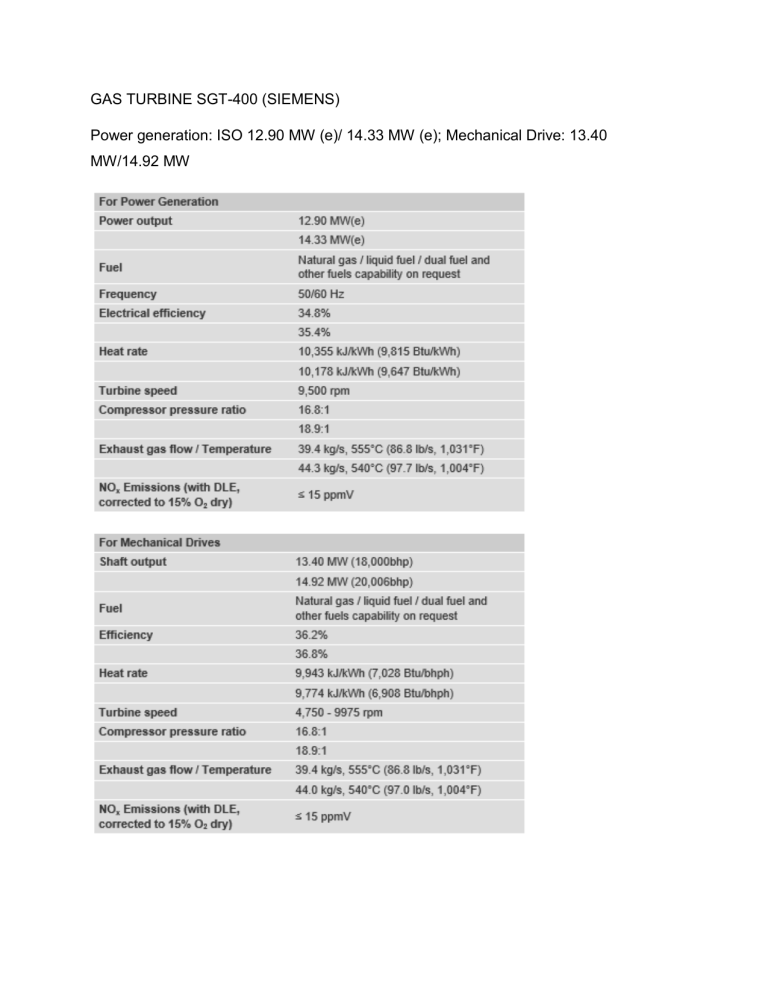

GAS TURBINE SGT-400 (SIEMENS) Power generation: ISO 12.90 MW (e)/ 14.33 MW (e); Mechanical Drive: 13.40 MW/14.92 MW Description Siemens gas turbine SGT-400. High availability and security of supply The Siemens twin-shaft industrial gas turbine SGT-400 is a blend of 25 years of experience and the latest combustion technologies. Compact gas generator Two-stage power turbine incorporating the latest aerodynamic and combustion technologies Turbine: Simple-cycle efficiency of up to nominally 35.4% Power generation: Power output of 12.90 MW(e) / 14.33 MW(e) Mechanical drive configuration: 13.40 MW / 14.92 MW Gas turbine: Equipped with a Dry Low Emissions (DLE) combustion system, achieving low NOX levels with gas and liquid fuels and a full dual-fuel capability The twin-shaft configuration of the SGT-400 provides excellent speed and load turndown flexibility: Uniquely simple design, employing a single gas generator rotor with twin bearings and a two-stage compressor turbine Free power turbine, two-stage overhung design Rotors are contained in heavy duty casings which are horizontally and vertically split, allowing full site maintenance Gas turbine equipped with a Dry Low Emissions (DLE) combustion system, achieving low NOx levels with gas and liquid fuels and a full dual-fuel capability With a power turbine speed of 4,800 to 10,000 rpm, generator or pump drive from the power turbine is usually via a speed-reducing gearbox Most compressor drive applications can be met without the need for a speedchanging gear SGT-400; ideal choice for a wide variety of application SGT-400: Ideal choice for a wide variety of applications. Benefits: Proven design resulting in high availability and security of supply Combines low emissions performance with a rugged industrial design Dual-fuel Dry Low Emissions (DLE) combustion system, meeting the most stringent legislation Twin-shaft arrangement for both power generation and mechanical drive, allowing commonality of parts in mixed duty installations Competitive cost-to-power ratio Compact size Site maintainability Alternate rapid core engine exchange option, minimizes downtime Power generation Siemens gas turbine SGT-400: High availability and security of supply In power generation the SGT-400 gas turbine benefits from the high simple-cycle efficiency (nominal up to 35.4 %) and its capability to operate on a wide range of gas fuel calorific values. For industrial cogeneration, the high steam-raising capability of more than 27 tones per hour contributes towards achieving overall plant efficiencies of 80 % or higher. In addition, the compact arrangement, on-site maintainability and inherent reliability of the SGT-400 have made it an ideal gas turbine for the demanding oil and gas industry. As a highly efficient unit the SGT-400 is used in the following fields of application: Simple-cycle applications Combined cycle applications Combined heat and power (CHP) Power generation for the oil and gas industry Onshore power generator for oil field service, refineries etc. Offshore platforms and FPSO vessels Mechanical drive The SGT-400 package for mechanical drive. The SGT-400 gas turbine is a proven unit for driving compressors and pumps, primarily for the oil and gas industry, both onshore and offshore. It offers cost-effective power and outstanding reliability, efficiency and maintainability for all mechanical drive applications. The turbine is designed to operate on a wide range of fuels. The twin-shaft configuration provides excellent speed and load turndown characteristics to allow maximum flexibility of operation. The SGT-400 mechanical drive package is very compact, providing a small footprint and a high power-to-weight ratio. Designed for applications where speeds and loads vary, the SGT-400 can operate over a range of different demands: Compressor applications Gas injection, gas processing and refrigeration projects utilizing Siemens bespoke centrifugal compressors (or other proprietary manufacturer’s compressors) Gas boost and gas transmission projects utilizing Siemens standard preengineered centrifugal pipeline compressors Pump applications Utilizing proprietary manufacturer’s driven unit pumps of Siemens or client choice, ideally suited to water injection and fluid transmission projects Maintenance Repairs, maintenance and customer support Multiple boroscope-inspection ports Site maintainability or optional rapid core exchange as required by customer Designed for maintenance: - Horizontally split compressor casing - Horizontally and vertically split inlet casing - Combustion chambers, flame tubes and igniters easily accessible for inspection - Large side-doors on enclosure for equipment change-out - Gas generator and power turbine removal on either side of package Customer Support Global support network of Authorized Service Centers Emergency service – 24 / 7 specialist helpdesk Full field service Remote diagnostic service available, including collaborative troubleshooting and remote problem solving OEM modernizations and upgrades In-house or on-site training programs Range of maintenance and service contracts available Combustion burners, chambers and igniters easily accessible for inspection Large side-doors on enclosure for equipment change-out Gas generator and power turbine removal on either side of package Vertical split between gas generator and power Designed for ease of access to turbine sections. Horizontally split compressor casing Horizontally and vertically split inlet casing