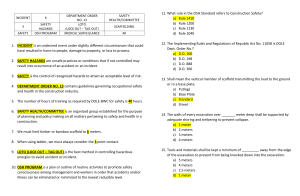

TOPICS: 1)Introduction: OSH 2)Importance of Safety and Health 3)Unsafe Acts and Unsafe Conditions 4)Construction Site Premises 5)Excavation Safety 6)Tools and Equipment 7)Construction Machinery: Mobile Equipment Safety 8)Construction Machinery: Crane Safety 9)Ladder Safety 10)Fall Protection 11) Temporary Structures 12) Environmental Safety 13) Occupational Health 14) Personal Protective Equipment 15) Demolition and Explosives Safety 16) Routine Site Safety Inspection 17) HIRAC/Risk Assessment 18) Job Hazard Analysis 19) Accident Investigation 20) Communicating OSH 21) Workplace Emergency Preparedness 22) Role of the Safety and Health Officer 23) Employees’ Compensation Program 24) Salient Features of OSH Legislations 25) Development of an OSH Program 1.0 Introduction: OSH Absolutely true: Every worker has the right to a SAFE and HEALTHY workplace! What is the STATUS of occupational safety and health (OSH) in MY workplace? 1. Accidents and injuries result to loss of lives, limbs, time and property 2. Most accidents at work could have been prevented 3. Sound prevention need to be implemented systematically in the national and enterprise / workplace level What is Occupational Safety and Health (OSH)? Occupational safety and health is a discipline with a broad scope involving three major fields: • Occupational Safety • Occupational Health and • Industrial Hygiene. OSH encompasses the social, mental and physical well-being of workers - the “Whole Person”. ILO 2.0 Importance of Safety and Health COSH training aims to provide: 1. Protection of life 2. Protection of Property 3. Protection of operation When accidents happen… There are a lot of effects when an accident happens including increase in tardiness and absenteeism which the lowers down the morale and productivity of workers and also affects the profit of the company. The Iceberg Effect on Cost of Accidents Direct Costs of Accidents – Tend to be the ones that we think of first. ✓ Emergency Medical Care ✓ Injury, sickness, damage to property ✓ Equipment Damage or Material Spoilage ✓ Compensation Payments ✓ Investigations of Legal Authority ✓ Insurance Premiums Indirect Costs of Accidents - those that are less obvious but they account for more on the overall cost 1) Injured Worker • lost productivity on day of injury • lost productivity due to follow-up care • lost productivity after returning to work 2) Worker’s Crew • completing added work • assisting injured worker • lost productivity due to inspection 3) Crew around Accident Site • watching events and discussing accident 4) Training Replacement Worker 5) Supervisors • investigating accident • preparing reports • time with management, owner or regulatory agencies Summary: Occupational Safety and Health Is important because: 1. It provides safety and health measures in different work environments and sectors. 2. It is an area that is concerned with the safety, health, as well as the welfare of people engage in organization 3. It also increases productivity when employees are healthy and happy. 3.0 Unsafe Acts and Unsafe Conditions Due to the massive acceleration in the development of construction sector, several injuries, diseases and other incidents have occurred. In fact the leading causes of fatal accidents in the construction industry are the following: • Excavation Collapse • Falls from Heights • Electrocution • Hit by Falling Objects • Accidents Involving Construction Equipment Why do people get into accidents? Filipinos have a lot to say when an accident happens. Some of the common misconception about the occurrence of an accident are the following: • “Oras na niya!” (It’s his time) • “Malas niya lang...” (It’s his misfortune) • “Tanga kasi!” (Imbecile) • “Ah! Kasama sa trabaho iyan!” (It’s part of his job) But, these are not the real causes .... THESE ARE ONLY EXCUSES.. Two Immediate Causes of Accidents: Unsafe Acts and Unsafe Conditions 1) Unsafe Condition • Physical or Chemical property of a workplace's Environment, Equipment / Machine, Material • Deviation from standard physical / chemical condition • Likely to cause injury, illness, relative property damage • An unsafe condition is any situation or condition (whether physical or chemical in nature) in a workplace's environment, equipment/machine, or material that is likely to cause injury, illness, and even property damage. (Examples of Unsafe Condition) 1. Defective tools, equipment, or supplies 2. Inadequate machine guards 3. Inadequate support and bracing for scaffolds 4. Inadequate warning system 5. Conditions or situation which may lead to fire or explosion 6. Poor housekeeping 7. Uneven walking surfaces 8. Excessive noise 9. Poor ventilation 10. Poor illumination 2) Unsafe Act Unsafe act is a performance of a task conducted in a manner that may cause injury, illness, property damage. This includes improper action or behavior. Unsafe act is also defined as a human action that deviates from standard practices. Factors Contributing to Unsafe Acts & Conditions 1. Improper Attitude 2. Physical Limitations 3. Lack of Knowledge or Skills 4. Lack of Supervision Safety State of freedom from risks, usually achieved through all measures and arrangements set to protect workers from injury or ill health. Freedom from accidents; Freedom from harm, injury and loss. Accident versus Incident 1. Accident is unplanned or unexpected occurrence / event that may result in property damage and does result in an injury or illness to a worker 2. Incident is an unplanned or unexpected occurrence / event that may result in property damage, but does not result in an injury or illness 3. Incidents are also called “near-misses” Hazard versus Risk • Hazard is anything (unsafe act, unsafe condition, substance, material, process, chemical, etc.) that has the potential to cause harm, damage, or adverse health effect on people • Risk is the chance or probability that a person will be harmed or experience an adverse health effect if exposed to a hazard A hazard is any source of potential damage, harm or adverse health effects on something or someone. Basically, a hazard is the potential for harm or an adverse effect (for example, to people as health effects, to organizations as property or equipment losses, or to the environment). Risk is a combination of the probability of the contact of a person to the hazard and the severity of the effect when a person comes into contact with a hazard. The risk is lowered either if it is unlikely that a person may come into contact with a hazard or the severity of the effect due to contact is low. Three Steps to Control Hazards and Accidents 1. Identify the hazard ▪ Inspection (before the accident occurs) ▪ Investigation (after the accident occurs) 2. Evaluate Determine if what you identified complies with safety standards, by means of Occ. Health & Safety Standards, OEL, TLV, PEL, NIOSH, others. 3. Correct the hazard 1. Engineering control 2. Administrative control 3. Personal protective equipment Engineering Methods – eliminate or reduce the hazard Initial design specification Substitution Isolation (Place) Ventilation Change in Process Administrative Methods - control of employees exposure Isolation (Time) Medical Examination Scheduled reduced work hours Increased breaks Workplace Monitoring SOP’s Personal Protective Equipment Use of a protective barrier to protect the worker from the hazard Summary: 1. Unsafe condition is the deviation from the standard physical / chemical condition 2. Unsafe act is the deviation from the standard practices 3. Unsafe condition and acts are not only encountered in the construction industry but also in everyday life 4. Accident results to harm to a person while incident does not result to harm to a person 5. Hazard is anything the has the potential to cause harm, damage, health effect, or environmental impact 6. Accidents are caused and accidents can be prevented 4.0 CONSTRUCTION SITE PREMISES What are the things to consider in ensuring a safe and healthy construction site premise? • Strategic planning of location of TemFacils, welfare facilities, entrances/exits, access, staging areas, parking areas, evacuation area, etc. • Strategically posted on-site and can easily be understood with labels and legends Planning for site layout is very crucial for the success for the project. Every project has its unique layout. Apart from other uncertainties like project designs, environmental effects and time constraints, site layout planning in itself is a typical multi objective problem. LAYOUT PLANNING Advantages of Layout Planning • Temporary facilities' location will be planned ahead of time • Effective use of available area • Avoids unauthorized construction of temporary facilities which are not relevant to the construction • Minimizes the time and motion of workers by planning where to locate the material laydown area or equipment positioning in relation with workers' location Perimeter Fences and Gates • Prevents entry of unauthorized people into the construction site • Secure the workers inside the construction site • Protects the public outside the construction site • To protect the construction equipment from theft • Protect the property within the construction from vandalism and sabotage Security Personnel • Protects the life of people within the construction site and the property by avoiding common threats such as theft or robbery, property vandalism, etc. • To minimize damage and help protect and secure the property immediately • Preventing public from entering the construction area Temporary Facilities • Temporary facilities like offices should be constructed in a way that it is not easily damaged by strong winds or typhoon • Provide and maintain an adequate weather tight temporary office • Shall have the necessary basic facilities, like water, light, etc. Welfare Facilities 1. Adequate sanitary and washing facilities 2. Adequate facilities for changing and for the storage and drying of work clothes 3. Adequate accommodation for taking meals and shelter 4. Suitable living accommodation for workers, as may be applicable 5. Separate sanitary, washing and sleeping facilities for men and women workers 6. Adequate supply of safe drinking water 7. it should be stored in closed containers 7.1. dispensed through taps or cocks 7.2. containers should be cleaned and disinfected at regular intervals not exceeding fifteen (15) days 7.3. notices shall be conspicuously posted in locations where there is water supply that is not fit for drinking 8. In compliance with DOLE DO 13, Section 16: Workers' Welfare Facilities Traffic Management 1) Organize a construction site so that vehicles and pedestrians using site routes can move around safely 2) Vehicles include construction heavy equipment 3) We must organize a construction site so that vehicles and pedestrians using site routes can move around safely. 4) The routes need to be suitable for the persons or vehicles using them, in suitable positions and sufficient in number and size. 5) The term ‘vehicles’ includes: cars, vans, lorries, low-loaders and mobile plant such as excavators, lift trucks and site dumpers etc. 6) The key message is: construction site vehicle incidents can and should be prevented by the effective management of transport operations throughout the construction process. 7) Keeping pedestrians and vehicles apart 8) - The majority of construction transport accidents result from the inadequate separation of pedestrians and vehicles. This can usually be avoided by careful planning, particularly at the design stage, and by controlling vehicle operations during construction work. a) Entrances and exits - provide separate entry and exit gateways for pedestrians and vehicles; b) Walkways - provide firm, level, well-drained pedestrian walkways that take a direct route where possible; 9) Minimizing vehicle movements - Good planning can help to minimize vehicle movement around a site. For example, landscaping to reduce the quantities of fill or spoil movement. To limit the number of vehicles on site: a) provide car and van parking for the workforce and visitors away from the work area; b) control entry to the work area; and c) plan storage areas so that delivery vehicles do not have to cross the site. 10) Visibility - If vehicles reverse in areas where pedestrians cannot be excluded the risk is elevated and visibility becomes a vital consideration 11) Signs and instructions - Make sure that all drivers and pedestrians know and understand the routes and traffic rules on site. GOOD HOUSEKEEPING Good Housekeeping 1. Good housekeeping shall be maintained at all times 2. Through cleanliness of building, yards, machines, equipment, 3. Regular waste disposal, and 4. Orderly arrangement of processes, operations, storage and filing of materials. Benefits of Good Housekeeping 1. Eliminates accident and fire hazards 2. Maintains safe and healthy work conditions 3. Saves time, money, materials, space, and effort 4. Improves productivity and quality of work 5. Boosts morale 6. Reflects a well-run organization 5 S and Good Housekeeping • Originally developed by HIROYUKI HIRANO • A systematic and step-by-step technique of waste elimination from work environment • Through better workplace organization, visual communication, and general cleanliness 1. Seiri – Sort - Suriin Identify and eliminate all unnecessary items from the workplace Decide what you need Remove unnecessary clutter 2. Seiton (Systematize – Sinupin) Put all essential materials in a systematic order Organize layout of tools and equipment Ensure everything is available as it is needed and at the “point of use” “A place for everything and everything in place.” 3. Seiso (Sweep - Simutin) Clean and/or polish the workplace to attain a dirt or dust-free state Inspecting for defects Divide areas into zones Define responsibilities for cleaning Tools and equipment must be owned by an individual 4. Seiketsu (Standardize - Siguruhin) Generate a maintenance system for the first three S Develop procedures, schedules, practices Regularly audit using checklists and measures of housekeeping “System should apply to all!” 5. Shitsuke (Self-Discipline – Sariling-Kusa) A condition where all members practice the above 4S spontaneously and willingly as a way of life Solid Waste Management (What is an MRF?) Materials recovery facility — includes a solid waste transfer station or sorting station, drop-off center, a composting facility, and a recycling facility Definition as per RA 9003: An Act Providing for an Ecological Solid Waste Management Program - In construction, MRF should be used as a laydown area for materials which can still be re-used or recycled. There should be a separate Garbage Yard for construction wastes with proper segregation. Fire Protection and Control Emergency Exits (As per OSH Standards Rule 1940: Fire Protection and Control) 1) At least two exits shall be provided in every floor and basement of every workplace capable of clearing the work area in five (5) minutes 2) Additional exits shall be provided if the travel distance from any occupied space in a high hazard occupancy exceeds twenty-three (23) meters 3) At least two exits shall be provided in every floor and basement of every workplace capable of clearing the work area in five (5) minutes 4) Additional exits shall be provided if the travel distance from any occupied space in a high hazard occupancy exceeds twenty-three (23) meters 5) Safe, continuous and unobstructed passageways with a minimum width of at least one meter, but not less than the width of the exist, shall be provided and maintained 6) No steps or stairs shall be used in horizontal exits. When there is a difference in level between cemented floor areas, ramps or inclines of not more than one to ten (1 to 10) slopes shall be installed 7) The construction of the exits, including stairs and means of illumination, shall be in accordance with the provisions of the Building Code, Electrical Code of the Philippines, and Fire Code of the Philippines Portable Fire Extinguishers 1) All places of employment shall be provided with portable fire extinguishers for protection against incipient fires and approved fire extinguishers shall be used 2) Extinguishers shall be installed on hangers or brackets conspicuously located in unobstructed areas readily accessible in the event of fire As per OSH Standards Rule 1940: Fire Protection and Control on Portable Fire Extinguishers A. All places of employment shall be provided with portable fire extinguishers for protection against incipient fires and approved fire extinguishers shall be used B. Portable extinguishers shall be maintained in fully charged and operable condition and kept in their designated places at all times when not in use C. Extinguishers shall be installed on hangers or brackets conspicuously located in unobstructed areas readily accessible in the event of fire D. Extinguishers having group weight not exceeding 18 kilograms shall be installed so that the top is not more than 1.5 meter above the floor. Those exceeding 18 kgs., except wheeled types, shall be installed not more than 1 m. above the floor E. Extinguishers shall be inspected monthly or at more frequent intervals when circumstances require to ensure they are in their designated places, to determine physical damages and that they are in good operable condition F. Mandatory monthly inspection of fire extinguishers shall be documented on fire extinguisher tags attached to the fire extinguisher G. At regular intervals of not more than one year, or when specifically indicated by an inspection, extinguishers shall be thoroughly examined, recharged or repaired H. On the place where extinguishers are located, the type and use of the extinguishers and instructions on its proper use shall be marked in visible and easily readable letters I. Extinguishers shall be hydrostatically tested before use and periodically tested at least once in every five (5) years or as may be required by the enforcing authority Construction Safety Signages - In compliance with DOLE DO 13, Section 9 1) Mandatory requirement on the use of PPE prior to entry to the project site. 2) Areas where there are potential risks of falling objects. 3) Areas where there are potential risks of falling. 4) Areas where there are tripping or slipping hazards. 5) Approaches to working areas where danger from toxic or irritant airborne contaminants/substances may exist which should indicate the name of the contaminant/substance involved and the type of respiratory equipment to be worn. 6) Areas where explosives and flammable substances are used or stored. 7) All places where contact with or proximity to electrical/facility equipment can cause danger. 8) All places where workers may come in contact with dangerous moving parts of machineries or equipment. 9) Location of fire alarms and fire-fighting equipment. 10) Instructions on the usage of specific construction equipment. 11) Periodic updating of man-hours lost. The OSH standard has the following formula as a guide in determining the sizes of different safety signages: A ≥ L²/2000 A & L expressed in the same unit of measurement A = Area of Safety Sign L = Distance of Observation Standard Color of Signs (As per OSH Standards, Table 11: Standard Colors of Signs for Safety Instructions and Warnings in Building Premises) 1) Red - Fire Protection. To call attention to fire protection equipment apparatus and facilities; Examples: - Fire stations and equipment (extinguishers, pumps, buckets, hose, hydrants) - Fire extinguishing systems (valves, alarm, sprinkler, piping, etc.) - Fire protection materials (doors, blankets, extinguishing agents) - To identify Danger, Stop Signals (red lights placed on barricades at temporary obstruction or on temporary construction; stop buttons for electrical switches used for the emergency stopping of machinery; emergency stop bards on hazardous machines such as rubber mills. 2) Green - Safety. Designating “safety” Examples: - location of first-aid equipment; location of safety and allied devices; safety bulletin boards 3) White - Traffic. White, black, or a combination of these are the basic colors for the designation of traffic and housekeeping marking. Solid white, solid black, single color stripping or alternate stripes of black and white. Examples: - (housekeeping) location of refuse cans; white corners for rooms or passageways, drinking fountains and food dispensing equipment location - (traffic) location and width of aisle-ways; dead ends of aisles or passageways; stairways and directional signs 4) Yellow - Caution. To designate caution and for marking physical hazards, such as striking against, stumbling, falling, tripping, and “caught in between”. Solid yellow, yellow and black stripes, yellow and black checkers or yellow with suitable contrasting background shall be used in interchangeably, using the combination which will attract the most attention in the particular environment. 5) Orange - Alert. To designate dangerous parts of machines or energized equipment which may cut, crush, shock or otherwise injure, and to emphasize such hazards when enclosure doors are open or when gear, belt or other guards around moving equipment are open or removed, exposing unguarded hazards. 6) Blue - Precaution. To designate caution, limited to warning against starting, use of, or the movement of equipment which is under repair or being worked upon. - “Men at Work” - signals for railroad tracks (if men are working or if tank cars are connected, or similar work) - “Under Repair” -signals warning of danger against use while undergoing repairs (elevators, kiln, boilers, electrical controls, ladders, scaffolding, vaults, etc.) 7) Purple - Radiation. To designate hazards. Yellow is used in combination with purple for markers, such as tags, labels, signs and floor markers. Electrical Safety The employer must train employees in safe work practices in working with electrical equipment Causes of Electrical Accidents 1) Contact with live conductors 2) Short circuiting 3) Arcs and sparks 4) Overloading 5) Inadequate grounding 6) Usage of substandard replacement 7) Wet environment Grounding - creates a low-resistance path from a tool to the earth to disperse unwanted current - when short circuit or lightning occurs, energy flows to the ground protecting you from electrical shock, injury, and death Signs that Electrical Hazards Exist 1) Tripped circuit breakers or blown fuses 2) Warm tools, wires, cords, connections, or junction boxes 3) Circuit breaker that shuts-off a circuit 4) Worn or frayed insulation around wire or connection Electrical Shock - the most serious electrical hazard This happens when you touch a live wire, a tool or a machine with poor insulation. You then become a conductor. The shock that you feel is the electrical current going through your body. Summary: 1. Although work processes are high risk, but a construction site can be managed to maintain a safe and healthy work environment 2. Layout plan, perimeter fences, and security personnel are vital to keep the people safe and to keep the property secured 3. Welfare facilities are needed to promote the health and well-being of workers 4. A good traffic management plan prevents accidents of people and the public near any construction activities 5. Good housekeeping eliminates accident and fire hazards 6. Proper segregation of wastes in construction is needed to comply with RA 9003 7. Emergency exits and portable fire extinguishers in a construction should comply with OSH Standards Rule 1940 8. Construction Safety Signages in a construction should comply with DOLE DO 13 Section 9 9. Electrical hazards should be identified and controlled in the construction site 5.0 EXCAVATION SAFETY What is an Excavation? (OSH Standards Rule 1413) 1. Any man-made cut, cavity, trench, or depression in the earth’s surface formed by earth removal 2. Excavation and trenching are among the most hazardous construction operations. OSHA defines an excavation as any man-made cut, cavity, trench, or depression in the earth’s surface formed by earth removal. Types of Excavation Works 1. Open Excavation a. An excavation in an open ground and can vary in shape and size b. Usually wider and is intended for basement floors of buildings 2. Pit Excavation a. Generally excavated to install manholes, pump stations, or underground tanks to construct pile caps and other types of foundations b. Pit excavations are usually four-sided and deeper than the narrowest horizontal dimension at the surface. c. Pits are generally excavated to install manholes, pump stations, or underground tanks. They are also excavated to construct pile caps and other types of foundations or to access or locate existing services. d. Pit excavations are usually four-sided and deeper than the narrowest horizontal dimension at the surface. e. Pits are generally excavated to install manholes, pump stations, or underground tanks. They are also excavated to construct pile caps and other types of foundations or to access or locate existing services 3. Trench a. Is a long narrow excavation which is deeper than it is wide, and open to the surface along its length (no wider than 15 ft / 4.5 m) b. To install or maintain underground services General Requirements Prior to Excavation 1. Carry-out joint site safety inspection with client or owner, consultant, and company representatives 2. Identify and locate underground facilities or utilities, (water, oil, gas pipelines, electric powerlines, telephone lines, sanitary sewer lines) Safety Risks in an Excavation 1. Soil collapse due to loose rock or soil 2. Falls (people, materials, equipment, tools) 3. Electrocution due to contact with above and underground utilities 4. Being struck by heavy equipment 5. Adjacent structure which may collapse due to an ongoing excavation work 6. Workers being trapped in an excavation due to lack of access and egress 7. Vehicular traffic Health Risks in an Excavation Soil collapse is the most feared excavation risk, but other potentially fatal risks may also occur in an excavation work: 1. Asphyxiation due to lack of oxygen (confined space condition in an excavation) 2. Inhalation of toxic gases or fumes Things to Consider Prior to Excavating 1. Soil classification 2. Depth of excavation 3. Proximity of adjacent structures 4. Weather and moisture conditions 5. Sources of vibrations 6. Overhead power lines 7. Underground utilities Types of Soil 1. Solid Rock – Rock formations (Adobe) 2. Type A – Most stable; clay stiff and firm soils -solid soils with substantial cohesion and no water table present 3. Type B – Medium stability; silt and unstable rock; disturbed soil. soils likely to crack or crumble -soil that can be excavated by hand tools, show signs of cracking after excavating, and possess a low to medium moisture content (i.e. heavily seamed silty clays, compacted clayey fill, and mixtures of clays and silts) 4. Type C – Least stable; gravel, loamy sand, submerged soil, soil from which water is freely seeping soft and loose soils - soils easily excavated by hand with little or no cohesion (i.e. sand, gravel, silt, organic soil, soft and wet clay, and loose fill) Principal Causes of Soil Collapse 1. Steep cutting angle 2. Super-imposed load 3. Shock and vibration 4. Water accumulation 5. Drying 6. No regular monitoring and inspection! Method of Excavation Protection 1. Sloping 2. Benching 3. Shoring or Timbering 4. Sheet Piling 5. Trench Boxes 6. Shotcrete TYPES OF SOIL COLLAPSE Sloping/Benching Shotcrete Shoring/Timbering Trenching Sheet Piling Tension Cracks 1. Usually form at a horizontal distance of 0.5 to 0.75 times the depth of the trench, measured from the top of the vertical face of the trench 2. These are the parts of an excavation susceptible to forming cracks which may then lead to soil collapse SLOPING Benching A method of protecting employees from cave-ins by excavating the sides of an excavation to form one or more series of horizontal steps with rise between steps. Shoring or Timbering (As per OSHS Rule 1413.01) Walls of every excavation over 1 m (3 ft) deep shall be supported by adequate shoring or timbering to prevent collapse, provided that this shall not apply to an excavation: 1. in which a worker is not required to enter for any purposes 2. cut in solid rock 3. the walls are sloped to forty-five degree (45) angle from the vertical or cut to the angle of repose 4. in which a worker is engaged in timbering or other work for the purpose of compliance with this Rule if precautions are taken to ensure his safety. 5. Shoring is the provision of a support system for trench faces used to prevent movement of soil, underground utilities, roadways, and foundations 6. Shoring or timbering is used when the location or depth of the cut makes sloping back to the maximum allowable slope impractical 7. Shoring systems consist of posts, wales, struts, and sheeting Shielding or Trench Boxes 1. Intended primarily to protect workers from cave-ins and similar incidents 2. Excavated area between the outside of the trench box and the face of the trench Should be as small as possible 3. The space between the trench boxes and the excavation side are backfilled to prevent lateral movement of the box 4. Shields may not be subjected to loads exceeding those which the system was designed to withstand Removal of Trench Boxes 1. Employees clear of area under shields during removal 2. Shoring removed from the bottom up, SLOWLY! 3. Backfill with removal Minimum Berm (As per OSH Rule 1413.02) 1. Excavated material shall be kept from the edge of the excavation to provide a clear berm of a distance not less than one third of the depth of the excavation 2. Where the disposal area is limited, a berm of reduced width of not less than 1 m. (3 ft.) may be allowed, provided the materials being excavated are stable, the shoring is designed to carry the additional load, and barriers are provided to prevent roll back of the excavated materials Tools, Materials, and Machinery (As per OSH Rule 1413.03) 1. Tools or materials shall be kept a minimum of 1 m (3 ft.) away from the edge of the excavation to prevent being knocked down into the excavation 2. No vehicle or other machinery shall be driven, operated or located near the edge of an excavation at least a distance one-third (1/3) of its depth Provision for Barricades (As per OSH Rule 1413.04) The top of the walls of an excavation more than 2.0 m. (6 ft.) deep shall be barricaded to a height of at least 1 m (3 ft.) to prevent the fall of workers Means of Access and Escape (As per OSH Rule 1413.05) 1. Every excavation over 1 m. (3 ft.) deep shall be provided with means of access and escape in case of flooding or soil collapse 2. Every excavation shall have at least one (1) ladder in every 16.6 m. (50 ft.) of length or fraction thereof 3. which shall extend at least 0.83 m. (2’6”) above the top of the excavation to provide a firm handhold when stepping on or off the ladder Inspection of Excavation (As per OSH Rule 1413.06) 1. Every part of an excavation over 2 m. (6 ft.) deep where workers work shall be inspected by the person in charge at least once everyday 2. It should also be inspected after a weather disturbance or earthquake Confined Entry 1. Shaft and tunnel excavations are to be considered confined entry situations and a hazard assessment and risk control analysis must be undertaken. 2. Where monitoring of hazardous atmospheres is required, the job site supervisor must be equipped with suitable testing equipment (i.e. explosive meter, oxygen, and toxic gas detectors) and be trained in proper monitoring procedures. It is recommended that continuous monitoring devices be used where monitoring is necessary. 3. Ventilation systems must be put in place to provide a safe atmosphere where they may be a lack of oxygen or unsafe accumulations of toxic vapors, gases, dusts, or other harmful substances. 4. The ventilation rate at the work face of the tunnel shall not be less than 2.75 cubic meter per second per square meter of face area (50 cubic feet/minute per square foot of face area). First Aid Facilities/Emergency Procedures Due to the nature of work, it is important that proper first aid supplies be provided at the excavation worksite. A first aid kit shall be provided at each shaft location. It is recommended that at least one worker on each shift shall be a certified first aider with CPR training. A basket stretcher and blankets must also be provided at each worksite, as well as a "parachute-type" full body harness for hoisting a worker to the surface, if necessary. Lighting/Electrical Installations Underground excavations must be provided with a source of electrical illumination for the full length of the tunnel and at the working face of the tunnel excavation [minimum 25 lux (2.5 foot-candles) of illumination]. In the event of electrical failure, an emergency lighting system must be in place. This may consist of battery operated flashlights suitably sized and located to assist workers in exiting the tunnel. Fire Protection A minimum of two, 2A-10BC rated multi-purpose type fire extinguishers shall be provided in each shaft and tunnel excavation. Combustible scrap materials such as wood shoring component, shall not be allowed to accumulate in the excavation. These shall be removed at least daily. Use of explosives All blasting operations must be undertaken by a certified blaster who is qualified to handle and use explosives. Explosives must be stored and transported. Access/Egress Vertical drilled shafts, shored with steel sleeves, are normally provided access by a straight fixed vertical ladder. Where the ladder exceeds 5 meters (15 feet) in length a rest platform or proper fall protection must be provided. This can be done by providing a worker with a full-body safety harness secured with a lifeline to a fall-arresting device. Summary: 1. Types of Excavation Works include open excavation, pit excavation, and trench 2. Excavation works are high risk because excavation failures like a soil collapse occur quickly, limiting the ability of workers to escape 3. There are safety and health risks in excavation works that need to be controlled 4. The causes of soil collapse are steep cutting angle, super-imposed load, shock and vibration, water accumulation, drying, and lack of regular monitoring and inspection 5. There are several methods to protect and excavation and prevent soil collapse 6. The type of soil should be considered in choosing the appropriate excavation protection 7. Minimum Berm for excavated material is 1/3 of the depth of the excavation 8. Tools, materials, and machineries should be kept at a safe distance away from the edge of the excavation 9. Excavation more than 2 m deep shall be barricaded to a height of 1 m 10. Ladders should be deployed in every 50 ft of length 11. Excavation should be inspected daily by a competent person 12. If there are harmful dusts, gases, or fumes, an excavation should be tested for hazardous atmosphere using a gas detector 13. There should be public protection and traffic management during excavation works 6.0 TOOLS & EQUIPMENT : HAND & POWER TOOLS Types of Tools 1. Hand Tools non-powered, Operated manually by bare hands 2. Portable Power Tools are operated through an additional power source Types of Power Tools 1. Electric Tools - electricity 2. Powered Abrasive Wheel Tool - with a wheel/disc for grinding, cutting, polishing, buffing 3. Pneumatic Tools - compressed air 4. Liquid Fuel - kerosene, gasoline 5. Hydraulic - pressurized liquid fluid/ hydraulic pressure (brakes), hammer drills, impact wrenches 6. Powder Actuated Tools - operate like a loaded gun Hand Tools - General Hazards 1. Misuse of tools or using tools for wrong tasks (screwdriver as chisel, pliers as hammers) 2. Poor / Improper maintenance 3. Using damaged tools 4. Poor housekeeping and improper storage (slips and trips) 5. Sparks that can ignite fire 6. Dust, flying, falling, and splashing objects Hand Tools - Control Measures 1. Inspect and remove unsafe hand tools 2. Keep workspace as clean as possible and do not leave tools laying around unattended 3. Saw blades, knives, or other tools be directed away from other workers working in close proximity 4. Tools must be sharp, dull tools can be more hazardous than sharp ones 5. If wooden handle on a tool such as hammer is loose, splintered, or cracked, the head of the tool may fly off 6. Wrench must not be used if its jaws are sprung, because it might slip 7. Impact tools such as chisels are unsafe if they have mushroomed heads 8. Avoid use of hand tools near flammable substances, spark can ignite a fire 9. Always wear appropriate PPE's Power Tools - General Hazards and Risks 1. Damaged electrical equipment - electrical shock/burn 2. Fall of worker secondary to electrocution 3. Dust, flying, falling, splashing fragments/objects 4. Fuel vapors that can burn or explode and also give off dangerous exhaust fumes 5. Getting hit by the tool's attachments (Pneumatic tools) and moving parts that can caught-in body parts 6. Noise and vibration 7. Sparks, gases, vapors, heat - fire and explosion 8. Misfires and explosions (powder actuated) Power Tools - General Control Measures 1. Never carry a tool by the cord or hose 2. Never yank the cord or the hose to disconnect it from the receptacle 3. Keep cords and hoses away from heat, oil, and sharp edges 4. Disconnect tools when not in use 5. Observers should be kept at a safe distance away from the work area 6. Avoid accidental starting. The worker should not hold a finger on the switch button 7. Tools should be maintained with care - keep sharp and clean 8. Follow instructions in the user's manual Machine Guarding 1. Is a static / fixed protective covering 2. Placed on the moving part of the tool to prevent contact to body parts 3. Also prevents dust, flying particles, or disintegrated cutting disc from splashing to the worker 4. Belts, gears, shafts, pulleys, sprockets, spindles, drums, fly wheels, chains, or other reciprocating, rotating, or moving parts of equipment must be guarded. Hazardous moving parts of a power tool need to be safeguarded. For example, belts, gears, shafts, pulleys, sprockets, spindles, drums, fly wheels, chains, or other reciprocating, rotating, or moving parts of equipment must be guarded if such parts are exposed to contact by employees. Electric Tools - Specific Control Measures 1. Electric tools should be operated within their design limitations 2. When not in use, tools should be stored in a dry place 3. Electric tools should not be used in damp or wet locations 4. Tools must have a three-wire cord and be grounded 5. Power cord should be double insulated Powered Abrasive Wheel Tool 1. Powered abrasive grinding, cutting, polishing, and wire buffing wheels may throw off flying fragments 2. Before an abrasive wheel is mounted, it should be inspected closely and sound or ring-tested 3. Failure to ring test could result to a cracked/ disintegrated wheel 4. Wheel can fly-off hitting workers in the area Pneumatic Tools - Hazards and Risks 1. Are powered by compressed air and include chippers, drills, hammers, and sanders 2. Main risk: getting hit by one of the tool's attachments 3. tool must be fastened securely to the hose to prevent it from becoming disconnected and fly-off 4. Other hazards include noise and dust Powder Actuated Tool 1. Generically called Hilti Gun or Ramset Gun 2. type of Nail Gun used to join materials to hard surfaces like steel / concrete by direct fastening 3. relies on a controlled explosion created by a small chemical charge, similar to the process that discharges a firearm 4. operate like a loaded gun and should be treated with the same respect and precautions 5. only specially trained employees must operate them Powder Actuated Tool - Control Measures 1. Should not be used in an explosive or flammable atmosphere 2. Before using the tool, inspect it to ensure it is clean, that all moving parts operate freely, and barrel is free from obstructions 3. tool should never be pointed to anybody 4. should not be loaded unless it is to be used immediately 5. loaded tool should not be left unattended 6. Hands should be kept clear of the barrel end Hydraulic Tools 1. Operated through pressurized liquid fluid / hydraulic pressure (brakes, hammer drills, impact wrenches) General Safety Precautions All hazards involved in the use of power tools can be prevented by following 5 basic safety rules: 1. Keep all tools in good condition with regular maintenance. 2. Use the right tool for the job. 3. Examine each tool for damage before use. 4. Operate according to the manufacturer's instructions. 5. Provide and use the proper protective equipment. Lock Out Tag Out Lockout is the isolation of energy from the system (a machine, equipment, or process) which physically locks the system in a safe mode. The energyisolating device can be a manually operated disconnect switch, a circuit breaker, a line valve, or a block (Note: push buttons, selection switches and other circuit control switches are not considered energy-isolating devices). Tag out is a labelling process that is always used when lockout is required. The process of tagging out a system involves attaching or using an information tag or indicator A lockout/tag out program will help prevent: • Contact with a hazard while performing tasks that require the removal, bypassing, or deactivation of safe guarding devices. • The unintended release of hazardous energy (stored energy). • The unintended start-up or motion of machinery, equipment, or processes. Summary: 1. Hand Tools are non-powered and operated by bare hands 2. Portable Power Tools are operated through additional power source 3. Types of Power Tools are Electric, Powered Abrasive Wheel Tool, Pneumatic, Hydraulic, Liquid Fuel 7.0 CONSTRUCTION MACHINERY (MOBILE EQUIPMENT SAFETY) What is a Heavy Equipment? Any machine with engine or electric motor as prime mover; with minimum operating weight of 1,000 kg and horsepower rating of 10 HP Used for: 1. Lifting 2. Excavating 3. Leveling 4. Drilling 5. Compacting 6. Transporting 7. Breaking works Bulldozer Machinery for leveling, earth moving, and clearing Motor Grader Leveling aggregates, grading wide expanses and roads, preparing roadbeds for the laying of pavement Wheel Loader Used for scooping and loading excavated dirt and rocks, and can also be used for carrying loads for short distances Compactor with Sheep Foot Attachment Used for compacting work such as roads, road fills, river dikes, dams, and foundations Dump Truck Used for hauling excavated dirt and rocks Excavator Used for excavation and loading work by an extendible working device and rotating function, while the main body of the machine itself generally remains stationary HEAVY EQUIPMENT ACCIDENTS Heavy Equipment Accidents 1. Electrocuted if equipment touches an overhead power line 2. Crushed if vehicle overturns 3. Run over by moving or backing vehicle 4. Crashed on a structure 5. Being flooded Legal Basis of Heavy Equipment Safety - DOLE Department Order 13, Series of 1998: Guidelines Governing Occupational Safety and Health in the Construction Industry Section 10: Safety on Construction Heavy Equipment Pre-construction 1. The General Constructor must ensure that appropriate certification is obtained from DOLE duly accredited organizations for the following: a) All heavy equipment operators assigned at the project site must be tested and certified in accordance with a standard trade test prescribed by Technical Education and Skills Development Authority (TESDA) in coordination with its accredited organization/s. b) All heavy equipment must be tested and certified in accordance with the standards prepared by DOLE or its recognized organization/s prior to commissioning of said equipment. Certified Operators 1. Only duly certified operators shall be allowed to operate their designated heavy equipment 2. All operators and riggers must wear personal protective equipmen During Construction Mobilization or Transport of Heavy Equipment 1) Load restriction of trailers carrying such heavy equipment 2) Load restrictions, height and width clearances as imposed by DPWH for all roads and bridges to be utilized during transport 3) Only duly certified operators are allowed to load and unload heavy equipment to trailer 4) Equipment to be transported must be properly secured to the trailer 5) The General Constructor must ensure that the following conditions are met or complied with: 6) 10.2.1 Mobilization or Transport of Heavy Equipment. a) Load restriction of trailers carrying such heavy equipment. b) Load restrictions, height and width clearances as imposed by Department of Public Works and Highways (DPWH) for all roads and bridges to be utilized during transport. c) Only duly certified operators are allowed to load and unload heavy equipment to trailer. d) Equipment to be transported must be properly secured to the trailer. Routine Inspection 1. Duly certified mechanics and operators shall conduct daily routine inspection of all heavy equipment deployed at the site 2. The General Constructor and the equipment owner shall maintain a separate logbook for data on maintenance, repairs, tests and inspections for each heavy equipment 3. Such logbook shall be used as a necessary reference during the conduct of equipment inspection 4. In the interest of accident prevention, duly certified mechanics and operators shall conduct daily routine inspection of all heavy equipment deployed at the site in accordance with standards set by TESDA in coordination with the Association of Construction Equipment Lessors (ACEL, Inc.). 5. a) Routine inspection of all heavy equipment must be performed by DOLE accredited professionals in accordance to standards set by DOLE recognized equipment suppliers. b) All equipment which do not comply with the minimum safety 6. standards for equipment certification shall be immediately removed from the work site for restoration or repair until they meet said standards or requirements. DO 13, Section 7.2 1. The General Constructor must provide for one (1) Construction Safety and Health Officer for every ten (10) units of heavy equipment assigned to the project site 2. To oversee the effective compliance with the Construction Safety and Health Program at the construction project site, in terms of heavy equipment utilization and maintenance Persons at Risk 1. Equipment Operator 2. Spotters 3. Workers on foot 4. Supervisors and Management People 5. Other construction site personnel Blind Spot 1. This is the area around a vehicle or piece of construction equipment that is not visible to the operator, either by direct line-of sight or indirectly by use of internal and external mirrors 2. Small heavy mobile equipment have small blind spots and heavy mobile equipment have large blind spots, both can cause serious injury or death 3. The taller and wider the machine is, the bigger is the blind spot area 4. Operators, spotters, and workers on foot need to be aware where the blind spots are Spotters for Heavy Equipment 1. serves as an extra set of eyes for drivers, equipment operators and individual workers on the site 2. making sure that a truck that’s backing up doesn’t run into anything or anyone 3. A properly trained spotter is needed if: a. Anytime an equipment operator doesn’t have a clear view of the site b. Is operating near workers on foot c. Is operating around energized power lines or equipment d. Is working on varied terrain 4. The spotter must be highly visible, and everyone on the job site should be aware of his or her role HEAVY EQUIPMENT SAFETY (COMMUNICATION) Communication 1. A standardized set of hand signals should be used 2. Operators should always know exactly where all ground based workers are located and make them give signals before proceeding 3. Spotters should always keep their attention focused on moving equipment and should be in constant communication with the operator Responsibilities of Workers on Foot 1. Wearing of high visibility vests 2. Keep a safe distance from heavy equipment 3. Know the equipment’s blind spots 4. Never assume that the equipment operator sees you Responsibilities of Heavy Equipment Operators 1. Safety features of equipment, know how to use and operate safely the equipment 2. Systematic maintenance and repair 3. Pre-operational inspection of equipment 4. Review manufacturer’s operating manual 5. Know where the blind spots are 6. Look for workers on foot around the equipment 7. STOP! when signaled; when waived at violently; or if you are in doubt 8. Maintain a safe operating speed 9. Keep machine under control at all times Instruction To Follow When Working Near Electric Cable 1. Wear rubber on leather sole shoes 2. Assign a watchman to prevent unintended contact with the electric cable. 3. Maintain the specified minimum distance. If the transmission voltage is high, prevent close distance to prevent sparks and create hazard even if contact is not made. 4. Always maintain the specified minimum distance especially when operating the backhoe, considering the movement of the boom. Transmission Voltage Minimum Distance 6.6 kV 3m 33.0 kV 4m 66.0 kV 5m 154.0 kV 8m 275.0 kV 10 m Summary: 1. Heavy equipment is a machine with engine or electric motor as prime mover, with minimum operating weight of 1,000 kg and horsepower of 10 HP. Heavy equipment are powerful machines that are useful in construction, however they are hazardous which may result to various accidents 2. DOLE DO 13, Section 10 requires all operators to have a TESDA NC and all heavy equipment to have a third-party testing 3. One additional safety officer must be provided for every 10 units of heavy equipment 4. The taller and wider the heavy equipment is, the bigger is its blind spot 5. All heavy equipment operating should have a designated spotter who is properly trained 6. Good communication between the operator and spotter is vital for the prevention of accidents 7. Workers on foot and heavy equipment operators both have responsibilities in making themselves and others safe 8.0 CONSTRUCTION MACHINERY (CRANE SAFETY) How does a tower crane work? 1. Tower Cranes are seen on almost every major construction site throughout the world 2. These machines are built to lift heavy loads efficiently and safely 3. A modern tower crane consists of three major sections: the base, the tower mast, and the slewing unit TYPES OF CRANE TYPES OF CRANE Truck Mounted Crane These types of cranes are mounted on a rubber tire truck and provide excellent mobility. The outriggers will extend vertically or horizontally and are used to stabilize and level the crane when it is hoisting a load of materials Mobile Cranes This is the most basic type of crane and consists of a steel truss or telescopic boom mounted on some kind of mobile platform. This platform could be wheeled, a rail or even a cat truck. The boom is hinged at the bottom and can be raised or lowered by cables or hydraulic cylinders Telescopic Crane A telescopic crane offers a boom that has a number of tubes that are fitted inside each other. Then hydraulic mechanisms extend or retract the tubes to length or shorten the boom anywhere within the jib's radius. Rough Terrain Crane The crane is mounted on an undercarriage that has four rubber tires and is designed to be use off road. The outriggers can extend vertically and horizontally to stabilize and level the crane when it is lifting a large load. Cranes and Hoists Crane and Hoist are usually utilized to transfer and carry certain objects, such as raw materials, products, equipment and etc., from one place to another. Cranes and hoists are specialized equipment designed to perform lifting and moving of loads. Their function and methods of operation are not like any other equipment or machine. They require specific instructions and training for safe operation and proper maintenance. Hazards of Crane Operations 1. Structural Failure 2. Overloading 3. Instability 4. Falling or slipping load 5. Electrical Hazards Important Guidelines to Help Avoid Crane Failures 1. Safety 2. Maintenance 3. Training 4. Planning 5. Supervision 1. Crane Safety • The most important aspect that the operator, employer, and worker of should learn • Ensure that all workers and subcontractors comply with all provisions of the OSH Standards and Code of Practice for Tower Crane Safety from DOLE-OSHC 2. Maintenance • Erection, dismantling, and transportation, and use of cranes affect its operable condition and lifespan • Metal parts corrode and electrical parts wear out • Cranes also naturally want to fall down • All engineering reports and maintenance records regarding the tower crane should be kept 3. Training • Operators, riggers, workers erecting and dismantling cranes, and even appointed people responsible for the lifting operations (foremen, engineers, supervisors) need to be trained not only about technicalities but also safe operations of crane • Cranes are designed to stay upright but the fact that accidents continue to happen is proof that many people are not fully aware of the risks or how to manage them 4. Planning • This stage is very important since this is to ensure that all parties involved have an understanding of what they want to do and how they will do it • There should be close coordination of movements and actions in the site • Planning will also ensure that the crane is use correctly and that the right crane is use for the job 5. Supervision • Once a plan is in place, there needs to be effective supervision to ensure that it is strictly followed • Regardless of pressures of time or money • Training and Experience play a big factor to ensure proper supervision of crane's safe operation Load Rating Chart - Make sure it is available and the Crane Operator can see it: 1. Rated Load Capacities 2. Telescopic Arm Length and Angle 3. Operating Speeds 4. Special Hazard Warning or Instruction Inspection and Testing: 1. Third party inspection 1.1. Accredited by DOLE/BWC 1.2. Yearly or after modification, alteration, repairs, transfer or re-install 2. Internal Inspection 2.1. Before using on site 2.2. Monthly Inspection/Maintenance 3. Operator must be trained and certified D.O. 13 – On Heavy Equipment “The General Contractor must provide for one (1) Construction Safety and Health Officer for every ten (10) units of heavy equipment assigned to the project site, to oversee the effective compliance with the Construction Safety and Health Program at the construction project site, in terms of heavy equipment utilization and maintenance” Pre - Construction Section 10.1-a “All heavy equipment operators assigned at the project site must be tested and certified in accordance with a standard trade test prescribed by TESDA in coordination with its accredited organization/s” Section 10.1-b “All heavy equipment tested and certified by DOLE or its recognized organizations prior to commissioning” During Construction Section 10.3. In the interest of accident prevention, duly certified mechanics and operators shall conduct daily routine inspection of all heavy equipment deployed at the site in accordance with standards set by TESDA in coordination with the ACEL. Summary: 1. Different Types of Cranes presents different types of hazards, Accountability of Responsibility to Competent Person and workers involved to operation helps to minimize the accidents. 2. Compliance to Legislations and Code of Practice to Tower Cranes Safety guides management for safe and smooth facilitation of Cranes/Construction Heavy Equipment. 9.0 LADDER SAFETY AND FALL PROTECTION Ladder Safety “No matter how quickly a job can be done, there is always time to fall” SAFE NOT SAFE Ladder Don'ts: 1. Overreach from a ladder 2. Use the top two rungs 3. Move a ladder while on it 4. Climb while holding a material 5. Share a ladder Always Remember: 1. Use the right ladder for the job 2. Inspect the ladder before use 3. Set-up the ladder properly 4. Follow the safety rules for climbing and using ladders Ladder Do's: 1. Instead of overreaching, move the ladder 2. Instead of using the top two rungs, get a taller ladder 3. Instead of moving a ladder while on it, get down and move the ladder 4. Instead of climbing while holding a material, use a toolbelt 5. Instead of sharing a ladder, get a second ladder Ladder Safety Requirements 1. Maintain three points of contact with the ladder at all times 2. Maintain the center line of your body between the ladder’s vertical support rails while working 3. Check bottom of shoes and ladder rungs for grease and dirt 4. Make sure ladder has non-skid pads 5. Ensure spreaders are fully extended and locked 6. Test pullies, springs, rung locks and ropes on extension ladders 7. Store ladders on their side or secure with a chain or cable when stored in an upright position Telescopic / Extension Ladders 1. A minimum of 36 inches overlap is required 2. Must be secured at the top 3. Must have a clear area where the feet of the ladder will be positioned 4. Must have area secured with cones or barrier tape, or have an attendant 4:1 Rule Follow 4:1 Rule when setting-up and using extension ladders “Using the wrong ladder will bring you back down to Earth...THE HARD WAY!” Summary: 1. Use the right ladder for the job 2. Follow proper do's and don'ts in using ladders 3. Maintain 3-point contact when climbing or going down the ladder 4. Follow 4:1 rule when setting-up and using extension / telescopic ladders 10.0 FALL PROTECTION What is Fall Protection? 1. A series of steps and safety measures conducted 2. To eliminate or control the injurious effects of an unintentional fall 3. While accessing or working at heights Planning for Fall Protection Whether you are performing maintenance on equipment at heights, or working at heights on a construction project, you have to plan your work with the goal of eliminating any chance of a fall. 1. Should be an integral part of the work planning process, from constructability, to systems installation, to use and maintenance 2. The workplace cannot be truly safe unless fall protection is incorporated into every phase of the process 3. Planning will keep workers safe and minimize fall exposures Legal Basis DO 128-13, Amending Rule 1414 on Scaffoldings of the 1989 OSH Standards\ Rule 1414.12: Fall Protection 1. For supported scaffolds: Fall protection equipment shall be provided on any scaffold 2m (6 feet) or more above ground 2. Shall be protected by guardrail from falling from all open sides and ends of the scaffold 3. Open sides and ends shall be allowed when the scaffold distance is 25 cm (10 in) or less from the structure being worked on 4. For suspended scaffold: Fall protection equipment shall be provided on any suspended scaffold 2m (6 feet) or more above ground 5. Employers shall provide fall protection for personnel erecting, installing or dismantling scaffolds 6. The employer shall designate a competent person, who shall be responsible for determining the feasibility and safety of providing fall protection Fall Protection Methods 1. Fall Prevention - A system that will prevent a person from falling to a lower level. Example: Railings 2. Fall Restraint - A system that will allow the worker to approach a fall hazard and work but will not allow the worker to fall to a lower level 3. Personal Fall Arrest System - A system that will protect a person from crashing on to a lower level after a fall. Example: Full body harness/lanyard When is Fall Protection Required? Fall prevention is required for falls onto dangerous equipment. Zero fall distance is allowed. a. For work on forms or steel reinforcing over 6 feet in height b. Fall protection is required for scaffolding over 6 feet in height. c. Fall protection required for walking / working surfaces over 6 feet in height in construction d. Fall protection is required for vertical ladders without cages over 24 feet e. No fall protection is required for portable extension ladders Hazards with working / walking surfaces ▪ Open-sided floors ▪ Holes ▪ Leading edges Fall Prevention: Guardrail System Requirements 1. Shall be installed along all open sides and ends of platforms 2. Each toprail or equivalent member of a guardrail system shall be able to withstand a force of at least 100 kg (220 pounds) 3. The height of toprails on supported scaffolds shall be 91 cm (36 in.) 4. Midrail shall be installed at a height approximately midway between the toprail of the guardrail system and the platform surface 5. Guardrails shall not be rough to prevent punctures or lacerations to personnel and to prevent snagging of clothing 6. Toeboards shall be at least 15 cm. (6 in.) in height 7. Toeboards may be made of wood, iron, steel or other equivalent material 8. Toeboards shall be securely fastened in place 9. Standard railings for open edges shall be at least 1 meter from the floor level to the upper surface of the top rail 10. Standard railings shall have posts not more than 2 meters (6.6ft) apart and an intermediate rail halfway between the top rail and the floor SHAFT OPENINGS STAIR/SLAB OPENINGS GUARDRAILS IN CONTRUCTION FLOOR OPENINGS WALL OPENINGS Personal Fall Arrest Systems (PFAS) 1. Used to protect an employee from hitting a lower level once they have fallen 2. Components include: a) An anchorage point b) Full body harness c) Deceleration devices d) Connectors – lanyards, rope grabs, anchorage connectors 3. When using personal fall arrest systems: a) If you fall, the impact force to the body has to be less than 1800 pounds, achieved by using shock absorbing lanyards and a harness b) Minimize fall distance, the maximum free fall distance can only be 6 feet c) There can not be any structures below in you fall distance d) Maximum weight of an individual w/tools is 310 pounds Full Body Harness Full Body harnesses must be inspected by the user before use. A documented annual inspection by a competent person is required as well. It is the responsibility of each Division/ Section to perform these annual inspections on their equipment. 1. Need to be inspected before use by the worker, and at least annually (documented) by a Competent Person 2. Harnesses should never be modified 3. Do not write on or paint harnesses unless material is approved for use 4. Should be taken out of service immediately if defective or exposed to an impact Harness Fitting A properly fitted harness is essential to minimize the shock to the body if you were exposed to a fall arrest. Harnesses do have limitations, if you are over three hundred ten pounds and under one hundred thirty pounds you will need specialized equipment. Harness Pressure Points If you are suspended by your fall arrest equipment you must be aware of the potential hazards of orthostatic intolerance. Excessive pressure from the straps can cut off blood flow to the legs and cause permanent damage after hanging for fifteen minutes. Some harnesses are equipped with step in straps designed to relieve these pressure points if a worker is hanging. Be sure to know how to use this type of equipment if you have it. Lanyards Only use the lanyard in accordance with the manufactures recommendations. Do not tie the lanyard back to itself unless it is design to do so. The clips must be designed for the type of anchorage point you are using. And as with any synthetic material equipment, do not use against sharp edges or objects. 1. A flexible line of rope, wire rope, or strap which generally has a connector at each end for connecting the body belt or body harness to a deceleration device, lifeline or anchorage. 2. Must not be tied back to themselves unless specifically designed for such use 3. Should have the appropriate clip for the intended anchorage points 4. Do not knot or wrap around sharp objects Lifelines • The lifeline is used to connect a personal fall arrest system (consisting of a harness and deceleration lanyard) to an anchor point that cannot be reached by the short lanyard. • The lanyard/lifeline connection point in a sense becomes the anchor point. The lifeline is not intended to stretch to add to the length of a fall. • The lifeline can be made of a flexible line such as a rope or cable, or it can be made of a strap or webbing material. • Lifelines can hang vertically from an anchor point and horizontally between two anchor points. Restraint Devices If guardrails are not feasible then fall restraint is the next best way to work if you are exposed to a fall hazard. Restraint systems must be installed and used under the supervision of a competent person. Because no free fall hazard is possible in restraint systems, the anchorage point requirement is one thousand pounds. 1. Provide access but prevent the fall 2. Limit anchorage requirement to 1000 lbs 3. May be more suitable for loading areas, scaffold erection and dismantling 4. Should be installed and used under the supervision of a Competent Person 5. Fall restraint assumes the employee cannot reach the edge, they are basically on a short leash. 6. If the employee can fall over the edge, then a personal fall arrest system must be used. FALL ARREST/RESTRAINT SYSTEM Planning for a Rescue Whenever working at heights where there is a potential of hanging from a harness after a fall, a written job hazard analysis is required. In the JHA, there must be a rescue plan to retrieve someone hanging from a harness within a short period of time. The goal of any rescue is to limit the hanging/suspension time of the fallen employee. With a harness, the suspension time is a maximum of 15 minutes, less is desirable. The plan should address the fact the worker may be unconscious. Ensure all the rescue equipment is in place or ready to be put in place. Ensure everyone is aware of the plan. 1. The rescue plan must be written in the hazard analysis 2. The goal is to rescue the employee as soon as possible and limit the hanging time to no more than fifteen minutes. 3. Plan for a worker that is unconscious. 4. Ensure all the rescue equipment in the vicinity 5. Call the supervisor or safety officer whenever someone has been in a fall arrest situation Summary: six feet - OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. 1. Fall protection is a series of steps and safety measures conducted to eliminate or control the injurious effects of an unintentional fall while working at heights 2. A body can fall up to 7 feet in 2/3 of a second 3. Fall protection should be part of the planning process prior to construction 4. DO 128-13, Rule 1414.12 is the legal basis of fall protection 5. Fall protection methods are: fall prevention, work positioning and fall restraint, and personal fall arrest system 6. Fall prevention includes: guardrail systems and floor coverings 7. PFAS includes: anchorage point, full body harness, deceleration devices, and connectors 8. Restraint devices prevents the fall of a worker by providing a short leash so that workers cannot reach the edge 9. There should be a rescue plan whenever working with the potential of hanging by a harness 11.0 TEMPORARY STRUCTURES What is a Scaffolding? This refers to a temporary or movable platform supported on the ground or suspended, used for access and/or working at considerable heights above ground Hazards in the Use of Scaffoldings 1. Overloading of the scaffoldings 2. Improperly erecting a scaffolding 2.1. incomplete / incompatible accessories 2.2. use of improvised accessories 2.3. erecting on an unstable ground 2.4. lack of bracings or supports 3. Safe access or standard catwalk not provided 4. Lack of fall protection (Guard Rails) 5. Contact with a live electrical cable, electrocution 6. Fall of person from height 7. Fall of materials and objects from height 8. Collapse of scaffold Risks in the Use of Scaffoldings 1. Fall of person from height 2. Fall of materials and objects from height 3. Collapse of scaffold 4. Electrocution Things to consider when selecting a scaffolding system 1. Weight of workers, tools, materials, and equipment 2. Site condition: Ground condition, proximity of electrical cables, vibration 3. Height of scaffold 4. Type of work that will be done 5. Duration of work and weather conditions 6. Requirements for pedestrian traffic 7. Means of access to the scaffold 8. Configuration of the building or structure being worked on Classification of Scaffoldings 1. Supported Scaffoldings • are platforms supported by legs, outrigger beams, brackets, poles, uprights, posts, frames, or similar rigid support 2. Suspended Scaffoldings • contain one or more platforms suspended by ropes or other non-rigid means from an overhead structure 3. Trestle Scaffoldings • Refers to scaffolds in w/c the supports for the platform are step ladders, tripods or similar movable contrivances. Supported scaffold Suspended scaffold Trestle scaffold Legal Basis of Scaffolding Safety As per DO 128-13, Section 1, Rule 1414.02 General Requirements 2.1.1 Every scaffold shall be of good construction of sound materials and strength for the purpose for which it is intended; 2.1.2. Timber used for scaffolds shall be in good condition, the bark completely stripped off, and not painted or treated in any manner that defects cannot be easily seen; and 2.1.3. All materials and parts of scaffold not in use or intended for reuse shall be kept under good condition and separate from other materials unsuitable for scaffolds Specific Requirements 1. Timber/bamboo Scaffolds – limited to a height of 6 meters from the ground or base. Over 6 meters height, steel scaffolds shall be used 2. Manufactured Scaffolds – more than 6 meters in height shall be designed by structural engineer and approved by appropriate authority 3. Site fabricated / conventional supported Scaffolds – exceeding 6m in height or a working load of 150 kg/sqm shall be designed and inspected by the structural engineer and approved by the appropriate authority 4. Suspended Scaffolds – shall be designed and inspected by a structural engineer if site fabricated 5. No scaffold shall be erected, moved, dismantled or altered except under the supervision of a competent person 6. Fall protection equipment and Personal Fall Arrest System – required when working in a height of 2m and above 7. All personnel involved in scaffolding activities shall have appropriate training and certification Competent Person As per DO 128-13, Section 1, Rule 1414.14: Training and Competency Requirement A) Competent Person i) All scaffolds competent person must undergo the standard scaffold training and assessment prescribed by DOLE and TESDA. ii) The competent person shall have the following certification: • COSH Training Certificate from DOLE or its accredited safety training organizations. • Must be a holder of TESDA prescribed Scaffold Erection Certificate. iii) At least 2 years of experience in scaffold erection. B) Scaffold Erector i) All scaffolds erectors must undergo the standard scaffold training and assessment prescribed by DOLE and TESDA. ii) Scaffold erectors shall have the following certification: • One Day Workers Safety Orientation from DOLE or its accredited safety training organizations. • Must be a holder of TESDA prescribed Scaffold Erector NC II. Design 1. Supported scaffolds and their components shall be capable of supporting at least 4 times the maximum intended load 2. Suspended scaffolds shall be capable of supporting at least 6 times the maximum intended load 3. All scaffolds designed by structural engineer shall be approved by appropriate authority 3.1. Strength and Stability 4. Any damaged or weakened scaffold members from any cause shall be immediately repaired, replaced or discarded 5. Scaffolds shall not be loaded in excess of the working load for which they are intended 6. Scaffolds shall be anchored or secured to permanent or rigid structures. In the absence of permanent structures, guys and sway bracing and/or outrigger shall be used Site Inspection and Preparation 1. Site inspection shall be carried out before actual erection to check ground conditions, overhead wires, obstructions, changes in surface elevation, and structural support 2. Site preparation shall be performed to ensure that the soil are level and firm, mud and soft soil are replaced with compacted gravel or crushed stone 3. On sloping grounds, the area where mudsills rest shall be leveled by excavating rather than backfilling Scaffold Erection As per DO 128-13, Section 1, Rule 1414.06: Scaffold Erection 1. No scaffold work shall be undertaken without the direct supervision of a competent / qualified person 2. Always maintain the base width to height ratio of 1:4 during erection forstabi_x0002_lity. If the height exceeds what is allowed, refer to Rule 1414.3.2.7 (Scaffolds shall be anchored or secured to permanent or rigid structures. In the absence of permanent structures guys and sway bracing and/or outrigger shall be used) 3. No scaffold activity shall be undertaken if the wind velocity exceeds 48 kph. 4. For erected scaffold, additional precaution shall be considered during typhoon 5. No other work shall be allowed to commence below the scaffold during erection phase Footings 1. Standards require that every scaffold should have footings, sills or supports that are sound, rigid and capable of supporting twice the maximum load to which the scaffold may be subjected without settlement or deformation 2. Unstable objects such as barrels, boxes, loose bricks shall not be used to support scaffolds 3. DO 128-13 Rule 1414.3.2. Strength and Stability of Scaffolds: The footing, sills or anchorage for scaffolds shall be sound, rigid, and capable of carrying twice the maximum intended load without settling or displacement. Unstable objects such as barrels, boxes, loose brick, or concrete blocks shall not be used to support scaffolds; Frame Scaffolding 1. Restrained from tipping by guys, ties, or equivalent when higher than 4:1 ratio 2. Must be capable of supporting 4 times the maximum intended load 3. Plumb and level scaffold frames until connections can be made with ease 4. Do not force members to fit 5. DO 128-13 Rule 1414.3.2.7: Scaffolds shall be anchored or secured to permanent or rigid structures. In the absence of permanent structures guys and sway bracing and/or outrigger shall be used 6. DO 128-13 Rule 1414.3.2.8: Scaffold components produced by different manufacturers shall not be intermixed unless the components fit together Scaffold Platform Requirements (DO 128-13 Rule 1414.2.2) Specific Requirements: 2.2.9. Each platform on all working levels of scaffolds shall be fully planked or decked between the front uprights and the guardrail supports. 2.2.10. Each platform unit (e.g, scaffold plank, fabricated plank fabricated deck, or fabricated platform)shall be installed so that the space between adjacent units and the space between the platform and the uprights is no more than 1 inch (2.5 cm) wide. 2.2.11. Each scaffold platform and walkway shall be at least 18 inches (46 cm) wide. 2.2.12. Each end of a platform, unless cleated or otherwise restrained by hooks or equivalent means shall extend over the centerline of its support at least 6 inches (15 cm) Stair Access (DO 128-13 Rule 1414.6.2) 6.2 Material and Personnel Access 6.2.1. Scaffold with one section height shall be provided with safe access. 6.2.2. Supporting members used in the construction of runways, ramps, stairs and ladders shall be securely fastened and braced. 6.2.3. When hooked-on ladder is used, a rest platform with a minimum width of 60cm (2 ft)shall be provided every 4m in height. 6.2.4. Ladders used for access shall protrude at least 1m above the landing place. 6.2.5. When major components are removed for the purposes of access it shall be designed. Scaffold Inspection and Tagging DO 128-13 Rule 1414.07: Scaffold Inspection and Tagging. All scaffoldings shall be inspected prior to use. Inspection and tagging shall be performed by a qualified or competent person as the case may be. All manufactured scaffolds shall follow the manufacturers' recommendations. 1. Direct connections shall be evaluated by a qualified or competent person who shall confirm, based on the evaluation, that the supporting surfaces are capable of resisting the loads to be imposed. 2. Inspections should be carried out daily and every shift. All site fabricated/conventional supported scaffolds exceeding 6 meters in height or a working load of 150 kg/m2 shall be evaluated, tested and approved by a qualified person. 3. All scaffold identification tags shall be of a solid green, yellow, or red color with black lettering. All scaffold tags shall be hanged in every scaffold access points. Green tags shall be hanged at each scaffolds access that have been inspected and are safe for use Yellow tags shall be placed whenever special requirements for safe use are required. Situation requiring yellow tags may include whenever scaffold has been modified to meet work requirements, and as a result could present a hazard to the user. Situation requiring Yellow tags shall be closely supervised Red “DANGER – UNSAFE FOR USE” tags shall be used during erection and dismantling when the scaffold is left unattended or when scaffold is inspected to be unsafe or defective Clearance from Power Lines Insulated Lines Voltage Minimum Distance Less than 300 Volts 300 Volts to 50 KV 3 feet (0.9m) 10 feet (3.1m) More than 50 KV 10 ft (3.1m) plus 0.4in (1cm) for each 1 KV over 50 KV Un-insulated Lines Voltage Less than 50 KV More than 50 KV Minimum Distance 10 ft (3.1m) 10 ft (3.1m) plus 0.4in (1cm) for each 1 KV over 50 KV Suspended Scaffoldings 1. Suspended scaffold and its accessories should be able to withstand 6 times its maximum intended load 2. Outrigger beams and accessories shall rest on surfaces capable of supporting at least 4 times the maximum intended load 3. Must be attached to the roof, tied to secured anchorage, or secured with counterweights Counterweights: 1. made of non-flowable material 2. Secured and not removed until scaffold disassembled Suspension Ropes 1. Support at least 6 times maximum load 2. Protected from friction during direction changes 3. Replace if there are physical damages like kinking, flattening Proper Use of Scaffoldings DON'TS 1. Never overload 2. Do not erect, move, dismantle and alter near power lines 3. No barrels, boxes, ladders on top of scaffolds 4. Do not use platform covered with mud/debris DO'S 1. Repair in place or replace damaged components 2. Prohibit work activities during high winds 3. Remove whole scaffold from service until repaired 4. Maintain safe clearance from electrical cables Good housekeeping practices to avoid these situations: Rusting Couplers Contributing factor: Drum has no drain holes, accumulating rain water, drum not painted promoting rust Corrective Actions 1. Storage drums for couplers to have their bottom drilled with drain holes 2. Metal drums if used for storage should be cleaned, painted and labeled 3. Retain adequate quantity of drums 4. Sort out and isolate corroded couplers/components, clean and treat them anti-rust solution. Summary: 1. Scaffolding is a temporary or movable platform used for access and/or working at considerable heights above the ground 2. Scaffoldings are useful in construction but they pose hazards and risks which may result to accidents 3. Classification of scaffoldings: supported and suspended 4. Legal basis of scaffolding safety is DOLE DO 128-13 5. Every scaffold shall be of good construction and sound materials 6. Timber/bamboo scaffold is limited to a height of 6m 7. Manufactured and site fabricated/conventional scaffolds exceeding 6m in height shall be designed and inspected by the structural engineer 8. Suspended scaffolds shall be designed by a structural engineer 9. Persons involved in scaffoldings should be either competent or scaffold erector (qualified) 10. Supported scaffold shall be capable of supporting at least 4 times the maximum intended load 11. Suspended scaffolds shall be capable of supporting at least 6 times the maximum intended load 12. Scaffoldings should be inspected and tagged prior to use 13. Remember the safe clearance of a scaffolding used near power lines 14. Do not move mobile scaffoldings while a person is on it 12.0 ENVIRONMENTAL SAFETY An environmental hazard is a substance, state or event which has the potential to threaten the surrounding natural environment and/or adversely affect human's health Industrial Hygiene The science and art devoted to the Identification, Evaluation, and Control of environmental factors or stresses arising in or from the workplace, which may cause sickness, impaired health and well-being, or significant discomfort and inefficiency among workers or citizens of the community.” MAIN TYPES OF WORKPLACE HAZARD PHYSICAL HAZARD WORKING @ HIGH ALTITUDE NOISE VIBRATION ILLUMINATION HEAT COLD 3 BASIC STEPS OF INDUSTRIAL HYGIENE 1. Identify the Hazard (Alamin, Kilalanin) 2. Evaluate the Hazard (Suriin, Sukatin) 3. Control the Hazard (Ituwid, Itama, Ayusin) Hazard Statement - Is a phrase that describes the nature of the hazard. It will also be determined by the application of the classification criteria. PHYSICAL HAZARD 1. Noise 2. Vibration 3. Illumination 4. Temperature Extreme 5. Pressure 6. Radiation 1. NOISE – is harmful and unwanted sound, characterized by 3 parameters: • Frequency - measured in (Hertz) cycles per second • Loudness - intensity of the sound, measured in Decibel (dB) • Duration – length of exposure (continuous, intermittent, burst, waxing / waning) Permissible Noise Exposure Level (OSHA 1981) – maximum sound level for a given amount of time, where a worker need not wear hearing protection, provided Duration / day Sound Level Hours 8 4 2 1 0.5 0.25 or less Decibels dB 90 93 96 99 102 105 Adverse health effects of noise • Elevation of the hearing threshold or minimum level of perceptible sound • Traumatic damage to the middle and inner ears • Rupture of the eardrum • Acoustic Trauma (Explosion, gunshot) - Deafness • Temporary Threshold shift (New Year’s fireworks) • Tinnitus • Poor communication 2. VIBRATION • It is a physical factor that acts on man by transmission of mechanical energy from sources of oscillation. • Usually refers to the inaudible acoustic phenomena, which are recognized by the tactile experience of touch and feeling. • It is a vector quantity with both a magnitude and direction. • Continuous low frequency oscillation that is more likely felt than heard • Affects the body through direct contact SOURCES OF VIBRATION: • Segmental vibration: Chain Saw, Portable Grinder, Jackhammer, Polishers, hand held power tools, • Whole Body Vibration: Tower Crane, Cars, Buses, Train, places with floor mounted machines Health Effects of Vibration • Inflammation of joints and muscles (wrist, elbow, shoulder) • Vibration white finger • Generalized fatigue 3. ILLUMINATION GENERAL LIGHTING Sometimes referred to as ambient light fills in between the two and is intended for general illumination of an area. LOCAL LIGHTING – NATURAL AND ARTIFICIAL Type of lighting which illuminates a relatively small area without illuminating the general surroundings significantly. Visibility of a workplace as a result of light: ▪ The source of light is either natural or artificial ▪ It is measured in lumens or lux Importance of Illumination – it is important that we see what we are doing. There are recommended illumination standards based on the visual demands of different activities. Below is a summary of illumination required based on activity. (Please refer to the table of Illumination Levels in the OSHS for the complete listing) VISUAL FATIGUE • Double vision • Headache • Painful irritation • Production of excess tears • Redness of eyes Heat & Cold Stress HEAT STRESS – when the workplace heat causes the body’s temperature to go higher than 37.5°C, like in the following exposure settings: a) High temperature b) High humidity c) Poor ventilation d) Multiple heat sources Acute Health Effects of Heat • Prickly heat - immature sweat glands • Heat fatigue - bad mood (water loss) • Heat cramps - muscle spasm (loss of water + salts) • Heat exhaustion - fatigue, dehydration, diaphoresis, nausea, vomiting (loss of water + salts + electrolytes) • Heat stroke - overheating, seizures (failure of thermoregulatory system) COLD STRESS - when the workplace temp causes the body’s temperature to go lower than 36.5°C as in ice plants, Broadcast Industry, Semiconductor Industry, Food processing plants, Ice Cream plants, Deep sea diving, Laboratories. Thermoregulatory mechanism to raise temperature is by CHILLING / SHIVERING. Health effects of Cold • Hypothermia, Chills (also another normal thermoregulatory mechanism) • Frostbite – medical condition where cold temperature constricts blood vessels, impedes blood flow to fingers, thus resulting in tissue and cell death Prevention & Treatment • Transition rooms where temperature is higher than the cold room • Rest breaks, warm food and drink • Thermal clothes PRESSURE HAZARD This is the atmospheric force that is constantly applied on the body, which may be affected by changes in altitude or artificially induced work conditions. Pressure is defined as the force exerted against an opposing fluid or thrust distributed over a surface, expressed in force or weight per unit of area (like pounds per square inch or “psi”. Critical injury and damage can occur with extremes of pressure. We perceive pressure in relation to the earth’s atmosphere—at sea level, about 14.7 psi. Pressure changes cause body stress. In human physiology studies, the typical unit of measure is in millimeters of mercury (mm Hg). Physiologic loss of hearing both is experienced as one increases altitude, and as one decreases altitude because inside the middle ear, this expanding air pushes the eardrum outward; or the vacuum created during compressing air pulls the eardrum inward. It has been recognized as from the beginning of caisson work (work performed in a watertight structure) that men working under pressures greater than at a normal atmospheric one, are subject to various illnesses connected with the job. RADIATION The motion of electrically charged particles produces electromagnetic waves. These waves are also called “electromagnetic radiation” because they radiate from the electrically charged particles. They travel through empty space as well as through air and can penetrate some other substances. Radio waves, microwaves, visible light and X-rays are all examples of electromagnetic waves. The electromagnetic spectrum can be divided into two at a wavelength of about 10 nm, which distinguishes Non-Ionizing Radiation and Ionizing Radiation. Visible light, infrared and microwaves are types of non-ionizing radiation. X-rays and Gamma rays are examples of ionizing radiation. IONIZING RADIATION A radiation consisting of particles, x-rays, or gamma rays with sufficient energy to cause ionization in the medium through which it passes. NON-IONIZING RADIATION refers to any type of electromagnetic radiation that does not carry enough energy to ionize atoms or molecules that is, to completely remove an electron from an atom or molecule Types of Non-Ionizing Radiation: 1. Ultraviolet (UV) Radiation 2. Infrared (IR) Radiation 3. Laser Radiation 4. Microwave Radiation Effects of Non-ionizing radiation - short duration exposure in excess of a few tenths ppm can result in discomfort (headache, dryness of mucous membranes and throat). CHEMICAL HAZARDS Chemicals are important in daily operations, including the life of a person. They exist as solids, liquids and gases. Their presence and use in the workplace are synonymous with growth and production. However, chemicals can still cause reactions when these come in contact with objects, people and/ or other chemicals. It is a type of occupational hazard caused by exposure to substances in the workplace. Routes of Entry into the body: A. Dermal Absorption/ Injection (Skin) Important “accidental” route of entry, health effects of chemicals • Localized irritation • Generalized reaction (sensitization or allergic reaction) • Absorption and vascular dissemination • Increase absorption with increased temperature and perspiration B. Ingestion • Accidental swallowing from eating in contaminated area • Smoking on the job with contaminated fingers and hands • Ingestion of inhaled materials C. Inhalation Most “important” route of industrial chemical exposure Determinants: • Concentration in the air • Duration of exposure • Amount of air inhaled D. Optical (Eye) Contamination Chemicals enter the body thru direct contact with the conjunctiva, then it passes into the canals that drain tears from the eye Vapors A substance diffused or suspended in the air, especially one normally liquid or solid. Occupational exposure is from: • Degreasing of metals • Printing • Dry-cleaning • Painting • Laboratory Analysis Mist A water in the form of particles floating or falling in the atmosphere at or near the surface of the earth and approaching the form of rain. Occupational exposure is via: • Wastewater treatment • Acids from electroplating • Oil mists from cutting & grinding operation • Mist from Spray painting operation Fumes Volatilized solid that condenses when they contact air: • Soldering operation • Welding • Lead-battery making • Mining operation Dust Refers to the suspension of solid particles in air. Dust are classified according to size: • Total Dust – all dust particles in the area • Respirable Dust – fraction of total dust which passes through a selector which can be inhaled and deposited in the lungs Control of chemical hazards: 1. At the Source • Substitution the chemical • Changing the process • Enclosing the source • Isolation of the source • Wetting of dusty work • Installing local exhaust 2. Along the Path • Applying dilution ventilation system • Good housekeeping • Improving general ventilation • Increasing distance between the source and the receiver 3. At the Receiver • Enclosing workers in control rooms • Rotation of workers • Training and Education • Use of PPE ERGONOMIC HAZARDS Ergonomics is a technique that brings together several disciplines to solve problems arising from work and the working environment. Ergos- work; Nomos- natural way • Ergonomic hazards cause pain and fatigue from various sources. • Lead to low productivity and output (mental and physical performance) The ILO defines ergonomics as “... The application of human biological science in conjunction with the engineering sciences to achieve the optimum mutual adjustment of man, and his work, the benefits being measured in terms of human efficiency and well-being.” “Ergonomics is the science of fitting jobs to the people who work in them” Ergonomic hazards can be seen in: • Poor workplace design – cramped leg area, crowded worktable, distant work materials • Awkward body postures – prolonged sitting, twisted body while bending • Repetitive movements – sewing, cutting, stamping • Static posture – prolonged standing without motion • Forceful motion – extreme pulling and pushing • Manual handling – improper carrying of materials, use of pliers. BIOLOGICAL HAZARDS Biologic hazards are the cause of infectious disease that can originate from people, animals and plants. They are characterized by 2 parameters: 1) can reproduce or replicate; 2) living or dead organisms. They come in the form of Bacteria, Viruses, Molds, Fungi & Parasites even Plants.. • Poor sanitation and housekeeping • Hospital works • Removal of industrial waste and sewage • Poor personal cleanliness Summary: 1. Industrial Hygiene is the identification, evaluation, and control of environmental hazards in the workplace. 2. Safety Data Sheets provides information for Identification, Evaluation, Control of Chemical Hazards. 3. Work Environment Measurement is needed for proper evaluation of Environmental Hazards. 4. Concentrations of hazards that exceed the TLVs can cause adverse effects to humans. 5. All hazards can be controlled (Engineering, Administrative & PPE), some situations will require more than one control measure to obtain optimum results. 6. As Safety Officer, we need to understand the Identification & Evaluation of Hazards for appropriateness of Controls to be recommended. 13.0 OCCUPATIONAL HEALTH Occupational Health Defined (ILO / WHO) “The promotion and maintenance of the highest degree of physical, mental and social well-being of workers in all occupations by… • PREVENTING workers from getting sick, • PROTECTING workers from health risks, • PLACING worker in tasks adapted to his ability.” Workplace Hazards 1. Safety Hazard - Something that has a potential for harm or injury a) Tripping, falling and slipping hazards. (Poor Housekeeping) b) Mechanical hazards c) Electrical hazards d) Fire e) Material Handling 2. Health Hazard - Something that has a potential to cause illness or ill health a) Physical Hazards b) Chemical Hazards c) Biological Hazards d) Ergonomic Hazards BASIC CAUSES ILLNESS / INJURY (WORK-RELATED ILLNESS / INJURIES) Workplace Factors 1. Exposure duration or the length of time of being vulnerable to work hazards. Constant exposure to amounts, which have low levels in the workplace over a prolonged period of time, increases the risk of disease after a latency period (the interval between exposure to a hazard(s) and the clinical appearance of disease); 2. Magnitude, level or dose of exposure. As the concentration or amount of a hazard is increased the likely it can do more harm. 3. Timing of exposure. This is related to exposure duration. A worker who is exposed to a hazard continuously or for several periods in a day is more at risk than those with less exposure 4. Multiplicity of exposure. Exposures to mixtures of hazards or several chemicals at the same time can cause synergistic or cumulative effects. Personal Factors 1. Age is an important factor since elderly and young workers have poor metabolic processes, which allow a buildup of toxic substances. In a normal adult, these substances can be easily neutralized. 2. Sex is a very important consideration, too. A hazardous agent may be toxic to female workers and not toxic to male workers or vice versa. For pregnant women, some toxins may cause developmental problems in the fetus. Lead and mercury have been documented to cause neurological defects in the offspring of exposed pregnant women. In both men and women, other toxins may affect their reproductive systems. 3. The genetic make-up of a worker should also be considered because those with history of allergies will find it difficult to work in an environment where their allergies would likely flare up. Also those with enzyme deficiencies may not be able to handle toxic substances that enter the body. 4. Your medical history is important to identify previous illnesses, which may be aggravated by substances, or agents found in the workplace. An anemic (weak and pale) worker who will be employed in a company using lead may continue suffering from anemia (condition characterized by an abnormally low number of red blood cells in the circulating blood) due to lead exposure. A worker diagnosed with a liver disease should be closely monitored if he/she would be working with solvents since which may compromise the liver functions. 5. Lifestyle factors such as smoking, alcohol consumption, physical inactivity, unhealthy diet, drug abuse, among others can alter a worker’s natural defense mechanisms and increase the chance of developing ill-effects. For example, higher risk of liver disease in a worker exposed to solvents and a history of alcohol consumption; or increased risk of hypertension in a worker with occupational stress who is also eating high salt and high fat diet. The risk of lung cancer is much greater in workers who have workplace exposure to asbestos fibers and who also Monitoring 1. Surveillance in occupational health practice covers periodic, systematic and continuous hazard assessment and medical examination. 2. Surveillance data will provide trends or emerging patterns in workplace hazards and illnesses. 3. Surveillance has to be followed by preventive action (appropriate control measures) and evaluation of the effectiveness of intervention. 4. Surveillance is conducted to meet regulatory requirements. Types of Monitoring 1. Ambient / Environmental (Work Environment Monitoring) 2. Biological (Blood, Urine, Stool, Chest X-ray, Tissue cultures) 3. Medical Surveillance (Employment Medical Examinations) WORK ENVIRONMENT MEASUREMENT is the direct measurement of hazards, environmental stresses and their hazardous effects on the workers’ health. BIOLOGICAL MONITORING is a way of assessing chemical exposures by measuring the chemical or its breakdown products in a biological sample (usually urine, blood or breath). MEDICAL SURVEILLANCE - is the systematic assessment of employees exposed or potentially exposed to occupational hazards. This assessment monitors individuals for adverse health effects and determines the effectiveness of exposure prevention strategies. Rule 1960: Occupational Health Services : Health Programs shall include: 1. Entrance or Pre-Employment 2. Periodic 3. Special examination 4. Transfer examination 5. Separation examination Medical Surveillance 1. Pre-employment or Entrance Exam 1.1. Medical history 1.2. Physical examination 1.3. Medical history and P.E. 1.4. Baseline blood levels of chemicals or their metabolites 2. Periodic examination - Annual Medical Examination Same as preemployment 3. Special examination • X-ray of affected body part • CT-scan of affected body part • Other appropriate laboratory examinations • May include random Drug Testing; Biological Monitoring, COVID-19 Testing 4. Transfer examination: • Base line health status prior to transfer. • comorbidity cases • results will determine the transfer. 5. Separation examination: • Medical history and PE. • Blood levels of chemicals or their metabolites Substance Abuse Impacts of Alcohol and Drugs at Work - Physical, Mental, Safety and Productivity Section 12. OCCUPATIONAL SAFETY AND HEALTH (OSH) PROGRAM b) For medium to high risk establishments with 10–50 workers and low to high risk establishments with 51 workers and above. – The OSH program, which shall be duly signed by the employer, must include at least the following: 1. Company commitment to comply with OSH requirements; 2. General safety and health programs, including: 3. Safety and health hazard identification, risk assessment and control (HIRAC), 4. Medical surveillance for early detection and management of occupational and work-related diseases, and 5. First aid and emergency medical services; 6. Drug-free workplace (RA 9165), 7. Mental health services in the workplace (RA 11036), and 8. Healthy lifestyle; Summary: 1. The purpose of medical surveillance in occupational health is to Identify, Evaluate and Control Occupational Illnesses in the workplace. 2. We can refer to Safety Data Sheet on the health effects and control of chemicals used in the workplace. 3. Occupational diseases and work-related illnesses can be prevented 4. Development of Company policies and programs are important to promote, protect and monitor workers’ health in compliance to Laws, standards and guidelines exist to promote health and well-being of workers; serves as legal basis for putting up a health program 14.0 PERSONAL PROTECTIVE EQUIPMENT If the hazard cannot be removed, and a worker is needed for the operation (or equipment), then the last resort is to put a barrier between the worker and the hazard – thus the PPE. Actually, PPE can be used in conjunction with engineering controls and administrative methods. Uses of PPEs 1. Where temporary control measures are necessary before engineering controls are installed 2. To supplement engineering controls in reducing exposure during maintenance and repair 3. During emergencies 4. It is the last line of defense However, PPEs protective devices have one serious drawback - they do not reduce or eliminate the hazard. The fact that a protective device may become ineffective when the wearer lacks sufficient knowledge on how to use it, adds to the limitation of these PPE. 1. Head protection – hardhat, cap, visor 2. Foot protection – safety shoes, boots 3. Hand protection – gloves 4. Eye protection – goggles or safety glasses 5. Hearing protection – ear plugs or ear muffs 6. Respiratory protection – SCBA, mask What is personal protective equipment? Personal protective equipment, commonly referred to as "PPE", is equipment worn to minimize exposure to serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, or coveralls, vests and full body suits. PPE Program is composed of the following elements: 1. Selection 2. Fitting 3. Health Aspects 4. Issue 5. Proper Use 6. Compatibility 7. Maintenance 8. Disposal 9. Information & Training 10. Supervision 11. Reviews 12. Checklist 1. Selection To be done by a suitably trained person with adequate information of the task, hazards, personnel, materials, etc. 2. Fitting When first issued, the user should also be trained to check the fit whenever the equipment is used. Ensure an adequate fit under supervision 3. Health Aspects Use of PPE can affect employees’ health (e.g. skin irritation, heat stress) A number of medical conditions may make it difficult to use certain equipment 4. Compatibility - If more than one type of PPE is required to be worn simultaneously, then the harmony of the individual items needs to be evaluated. The PPE also needs to be compatible with the task involved 5. Issue Provision should be made to control the issue of PPE to employees, remembering that several types of equipment may be available. 6. Proper Use PPE is effective if worn properly for the appropriate task 7. Maintenance (Cleaning and Storage) Depending on type of equipment used, procedures need to be established for its cleaning and maintenance when necessary 8. Disposal Used PPE can be contaminated with toxic agents and disposal procedures need careful consideration. Depending on the circumstances, equipment may need to be treated as toxic waste 9. Information and Training Employees have to be given sufficient information and proper training about the hazards associated with their jobs to enable them to work safely with minimal risk to health. 10. Supervision A PPE program is unlikely to be successful unless the first line supervisory personnel are knowledgeable and held accountable for effective use of PPE Supervisors must set an example by wearing PPE as appropriate and ensure its use by others 11. Reviews Periodic evaluation to confirm that the agreed procedures are appropriate and being followed Formal audit carried out by a third party with specialist advisers 12. Checklist To ensure use of properly fitted, effective PPE for specific jobs PPE is the last line of defense, hence, its effectiveness may be crucial to the health of the workers Summary: PPE remains as the last resort to protect the worker Use of the PPE does not remove the hazard, it merely provides a barrier to shield the wearer. 15.0 DEMOLITION and EXPLOSIVES SAFETY What is DEMOLITION? 1. Complete or partial dismantling of a building or structure by pre-planned or controlled methods or procedures. 2. Safe Demolition Requires Adequate Planning (Rule 1417 OSHS). Demolition Technique 1. Sequential – gradual reduction of height in reverse order to its construction 2. Induced – key structural members are weakened or removed, causing the whole part of the structure to collapse. Methods of Demolition 1. Manual – use of hand held tools 2. Mechanical – use of heavy equipment, wires and chain, power shear, etc. 3. Explosives – use of explosives MECHANICAL MANUAL USE OF EXPLOSIVES Hazards Associated with Demolition: 1. Falls 1.1. Falling through fragile roofing material 1.2. Falling through openings 1.3. Falling from open edges 1.4. Falling out of elevating work platforms 2. Lift shafts 2.1. Collapse of flooring 2.2. Collapse of ground 2.3. Tripping over debris 3. Being Hit/Trapped/Crushed by Objects 3.1. Falling debris (from service ducts and lift shafts) 3.2. Accidental/uncontrolled collapse of a structure 4. Use of equipment (crane lifting loads) - Failure of structural members (load bearing steelwork) 5. Manual Handling 5.1. Using equipment 5.2. Operating equipment 6. Manual Demolition 6.1. Lifting material 6.2. Cleaning up 6.3. Loading trucks/bins 7. Hazardous Substances – 7.1. Lead - lead based paint, tanks containing lead base petrol – 7.2. Asbestos - sprayed coating, isolation materials, fire resistant wall/partitions, cement sheets, flooring materials – 7.3. PCBs - stones, bricks and concrete aggregates 8. Dangerous Goods – Flammable liquids/vapors and sludge from industrial process and confined space 9. Noise and Vibration 9.1. Equipment 9.2. Falling debris 9.3. Explosives 10. Electric Shocks - Live wires from structures 11. Fires and Explosion 11.1. Flammable materials 11.2. Welding or cutting 11.3. Leaks of explosives gases from accidental damage of pipes 11.4. Arson especially when the site is unattended 12. Equipment 12.1. Electrocution 12.2. Plant Failure 12.3. Dropping material 12.4. Equipment striking persons 12.5. Noise and Vibration 12.6. Flying particles Dust and other airborne 12.7. hazards 12.8. Falling objects onto operators OSHS Rule 1417 – 1418 1. Structures over 6m high must be under the supervision of a competent person 2. The area is strictly for demolition workers only (Demolition area - w/in a distance equal to 1.5 x H of structure) 3. If the above distance is not possible, the structure shall be fenced all around 4. Danger signs must be posted around the structure 5. All electrical services must be ensured to have been cut – off 6. Demolition should proceed storey by storey, in a descending order; work on the upper floors should be completely over before removing the supporting members on the lower floor 7. No part of the structure shall be overloaded w/ debris or any other material 8. Stairs (including all railings), passageways & ladders must be demolished last. Controls needed 1. Engineering (Elimination, Isolation, Substitution) 1.1. Install screen on equipment to protect from dust and noise 1.2. Install barriers and fences 1.3. Mark off hazardous areas 1.4. Disconnect services to the demolition site 1.5. Ensure there are no sparks or ignition sources where there is risk of fire or explosion 1.6. Ensure separation between the public and demolition activities 1.7. Use power shears, in place of grinding or oxy-acetylene cutting, where there is a risk of fire 1.8. Install safe working platforms (scaffolds and elevating work platforms) 1.9. Install edge protection to open edges of landings, stairways and fixed platforms 1.10. Use shoring and bracing to support loads 1.11. Modify tools or equipment 1.12. Provide guarding to machinery or equipment 1.13. Provide shatterproof/guarded widescreens on equipment 1.14. Install anchor points for fall arrest systems 1.15. Spray water to suppress dust 1.16. Use chutes for dropping debris and cranes for lowering loads 1.17. Install vehicle buffers where equipment is exposed to an open edge 1.18. Provide flash arresters on gauges and hoses of welding equipment 2. Administrative Tools 2.1. Limit the amount of time a person is exposed to a particular hazard 2.2. Implement and document safe working procedures for all hazardous tasks 2.3. Train and instruct all personnel 2.4. Identify hazardous substances prior to work 2.5. Implement safe procedures for handling hazardous substances 3. Personal Protective Equipment 3.1. Hard Hats 3.2. Full Body Harnesses and Lanyards 3.3. Boots Generally procedure for demolition are: ▪ All utilities shut off ▪ All glasses removed ▪ Shoring or other measures implemented ▪ Protection of workers from fall ▪ Stairs to be demolished last Summary: 1. Risk from Hazards in Demolition in Safety can be mitigated by proper planning prior to the start of Demolition and applications of Controls (Engineering, Administrative, PPE) 2. Compliance to Regulatory Requirements during demolition activities facilitates Safe Demolition Activity. 16.0 ROUTINE SITE SAFETY INSPECTION Safety Inspection is a systematic way of identifying potential workplace hazards before they cause a health and safety problem. Reasons Of Workplace Inspection 1. Identify and/or eliminate hazards 2. Assess the potential losses from the Hazards 3. Select control measures designed to eliminate or reduce the hazards to an acceptable level 4. Monitor the effectiveness of control measures 5. Review compliance with established standards Keys To Effective Inspection 1. Create checklists 2. Schedule your inspections and inspect on schedule 3. Focus on one hazard at a time 4. modify checklists as needed 5. Follow-up corrective action 6. Communicate and involve employees 7. Acknowledge participation What Items Need to Be Inspected? 1. Environmental factors - illumination, dust, fumes, gases, mists, vapors, noise, vibration, heat, radiation sources 2. Hazardous supplies and materials - explosives, flammables, acids, caustics, toxic or nuclear materials or by-products 3. Power source equipment - steam and gas engines, electrical motors 4. Electrical equipment - switches, fuses, breakers, outlets, cables, extension and fixture cords, grounds, connectors, connections 5. Hand tools - wrenches, screwdrivers, hammers, power tools 6. Personal protective equipment - hard hats, safety glasses, safety shoes, respirators, hearing protection, gloves, etc. 7. Personal service and first aid facilities - Drinking fountains, wash basins, soap dispensers, safety showers, eyewash fountains, first aid supplies, stretchers 8. Fire protection and emergency response equipment - alarms, water tanks, sprinklers, standpipes, extinguishers, hydrants, hoses, self-contained breathing apparatus, toxic cleanup, automatic valves, holes, phones, radios 9. Walkways / roadways - ramps, docks, sidewalks, walkways, aisles, vehicle ways, escape routes 10. Elevators, electric stairways, and manlifts - controls, wire ropes, safety devices 11. Working surfaces - ladders, scaffolds, catwalks, plat-forms 12. Material handling equipment - cranes, trollies, conveyors, hoists, forklifts, chains, ropes, slings 13. Storage facilities and area both indoor and outdoor - bins, racks, lockers, cabinet, shelves, tanks, closets 14. Structural openings - windows, doors, stairways, sumps, shafts, pits, floor openings 15. Building structures - floors, roofs, walls, fencing, columns 16. Miscellaneous - any item that do not fit in preceding categories SAMPLE RE-ENTRY FORM Hazard Action Plan Accountability Madilim sa Elevator Engr Control- Magkabit Operations Dept. Shaft at maaring may ng karagdagan ilaw sa madapa o mahulog shaft (Unsafe Condition: Admin Control- Maglagay Operations and Safety Low illumination ng “Warning Signs”. Dept. Physical Hazard) Magbigay ng kaalaman sa pangangalaga ng mata PPE-Not applicable Warehouse Dept. Target Date Feb. 21, 20XX: Prior to start to work Output Maliwanag na lugar na pinagtratrabahuan Feb. 25, 20XX Dagdag Paalala sa Kaligtasan Feb. 21, 20XX: Prior to start to work No PPE applicable for dark areas 17.0 HIRAC - Hazard Identification, Risk Assessment, and Control RISK ASSESSMENT is a term used to describe the overall process or method where you: 1. Identify hazards and risk factors that have the potential to cause harm (hazard identification). 2. Analyze and evaluate the risk associated with that hazard (risk analysis, and risk evaluation) 3. Determine appropriate ways to eliminate the hazard, or control the risk when the hazard cannot be eliminated (risk control). When to Create HIRAC? Every activity / task should have a corresponding HIRAC, prioritizing the following considerations: 1. High Frequency of Accidents 2. Increase occurrence of Near-Misses 3. History of Serious Accidents / Fatalities 4. Potential for Serious Harm 5. New Jobs or New Equipment 6. Changes in Procedures or Standards LIKELIHOOD (PAGKAKATAON) Likelihood Score Likelihood Description Unlikely that this consequence from the hazard will occur 1 - Unlikely at this workplace or at the company at any time. (N=0) Has occurred in the workplace or at the company 2 - Likely previously. (N=1) Has occurred several times in the workplace or at the 3 - Very Likely company and is very likely to occur at some time on this site. (N>1) Probability 1%-25% 26% - 70% >71% Severity Score 1 - Low 2 - Moderate 3 - High SEVERITY (GAANO KATINDI) Property Damage Safety and Health Description Description No injury to minor No damage or slight discomfort;First aid treatment; damage ≤PhP10,000 Near Miss, or Medical Treatment Injuries resulting to Lost Time Incident, or Temporary Total Disability Moderate damage, PhP10,001 to PhP500,000 Permanent Partial Disability (PPD), Extensive damage, Permanent Total Disability (PTD), >PhP500,000 or Fatality Environmental Impact No measurable impact, minimal environmental disturbance in work area. Minor non-conformance of procedures, No complaints Temporary or minor reversible impact. Contained at the site. Minor noncompliance to legal requirements or procedures, Single complaint from general public. Permanent damage with external impact. Medium term clean up or correction. Large number of complaints. Regional or national media coverage. Notice of violation with penalty. Order to cease operation. Sample HIRAC Form 1. Hazard Identification 2. Risk Assessment (Evaluation) Hazard(s) Possible Effects Probability Severity Risk Madilim sa Elev. Shaft at maaring may madapa o mahulog (Physical Hazard) Minor Illness/Injury to Permanent Partial/Total Disability or Fatality 3. Risk Control Proposed Control Measure (s) Engr Control - Magkabit ng karagdagang ilaw sa shaft 3 Communicating Inspection Results • Discuss them at safety meetings • Post the complete checklists • Post maintenance requests 3 (9) High Admin Control - Maglagay ng warning signs. Magbigay ng kaalaman sa pangangalaga ng mata. PPE - N/A Summary: The Keys for Effective Inspection are; 1. Create checklists 2. Schedule your inspections and inspect on schedule 3. Focus on one hazard at a time 4. Modify checklists as needed 5. Follow-up corrective action 6. Communicate and involve employees 7. Acknowledge participation 8. Hazard Identification, Risk Assessment and Control (HIRAC) are useful to prevent or control accident/illness at the workplace and for classification of risk level of establishments. 9. Application of HIRAC in Routine Site Safety Inspection makes a valuable output in organization for OSH management. 18.0 JOB HAZARD ANALYSIS Every valuable HIRAC is achieved with a Job Hazard Analysis or JHA. It is a collective effort that focuses both on the different jobs in a company, and a group of people tasked to identify them. JHA involves the following steps: 1. Identify basic steps of a job 2. Determine associated hazards 3. Make recommendations to control the hazards Uses of a JHA 1. Create / improve SOP’s 2. Guide in observing employee performance 3. Accident investigation 4. Safety inspection Prioritizing JHA’s 1. High Frequency of Accidents 2. Increase occurrence of Near-Misses 3. History of Serious Accidents / Fatalities 4. Potential for Serious Harm 5. New Jobs 6. Changes in Procedures or Standards JHA Team 1. Supervisor 2. Employee most familiar with the job 3. Other employees who perform the job 4. Experts or specialists (maintenance, occupational hygienists, ergonomists, engineers) Hazard Guide: 1) The method or physical actions required for that specific step. 2) The materials used. 3) The machine / equipment used. 4) The environmental conditions under which the step is normally performed. Uses of Job Hazard Analysis 1) Developing or updating SOP’s 2) Training employees 3) Observing employee performance 4) Conducting inspections 5) Investigating accidents JOB HAZARD ANALYSIS Dept./Division: Job Location: Project Mgt. Department Performed by: Operation Title: Steps In Manual Cutting of Steel Bars Employee Position: Worksite Incident: Safety Officer Verified By: APO Hand Injury APO BASIC JOB STEP EXISTING & POTENTIAL RECOMMENDED CORRECTIVE ACTION 1. Get a Steel Bar 2. Measure the steel bar 3. Cut the steel bar 1.1 Cut from sharp edges of steel 1.1.A Engg.: N/A bar 1.1.B Admin: work instructions 1.1.C Ergo: proper sitting posture 1.1.D PPE: N/A 2.1 Finger cut while conducting 2.1.A Engg.: Use measuring tape measurement 2.1.B Admin: Training in measuring 2.1.C Ergo: observe proper sitting procedure 2.1.D PPE: wear gloves 3.1 metal splinters hitting the eye 3.1.A Engg.: use sharp cutting tools 3.2 pinch injury while finger is caught in between the cutting tool equipment 3.1.B Admin: proper work procedure 3.1.C Ergo: observe proper tool handling 3.1.D C PPE: gloves 3.2.A Engg.: Substitute with cutting machine 3.2.B Admin: Training on use of cutting machine 3.2.C Ergo: observe proper work postures 3.2.D PPE: wear gloves 19.0 ACCIDENT INVESTIGATION Accidents are the result of Unsafe Acts and Unsafe Condition. Identifying the causative factors can prevent recurrence and save valuable lives. 1. Accident is unplanned, uncontrolled and undesirable. 2. Disrupts normal function of the organization due to injuries/ fatality of workers or damage to property. 3. Accident can be prevented from recurring through an efficient root cause investigation. Accident Causation: 1. Refers to the factors that are the primary reasons behind an accident. 2. For occupational health and safety professionals, determining causation factors in any workplace injury or accident is the key. REMEMBER: ACCIDENTS are caused... so ACCIDENTS can be prevented Mr. Heinrich’s Survey 88% Unsafe or Unhealthy Acts 10% Unsafe or Unhealthy Conditions 2% Acts of Nature Therefore: 98% Accidents are Preventable 2% Non-Preventable Heinrich's Domino Theory According to Heinrich, an "accident" is one factor in a sequence that may lead to an injury. • The factors can be visualized as a series of dominoes standing on edge; when one falls, the linkage required for a chain reaction is completed. • Each of the factors is dependent on the preceding factor. Heinrich's Accident Triangle PURPOSE OF ACCIDENT INVESTIGATION 1. To establish all facts 2. To draw conclusion 3. To make recommendations 4. To prevent recurrence Investigations are conducted to: 1. Prevent recurrence 2. Comply with policies and regulatory requirements 3. Improve Supervisor’s Management Approach 4. Maintain employee awareness - HSE Accident Investigations are usually considered a Supervisors responsibility. Advantages of Supervisors over other investigators: 1. More familiar with the people involved 2. Better understanding of the operations and equipment 3. Personal interest in Investigations Mandatory Reports: OSHS Rule 1050 Notification and Keeping of Records of Accident and/ or Occupational Illness 1053.01 Notification - All work accidents or occupational illnesses resulting in disabling conditions or dangerous occurrence shall be reported by the employer to the Regional Labor Office 1. Employers Work Accident/Illness Report (DOLE/BQF/WAIR) 2. 2 copies to concerned Regional Office & copy furnished BWC 3. Shall be submitted by the employer on or before the 30th day of the month following the date of the occurrence of the accident. SAMPLE ACCIDENT/INCIDENT FORM cont. Actual Loss Measurements (injuries): • Disabling injury frequency rate (FR) • Annual Work Accident/Illness Exposure Data Report (AEDR) (DOLE/BWC/IP-6) • 2 copies to concerned Regional Office & copy furnished BWC • Submitted on or before January 20 of the following year with or without accident • Disabling injury severity rate (SR) • Disabling injury index • Serious injury frequency rate (FR) • Non-LTI frequency rate (FR) AEDR Computations. Assume: • # of Disabling Injuries = 10 • Total Emp-Hr Exp = 200,000 FREQUENCY RATE: No. of disabling injury x 1,000,000 10 x 1,000,000 FR = = = 50 Total Employee−Hour Exposure 200,000 Assume: • Total days lost = 200 • Total Emp-Hr. Exp = 200,000 SEVERITY RATE: Total days lost X 1,000,000 200 x 1,000,000 SR = = = 1000 Total Employee−Hour Exposure 200,000 Disabling Injury Index: (disabling injury FR) x (disabling injury SR) 50 x 1,000 DII = = = 50 1,000 1,000 Summary: 1. Accidents disrupts normal function of the organization due to injuries/ fatality of workers or damage to property. 2. Accident can be prevented from recurring through an efficient root cause investigation. 3. Primary causes of accidents are unsafe/unhealthy acts & conditions 4. Basic procedures in the conduct of accident investigation must be followed 5. Results of accident investigation must be documented properly and thoroughly. 6. Make recommendations based on the investigation. 7. Dangerous occurrences in the workplace must be addressed. 20.0 COMMUNICATING OSH Employers respond to: 1. Compliance requirements 2. Status of compliance 3. Costs 4. Productivity indicators 5. ”Need to know” and what can be done 6. Efficient, effective way to implement OSH Workers respond to: 1. How to keep themselves safe and healthy 2. Linking OSH to their productivity 3. Contributing to the achievement of the company DO 198-18 SECTION 14: Safety Officer (DO13 Section 12: Safety and Health Information) Duties and Responsibilities of a Safety Officer 1. Oversee the overall management of the OSH Program in coordination with the OSH Committees; 2. Frequently monitor and inspect any health or safety aspect of the operation being undertaken with the participation of supervisors and workers. 3. Assist government inspectors in the conduct of safety and health inspection at any time whenever work is being performed or during the conduct of an information and OSH reports as required by the OSH Standards; and 4. Issue work stoppage order (WSO) when necessary based on the requirements and procedures provided by the OSH Standards. LABOR ADVISORY O4-20I9 - APPOINTMENT OF SAFETY OFFICER SAFETY OFFICER The Safety Officer shall be certified by the company's Human Resource (HR) unit/section based on the qualification requirements such as completion of the prescribed training and minimum years of OSH experience as provided for under Section 14. Thus, the appointment of its own safety officers and the appropriate category level of Safety Officer ( i.e. Safety Officer 1, Safety Officer 2, Safety Officer 3 and Safety Officer 4) shall be issued by the company. DO 198-18 SECTION 16: Safety and Health Training (Workers’ OSH Seminar) The Mandatory 8-hour Module conducted by the Safety Officer of the workplace as prescribed by the OSH Standards DO 198-18 SECTION 11: OSH Information (DO13 Section 12: Safety and Health Information) The employer, contractor or subcontractor, if any, shall provide the workers in all establishments, projects and all other places where work is being undertaken adequate and suitable information on Occupational Safety & Health DO 198-SECTION 12: OSH Program (OSHS Rule 1966 – Occupational Health Program) 1. Company Commitment to Comply with OSH Requirements 2. General Safety and Health Programs 3. Safety and health Hazard Identification, Risk Assessment and Control (HIRAC) 4. Medical Surveillance for early detection and management of occupational and work-related diseases 5. First aid and emergency medical services 6. Promotion of Drug Free workplace, Mental health Services in the Workplace, Healthy lifestyle 7. Prevention and Control of HIV AIDS, Tuberculosis, Hepatitis B 8. Composition and Duties of Health and Safety Committee 9. OSH Personnel and Facilities 10. Safety and Health Promotion, Training and Education 11. Orientation of all workers on OSH 12. Conduct of Risk Assessment, evaluation and Control 13. Continuing training on OSH for OSH Personnel 14. Work permit System 15. Toolbox/Safety Meetings, job safety analysis A toolbox meeting is a briefing of safety measures to supervisors, workers, and safety team held every morning before commencing their respective duties. 21.0 WORKPLACE EMERGENCY PREPAREDNESS Definition of Terms: Emergency A serious situation or occurrence that demands immediate action. Disaster It is the result of a calamitous event causing massive death, injury or damage. Natural emergencies 1. Flood 2. Volcanic eruption 3. Earthquake 4. Typhoon 5. Drought 6. Tsunamis Man Made Emergencies - These can be a result of human error or willful intent 1. Industrial fires 2. Chemical spills / leaks 3. Chemical threat 4. Bomb threats / explosions 5. Structure collapse 6. Construction cave-in 7. Biological threats POLICE The agency who deal with security of person and property, which can cover all the categories of emergency. They also to some extent deal with punishment of those who cause an emergency through their deliberate actions. FIRE SERVICE Who deal with potentially harmful fires, but also often rescue operations such as dealing with road traffic collision. Their actions help to prevent loss of life, damage to health and damage to or loss of property. EMERGENCY MEDICAL SERVICE These services attempt to reduce loss of life or damage to health. This service is likely to be decisive in attempts to prevent loss of life and damage to health. In some areas "Emergency Medical Service" is abbreviated to simply EMS. Summary: 1. The best way to minimize potential loss is Advance Planning for Emergencies 2. Practicing your emergency responses avoids panic and confusion 22.0 ROLES OF CONSTRUCTION SAFETY AND HEALTH OFFICERS DO 198-2018: Section 3 - DEFINITION OF TERMS SAFETY OFFICER 1. Refers to any employee or officer of the company trained by DOLE or DOLEAccredited Training Organization and tasked by the employer to implement an OSH program, and ensure that it is in accordance with the provisions of OSH standards. 2. A person engaged in the prevention of accidents, incidents and events that harm people, property or the environment. 3. Is one who applies the expertise gained from a study of safety sciences, principles and practices and from professional safety experiences. SAFETY OFFICER RELATIONSHIPS INSIDE THE COMPANY 1. With the Site Manager The Safety Officer is accountable to this executive for the proper interpretation and fulfillment of the duties and responsibilities of this position and related authority, in concurrence with the dictates of the corporate manager of safety and hygiene (if such a position exists within the corporation). 2. With Department Heads and Supervisors The Safety Officer is responsible for providing advice and guidance about safety and industrial hygiene appropriate to their processes, installations, and procedures of the construction site. 3. With Department Heads and Supervisors The Safety Officer is responsible for providing advice and guidance about safety and industrial hygiene appropriate to their processes, installations, and procedures of the construction site. 4. With Employees The Safety Officer is responsible for providing advice and guidance about any employee's specific job or work area in the interest of preventing accidents and controlling property damage. 5. Outside the Company Here, the Safety Officer must establish appropriate relationships with professional and organizational groups. The Primary Duty of a Safety Officer 1. Secretary to the Health and Safety Committee: 1.1. Prepare minutes of the meeting 1.2. Report status of recommendation made; 1.3. Notify members of the meetings 2. Submit to the employer a report of the activities of the committee, including recommendations made. 3. Acts in an advisory capacity on all matters pertaining to health and safety for the guidance of the employer and the workers. 4. Conducts investigation of accidents as member of the health and safety committee and submits his separate report and analysis of accidents to the employer 5. Coordinates all health and safety training programs for the employees and employer. 6. Conducts health and safety inspection as member of the committee. 7. Maintains or helps in the maintenance if an efficient accident record system and coordinates action taken by supervisors to eliminate accident causes. ACCOUNTABILITY OF SAFETY OFFICERS 1. Reduction of the frequency and severity of accidents. The same criteria for measurement must be consistently used throughout the company. 2. Reduction of costs stemming from accidents. "Weightings" must be used to correct for dissimilarities between operations in different areas of the company. 3. The efficiency and smoothness of a department's operations within operations of the plant as a whole. DO 198-2018: Section 14 - SAFETY OFFICER Summary: 1. The Occupational Safety and Health Officer is the key person to developing a safety program 2. Promoting safe work practices improves employee motivate and participation on health and safety activities 23.0 EMPLOYEES COMPENSATION PROGRAM On to Employees’ Compensation Program (ECP), here to address workers who suffer injuries, illnesses and death when work-related. It was established as an improvement over the old Workmen’s Compensation Program (WCP), as created by a written policy (P.D. 626) under the Labor Code of the Philippines. Both programs provide benefits to workers in case of work-connected contingencies. Compensable Diseases: Under Annex “A” of PD 626 as amended: For an occupational disease and the resulting disability or death to be compensable, all of the following conditions must be satisfied: 1. The employee’s work and / or the working conditions must involve risk/s that caused the development of the illness; 2. The disease was contracted as a result of the employee’s exposure to described risks; 3. The disease was contracted within a period of exposure and under such other factors necessary to contract it; 4. There was no deliberate act on the part of the employee to disregard the safety measures or ignore established warning or precaution 5. Not any disease is compensable 6. Only diseases caused by work or the working environment is compensable 7. List of 32 Occupational Diseases with specific conditions set - conditions or risk factors on the job must be present for the disease to be compensable Newly amended rules in Annex “A” of PD 626: • Cardiovascular Diseases, BR No.11-05-13, May 26, 2011 • Cerebrovascular Accidents, BR No.11-05-13, May 26, 2011 • Essential Hypertension, BR No.11-05-13, May 26, 2011 • Tuberculosis (Pulmonary & Extra pulmonary) BR No.11-11- 29, Nov 28, 2011 • Pneumoconiosis BR No.12-09-18, Sept 27, 2012 • Pneumonia, BR No.12-09-18, Sept 27, 2012 • Occupational Asthma, BR No.12-09-18, Sept 27, 2012 • Asbestos-related Diseases, BR No.12-09-18, Sept 27, 2012 • Hypersensitivity Pneumonitis, BR No.12-09-18, Sept 27, Year 2012 • Byssinosis, BR No.12-09-18, Sept 27, 2012 • Other diseases not in the list may still be compensable if employee can establish causal connection with the nature of his work or the working environment. Compensable injuries: For the INJURY and the resulting disability or death to be compensable, the injury must be the result of an accident arising out of or in the course of employment. Work – Connected Injuries 1. Happened in the workplace 2. Happened while performing official function 3. Outside of workplace but performing an order of his employer 4. When going to or coming from work 5. While ministering to personal comfort 6. While in a company shuttle bus 7. During a company sponsored activity Progression of Illness (deterioration) or injury: Where the primary illness or injury is shown to have arisen in the course of employment, every natural consequence that flows from the illness or injury shall be deemed employment related. Excepting Instance: 1. Intoxication 2. Notorious negligence 3. Willful intent to injure oneself or another ECP Benefits: 1. Loss of Income Benefit 2. Medical Benefit 3. Career’s allowance 4. Death benefit 5. Rehabilitation service 1. Loss of income benefit - It is the incapacity to work (DISABILITY) as a result of the illness or injury that is being compensated. Types of Disability: 1. Total Temporary Disability TTD 2. Partial Total Disability PTD 3. Partial Permanent Disability PPD 2. Medical Benefits ▪ Ward services for hospital confinement ▪ Medical attendance by an accredited doctor ▪ Surgical expense benefit ▪ Reimbursement of cost of medicines 3. Career’s Allowance • Granted to employee who gets permanently and totally disabled and has difficulty taking care of basic personal needs • PhP1,000/month allowance for the private sector employees only (for public sector employees starting 2018) 4. Death Benefits • Monthly Income Benefit pension to beneficiary plus 10% for each dependent child not exceeding five • Funeral benefit of PhP20,000 for private sector; PhP3,000 for public sector (PhP20,000 for public sector starting May 31, 2013) 5. Rehabilitation Services for ODW’s What is the KAGABAY Program? It is a component of the ECP that extends Rehabilitation services to Occupationally Disabled Workers (ODW’s) Employees’ Compensation Commission 4th and 5th Flr, ECC Building, 355 Sen. Gil J. Puyat Avenue, Makati City Summary: 1. Employees Compensation is for Work-related injuries only 2. Proper documentation is required for filing a claim. 24.0 SALIENT FEATURES of OSH LEGISLATIONS Health and Safety Legislation is best discussed with the understanding provided through four (4) references, namely: 1. P.D.442, Labor Code of the Philippines; 2. Book IV, Title I (Chapter I, Medical & Dental Services – Chapter II: Occ. Safety & Health Standards 3. REPUBLIC ACT NO. 11058 ENTITLED “An Act Strengthening Compliance With Occupational Safety And Health Standards And Providing Penalties For Violations Thereof” and the 4. Implementing Rules and Regulations DOLE D.O. 198 series of 2018 Section 4A – DUTIES OF EMPLOYER 1. Capacity building of all workers including mandatory trainings; 2. Provision of information on OSH; 3. Use of devices/equipment with approved industry standards; 4. Compliance with all the requirements of the OSH Standards; 5. Provide appropriate DOLE tested & approved PPEs FREE of charge to the workers. Section 4B – DUTIES OF THE WORKER 1. Participate in capacity building activities on safety and health and 2. Comply with instructions to prevent accidents or imminent danger situations in the workplace 3. Observe prescribed steps to be taken in cases of emergency 4. Proper use of all safeguards and safety devices furnished for workers’ protection and that of others Section 4C – DUTIES OF OTHER PERSONS 1. Any other person, including the builder or contactor who visits, builds, renovates or installs devices or conducts business in any establishments or workplace, shall comply with the provisions of this Rules and all other regulations issued by the Secretary of Labor and Employment. 2. Whenever 2 or more undertakings are engaged in activities simultaneously in one 1 workplace, it shall be the duty of all concerned to collaborate and cooperate to ensure compliance with OSH standards and regulations, other OSH related topics and programs; 3. REPORT TO THEIR IMMEDIATE SUPERVISOR any work hazard that may be discovered in the workplace. WORKERS’ RIGHTS Section 5 - THE RIGHT TO KNOW: The different types of hazards in the workplace; Be provided with training, education and orientation; Section 6 - THE RIGHT TO REFUSE UNSAFE WORK: To refuse unsafe work without threat or reprisal from the employer in cases of imminent danger. Affected workers may be temporarily assigned to other work areas; Section 13 - OCCUPATIONAL SAFETY AND HEALTH COMMITTEE Section 15 - OCCUPATIONAL HEALTH PERSONNEL AND FACILITIES The employer may not establish an emergency hospital or dental clinic in the workplace where there is a hospital or dental clinic which is located not more than five (5) kilometers away from the workplace, accessible in not more than twenty-five (25) minutes travel time. Section 16 - SAFETY AND HEALTH TRAINING 1. First-Aider - Standard first aid training 2. OH Nurse - At least forty (40)-hour Basic OSH training course for OH Nurses 3. OH Dentist - At least forty (40)-hour Basic OSH training course 4. OH Physician - At least fifty-six (56)-hour Basic OSH training course for OH Physicians The workers’ OSH seminar and other trainings/orientations as required by the employer and by any law shall be at no cost on the worker and considered as compensable working time. Section 17 - OCCUPATIONAL SAFETY AND HEALTH REPORTS All employers, contractors or subcontractors, if any, shall submit to DOLE all safety and health reports, and notifications such as but not limited to: 1. Annual Medical Report (AMR); DOLEBWCHSDOH-47-A 2. Report of the Safety Organization; (RSO) the OSH Committee Report DOLEBWCOHSDIP-5 3. Employer’s Work Accident Illness Report (WAIR); DOLEBWCOHSDIP-6 4. Annual Work Accident or injury Exposure Data Report (AEDR). DOLEBWCOHSDIP6b 5. Government Safety Engineers Accident Investigation Report (Work-ALERT Form IP-6a_1) Section 21 - COST OF SAFETY AND HEALTH PROGRAM The total cost of implementing a duly approved OSH program shall be an integral part of the operations cost. It shall be separate pay item in construction and in all contracting or subcontracting arrangements. Section 29 - PROHIBITED ACTS AND ITS CORRESPONDING PENALTIES There shall be willful failure or refusal to comply with the OSH standards if the following exists: 25.0 DEVELOPMENT OF AN OCCUPATIONAL SAFETY & HEALTH PROGRAM Compulsory to all industries is the development and implementation of an OSH PROGRAM • Is a systematic plan to IDENTIFY, EVALUATE and CONTROL hazards and respond to EMERGENCIES. • It lays out responsibilities, resources, and procedures for keeping the workplace safe and healthy. DO 198-2018 SECTION 12: OSH Program Covered workplaces shall develop and implement a suitable OSH program in a format prescribed by DOLE which shall be posted in prominent places. A. For establishments with less than 10 workers and low risk establishments with 10-50 workers. – The OSH program, which shall be duly signed by the employer, must include at least the following: 1. Company commitment to comply with OSH requirements; 2. General safety and health programs, including: • Safety and health hazard identification, risk assessment and control (HIRAC), • Medical surveillance for early detection and management of occupational and work-related diseases, and • First aid and emergency medical services; 3. Promotion of the following health domains: • Drug-free workplace (RA 9165), • Mental health services in the workplace (RA 11036), and • Healthy lifestyle; 4. Prevention and control of the following health domains: • Human Immunodeficiency Virus and Acquired Immune Deficiency Syndrome (RA 8504), • Tuberculosis (EO 187-03), and • Hepatitis B (DOLE DA 05-2010); 5. Complete company or project details; 6. Composition and duties of the OSH committee; 7. OSH personnel and facilities; 8. Safety and health promotion, training and education, including: • Orientation of all workers on OSH, and • Conduct of risk assessment, evaluation and control; 9. Conduct of toolbox or safety meetings and job safety analysis, if applicable; 10. Accident/incident/illness investigation, recording and reporting; 11. Provision and use of PPE; 12. Provision of safety signage; 13. Provision of workers’ welfare facilities; 14. Emergency and disaster preparedness and mandated drills; 15. Solid waste management system; and 16. Control and management of hazards. B. For medium to high risk establishments with 10–50 workers and low to high risk establishments with 51 workers and above. – The OSH program, which shall be duly signed by the employer, must include at least the following: 17. Dust control and management, and regulations on activities such as building of temporary structures, and lifting and operation of electrical, mechanical, communications system, and other equipment; 18. Prohibited acts and penalties for violations; and 19. Cost of implementing company OSH program. Summary: 1. Developing an OSH program is a requirement of the Philippine Law 2. It serves to protect the worker and the employer. 3. Enforcement is one response, but not the only response!