface finish of chain. Contact us for special requirements. USE To protect both operators and materials, observe these precautions when using chain slings: • Before use, inspect chain and attachments following the instructions under “INSPECTION” below. • Do not exceed working load limit. Any of the factors listed here can reduce the load the chain will hold: ○ Acceleration in rate of load application – can produce dangerous overloading. ○ Variation in the angle of the load to the sling – as the angle decreases, the working load of the sling will increase. ○ Twisting, knotting or kinking – subjects links to unusual loading, decreasing the working load of the sling. ○ Use for purposes other than those for which slings are intended – can reduce the working load of the sling. ○ Free chain of all twists, knots and kinks. ○ Center load in hook(s); hook latches must not support load. ○ Avoid sudden jerks when lifting and lowering. ○ Balance all loads; avoid tipping of loads. ○ Use pads around sharp corners. ○ Do not drop load on chains. ○ Match the size and working load limit of attachments such as hooks or rings to the size and working load limit of the chain. ○ For overhead lifting, use only alloy chain and attachments (Grade 80). INSPECTION It is important both to inspect chain slings regularly and to keep a record of all chain inspections. Follow this guide for such an inspection system. • Before inspecting, clean chains with a non-acid/non-caustic solvent so that marks, nicks, wear and other defects are visible. • Inspect each link for these conditions to remove from service: ○ Twists or bends. ○ Nicks or gouges. ○ Excessive wear at bearing points. ○ Stretch. ○ Distorted or damaged master links, coupling links or attachments especially spread in throat opening of hooks. • Mark plainly with paint each link or attachment showing any of the conditions listed here to indicate rejection; remove from service until properly repaired. Page 14 ALLOY CHAIN SLINGS - GRADE 80 Grade 80 Alloy Chain Slings are designated throughout the industry by the following symbols: First Symbol (Basic type) S Single Chain Sling with master & hook or hook each end C Single Choker Chain Sling with masterlink each end D Double Chain Sling with standard masterlink and hooks T Triple Chain Sling with standard masterlink and hooks Q Quadruple Chain Sling with standard masterlink and hooks Second Symbol (Type of masterlink or end link) O Standard Oblong masterlink – recommended for all types P Pear shaped masterlink – available on request Third Symbol (Type of Hooks) S Sling Hook G Grab Hook F Foundry Hook 90˚ TYPE CO TYPE SOS TYPE DOS TYPE SOG TYPE DOG 45˚ 30˚ 60˚ 45˚ 30˚ 60˚ TYPE QOG TYPE TOS Alloy Slings can be assembled with shortening hooks. Page 15 Manual & Electric Hoists HOIST and CRANE SYSTEMS Bridge Crane Systems Air Hoists Double chain fall line 6 Ton Trolleys & Beam Clamps Some items available for rental. Page 16 CAROLINA’S RIGGING - CRANE INSPECTION DIVISION Crane Division capabilities: Annual, Quarterly, Monthly inspections Preventive maintenance programs OSHA compliance inspections New cranes (including runway and electrification) New hoists and trolleys Variable frequency drives (VFDs) Operator training Load testing to 100 tons, using free weights Electrical or capacity upgrades Conductor bar and festoon systems Radio remote systems 24/7 emergency service Workstation bridge, monorail and jib cranes Custom design and engineering Page 17 TIE DOWN EQUIPMENT 1” Utility Straps with “S” Hooks - 400 lbs. Working Load Limit 2” Ratchet Straps - 3,333 lbs. Working Load Limit 3” Ratchet Straps - 3,250 lbs. Working Load Limit 4” Ratchet Straps - 3,750 lbs. Working Load Limit End Fittings Options: Same as above for Ratchet Straps Page 18 HARDWARE - TOOLS - FITTINGS Hook & Hook HOIST RINGS Page 19 SAFETY EQUIPMENT Rope Grab Universal 2-D Ring 3-D Ring Ironworker Rope Lanyards Web Lanyards Shock Absorbers Tie Back Lanyards 100% Tie-off Lanyards Page 20 • • • • ALL STEEL SOLID WELDED OPTIONS AVAILABLE ACCESSORIES • • TAMPING BLOCKS LIFTING LUGS TITAN • SAFETY PAINTED BASIC 5, 6 & 8 • • BASIC 3 LIFTABLE HIGH TAPERED • DRAG BAR • ROLL-UP BOTTOM FREE STANDING BASIC BEDDING • WALK BAR 10 TONS CAPACITY Page 21 SLING GUIDELINES ANSI and OSHA Regulations Page 22 JOHNSON ARCHITECTURAL HARDWARE WE ARE PROUD DISTRIBUTORS FOR: J. D. Neuhaus Newco Manufacturing Skookum Hilman Rollers CM Hoists & Forgings Morse-Starrett The Crosby Group Chicago Hardware Seattle Glove Cooper Tools Caldwell Group Tandemloc Harrington Hoist Thern Winches/Tuggers Taylor Chain Samson Rope Yale Cordage Muncy/Upson Walton Safewaze Fall Protection Klein Tools Laclede DBI/Protecta Fall Protection Bridon American Wire Rope Jet Rud Chain Actek Hoist Rings KWS Gunnebo Johnson Renfroe Plate Clamps Ohio Hoist & Puller Johnson Architectural Hardware Block Division, Inc. Maritime Cordage Nabrico Deck Hardware Zinco Hydraulics Safety Clamps Dica Outrigger Pads Pewag Seahawk Paint Wyeth-Scott Power Pullers Spanset Norco Virginia Fasteners Tuffy HP Slings Letellier Miller Construction Products Spanco Little Mule Peck & Hale My-Te Page 23