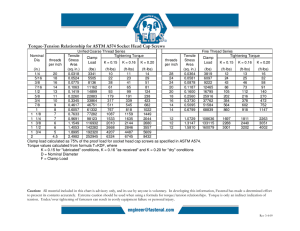

Torque-Tension Relationship for ASTM A193 B7 Bolts and Studs Nominal Dia. (in.) 1/4 1/4 5/16 5/16 3/8 3/8 7/16 7/16 1/2 1/2 9/16 9/16 5/8 5/8 3/4 3/4 7/8 7/8 1 1 1 1 1 1 1 1 1 1 1 2 2 2 1/8 1/8 1/4 1/4 1/2 1/2 5/8 3/4 7/8 1/4 1/2 Threads Per Inch 20 28 18 24 16 24 14 20 13 20 12 18 11 18 10 16 9 14 8 14 7 8 7 8 8 6 8 8 8 8 8 8 Minimum Tensile Strength (lbs.) 3978 4547 6554 7258 9686 10979 13289 14840 17737 19994 22743 25373 28250 31995 41808 46620 57717 63684 75718 84986 95409 98807 121139 124963 186480 175657 221841 260269 301766 346330 444663 555267 Minimum Yield Strength (lbs.) 3341 3819 5505 6097 8136 9222 11162 12465 14899 16795 19104 21313 23730 26876 35118 39161 48482 53495 63603 71388 80144 82998 101757 104969 156644 147551 186346 218626 253483 290917 373517 466425 Est. Shear Strength (lbs.) 2016 2441 3401 3931 5083 6063 6997 8173 9425 11146 12150 14159 15131 17999 22643 26344 31438 36035 41316 48473 51969 54570 66722 69664 105376 97013 125992 148450 172748 198887 256688 321851 Clamp Load (lbs) 2506 2864 4129 4573 6102 6916 8372 9349 11175 12596 14328 15985 17798 20157 26339 29371 36362 40121 47702 53541 60108 62248 76318 78727 117483 110664 139760 163970 190112 218188 280138 349819 Tightening Torque K = 0.12 K = 0.15 K = 0.20 (ft-lbs) 6 7 13 14 23 26 37 41 56 63 81 90 111 126 198 220 318 351 477 535 676 700 954 984 1762 1660 2271 2869 3565 4364 6303 8745 (ft-lbs) 8 9 16 18 29 32 46 51 70 79 101 112 139 157 247 275 398 439 596 669 845 875 1192 1230 2203 2075 2839 3587 4456 5455 7879 10932 (ft-lbs) 10 12 22 24 38 43 61 68 93 105 134 150 185 210 329 367 530 585 795 892 1127 1167 1590 1640 2937 2767 3785 4782 5941 7273 10505 14576 The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Clamp load calculated as 75% of the yield strength for the B7 specified in ASTM A193. Torque values calculated from formula T=KDF, where Coatings such as Teflon or Xylan offer extremely low coefficients of friction. Often we will experience K values around 0.12 or even lower. K = 0.15 for "lubricated" conditions and K = 0.20 for "dry" conditions D = Nominal Diameter F = Clamp Load Tensile and Yield strengths in accordance with ASTM A193 Minimum ultimate tensile strength: 125,000 PSI (up through 2-1/2") and 115,000 PSI (over 2-1/2 through 4) Minimum yield strength: 105,000 PSI (up through 2-1/2") and 95,000 PSI (over 2-1/2 through 4) Estimated Shear Strength based off of 60% of minimum tensile strength using the thread root area. It is not part of the ASTM A193 specification. Caution: All material included in this chart is advisory only, and its use by anyone is voluntary. In developing this information, Fastenal has made a determined effort to present its contents accurately. Extreme caution should be used when using a formula for torque/tension relationships. Torque is only an indirect indication of tension. Under/over tightening of fasteners can result in costly equipment failure or personal injury. Rev 3-4-09