Specialty Materials: Dielectrics, Magnetics, Composites, Semiconductors

advertisement

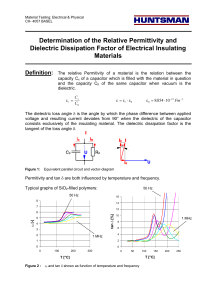

Module X : Specialty Materials Dielectrics & insulating materials – Characteristics; Ceramics – Mica and glass; Magnetic materials – basis of magnetism – Soft and hard magnetic materials; Composites : Classification – Particulate, fibrous and laminated composites – Hybrid composites – Application of composites in electrical and electronic components; Semiconductors – Extensive and intensive; Metallic solids –Characteristics Dielectrics Electrically insulating materials Materials which are used to prevent loss of electricity through certain parts in an electrical system Electrical insulating materials having an electrical conductivity of < 10-6 mho per cm and they act as stores of electrical charges In these materials, it is almost not possible to excite the electrons from the valence band to conduction band by an applied field Generally dielectrics are also called as insulators, thereby poor conductors of electricity. However they allow movement of some electrons at abnormally high temperatures, causing a small flow of current • Solid Dielectrics – Ceramic, Plastic, Mica, Glass and Ebonite – hard rubber • Dielectric Liquid – Distilled Water • Dielectric Gas – Dry Air, vacuum, nitrogen and helium All dielectric materials are insulating materials The difference between a dielectric and an insulator lies in their applications If the main function of non-conducting material is to provide electrical insulation, then they are called as insulator On the other hand, if the main function of non-conducting material is to store electrical charges then they are called as dielectrics The dielectric materials can be classified into • Active dielectrics When a dielectric material is kept in an external electric field, if it actively accepts the electricity, then it is known as active dielectric material Thus, active dielectrics are the dielectrics, which can easily adapt themselves to store the electrical energy in it Ex : Piezoelectric materials • Passive dielectrics Passive dielectrics are the dielectrics, which restrict the flow of electrical energy in them. So, these dielectrics act as insulators Ex : All insulating materials such as glass, mica, rubber etc., Properties • Generally, the dielectrics are non-metallic materials of high resistivity • They have a very large energy gap (more than 3eV) • All the electrons in the dielectrics are tightly bound to their parent nucleus • As there are no free electrons to carry the current, the electrical conductivity of dielectrics is very low • They have negative temperature coefficient of resistance and high insulation resistance The choice of dielectrics depends on mechanical, electrical, chemical and thermal properties Characteristics of dielectrics 1. Resistivity It is the reciprocal of conductivity (capacity of a material to conduct the electric current) because a good resister possesses low conductivity or high resistivity Based on the measurement of flow of direct current into the insulation after electrification of 1 min Have insulation resistance ranging from 109 to 1020 ohm.cm at room temperature In general, low insulation resistance materials deteriorates very fast under weathering conditions 2. Dielectric polarization When an electric field is applied to a dielectric material, there is a change or displacement that takes place within the material through induced dipole, called dielectric polarization This displacement takes place in such a way that negative charges move towards positive electrode and vice versa Since the charges are not free to move, they do not flow but the interior of the body becomes non - equipotential 3. Dielectric constant It is a measure of polarisation of the dielectrics The capacity of a material to store electric charge in the presence of an electric field Ratio of the electrical capacity of the condenser containing the material to the capacity of the same conductor with the material replaced by vacuum (Or) Dielectric constant = Absolute permittivity (ε) / Permittivity of free space (εo ) εr =ε/εo Permittivity represents polarizable nature of material Its unit is farad/metre 4. Dielectric strength The electrical strength that must be applied to cause disruptive effect or discharge or accumulate current through the body of a material 5. Dielectric losses Caused due to absorption of electrical energy (under an alternating current gives rise to dissipation of electrical energy in the insulating material) and by the leakage of current through the insulating material (as a result of conduction) – electric shock during rainy season A measure of the power loss in the insulation and it should be low Very important in high voltage cables 7. Heat and temperature resistance Some heat is always generated even in insulators used at low T Hence insulators used must be capable of resisting the heat as well as temperature increase 8. Thermal aging The insulators become weak as well as less serviceable because of working at elevated T for long times or in contact with O2 or air A good insulator should have less thermal aging 9. Mechanical strength A measure of tensile strength and compressive strength of an insulator It depends on – • High T and humidity (should be non – hygroscopic) • Viscosity in case the dielectric is a liquid • Porosity (less porous, otherwise moisture enters into pores) • Least thermal expansion and contraction • Chemically inert to action of oils, solvents, acid, alkalis, etc., Selection of a dielectric material • Should have high value of dielectric constant. It determines the capacity to develop charges on its surface due to polarization • Should have low dissipation factor – lower the dissipation factor, smaller is the dielectric loss • Should have sufficiently high dielectric strength – higher the strength, greater is the voltage per unit thickness (it can withstand before breakdown) • Should have high insulating resistance – higher the insulating resistance, lower is the leakage current through the dielectric Applications of Dielectric Material • These are used for energy storage in capacitors • To enhance the performance of a semiconductor device, high permittivity dielectric materials are used • Dielectrics are used in Liquid Crystal Displays • Ceramic dielectric is used in Dielectric Resonator Oscillator - the frequency determining element, to produce signals with excellent signal stability (used widely in today's electronic warfare, missile, radar and communication systems) • Barium Strontium Titanate thin films are dielectric which are used in microwave tunable devices providing high tunability and low leakage current • Parylene (polymer with benzene ring attached with c=c on either sides) is used in industrial coatings acts as a barrier between the substrate and the external environment • In electrical transformers, mineral oils are used as a liquid dielectric and they assist in the cooling process • Castor oil is used in high-voltage capacitors to increase its capacitance value • Electrets, a specially processed dielectric material acts as electrostatic equivalent to magnets Insulating materials – materials in which electrical conduction does not occur Classification Insulating materials Gaseous Flexible Liquid Hard Heat insensitive (paper, mica, MgO) Thermosetting Solid Thermoplastic Rigid (glass, mica, porcelain, thermosetting) Based on the function, insulating materials are classified into – Thermal insulators and Electrical insulators I. Gaseous insulating materials Ex : Air, N2, H2, CO2 Dielectric air provides insulation between the over head transmission lines very cheaply The life of an electrical equipment is reduced by the O2 present in air, which leads to oxidation Similarly, if air is used in conjugation with an oil, then oxidation of oil causes sludge formation which leads to loss of mechanical stability of electrical equipment H2 is used to reduce windage losses in rotating machinery N2 is used in place of air – O2 causes oxidation CO2 is used in flexed capacitors and as pre impregnant of oil filled high voltage cables and transformers II. Liquid insulating materials Used for eliminating the air or other gases or heat transfer purposes Generally used in conjugation with solid insulants Classified according to the temperature range in which they are used i) Mineral oils (HC oils) Used in the temperature range of – 50 oC to 110 oC The electrical properties and resistance to thermal expansion are influenced by the presence of non – hydrocarbon compounds – O, N, S, etc Widely used in transformers, circuit breakers (an electrical switch designed to protect an electrical circuit from damage caused by overcurrent/overload or short circuit), switch gears (a device that is used to switch, control and protect the circuits as well as devices), capacitors, etc Circuit breakers Switch gears Arc resitance ii) Askarels – synthetic fire resistant materials Non inflammable synthetic insulating liquid used in the temperature range of – 50 oC to 110 oC Chlorinated HC are the most widely used dielectrics because of their excellent arc resistance (the ability of an insulating material to withstand a high voltage electric arc and resist the formation of a conducting path along its surface), high dielectric strength, low dielectric constant (4-6) and small dielectric loss at ordinary T iii) Silicone fluids Used in the T range of – 90 oC to 220 oC, non conductive to metals upto 200 oC Disadv : broken down into H2, C, SiC and SiO2, can’t be used as switch gear oils iv) Fluorinated liquids Used in the T range of – 50 oC to 200 oC Non inflammable and highly chemically stable Provide much better heat transfer from the windings and magnetic circuits in comparison with HC and silicone oils Disadv : highly volatile and get deteriorated in presence of moisture v) Vegetable oils The oldest insulating liquids and used in the T range of – 20 oC to 100 oC Drying oils (linseed, tung oil, etc) are suitable in the formulations of insulating varnishes (used in transformers & motor coils - machine which is used to change the energy from electrical to mechanical) Non drying oils are used as plasticisers in insulating resin composites III. Solid insulating materials Classified according to the T up to which they can be used Limiting temperature – T up to which insulating properties can be retained i) Power and press boards Made from wood cellulose Ex : paper, card boards Paper is used as an insulation in multilayers in the form of oil impregnated from moisture by a lead sheath, generally used at voltages above 15,000 V Vulcanized fibre sheet or board – treating paper with a solution of ZnCl2 and then pressing to get a thickness of 1.5 – 25 mm This board has good mechanical strength when impregnated with diphenyls and vegetable oils ii) Fibrous insulators Ex : silk, cotton, wool, jute, rayon, nylon, fibre glass These are used for their high mechanical strength, flexibility, durability with extreme finesse and easy processing Disadv : low dielectric strength and moisture absorption But inorganic fibrous materials such as glass fibre and asbestos (hydrated aluminium silicate) can be used at high T, up to 180 oC Varnish glass cloth has been employed in winding of those electric machines which work at high T iii) Varnished Cambrics – linen or cotton fabric with varnish or insulating oil Used as a series of thin layers But they need protection from moisture and generally used at low voltages only iv) Flexible insulating materials a) Natural resins – Rosins (varnish manufacturing), Shellac (good adhesive property), Amber (manufacturing instruments), etc b) Rubber compounds For specific purposes, they are changed from plastic form to elastic compound by combination with S Synthetic rubber are also used for their chemical resistance and dielectric strength Ex : Silicone rubber, butadiene rubber, chloroprene rubber v) Synthetic resins Extremely flexible, high tear strength and tensile strength a) Polyethylene An important insulating material for high frequency applications Possesses dielectric constant of 2.3 and its low electrical losses are so good at radio frequencies, less hygroscopic Available in the form of powder, sheet, film, rod, pellet, tube and foam Disadv : can’t withstand high T and melts at 110 oC, but cross linking PE is used for high voltage application Its stiffness is a handicap, Degraded by oxidation Undergoes cracking during service because of actions of greases and HC Uses As radio frequency insulator in radio, television and communication circuit cables In power cables and submarine cables, etc b) Teflon An ideal dielectric material with dielectric constant of 2 – 2.2 The most thermally and chemically stable insulator Because of its stiffness, it must be used in thin layers Withstand high T above 200 oC than any other semi flexible insulation Available in the form of tapes, rods, sheets, tubing's and moulds Electrically stable up to 327 oC (m.pt) Can be readily machined but can be moulded with difficulty Uses As capacitor dielectrics and insulating material for almost all kinds of windings Heat resistant materials are made by combining Teflon with glass cloth vi) Rigid insulators a) Glass – amorphous material, a mixture of silicates, phosphates, borates and other materials b) Ceramics Properties of electrical insulation I. Electrical properties a) Resistivity Even the best electrical insulating materials allow some current to pass when a voltage is applied due to presence of ions (polarization) but conductivity is small when compared to a metal The resistivity of a insulating materials decreases as the T increases b) Surface resistivity There are two types of conductance i) Bulk conductance – conductance offered by the entire insulating material. It is large ii) Surface conductance – conductance across its surface. It is small, except water and ionizable impurities are present To avoid surface conductivity, the surface path length of an insulator is increased by making the surface into series of ridges and valleys c) Dissipation factor When electric current is passed through an electric cable, some current will flow across the insulating material called leakage current This leakage current will be opposed by the insulating material so that heat will be produced which will be dissipated into the atmospheric air This heat loss is measured by a parameter called dissipation factor For an ideal insulating material, it should be as low as possible II. Thermal conductivity Heat generated in an electrical equipment must be dissipated by thermal conductivity to avoid overheating and damage to equipment In general, dielectrics are poor conductor of heat therefore, it is necessary to add filler to an electric insulating material to dissipate the heat For ex., inorganic fillers are added to organic insulators to increase thermal conductivity Liquid and gaseous insulators are used as coolants. Ex : transformer oil, H2, He, SF6 in transformer to protect electric arc III. Chemical properties Dielectrics should be resistance to oils, liquids, gas fumes, acid and alkalis Sometimes, acid fumes are generated To withstand it, epoxy resins insulators are used Organic dielectrics are flammable. In order to prevent flammability due to short circuit, these dielectrics are filled with Antimony trioxide or other fillers Dielectrics should be resistance to water Reactions with water can degrade/destroy any insulating materials IV. Mechanical properties Flexibility, tear & tensile strength, shear strength & abrasive resistance are the most important mechanical properties required by dielectrics For electrical machines, dielectrics should have sufficient mechanical strength to withstand vibration For cables, flexibility is very important Ceramics Means burnt materials Made from burning clay materials (inorganic silicates, metallic oxides and their combinations – carbides, borides and nitrides) Ceramics are any inorganic, non metallic solids produced by burning at elevated T Hard, strong, dense and brittle Either crystalline or amorphous and thermoplastic in nature Possess excellent dielectric and mechanical properties Dielectric constant varies between 4 – 10 Components A fine grained or plastic portion – imparts plasticity and workability – clay A crystalline or non plastic portion – contributes mechanical strength – silica A flux or glassy material – helps in bonding and cementing the ingredients together - Feldspar Classification of ceramics Based on their composition, ceramics are classified as Oxides, Carbides, Nitrides, Sulfides (MoS2), Fluorides ( KAlSi3O8 or NaAlSiO3 or CaAl2Si2O8), etc. Based on application Traditional ceramics are made from three basic components: clay, silica (flint) and feldspar Engineering ceramics consist of highly pure compounds of aluminium oxide (Al2O3), silicon carbide (SiC) and silicon nitride (Si3N4) Based on application Glasses Glasses are a familiar group of ceramics – containers, windows, mirrors, lenses, etc They are non-crystalline silicates containing other oxides, usually CaO, Na2O, K2O and Al2O3 which influence the glass properties and its colour Clay products It is found in great abundance and popular because of ease with which products are made Clay products are mainly two kinds – structural products (bricks, tiles, sewer pipes) and white- wares (porcelain, chinaware, pottery, etc.) Abrasive ceramics These are used to grind, wear, or cut away other material The prime requisite for this group of materials is hardness or wear resistance in addition to high toughness (hardness is expressed in mho scale, Diamond - 10) As they may also exposed to high temperatures, they need to exhibit some refractoriness Diamond, silicon carbide, tungsten carbide, silica sand, aluminium oxide / corundum are some typical examples of abrasive ceramic Refractories They have capacity to withstand high temperatures without melting or decomposing; and their inertness in severe environments Thermal insulation is also an important functionality Cements cement, plaster of paris (CaSO4)2.H2O) and lime come under this group of ceramics The characteristic property of these materials is that when they are mixed with water, they form slurry which sets subsequently and hardens finally Thus it is possible to form virtually any shape They are also used as bonding phase, for example between construction bricks of refractories Cement Plaster of paris Lime Applications of ceramic materials • Alumina (Al2O3) - is used in many applications such as to contain molten metal, where material is operated at very high temperatures under heavy loads, as insulators in spark plugs, and in some unique applications such as dental and medical use. Chromium doped alumina is used for making lasers • Aluminium nitride (AlN) - because of its good electrical insulation and high thermal conductivity, it is used in many electronic applications such as in electrical circuits operating at a high frequency. It is also suitable for integrated circuits • Diamond (C) - is the hardest material known in nature. It has many applications such as industrial abrasives, cutting tools, abrasion resistant coatings, etc. it is also used in jewellery • Lead zirconium titanate (PZT) - is the most widely used piezoelectric material, and is used as gas igniters, ultrasound imaging, in underwater detectors • Silica (SiO2) - Silica-based materials are used in thermal insulation, abrasives, laboratory glassware, etc. it also found application in communications media as integral part of optical fibers. Fine particles of silica are used in tires, paints, etc. • Silicon carbide (SiC) - one of best ceramic material for very high temperature applications. It is used as coatings on other material for protection from extreme temperatures. It is also used as abrasive material. It is used as reinforcement in many metallic and ceramic based composites. It is a semiconductor and often used in high temperature electronics. Silicon nitride (Si3N4) has properties similar to those of SiC but is somewhat lower, and found applications in such as automotive and gas turbine engines • Titanium oxide (TiO2) - mostly found as pigment in paints. It also forms part of certain glass ceramics. It is used to making other ceramics like BaTiO3 • Titanium boride (TiB2) - exhibits great toughness properties and hence found applications in armour production. It is also a good conductor of both electricity and heat • Uranium oxide (UO2) - mainly used as nuclear reactor fuel. It has exceptional dimensional stability because its crystal structure can accommodate the products of fission process • Yttrium aluminium garnet (YAG, Y3Al5O12) - has main application in lasers (Nd-YAG lasers) • Zirconia (ZrO2) - used in producing many other ceramic materials. It is also used in making oxygen gas sensors, as additive in many electronic ceramics. Its single crystals are part of jewellery Mica An inorganic mineral compound Group of minerals which are physically and chemically similar – silicates of alumina with silicates of soda potash and magnesia Exhibits two dimensional sheet or layer structure General formula – XY2-3Z4O10 (OH, F)2 X – K, Na, Ba, Cs, (H3O), (NH4) X – Na – common mica Ca – brittle mica Y – Al, Mg, Fe2+, Li, Cr, Mn, V, Zn Lepidolite Z – Si, Al, Fe3+, Be, Ti Ex : Muscovite – KAl2 (Si3 Al) O10 (OH, F)2 Lepidolite - K(Li,Al)3(Al,Si,Rb)4O10(F,OH)2 Phlogopite - K2Mg6(Si6Al2O20)(OH)4 Phlogopite Muscovite General properties • Crystalline in nature • Can be split into very thin flat sheets • Rigid, tough and strong • Excellent naturally occurring insulating material • Dielectric constant varies from 5 – 7.5 • Since it is a sheet mineral, it can be split into strong, flexible film having high T resistance and electrical insulation property • Chemically inert, elastic dielectric, flexible, hydrophilic and light weight Mica products 1. Mica sheets/micanites Produced by applying shellac (a yellow natural resin produced by the lac insect – polyhydroxy organic acid + wax) on either sides of the mica to form a sheet Paper/cloth is glued on one side/both sides of the sheet to increase the tensile strength of sheet mica Used in electrical equipment and applications in the form of washers, spacers, tubes, etc 2. Mica tapes/wrappers Very thin materials, which can be impregnated with resin Good dielectric strength, thermal conductivity Low dissipation factor Used in insulating high voltage coils, motors and other areas of rotating machines Used for making of fire resistant cable 3. Mica paper Since mica is crystalline in nature, it lacks flexibility To improve its flexibility, mica is broken into small pieces in aqueous solution and then formed into thin sheet by applying heat and pressure It is then rolled in the form of paper Has excellent insulating property – both thermal and electrical High T resistant, up to 1,000 oC High tensile strength Has good resin penetration and air permeability Used in transformers, capacitors 4. Glass bonded mica Consists of glass and mica in the ratio from 40:60 to 60:40 Prepared by heating a mixture of powdered glass and grounded mica to a plastic state (600 oC) and then compressed/moulded Has the lowest tensile strength and the highest thermal conductivity among glass and glass ceramics Applications of mica • The worlds largest mica deposits are found in igneous, sedimentary and metamorphic rocks found in Bihar and Nellore districts • Sheet mica has been used as electrical condensers as insulation sheets between commutator segments or in heating factors • Sheets of Muscovite are applied in optical instruments • Lepidolite is used for manufacture of warmth resistant glass • Phlogopite is used for spark plugs • Mica capacitors are low loss capacitors which are used where the high frequency is required and their value does not change much over time • Electrical components - includes transistors, where mica can be used to amplify particular signals and block out others. Also commonly used as insulation in power diodes, semiconductors and rectifiers. Mica can help to fully insulate semiconductors from their chassis, helping to dissipate heat and keep the components cool • It is one of the important ingredient in makeup and various cosmetics. It gives a shimmery effect and adds sparkle • To have attractive background of your scrapbook mix water and mica powder and spray it on the scrapbook. Mix in oil paint to give extra painting effects Mica products Mica plates Mica sheet Capacitor Cosmetics Mica tube Paints Glass Glass is a super cooled liquid of infinite viscosity ∆, 1650 𝑜𝐶, 𝑒𝑙𝑒𝑐𝑡𝑟𝑖𝑐 𝑓𝑢𝑟𝑛𝑐𝑒 Quarz/SiO2 → colourless liquid cooled rapidly → clear colourless, glassy mass (super cooled liquid) Quartz glass Quartz glass is used for manufacture of laboratory apparatus, it can withstand rapid changes of T Amorphous, hard, brittle and transparent substance Chemically inert, absorb, reflect and transmit light Has no definite melting point Defined physically as a hard, rigid, under cold, brittle, non crystalline substance having no definite m.pt and sufficiently high viscosity to prevent crystallisation Chemically as a fused mixture of silicates, alkali and alkaline earth compounds and other glass constituents such as CaO, MgO, SnO2, BaO, PbO High electrical insulation and low thermal conductivity Capacity of absorbing decorative colours without loss of transparency Widely used in electrical industries because of its low dielectric loss and slow ageing Important glasses for insulating purposes 1. Lead/Flint glass Prepared by mixing Lead oxide, Silica and alkali with Lead content as high as 92% Properties High refractive index, ratio of velocity of light in vacuum to velocity in a specific medium Low hardness, high dissipation factor High density (8), low softening temperature Uses Used in optical work because of their high index of refraction and high dispersion Used in manufacture of electric bulbs, neon tubing and radiators because of high electric resistance Used as a shield to protect from X-rays and 𝛄 rays in medical and atomic fields respectively 2. Borosilicate/Pyrex/Jena glass Prepared by fusing Silica (80%) and B2O3 (10-20%) with Alumina (3%), K2O (3%) and Na2O Properties Possess low thermal coefficient of expansion and high chemical resistance (get better result by replacing Na2O by more B2O3 & Alumina) Also possess very high softening points and excellent resistivity (shock proof) Uses Used in manufacture of baking dishes (kitchen wares), laboratory glassware, insulators and washers Manufacture of pharmaceutical containers like syringes, vials etc, because of their chemical inertness A good material in fabricating slides and lenses for microscopes, telescopes and other optical devices Modern high powered flash lights and studio spotlights Applications 3. Glass wool A fibrous wool like material Composed of intermingled fine threads or filaments of glass using a binder Obtained by forcing molten mass of glass through small orifices The glass wool formed in this way is carried away by a conveyor belt on which it is hurled Properties Non-combustible, fire proof, low electrical conductivity and heat proof material Does not absorb moisture and water, High tensile strength (18 times that of steel) Chemically resistant to a number of chemicals Uses Used for electrical, heat and sound insulation purposes Ex : domestic and industrial appliances like oven, motors, vacuum cleaners, insulating metal pipelines, walls and roof of houses Used for filtration of corrosive liquids such as acids and alkalies Manufacturing fibre glass by blending with resins Applications Fibre glass 4. Vitreosil/99.5% Silica glass Prepared by heating pure sand (SiO2) to its melting point (> 1750 oC) Can’t be shaped easily because of high viscosity of the glass and bubbles formation due to absence of flux. The final product is translucent When heated for a long time above its m.pt, a transparent glass known as clear silica glass is obtained Uses Used for chemical plants, chemical lab wares and for electrical insulating materials in electrical heaters and furnaces (heat is applied by induction heating of metal) Magnetic materials Those materials which are attracted by magnets and can be magnetized easily Show the existence of magnetic field around them when they are magnetized Ex : Pure Iron, Nickel-Iron ally, Cobalt steel, Chromium steel Basis of magnetism Magnetism is associated with the electrons in the atoms Atoms are believed to be tiny bar magnets or magnetic dipoles each having North & South poles In the unmagnetized state (randomly oriented), tiny atomic magnets are oriented randomly Magnetic effect of one atom cancels other atom therefore, material as a whole is non magnetic In the horizontally oriented state, N pole of one atom faces S pole of another Each row of atoms form a thin magnet and many parallel horizontal rows form a single composite magnet If the applied magnetic field is removed – Some magnetic materials lose their magnetism due to change in magnetic orientation ie horizontal to random Some materials do not lose their magnetism but magnetism is lost either by heat or physical shock Curie temperature - temperature beyond which a magnetic material loses its magnetic power For Iron, Curie T is 799 oC Classification of magnetic material Classification of magnetic material Based on relative permeability Ferro magnetic Para magnetic Diamagnetic Based on application Soft magnetic materials Hard magnetic materials Permeability – the measure of the ability of a material to support the formation of a magnetic field within itself A degree of magnetization that a material obtains in response to an applied magnetic field Diamagnetic materials The relative permeability is slightly less than unity When a substance is placed in an electric field, it induces a charge in the orbital motion of the electron and produces a temporary magnetism in the substance When the substance is taken away from the external field, the substance loses its magnetic property The net magnetic moment is zero in diamagnetic substance because when an external field, H is applied to a diamagnetic substance then the magnetic moment of electrons is aligned to the opposite direction of the applied field Diamagnetic Substances produce negative magnetization, χm Ex : Cu, Ag, Au, etc Paramagnetic materials The relative permeability is slightly greater than unity Each atom in a magnetic material possesses a permanent dipole moment due to incomplete cancellation of electron spin and orbital magnetic moment Therefore in the absence of an electrical field, orientation of magnetic moment is random They freely rotate and give rise to para magnetism Produce positive magnetization Ex : Al, Cr, Mo, Ti, Zr– they are not used in electrical engineering field Ferromagnetic materials The relative permeability is greater than unity and depends on the applied field strength Materials which can retain their magnetism even after the magnetic filed is removed Produce very strong magnetization Ex: Fe, Co, Ni, Cr and their alloys However at one point or temperature the ferromagnetic materials tend to lose its magnetic properties (Curie point or Curie Temperature) Antiferromagnetic materials The magnetic moments are aligned in opposite directions and are equal in magnitude In presence of H, these materials are weakly magnetized in the direction of the field Ex : MnO, FeO, CoO, NiO Soft magnetic materials Easy to magnetize but lose their magnetism quickly and completely when the applied filed is removed Therefore they can be magnetized and demagnetized easily Used in electric motors, generators, transformers, telephone receivers, radars, etc., Ex : soft iron, wrought iron, Iron-Silicon alloy, Iron-Nickel alloy, Ferrites (FeO with oxides of Co, Ni) Hard magnetic materials Materials which retain their magnetism even after removal of the external field Used to make permanent magnets Used in loud speakers, electrical measuring instruments Ex : carbon steel, Tungsten steel Pressed/sintered metal powder magnets – compressing metal particles inside a solid mass at a T < m.pt B – induced magnetic field, H – applied magnetic field Semiconductors Electrical conductivity of a material is classified into insulators, conductor and semiconductor based on the distance between valence band and the conduction band (energy gap – amount of energy a valence electron must have in order to jump from valence to conduction band) Fermi level - the highest energy level that an electron can occupy at the absolute 0 T It lies between the valence band and conduction band because at absolute 0 T, the electrons are all in the lowest energy state Due to lack of sufficient energy at 0 Kelvin, the Fermi level can be considered as the sea of fermions (or electrons) above which no electrons exist Differences between conductor, semiconductor and insulator Conductor Semiconductor insulator Easily conducts electric current Conductivity lies between Does not conduct electrical conductor and insulator current under normal conditions Single element materials – Cu, Pure intrinsic state is neither a Valence e- are tightly bound to Ag, Au, etc good conductor nor insulator the atom. Therefore few free Single element SC – Sb, As, B, e- are available for conduction Po, Te, Si, Ge (4 valence e-) Once valence electron is Compound SC – Gallium Most insulators are arsenide, Indium phosphide, compounds rather than single loosely bound to the atom Therefore, a small amount of SiC, Gallium nitride, SiGe element materials energy is required to free the electron from the atom Ex : Glass, mica, rubber Since they overlap, electron in The band gap is small so that The gap is crossed only when a the valence band move freely when a valence e- absorbs a very high voltage is applied into the conduction band photon, it crosses the gap Types of semiconductor I. Intrinsic semiconductor Extremely pure elements like Si, Ge, Se having 4 valence e- in their atom Their forbidden gap energy is about 1 ev Also called an undoped semiconductor or i-type semiconductor Have crystalline structure in which each atom forms four covalent bonds by sharing with four neighbouring atoms As the temperature of the semiconductor is increased, the e- gain more thermal energy and thus break free from their shell The process of ionization of the atoms in the crystal lattice creates a vacancy in the bond between the atoms The position from which the e- gets excited leaves a hole which is occupied by a nearby e- and this process continues The e- gets excited goes to conduction band thus leaving a hole in valence band In this way, the hole travel from one atom to another In the intrinsic SC, the number of free e- is equal to the number of holes ne- = nh = ni When the T of an intrinsic SC is 0 K, it behaves like an insulator, T > 0 K, the e- gets excited Similarly, when an electric field is applied across an intrinsic SC at room T, e- in conduction band moves to the anode While the positive hole in the valence band moves to the cathode Hence current in an intrinsic SC consists of simultaneous movement of conduction band e- and valence band hole in opposite direction II. Extrinsic semiconductor The conductivity of SC can be improved by introducing a small number of atoms called impurities The process of adding impurity atoms to the pure SC is called Doping Generally, only 1 atom in 107 is replaced by a dopant The addition of dopant reduces the energy gap thereby allowing more e- to flow from valence to empty conduction band By appropriate doping, conductivity may be increased by 10,000 times Based on the nature of doping agent, the extrinsic SC is further classified into – a) n-type extrinsic semiconductor A pure SC – tetravalent (Si or Ge) is doped with a pentavalent impurity (P, As, Sb, Bi), 4 e- are used to form a bond with Si and the 5th e- remains loosely bound to the donor atom itself This e- is easily excited from valence band to conduction band when light is supplied Each P atom donates one free e-. The number of free e- depends on the amount of impurity (donor) added to the Si A small amount of impurity (P) generates millions of free e- Though n-type SC has large number of free e-, but these e- are given by dopant, which is electrically neutral Therefore, the total electric charge is also neutral b) p-type extrinsic semiconductor A trivalent impurity (B, Ga, In, Al) is added to an intrinsic SC, (Si), it is called p-type semiconductor B has 3 valence e-, they form 3 covalent bonds with the neighbouring 3 Si atoms leading a hole with the 4th Si atom This shows each B atom accepts one e- to fill the hole. Therefore, the dopant is called acceptor A small addition of impurity provides millions of holes Similar to n-type, p-type is also neutral The hole travels to adjacent Si atom leaving a new hole there Here the conduction is due to excitation of a hole Although the intrinsic SC is a pure SC it is not used for practical manufacturing as has low conductivity. The number of free charge carriers is less hence it has higher resistance to conduction of charges Whereas an extrinsic SC has greater conductivity as it has a number of free charge carriers. Hence external SC are preferred for practical manufacturing of SC components and devices Applications of semiconductor • Temperature sensors are made with semiconductor devices • They are used in 3D printing machines. Used in microchips and self-driving cars • Used in calculators, solar plates, computers and other electronic devices • Transistor and MOSFET (metal–oxide–semiconductor field-effect transistor – to switch electric signals) used as a switch in Electrical Circuits are manufactured using the semiconductors Metallic solids Metallic solids such as Cu, Al, Fe are formed by metal atoms Described as a uniform distribution of atomic nuclei within a ‘sea’ of delocalized eAtoms are held together by metallic bonding which give rise to high thermal and electrical conductivity, metallic lustre, malleability and hardness Bonding in metallic solids is different from other solids Valence e- are delocalized providing a strong cohesive force that holds the atoms together Electron is not bonded with any particular atom Very little energy is needed to remove e- from a solid metal When an electrical potential is applied, the e- can migrate through the solid toward the positive electrode, thus producing high electrical conductivity Therefore metallic solids consist of positive metal ions (kernels) in a cloud of valency e- (e- cloud) The positive ions will tend to repel one another, but are held together by the negatively charged electron cloud Na – 1s22s22p63s1 Properties of Metallic solids Many of the characteristic properties of metals are attributable to the non-localized or freeelectron character of the valence electrons Electrical conductivity Most metals are excellent electrical conductors because the electrons in the electron sea are free to move and carry charge Under the influence of electric field, delocalized valence e- move readily and conduct electricity throughout the metal from one end to the other (towards positive charge anode) Conductivity decreases with rise in T, because of increased thermal vibrations of the metal atoms cause scattering of e- thereby obstructing free flow of eThermal conductivity Metals conduct heat because the free electrons are able to transfer energy away from the heat source and also because vibrations of atoms move through a solid metal as a wave When one end of a metallic substance is heated, the kinetic energy of the electrons in that area increases. These electrons transfer their kinetic energies to other electrons in the sea via collisions Therefore heat travels from hotter to colder part of the metal Malleability and Ductility When an ionic crystal (NaCl) is beaten, it is broken into many smaller pieces. Because the atoms in the crystals are held together in a rigid lattice that is not easily deformed In the case of metals, the sea of electrons in the metallic bond enables the deformation of the lattice. Therefore, when metals are beaten, the rigid lattice is deformed and not fractured Metallic Luster When a beam of light falls on the surface of the metal, the electric field of light oscillates the e(at a wavelength) present on the metal surface Wavelength of e- is absorbed by the light and remaining light is transmitted Therefore metal surface exhibits shining appearance High Melting and Boiling Points The strong attraction between atoms in metallic bonds makes metals strong and gives them high density, high melting point, high boiling point, and low volatility The exceptions to this include zinc, cadmium, and mercury due to completed ns2 configuration Mercury is a liquid under ordinary conditions and has a high vapour pressure The metallic bond can retain its strength even when the metal is in its melt state For example, gallium melts at 29.76oC but boils only at 2400oC. Therefore, molten gallium is a non volatile liquid Composites A material which is composed of two or more materials at a microscopic scale and have chemically distinct phases Heterogeneous at a microscopic scale but statically homogeneous at macroscopic scale Constituent materials have significantly different properties Components which are made to form composites are mutually insoluble and form distinct phases properties of composites are determined by properties, amount, shape and size of the constituents Ex : Reinforced Concrete Cement (RCC) – steel is reinforced into concrete mixture to give strength Ball – rubber is embedded between cellulose material (cotton) to give more strength to rubber Natural composites Peanut husk, banana skin Wood – a strong and flexible cellulose is surrounded by soft protein, collagen Why do we need composite materials? • Strength • Stiffness • Toughness • Corrosion resistance • Wear resistance • Reduced weight • Fatigue life • Thermal/Electrical insulation and conductivity • Acoustic insulation • Energy dissipation • Attractiveness, cost •Tailorable properties Advantages • High strength, stiffness, toughness • Low electrical conductivity, thermal expansion • Corrosion and oxidation resistance • Reduced weight • Applications • Electronic circuit boards (PCB) • Marine, aeronautical applications • High temperature refractories Constituents of composites Composite Dispersed phase Matrix Metal Ceramic Polymer Carbon and graphite Fibre Particulates Flakes Whiskers Matrix • Contribute bulk of the composite, encloses the composite • Binds the dispersed phase • Distribute the applied external load to the dispersed phase • Protects the dispersed phase from chemical action, abrasion from environment • Prevents the propagation of brittle cracks due to its plasticity and softness Requirements • Ductile and corrosion resistant • High bonding strength between matrix phase and disperse phase Dispersed phase • Stronger and harder, determines the internal structure of composite • Contribute desired properties • Responsible for load carrying and transfer strength to matrix I. Fibre reinforced composites It consists of filament (high tensile strength/specific gravity), matrix and bonding agent (binds disperse phase to matrix) It has high aspect ratio, stiffness and specific modules Shape, orientation and composition of fibre decide property of composites Fibre Inorganic (high modulus, high thermal stability) Organic (low density, flexibility and elasticity) Polyester Aramid Carbon Natural (cotton, jute, hemp) Glass Ceramic Boron Metallic fibre Examples for Fibre reinforced polymer (FRP) 1. Glass fibre reinforced polymer The earliest known fibre The polymer can be either thermoplastic or thermosetting Glass fibre is used for improving the characteristics of polymer matrices – nylon, polyester, etc., Possesses lower density, high tensile strength, resistance to corrosion and chemicals Applications Automobile parts, storage tanks, plastic pipes, etc., Disadvantages Prone to breakage when subjected to high tensile stress for long time 2. Carbon fibre reinforced polymer Dispersed phase – graphite Gives excellent resistance to corrosion Lighter density, stiffest fibers known Properties of graphite remain unchanged even at very high T Applications Structural components of aircraft and helicopters, bicyle, motorcycle Sports materials – tennis racket Musical instruments strings Disadv Highly expensive 3. Aramid fibre reinforced polymer Aramid is a synthetic fiber made from the polymer aromatic polyamide It was first introduced in the 1960s as a meta-aramid and later as para-aramid Meta-aramid bonds are not aligned but are rather in a zigzag pattern and therefore will not develop the higher tensile strength of para-aramid bonds The trademark names of aramid fibers are Kevlar (para) and Nomex (meta) Properties A high heat, fire resistance and strong synthetic fibre Density is less than glass and granite fibres High tensile strength, high modulus, low weight and non conductive fibre Good resistance to abrasion But sensitive to acids, alkali and UV radiation Applications Making of helmets, hockey sticks, tennis strings and asbestos replacement 4. Alumina reinforced metal (matrix) composite Improved stiffness, abrasion resistance and creep resistance Used for making components of turbine engines Offers good compressive strength rather than tensile strength in automobiles 5. Metal reinforced composites Dispersed phase – alloys of Al, Mg, Cu, Ti with 20 -50 % of C, SiC, B, etc., Used at high T, possess high strength Easily handled unlike glass fibre Used in aerospace and new engine applications Steel wire is the most extensively used fibre 6. Ceramic (SiC) reinforced composites Known as Cermites (ceramic + metal) Ex : TiC embedded in a matrix of a metal – Co or Ni Ceramic refractory carbide (WC) with Co or Ni Applications As cutting tools for hardened steel As both matrix and dispersed phase are refractory, they can withstand high T generated due to friction during cutting action on the hard materials Flakes Thin, flat solid having 2D geometry, placed in a matrix Ex : mica and glass Flakes provide – Uniform mechanical properties in the plane of the flakes Higher strength, flexural modulus (tendency of a material to undergo bending) Higher dielectric strength and heat resistance Better resistance to penetration by liquid and vapour Lower cost compared to fibre Often used in place of fibre Metal flakes that are in close contact with each other in polymer can conduct electricity and heat while mica and glass flakes resist both Whiskers A thin strong filament or fibre made by growing as crystals or single crystal grown with nearly zero defects High L/D ratio and strongest known material but its usage is restricted due to its cost and difficulty in incorporation Usually discontinuous and short fibres of different cross section Ex : Graphite, SiC in ceramic matrix and SiC in Al (used in automobiles) Properties depend on distribution, orientation and geometry of whisker void content Smaller void content gives low susceptibility to weathering Higher void content increases thermal and insulating properties Types of reinforcement Reinforcement Particle Large Dispersion particle strengthened Fiber Continuous long (aligned) Structural Discontinu ous (short) Aligned Laminates Randomly oriented Sandwich panels I. Particulates Small pieces of hard solid material (metallic/non-metallic) ranging from microscopic to macroscopic Distribution is uniform throughout making it isotropic (material properties same in all directions) composite Function Increase surface hardness Cause constraint (retard) on plastic deformation Increases performance at elevated temperature, abrasion resistance and strength Thermal and electrical conductivities are modified Decrease shrinkage and friction Decrease cost of composite Ex : Laminate composite : Capacitors – alternating layers of an insulator and a conductor Conductivity in parallel plates (Al) and insulation in perpendicular direction (mica) Particulates can be mixed with matrix in the form of metal (Al alloy), polymer (rubber), Ceramic (concrete) Examples a. Large particle (1 – 50 𝜇𝑚) b. Dispersion strengthened ( < 0.1 𝜇𝑚) i) Ceramites – ceramic particle (strong and brittle) in a metal matrix (WC & TiC + Co/Ni) Used for cutting tools for hardened steel ii) Vulcanized rubber - natural rubber with S and other curatives Strengthened with 20 – 50 nm carbon black particles iii) Concrete : matrix – cement and water Dispersed phase is sand and pebbles The function of sand pebbles is to increase the modulus of matrix, decrease permeability and ductility of matrix b. Dispersion strengthened ( < 0.1 𝜇𝑚) Can be carbides, oxides, borides Ex : sintered Al powder (fine Al2O3 in pure Al matrix) (applying a powdered material into a solid by heating below m.pt Ductile matrix + hard particle using powder metallurgy, composite is formed This oxide prevents grain growth and movement of dislocations at the boundaries or through them and produces high strength, high creep resistance and insensitivity to high-temperature exposure Particles distribution in a matrix II. Fibre reinforcement a. Continuous The fibres are long and strength of the composite depends upon the direction of the fibre in which they are aligned If oriented to one direction ie longitudinal direction, more strength will be present along this direction b. Discontinuous Fibres are short. Generally fibres are randomly arranged Ex for fibres : polymer, metal, ceramic Mechanical properties are isotropic Have low strength than continuously arranged fibres Woven, aligned and randomly oriented III. Structural composites a. Laminar Composed of 2D sheets or panels that have a preferred high strength direction such as plywood Layers are stacked and cemented together such that the orientation of high strength direction varies with each successive layer b. Sandwich panel Consists of two strong outer sheets called faces separated by a layer of less dense material, called core Ex : Foam material Advantages Light weight and large bend stiffness Hybrid composites Two or more fibres are incorporated within a single matrix Between two fibres one is generally organic and another is inorganic in nature Classification Based on the possible interactions connecting the two fibres Class I - Hybrid materials are those that show weak interactions between the two phases – van der waals, H-bonding, electrostatic attraction Class II - Connected by strong chemical interactions between them –covalent bond Advantages Inorganic clusters or nanoparticles with specific optical, electronic and magnetic properties can be incorporated in organic polymer matrices Applications Scratch resistance coating with hydrophobic or anti fogging properties (chemicals that prevent condensation of water) Nanocomposite devices for electronic and opto electronic applications – LED, photodiodes, solar cells, gas sensors, etc., Fire retardant materials for construction industry (epoxy polymer or aromatic compound with hetero atom) + fibre (Glass, Aramide) Composite electrolyte in solid state Lithium batteries Dental filling materials Recreational products – skating shoe, base ball shafts, bicycle frames Space shuttle Applications of composites in electronics and electrical industries 1. A PCB substrate must have good dielectric performance ie, it must insulate the conductive layers from one another by blocking electrical conductivity, to minimize electrical signal loss, crosstalk between conductive layers and noise The majority of PCBs are made with E-glass/epoxy Resin alternatives include vinyl ester and polyester, for commodity boards, and cyanate ester, polyimide and bismaleimide triazine (BT) for more demanding, elevated-temperature applications 2. Electromagnetic shielding The effect of electromagnetic shielding is to reduce the electromagnetic field effect in a certain area generated by some radiation sources, and to effectively control the harm caused by electromagnetic radiation from one area to another Coating fillers with magnetic materials or incorporation of magnetic mat. in the polymer matrix Carbon – carbon composites have good shield effectiveness 3. Risk from electromagnetic radiation If human beings are exposed to the EM waves, the network of veins in high risk organs such as eyes might be affected due to heat build-up in the eyes by the EM waves which could not be easily dissipated The use of low-resistance conductor material has a reflection and guiding effect on electromagnetic energy flow and within the conductor material It create the current and magnetic polarization which is opposite with the source of electromagnetic field, thereby reduce the effect of radiation source in electromagnetic field, by shielding effectiveness Ex: carbon-polymer composite materials is used to protect people and electronic equipment from exposure to electromagnetic radiation 4. Conductive mechanism of composite conductive polymer With the increase of the concn. of conductive filler, the conductivity of the polymer increases slowly When the concentration reaches a certain value, the conductivity increases sharply, the polymer becomes a conductor, and the filler concentration continues to increase but conductivity has not changed much The conductivity filler concentration at which the conductivity changed abruptly is called the 'diafiltration threshold’ when the content of the conductive filler reaches the 'diafiltration threshold', the conductive particles contact each other to form an infinite network The formation of conductive channels, carriers can freely move within the system thereby making the composite conductive 5. Electrical switching and insulation Properties that composite materials have include : • Dielectric strength • High thermal conductivity • Low electrical conductivity for insulation • Electromagnetic shielding effectiveness • Heat resistance • Low coefficient of thermal expansion • Durability to withstand repeated use without a decrease in performance • Moisture resistance for safety and durability • Sound baffling for quieter operation 6. Wearable electronics – worn by a person for memory communication and senses Ex : smart watches/chips • Graphene/CNT polymer composites are widely being used to make wearable electronics • Silver nanofillers in elastomer composite used in wearables 7. Electronic sensors Carbon black polymer odour and flavour sensors for detecting vapours Used for environmental monitoring to check air quality, crime prevention such as bomb detection, quality control Reinforcing phase: Dispersed carbon black particles Reinforcing medium : Polystyrene 8. Satellite electronics mounted on composite panel 9. Lightning harvester Graphene based composite technology is used to manufacture ultra-long cables - of circa 8 miles in length These ultra-long cables would have a highly-conductive coating of graphene - effectively making them lightning rods which can reach up into the clouds Clouds contain a massive amount of energy, in the form of static electricity, or the difference in voltage between the bottom of a cloud and the ground Lightning occurs when this voltage difference builds up to such an extent that electricity leaps across this gap The highly-conductive graphene coating on a GC (ground check cable ) composite cable (held aloft by weather balloons) is used to harness electricity from clouds As Electricity flows - even the extremely large bursts from lightning strikes - would travel down the graphene-coated cable into a super-capacitor array, which could then release electricity into the power grid in a controlled way