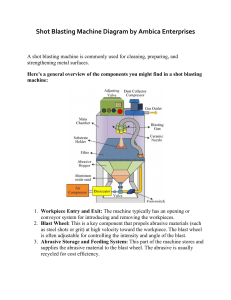

Shot Blasting Machine Spare Parts List by Ambica Enterprises Unlock the full potential of your shot blasting machine with our extensive range of top-quality spare parts. Enhance your abrasive delivery system with precision-engineered nozzles, flexible hoses, efficient injectors, and durable elbows and tees. Our comprehensive collection ensures seamless abrasive flow and optimal performance. Revolutionize your abrasive recovery and cleaning system with cutting-edge technology. Choose from advanced separators, elevators, and dust collectors to maintain peak efficiency. Our abrasive cleaning systems, featuring vibratory cleaners, magnetic separators, or a powerful combination, guarantee pristine results. Take command of your shot blasting process with our stateof-the-art machine control and monitoring components. Our user-friendly control panels empower operators to fine-tune parameters such as pressure, flow rate, and cycle time. Realtime gauges provide accurate readings, while safety interlocks ensure a secure operating environment. Ensure longevity and reliability with our wear parts selection. Shield your equipment from wear and tear with high-quality liners crafted from rubber, polyurethane, or ceramic materials. Our turbine blades, engineered for durability and balance, propel abrasive materials efficiently. Gaskets and seals, designed to withstand abrasive environments, prevent leaks and ensure optimal airflow. Discover a comprehensive list of shot blasting machine spare parts, thoughtfully categorized based on their functions: 1. Abrasive Delivery System: Nozzles: Direct the abrasive blast stream onto the workpiece, available in various shapes and sizes for desired blast patterns. Hoses: Flexible conduits transporting abrasive material from the storage hopper to the blast nozzle, resistant to wear and tear. Injectors: Regulate abrasive material flow into the air stream, with options like venturi or air-operated for diverse applications. Elbows and Tees: Alter the direction of abrasive flow, requiring durability and smooth bends to prevent blockages. 2. Abrasive Recovery and Cleaning System: Separator: Separates spent abrasive from debris and dust generated during blasting, utilizing cyclone or screen separation methods. Elevator: Lifts separated abrasive back to the storage hopper for reuse, employing options like bucket elevators, screw conveyors, or pneumatic conveyors. Dust Collector: Filters dust particles from the air before release, featuring cartridge, bag filter, or wet dust collector options. Abrasive Cleaning System: Removes contaminants like oil, grease, and metal fines from abrasive material, using vibratory cleaners, magnetic separators, or a combination. 3. Machine Control and Monitoring: Control Panel: Enables operators to start, stop, and adjust blasting parameters such as pressure, flow rate, and cycle time. Gauges: Provide real-time readings of critical parameters like air pressure, abrasive level, and dust collector filter pressure. Safety Interlocks: Prevents machine operation if safety conditions like open access doors or low abrasive levels are not met. 4. Other Wear Parts: Liners: Protect the blast chamber and other components from wear and tear, available in rubber, polyurethane, or ceramic materials. Turbine Blades: Propel abrasive material in the blast wheel, requiring resistance to wear and tear and balance for smooth operation. Gaskets and Seals: Prevent leaks and ensure proper airflow, constructed from materials resistant to abrasive environments. To obtain an accurate and up-to-date spare parts list, I recommend contacting Ambica Enterprises directly through their official channels, such as their website or customer support. Typically, spare parts for shot blasting machines may include components such as: 1. Blast Wheel Components: o Blades o Control cages o Impellers 2. Wear Parts: o Liners o Wheel housing liners 3. Dust Collector Components: o Filter cartridges o Pulse valves o Dust bags 4. Conveyor Components: o Belts o Rollers o Bearings 5. Control System Parts: o Electronic components o Control panels o Sensors 6. Abrasive Media: o Steel shot o Steel grit o Abrasive blast media 7. Seals and Gaskets: o Door seals o Housing gaskets 8. Safety Equipment: o Blast suits o Gloves o Helmets Remember, the specific parts and their availability may vary based on the make and model of the shot blasting machine. It's best to consult with the manufacturer or supplier for precise information tailored to your machine's specifications. Buy Shot Blasting Machine Online in India: Contact Us Name - Ajay Singh CEO of Ambica Enterprises Email - inquiryi46@gmail.com Mobile Number - +91-9653765900 Company Name - Ambica Enterprises Address - Jodhpur, Rajasthan, India Website - 1: https://www.shotblastingmachines.in/ Website - 2: https://shotsblastingmachine.com/ Thanks! ❤️❤️❤️