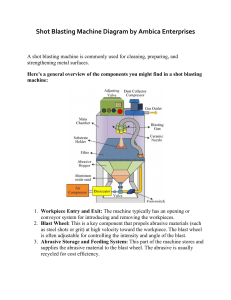

Spare Parts for Shot Blasting Machine by Ambica Enterprises Discover top-quality spare parts for your shot blasting machine at Ambica Enterprises. From powerful blast wheels to precisionengineered wear plates, we offer a comprehensive range of genuine replacement components. Ensure optimal performance, longevity, and efficiency for your equipment. Shop now for reliable spare parts and keep your shot blasting machine operating at peak performance. Unleash the full potential of your machinery with our trusted solutions. Keeping your shot blasting machine in tip-top shape is key to a smooth and efficient operation. Here's a handy list of spare parts to have on hand, categorized by their role: Abrasive Delivery All-Stars: Nozzles: Your blast stream's MVP! Choose from shapes like venturi, long venturi, or even deflector nozzles depending on your desired coverage and pattern. Hoses: The veins of your machine, carrying the abrasive from storage to the nozzle. Opt for flexible, wear-resistant hoses to avoid blockages and downtime. Injectors: The air traffic controllers of the abrasive flow. Venturi or airoperated, they ensure just the right amount of abrasive joins the air stream for optimal blasting. Elbows & Tees: Your blast path's navigators. Durable elbows and tees with smooth bends keep the abrasive flowing smoothly, preventing unwanted blockages and ensuring consistent blasting. Abrasive Recovery & Cleaning Crew: Separator: This hero sorts the good from the bad, separating spent abrasive from dust and debris. A clean separator means a happy machine! Elevator: The tireless hauler, lifting the separated abrasive back to the hopper for another round. Bucket, screw, or pneumatic – choose your champion! Dust Collector: The air purifier, trapping dust particles before they escape. Cartridge, bag filter, or even a wet warrior – keep your work environment clean and healthy. Abrasive Cleaning System: This detailer keeps your abrasive media in peak condition. Vibratory cleaners or magnetic separators remove contaminants like oil and metal fines, ensuring efficient blasting. Machine Control & Monitoring Mavens: Control Panel: Your command center! Start, stop, adjust – it's all here. Keep it clean and intuitive for smooth operation. Gauges: The watchful eyes, giving you real-time updates on air pressure, abrasive levels, and more. Don't blast blindly – stay informed! Safety Interlocks: Your guardian angels. Open access doors? Low abrasive? They'll hit the brakes before things get dicey. Prioritize safety, always! Wear & Tear Warriors: Liners: Think of them as protective suits for your machine's interior. Rubber, polyurethane, or ceramic – choose the right armor against the abrasive onslaught. Turbine Blades: The whirling dervishes, propelling the abrasive in the blast wheel. Keep them balanced and wear-resistant for smooth, powerful blasting. Gaskets & Seals: The unsung heroes, preventing leaks and ensuring proper air flow. High-quality materials are essential in this abrasive environment. If you're looking for spare parts for a shot blasting machine, it's important to identify the specific components you need. Shot blasting machines typically consist of various parts, including: 1. Blast Wheel or Turbine: This is a crucial component that propels abrasive material (like steel shot or grit) at high velocity to clean or prepare a surface. 2. Blast Cabinet: The enclosure that contains the blasting operation and prevents the abrasive material from spreading. 3. Abrasive Reclaim System: This system collects and recycles the abrasive material for reuse, reducing waste. 4. Dust Collector: To capture and filter dust generated during the blasting process, ensuring a clean and safe working environment. 5. Bucket Elevator: Used to lift and transport abrasive material within the system. 6. Conveyor System: Some shot blasting machines may have a conveyor for moving workpieces through the blasting process. 7. Control System: The electronic or computerized system that manages and controls the various functions of the shot blasting machine. 8. Liners and Wear Plates: These are parts that experience wear over time and may need replacement. 9. Seals and Gaskets: Important for maintaining the integrity of the blast cabinet and preventing abrasive leakage. 10. Motor and Drive Components: Various motors and drives power the different moving parts of the machine. When looking for spare parts, it's advisable to contact the manufacturer of your shot blasting machine or a reputable supplier in the industry. Provide them with the machine's model and serial number, along with details about the specific part you need. This information will help ensure that you get the right spare parts for your machine. Keep in mind that regular maintenance and timely replacement of worn parts are essential for the efficient and safe operation of shot blasting machines. Buy Shot Blasting Machine Online in India: Contact Us Name - Ajay Singh CEO of Ambica Enterprises Email - inquiryi46@gmail.com Mobile Number - +91-9653765900 Company Name - Ambica Enterprises Address - Jodhpur, Rajasthan, India Website - 1: https://www.shotblastingmachines.in/ Website - 2: https://shotsblastingmachine.com/ Thanks! ❤️❤️❤️