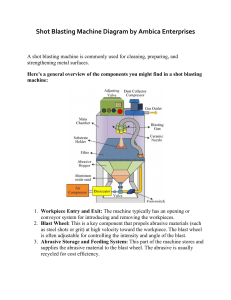

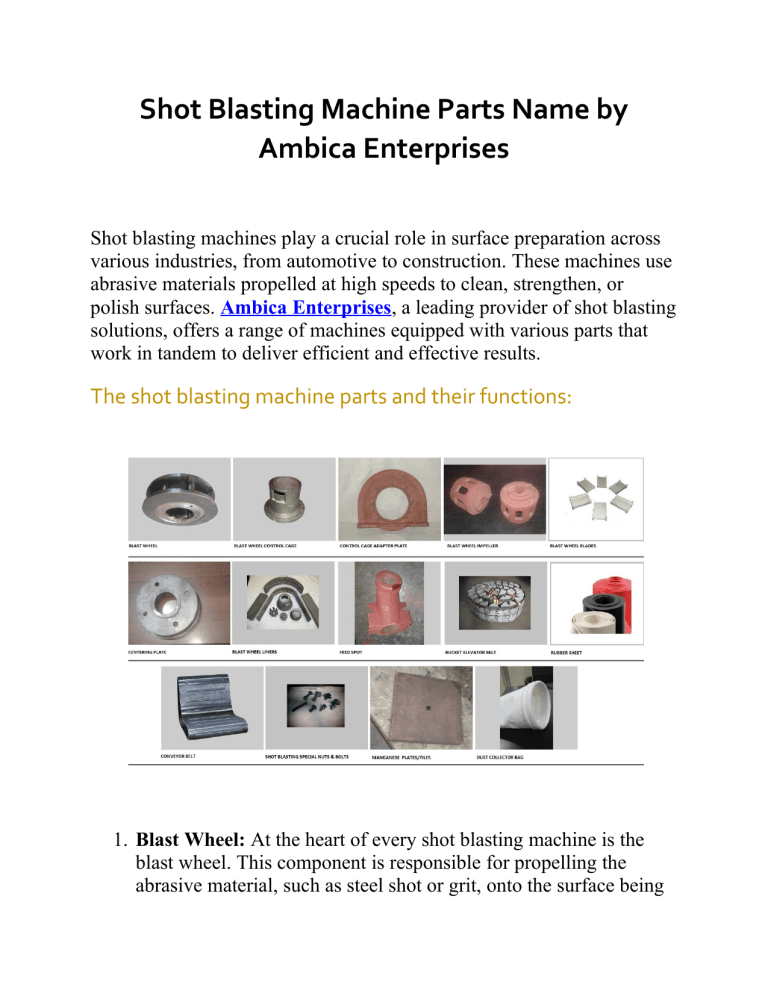

Shot Blasting Machine Parts Name by Ambica Enterprises Shot blasting machines play a crucial role in surface preparation across various industries, from automotive to construction. These machines use abrasive materials propelled at high speeds to clean, strengthen, or polish surfaces. Ambica Enterprises, a leading provider of shot blasting solutions, offers a range of machines equipped with various parts that work in tandem to deliver efficient and effective results. The shot blasting machine parts and their functions: 1. Blast Wheel: At the heart of every shot blasting machine is the blast wheel. This component is responsible for propelling the abrasive material, such as steel shot or grit, onto the surface being 2. 3. 4. 5. 6. treated. Ambica Enterprises ensures the quality and precision of their blast wheels, which are designed to achieve optimal blasting performance. Abrasive Flow Control Valve: Precision in abrasive flow is essential for achieving desired surface treatment results. The abrasive flow control valve regulates the amount of abrasive material released into the machine, ensuring a consistent and controlled blasting process. Ambica Enterprises incorporates highquality flow control valves in their machines to maintain accuracy and efficiency. Cabinet or Chamber: The cabinet or chamber of a shot blasting machine encloses the area where the blasting process takes place. It is designed to contain and control the abrasive material, preventing it from escaping into the surrounding environment. Ambica Enterprises pays attention to the design and construction of the chamber to maximize the efficiency of the shot blasting process. Dust Collector: Shot blasting generates a significant amount of dust and debris. A dust collector is an essential component that extracts and filters the airborne particles, ensuring a clean and safe working environment. Ambica Enterprises integrates efficient dust collector systems into their machines to comply with environmental and safety standards. Blast Nozzle: The blast nozzle is the point of exit for the abrasive material from the machine. Ambica Enterprises provides highquality blast nozzles that are durable and resistant to wear, ensuring a longer lifespan and consistent performance. Bucket Elevator: After the abrasive material has been used, it needs to be collected and recycled. The bucket elevator is responsible for lifting the used abrasive material from the chamber to the separator, where it is cleaned and prepared for reuse. Ambica Enterprises manufactures reliable bucket elevator systems to facilitate a continuous and efficient shot blasting process. Shot Blasting Machine Parts Name 1. Blast Wheel 2. Abrasive Media 3. Blast Cabinet 4. Dust Collector 5. Bucket Elevator 6. Separator 7. Control Cage 8. Blast Nozzle 9. Blast Hose 10. Vibratory Screen 11.Abrasive Reclaimer 12. Shot Peening Nozzle 13.Impeller 14. Wheel Housing 15.Blast Wheel Motor Abrasive Propulsion: Centrifugal wheel Impeller blades (control media flow) Wear liners (protect housing from abrasion) Media Circulation: Elevator (lifts used abrasive) Separator (removes dust and debris from media) Hopper (stores fresh abrasive) Part Handling: Turntable (rotates parts for even blasting) Conveyor belt (transports parts through blast chamber) Hooks/fixtures (securely hold parts) Dust Control: Blast chamber (encloses blasting area) Vacuum system (captures dust and debris) Filters (clean extracted air) Control & Monitoring: Control panel (adjusts blasting parameters) PLC (automates machine operation) Sensors (monitor machine performance) Additional Components: Nozzles (direct abrasive stream) Blast media (steel shot, grit, etc.) Work gloves (protect operator hands) Safety glasses (protect operator eyes) Conclusion: In the realm of shot blasting machines, understanding the key components is crucial for optimizing performance and achieving desired surface treatment results. Ambica Enterprises stands out as a reputable provider, offering shot blasting solutions with meticulously designed parts to ensure durability, efficiency, and precision. Whether it's blast wheels, abrasive flow control valves, or dust collectors, each component plays a vital role in delivering high-quality shot blasting services across diverse industries. Buy Shot Blasting Machine Online in India: Contact Us Name - Ajay Singh CEO of Ambica Enterprises Email - inquiryi46@gmail.com Mobile Number - +91-9653765900 Company Name - Ambica Enterprises Address - Jodhpur, Rajasthan, India Website - 1: https://www.shotblastingmachines.in/ Website - 2: https://shotsblastingmachine.com/ Thanks! ❤️❤️❤️