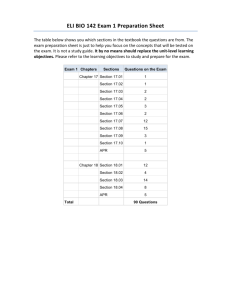

0201KTU SERIES LETTER OF TRANSMITTAL COMPONENT MAINTENANCE MANUAL 28-47-05 FUEL QUANTITY TANK UNITS REVISION NO.6 Issued Apr 06 Technical content changes are listed below. Section Change Title Page Added new codes and updated address information Record of Revisions Recorded permanent revision: Rev. 6 Record of Temporary Revisions Updated to reflect current pages Service Bulletin List Updated to reflect current pages List of Effective Pages Updated to reflect current pages Table of Contents Updated to reflect current pages List of Illustrations Updated to reflect current pages Introduction Updated to reflect current pages Modifications Updated to reflect current pages Description and Operation Corrected data in Data Table in accordance with CDR 5110 Testing and Fault Isolation Corrected data in Table 103 in accordance with CDR 5110 Illustrated Parts List Added new figure, Fig. 1A, in accordance with CDR 5110 Incorporate the revision as follows: Action 1. Reason Title Page Remove and destroy page 1/2 (Feb 27/02) Update to reflect current pages Insert pages TP-1 and TP-2 (Apr 17/06) Record of Revisions Remove and destroy page RR-1/2 (Feb 27/02) Update to reflect current pages Insert pages ROR-1 and ROR-2 (Apr 17/06) Letter of Transmittal No.6 Uncontrolled when reproduced 28-47-05 Page LOT-1 Apr 17/06 0201KTU SERIES LETTER OF TRANSMITTAL (Continued) COMPONENT MAINTENANCE MANUAL 28-47-05 Action 1. Reason Record of Temporary Revisions Remove and destroy page RTR-1/2 (Feb 27/02) Update to reflect current pages Insert pages RTR-1 and RTR-2 (Apr 17/06) Service Bulletin List Remove and destroy page SBL-1/2 (Feb 27/02) Update to reflect current pages Insert pages SBL-1 and SBL-2 (Apr 17/06) List of Effective Pages Remove and destroy page LEP-1/2 (Feb 27/02) Update to reflect current pages Insert pages LEP-1 and LEP-2 (Apr 17/06) Table of Contents Remove and destroy pages T/C-1 and T/C-2 (Feb 27/02) Update to reflect current pages Insert pages TOC-1 and TOC-2 (Apr 17/06) List of Illustrations Remove and destroy page LI-1/2 (Feb 27/02) Update to reflect current pages Insert pages LOI-1 and LOI-2 (Apr 17/06) Introduction Remove and destroy page INTRO-1/2 (Feb 27/02) Update to reflect current pages Insert pages INT-1 and INT-2 (Apr 17/06) Modifications Remove and destroy page MOD-1/2 (Feb 27/02) Update to reflect current pages Insert pages MOD-1 and MOD-2 (Apr 17/06) Description and Operation Remove and destroy page 4 (Feb 27/02) Update to reflect current page Insert page 4 (Apr 17/06) Letter of Transmittal No.6 Uncontrolled when reproduced 28-47-05 Page LOT-2 Apr 17/06 0201KTU SERIES LETTER OF TRANSMITTAL (Continued) COMPONENT MAINTENANCE MANUAL 28-47-05 Action 1. Reason Testing and Fault Isolation Remove and destroy page 104 (Feb 27/02) Update to reflect current page Insert page 104 (Apr 17/06) Illustrated Parts List Remove and destroy pages 1001 to 1024 (Feb 27/02) Update to reflect current pages Insert pages 1001 to 1038 (Apr 17/06) 2. Retain this letter of transmittal. Letter of Transmittal No.6 Uncontrolled when reproduced 28-47-05 Page LOT-3 Apr 17/06 FOR EUROPE, AFRICA, INDIA AND MIDDLE EAST CONTACT: Smiths Aerospace Customer Services – Cheltenham, Bishops Cleeve, Cheltenham, Glos. GL52 8SF, United Kingdom Telephone: + 44 (0) 1242 673355 Facsimile: + 44 (0) 1242 669165 E-Mail: cs.support@ smiths-aerospace.com FOR ASIA, AUSTRALASIA AND THE PACIFIC CONTACT: Smiths Aerospace Australia Pty Ltd 3 Hakea Street, Brisbane Airport, QLD4007, Australia FOR THE AMERICAS CONTACT: Telephone: + 61 7 3860 0700 Facsimile: + 61 7 3860 0701 E-Mail: Customer.support@ smiths-aerospace.com.au Telephone: + 1 (727) 539 1631 Facsimile: + 1 (727) 539 0680 E-Mail: csasupport@ smiths-aerospace.com Smiths Aerospace P.O. Box 9013, Clearwater, FL 33758 United States of America COMPONENT MAINTENANCE MANUAL WITH ILLUSTRATED PARTS LIST FUEL QUANTITY TANK UNITS 0201KTU3 0201KTU4 0201KTU5 0201KTU6 0201KTU7 0201KTU8 0201KTU9 0201KTU10 0201KTU11 0201KTU12 0201KTU13 0201KTU14 0201KTU15 0201KTU16 0201KTU17 0201KTU18 0201KTU19 0201KTU20 0201KTU21 0201KTU22 0201KTU23 0201KTU24 0201KTU25 0201KTU29 0201KTU30 0201KTU31 0201KTU32 0201KTU33 0201KTU34 0201KTU35 © Smiths Group plc 2006 Initial Issue: 6 Aug 1981 Uncontrolled when reproduced 28-47-05 Revision 6 Page TP-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Initial Issue: 6 Aug 1981 Uncontrolled when reproduced 28-47-05 Revision 6 Page TP-2 Apr 17/06 0201KTU SERIES RECORD OF REVISIONS Keep this record in the front of the manual. When you get a revision, put the revised pages into the manual and write the revision number, the revision issue date, the insertion date and your initials. REV. No. ISSUE DATE INSERTION DATE 1 31/03/83 2 20/02/85 3 08/09/87 4 05/02/92 5 27/02/02 Smiths 6 17/04/06 Smiths INSERTED BY REV. No. ISSUE DATE INSERTION DATE INSERTED BY Previously incorporated Uncontrolled when reproduced 28-47-05 Page ROR-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page ROR-2 Apr 17/06 0201KTU SERIES RECORD OF TEMPORARY REVISIONS Keep this record in the front of the manual. When you get a temporary revision, put the revised pages into the manual and write the temporary revision number, the page number(s), the date and your initials. TEMPORARY REV. No. PAGE NUMBER Uncontrolled when reproduced ISSUE DATE INSERTED BY REMOVED BY PERMANENT REVISION No. DATE REMOVED 28-47-05 REMOVED BY Page RTR-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page RTR-2 Apr 17/06 0201KTU SERIES SERVICE BULLETIN LIST Service Bulletin Number Service Bulletin Revision Number Date Service Bulletin Incorporated into Manual Purpose of Service Bulletin SB28-318 1 13/03/79 Design improvement to protect diodes from stress caused by thermal expansion SB28-326 0 07/08/87 Introduction of new design standard for welding terminal stud to outer tube assembly. Uncontrolled when reproduced 28-47-05 Page SBL-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page SBL-2 Apr 17/06 0201KTU SERIES LIST OF EFFECTIVE PAGES Subject Page Title Page TP-1 TP-2 Subject Page Date Apr 17/06 * Blank Apr 17/06 * Fits and Clearances 801/802 Feb 27/02 Record of Revisions ROR-1 ROR-2 Apr 17/06 * Blank Apr 17/06 * Special Tools, Fixtures and Equipment 901/902 Feb 27/02 Record of Temporary Revisions RTR-1 RTR-2 Apr 17/06 * Blank Apr 17/06 * Service Bulletin List SBL-1 SBL-2 Apr 17/06 * Blank Apr 17/06 * List of Effective Pages LEP-1 LEP-2 Apr 17/06 * Blank Apr 17/06 * Table of Contents TOC-1 TOC-2 Apr 17/06 * Apr 17/06 * List of Illustrations LOI-1 LOI-2 Apr 17/06 * Blank Apr 17/06 * Introduction INT-1 INT-2 Apr 17/06 * Apr 17/06 * MOD-1 MOD-2 Apr 17/06 * Blank Apr 17/06 * 1 2 3 4 Feb 27/02 Feb 27/02 Feb 27/02 Apr 17/06 * 101 102 103 104 105/106 Feb 27/02 Feb 27/02 Feb 27/02 Apr 17/06 * Feb 27/02 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 1012 1013 1014 1015 1016 1017 1018 1019 1020 1021 1022 1023 1024 1025 1026 1027 1028 1029 1030 1031 1032 1033 1034 1035 1036 1037 1038 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Blank Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Blank Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Apr 17/06 Modifications Description and Operation Testing and Fault Isolation Date Disassembly 301 302 Feb 27/02 Feb 27/02 Cleaning 401 402 Feb 27/02 Feb 27/02 Check 501 502 503/504 Feb 27/02 Feb 27/02 Feb 27/02 Repair 601/602 Feb 27/02 701 702 703 704 Feb 27/02 Feb 27/02 Feb 27/02 Feb 27/02 Assembly Illustrated Parts List * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * An asterisk indicates a page changed or added. Uncontrolled when reproduced 28-47-05 Page LEP-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page LEP-2 Apr 17/06 0201KTU SERIES TABLE OF CONTENTS Page INTRODUCTION................................................................................................................................... INT-1 1. 2. 3. 4. General ....................................................................................................................................... Software Data ............................................................................................................................. Electrostatic Sensitive Devices................................................................................................... Verification .................................................................................................................................. INT-1 INT-1 INT-1 INT-2 MODIFICATIONS.................................................................................................................................. MOD-1 1. 2. General ....................................................................................................................................... Modification Details .................................................................................................................... MOD-1 MOD-1 DESCRIPTION AND OPERATION....................................................................................................... 1 1. 2. Description.................................................................................................................................. Data ............................................................................................................................................ 1 4 TESTING AND FAULT ISOLATION ..................................................................................................... 101 1. 2. 3. 4. Test Conditions........................................................................................................................... 101 Unit Testing................................................................................................................................. 101 Procedure ................................................................................................................................... 101 Trouble Shooting ........................................................................................................................ 105/106 DISASSEMBLY..................................................................................................................................... 301 1. 2. General ....................................................................................................................................... Procedure ................................................................................................................................... 301 301 CLEANING............................................................................................................................................ 401 1. 2. Cleaning Agents ......................................................................................................................... Procedure ................................................................................................................................... 401 401 CHECK.................................................................................................................................................. 501 1. 2. 3. 501 501 501 General ....................................................................................................................................... Detailed Procedures ................................................................................................................... Procedures ................................................................................................................................. REPAIR................................................................................................................................................. 601/602 Uncontrolled when reproduced 28-47-05 Page TOC-1 Apr 17/06 0201KTU SERIES TABLE OF CONTENTS (Continued) Page ASSEMBLY........................................................................................................................................... 701 1. 2. 3. 4. 701 701 701 703 General ....................................................................................................................................... Tools ........................................................................................................................................... Procedure ................................................................................................................................... Storage After Component Maintenance ..................................................................................... FITS AND CLEARANCES .................................................................................................................... 801/802 SPECIAL TOOLS, FIXTURES AND EQUIPMENT............................................................................... 901/902 1. Tools, Fixtures and Equipment................................................................................................... 901/902 ILLUSTRATED PARTS LIST ................................................................................................................ 1001 1. 2. 3. 4. 5. 6. 1001 1001 1005 1007 1009 1019 Ordering...................................................................................................................................... Introduction ................................................................................................................................. Vendor Codes, Names and Addresses ...................................................................................... Equipment Designator Index ...................................................................................................... Alpha/Numeric Index .................................................................................................................. Detailed Parts List....................................................................................................................... Uncontrolled when reproduced 28-47-05 Page TOC-2 Apr 17/06 0201KTU SERIES LIST OF ILLUSTRATIONS Page Fig. Fig. 1 Typical 0201KTU Series Tank Unit Fitted to Wing, Centre and Collector Tanks............... 2 Fig. 2 Typical 0201KTU Series Tank Unit Fitted to Pannier Tanks.............................................. 3 Fig. 101 Test Connections................................................................................................................ 102 Fig. 501 Test Connections................................................................................................................ 502 IPL Fig.1 Tank Unit ............................................................................................................................ 1020 IPL Fig.1A Tank Unit ............................................................................................................................ 1034 Uncontrolled when reproduced 28-47-05 Page LOI-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page LOI-2 Apr 17/06 0201KTU SERIES INTRODUCTION 1. General A. AECMA Simplified English to PSC-85-16598 is used in this manual. B. This manual contains Description, Operation and Maintenance procedures. It also contains an Illustrated Parts List (IPL). IPL Figure and Item numbers in parentheses follow the part names to identify them. C. The figure/item numbers in parentheses in the text agree with those used in the illustrated parts list. Only the primary figure/item numbers are used, unless it is necessary to show them differently. D. All dimensions and quantities in this manual are in Imperial units with SI units in parentheses. A full point shows a decimal part of an Imperial unit. A comma shows a decimal part of an SI unit. 2. E. All the materials in this manual have a Ref. Item identification that is given in the materials paragraph. F. Use approved persons and good aircraft engineering procedures for all the procedures listed in this manual. Software Data A. B. 3. Any software or software data supplied to you in relation to the hardware described in this manual is proprietary to Smiths Group plc. The software or software data is supplied to you on the understanding that: (1) You will not show the software outside your organization without our prior written permission. (2) You will not reproduce the software without our prior written permission. (3) You will not alter or amend the software. Smiths Group plc accepts no responsibility for any costs, claims, damages, liabilities and expenses incurred directly or indirectly by us and however arising as a consequence of your breach of any part of the undertaking set out above. Electrostatic Sensitive Devices A. B. Circuit board assemblies contain semi-conductor devices that can be damaged by transient voltages, including: (1) Static charges of a level normally present on the human body (2) Clothing (3) Non-conducting items in common workshop use. Maintenance operations on modules containing Electrostatic Sensitive Devices (ESDs) must be carried out in accordance with current workshop practice. Uncontrolled when reproduced 28-47-05 Page INT-1 Apr 17/06 0201KTU SERIES 4. Verification TESTING AND FAULT ISOLATION DISASSEMBLY Through field experience ASSEMBLY Uncontrolled when reproduced 28-47-05 Page INT-2 Apr 17/06 0201KTU SERIES MODIFICATIONS 1. General When modifications are introduced on units covered by this manual, the text will be revised to include the latest modification. The modifications will be listed below together with a statement on whether the maintenance information is affected when any modification is not embodied. When maintenance is affected, the list will cross-refer to details. 2. Modification Details Modification No. Codes Affected Effect on Maintenance 01 All except 0201KTU30 to 35 inclusive None 02 All None Uncontrolled when reproduced 28-47-05 Page MOD-1 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page MOD-2 Apr 17/06 0201KTU SERIES DESCRIPTION AND OPERATION 1. Description A. General The tank units referred to in this manual form component parts of a BAe 146 fuel quantity indicating system concerned with the measurement of the quantity of fuel in a tank. The tank units, which are fitted on the inside of the fuel tank, function as capacitive probes whose capacitive value is varied by the level of fuel in the associated fuel tank, the change in capacitance is proportional to the quantity of fuel. Measurement of the capacitance in a group of tank units indicates the quantity of fuel present. Several tank units connected in parallel are used in each tank to maintain accuracy in conditions of changing aircraft attitude. B. Detail Refer to Figures 1 and 2. Each tank unit comprises a pair of coaxial electrodes in the form of aluminium tubes isolated from each other and assembled in spatial relationship by insulated spacers. On code 0201KTU-11 only the inner tube of the tank unit is replaced by an aluminium alloy rod. In some of the tank units, the inner tube is constructed using sections of tube of different diameters joined end to end. This is called ‘characterisation’ and is to achieve a linear change of capacitance with fuel quantity. Each tank unit incorporates a pair of rectifying diodes, a third diode is included in tank units where temperature compensation is provided. An a.c. voltage applied to the capacitive impedance of the tank unit is rectified and transmitted as a d.c. signal to a processor unit. Electrical connections are made via a terminal block attached to the outer tube. The terminal block housing is baulked differently at each terminal, to match up with the cable assembly insulators, to prevent misconnection. Provision for mounting the tank unit in the wing, centre and collector tanks is by means of two insulated mounting clamps which are positioned near each end of the tank unit. The mounting clamp, situated near the top of the unit, is free for both rotational and longitudinal movement to facilitate the mounting of the unit in its associated fuel tank. Provision for mounting the tank unit in the pannier tanks is by means of an insulated mounting clamp at the lower end and a support ring at the top. Uncontrolled when reproduced 28-47-05 Page 1 Feb 27/02 0201KTU SERIES Fig.1 Typical 0201KTU Series Tank Unit Fitted to Wing, Centre and Collector Tanks Uncontrolled when reproduced 28-47-05 Page 2 Feb 27/02 0201KTU SERIES Fig.2 Typical 0201KTU Series Tank Unit Fitted to Pannier Tanks Uncontrolled when reproduced 28-47-05 Page 3 Feb 27/02 0201KTU SERIES 2. Data A. Name, Code Number, Length, Weight and Location Length Weight in. (mm) lb (kg) 0201KTU3 21.04 (534,42) 0.48 (0,22) 0201KTU4 20.55 (521,97) 0.48 (0,22) 0201KTU6 17.95 (455,93) 0.44 (0,20) 0201KTU7* 16.44 (417,58) 0.42 (0,19) 0201KTU8 14.50 (368,30) 0.40 (0,18) 0201KTU9 13.72 (348,49) 0.37 (0,17) 0201KTU10 12.79 (324,87) 0.35 (0,16) 0201KTU11 12.16 (308,86) 0.35 (0,16) 0201KTU12 10.32 (262,13) 0.33 (0,15) 0201KTU13 9.14 (232,16) 0.31 (0,14) 0201KTU20 32.20 (817,88) 0.62 (0,28) 0201KTU21* 17.57 (446,28) 0.42 (0,19) 0201KTU22 28.00 (711,20) 0.57 (0,26) 0201KTU29 20.29 (515,37) 0.46 (0,21) 0201KTU30* 16.44 (417,58) 0.40 (0,18) 0201KTU31 14.50 (368,30) 0.40 (0,18) 0201KTU32 10.32 (262,13) 0.31 (0,14) 0201KTU5 20.29 (515,37) 0.48 (0,22) 0201KTU14 13.00 (330,20) 0.37 (0,17) 0201KTU15 11.58 (294,13) 0.33 (0,15) 0201KTU16 11.43 (290,32) 0.33 (0,15) 0201KTU17 11.14 (282,96) 0.33 (0,15) 0201KTU18 9.03 (229,36) 0.31 (0,14) 0201KTU19 9.00 (228,60) 0.31 (0,14) 0201KTU23 28.14 (714,76) 0.57 (0,26) 0201KTU24 22.90 (581,66) 0.52 (0,24) 0201KTU25 19.44 (493,77) 0.51 (0,23) 0201KTU33 32.20 (817,88) 0.62 (0,28) 0201KTU34* 17.57 (446,28) 0.42 (0,19) 0201KTU35 28.00 (711,20) 0.57 (0,26) Location (Fuel Tank) Unit Code No. Wing Left and Right Inner Collector Outer Collector Pannier Centre NOTE: * Internal temperature compensation diode fitted. Uncontrolled when reproduced 28-47-05 Page 4 Apr 17/06 0201KTU SERIES TESTING AND FAULT ISOLATION CAUTION: ALL TESTING AND FAULT ISOLATION PROCEDURES THAT INVOLVE THE HANDLING AND TRANSPORTATION OF ESDs (ELECTROSTATIC SENSITIVE DEVICES) MUST BE CARRIED OUT IN ACCORDANCE WITH INTRODUCTION, PARA 3. NOTE: Make allowances for the accuracy of the test equipment. All of the tolerances given in TESTING AND FAULT ISOLATION are specification values. 1. Test Conditions Unless otherwise specified, all tests are to be done under the following ambient conditions: Temperature: 2. +15 to + 25°C Unit Testing The following tests are the only tests that are necessary to establish serviceability of the unit. The procedure must also be applied to a tank unit when any component has been renewed. The cable connections to the tank units are made by insulated faston connectors. When releasing, the cables must not be used to pull off the connectors. A. Equipment Required The equipment written in Table 101 is necessary. Equivalent items can be used. Table 101 Test Equipment Description Reference/Part No. Insulation Resistance Tester, 500V d.c. Capacitance Fuel Gauge Test Set Commercially available Test Cable 0601KQC-02 or 0601KQC-03 3684LMT Test Cable 3711LMT End Plates (2 off) 6030LMT Wooden Vee Blocks (2 off) 3. - - Vendor Smiths Commercially available Procedure A. Insulation Resistance Test Check the insulation resistance between the drive terminal and the inner electrode. The reading obtained should not be less than 20Mohms when measured with a 500V d.c. potential applied for not less than 10 seconds. B. Diode Functioning Check (1) Using the Capacitance Fuel Gauge test set, proceed as follows: (a) Connect the test set to an external power source via the ‘POWER’ connector 2, using test cable 3711LMT. The supply should be 115V, 400Hz or 28V d.c. (b) Connect the tank unit to the test set connector (3) as shown in Fig.101 using test cable 3684LMT. Uncontrolled when reproduced 28-47-05 Page 101 Feb 27/02 0201KTU SERIES Fig.101 Test Connections (c) Turn on the power source and move the test set panel switches to the positions indicated: Switch 14 to Position 1 Switch 16 to USE Switch 17 to USE Switch 18 to USE Switch 23 to 30k Switch 24 to -D.C. Switch 29 to MEG. (d) Select switch 14 to the positions detailed in Table 102 and note the reading on panel meter (15) is as detailed in the table. Table 102 Diode Functioning Check Readings Switch 14 Position Panel Meter (15) Reading 1 > 30Mohm 2 > 30Mohm 3 > 30Mohm 7 10kohm ± 5kohm 8 25kohm ± 10kohm Uncontrolled when reproduced Travelling decimal point Temperature compensated tank units only 28-47-05 Page 102 Feb 27/02 0201KTU SERIES C. Measurement of Tank Unit Initial Capacitance (1) Support the tank unit on the two wooden vee blocks, and fit an end plate 6030LMT to each of its ends. NOTE: The end plates simulate the tank structure, and when they are assembled, provide a clearance of 6.35mm (0.25in.) between the ends of the tank unit and the plates. (2) Using a suitable bonding wire, connect the end plates to each other and to the test set’s BOND terminal 10. (3) Move the test set switches to the positions indicated: Switch 14 to 1 (or any except 9) Switch 16 to USE Switch 17 to USE Switch 18 to USE Switch 23 to 30k Switch 24 to -D.C. Switch 29 to MEAS. TU (4) Allow the test set 5 minutes to warm up. (5) Using the capacitance Off-Set Adjuster, panel item 22, bring the panel meter (15) reading to zero. (6) Connect the tank unit to the test set as shown in Figure 101 using 3684LMT and check that the panel meter indication is within the initial capacitance values provided in Table 103 for the appropriate tank unit. Uncontrolled when reproduced 28-47-05 Page 103 Feb 27/02 0201KTU SERIES Table 103 Initial Capacitance Unit Code No. Initial Capacitance (pF) 0201KTU 3 52.1 ± 0.5 0201KTU 4 56.6 ± 0.5 0201KTU 5 56.92 ± 0.50 0201KTU 6 48.9 ± 0.5 0201KTU 7* 46.51 ± 0.46 0201KTU 8 41.37 ± 0.41 0201KTU 9 34.0 ± 0.4 0201KTU10 18.0 ± 0.2 0201KTU11 13.7 ± 0.2 0201KTU12 15.77 ± 0.20 0201KTU13 10.3 ± 0.2 0201KTU14 40.1 ± 0.4 0201KTU15 15.2 ± 0.2 0201KTU16 23.6 ± 0.3 0201KTU17 31.1 ± 0.3 0201KTU18 18.9 ± 0.2 0201KTU19 18.8 ± 0.2 0201KTU20 62.78 ± 0.50 0201KTU21* 43.14 ± 0.43 0201KTU22 59.79 ± 0.50 0201KTU23 40.7 ± 0.4 0201KTU24 42.7 ± 0.4 0201KTU25 39.0 ± 0.4 0201KTU29 52.6 ± 0.5 0201KTU30* 45.8 ± 0.5 0201KTU31 40.0 ± 0.4 0201KTU32 14.4 ± 0.2 0201KTU33 67.5 ± 0.7 0201KTU34* 29.8 ± 0.3 0201KTU35 61.0 ± 0.6 NOTE: * Internal temperature compensation diodes fitted. Uncontrolled when reproduced 28-47-05 Page 104 Apr 17/06 0201KTU SERIES 4. Trouble Shooting The material shown in tabular form suggests some probable causes of failure of the unit to meet the test requirements detailed in paragraph 3. Also given are suggested corrective procedures. Trouble A. B. C. Failure of insulation resistance test Failure of diode functioning check Failure of initial capacitance test Probable Cause Correction (1) Dampness in unit Dry in a warm oven at a temperature not in excess of 70°C -80°C (2) Unserviceable terminal block assembly Renew terminal block assembly (3) Contamination of terminal block assembly connections or cross pins Open or short circuited diodes Damaged or loose tubes Apply procedure as detailed in Cleaning (2) Damaged or loose cross pins Renew cross pins (3) Contamination of cross pins Apply procedure as detailed in Cleaning (4) Damaged pin connections to inner tube Change terminal block (1) (1) Uncontrolled when reproduced Renew terminal block assembly Renew tubes 28-47-05 Page 105/106 Feb 27/02 0201KTU SERIES DISASSEMBLY ALL DISASSEMBLY PROCEDURES THAT INVOLVE THE HANDLING AND TRANSPORTATION OF ESDs (ELECTROSTATIC SENSITIVE DEVICES) MUST BE CARRIED OUT IN ACCORDANCE WITH INTRODUCTION, PARA 3. CAUTION: 1. General Make sure that the workbench, tools and parts are fully clean. Approved spares only should replace faulty parts, after inspection for serviceability. Refer to TESTING AND FAULT ISOLATION to establish the most probable cause of the malfunction, this is to determine the extent of disassembly. The detailed procedures provide the complete disassembly of the tank unit but may be modified to suit the renewal of specific components. Following the renewal of any components, carry out the full testing procedure detailed in TESTING AND FAULT ISOLATION. During DISASSEMBLY, the ILLUSTRATED PARTS LIST (IPL) is referred to. The numbers in brackets after the components referred to in DISASSEMBLY refer to the figure and item numbers in the IPL. 2. Procedure A. Removal of Mounting Clamps on Tank Units Fitted to Wing, Centre and Collector Tanks (1) (2) Top Mounting Clamp (a) Remove the rivet from the top of the outer tube by drilling off the rivet head and tapping out the rivet shank. Ensure that the rivet shank is recovered from the tank tubes. (b) Remove the mounting clamp by sliding it off the end of the tank unit outer tube. (c) Check that the drilled hole in the outer tube from which the rivet shank was removed is not damaged. Use a low-pressure air-line to remove any swarf from the tank unit assembly. Bottom Mounting Clamp (a) Remove the two rivets securing the mounting clamp to the outer tube of the tank unit by drilling off the rivet heads and tapping out the rivet shanks. Ensure that both of the rivet shanks are recovered from the tank tubes. (b) Remove the mounting clamp by sliding it off the end of the tank unit outer tube. (c) Check that the drilled holes in the outer tube from which the rivet shanks were removed are not damaged. Use a low-pressure air-line to remove any swarf from the tank unit assembly. Uncontrolled when reproduced 28-47-05 Page 301 Feb 27/02 0201KTU SERIES B. Removal of Support Ring, Support Ring Sleeve and Mounting Clamp on Tank Units Fitted to Pannier Tanks (1) Support Ring (a) (2) (3) C. D. Ease the ring out of its sleeve. Avoid the use of levers as they may damage the sleeve. Support Ring Sleeve (a) Remove the two rivets securing the sleeve to the outer tube of the tank unit by drilling off the rivet heads and tapping out the rivet shanks. Ensure that both of the rivet shanks are removed from the tank tubes (b) Remove the sleeve by sliding it off the end of the tank unit outer tube. (c) Check that the drilled holes in the outer tube from which the rivet shanks were removed are not damaged. Use a low-pressure air-line to remove any swarf from the tank unit assembly Mounting Clamp (a) Remove the two rivets securing the mounting clamp to the outer tube of the tank unit by drilling off the rivet heads and tapping out the rivet shanks. Ensure that both of the rivet shanks are recovered from the tank tubes. (b) Remove the mounting clamp by sliding it off the end of the tank unit outer tube. (c) Check that the drilled holes in the outer tube from which the rivet shanks were removed are not damaged. Use a low-pressure air-line to remove any swarf from the tank unit assembly. Removal of Cover Ring and Terminal Block Assemblies (1) Remove the cover ring assembly by depressing the spring clip on either side of the cover and sliding the cover off the terminal block and over the end of the tank unit outer tube. Recover the spring clips from the side of the terminal block. (2) Remove the nut and washer from the stud passing through the terminal block. (3) Remove the terminal block by lifting it from the tank unit. Recover the washer, internal lock, from under the drive terminal. Dismantling the Tank Unit Tubes (1) Remove the two cross pins that hold the inner and outer tubes together. (2) Remove the inner tube, complete with the inner cross pins, from the outer tube. (3) Remove the inner cross pins from the inner tube. Uncontrolled when reproduced 28-47-05 Page 302 Feb 27/02 0201KTU SERIES CLEANING WARNING: CERTAIN CLEANING FLUIDS ARE FLAMMABLE AND TOXIC. THEY MUST BE USED IN A WELL VENTILATED AREA. CAUTION: ALL CLEANING PROCEDURES THAT INVOLVE THE HANDLING AND TRANSPORTATION OF ESDs (ELECTROSTATIC SENSITIVE DEVICES) MUST BE CARRIED OUT IN ACCORDANCE WITH INTRODUCTION, PARA 3. 1. Cleaning Agents Cleaning agents equipment and materials are written in Table 401. Equivalent substitutes may be used. Table 401 Cleaning Agents, Equipment and Materials Item * Ensolv * Axarel * Triklone A and Triklone N * Lotoxane Vendor Croftshaw Solvents Ltd., 32-33 Oakwood Hill Industrial Estate, Loughton, Essex, IG10 3TZ, U.K. Petroferm Inc. 5145 First Coast Highway, Ferandina Beach, Florida 32034, U.S.A. ICI Chemicals & Polymers Group, Solvents Marketing Dept., PO Box 19, Runcorn, WA7 4LW, U.K. Arrow Chemicals Ltd., Stanhope Road, Swadlincote, Derbyshire, DE11 9BE, U.K Non-corrodible container (2 off) Soft bristle brush Commercially available * Any of these chemicals can be used as the cleanser. 2. Procedure A. External Cleaning (1) B. Thoroughly clean the exterior of the tank unit using a soft bristle brush and cleanser, paying particular attention to the terminal block assembly. Dry the unit in a clean lowpressure air-jet. Internal Cleansing This procedure is necessary if it is suspected that there is contamination (in the form of deposits) of the cross pins within the tank unit assembly. Failure of the tank unit to comply with the requirements of the Initial Capacitance check detailed in TESTING AND FAULT ISOLATION may indicate that internal cleaning is necessary. Uncontrolled when reproduced 28-47-05 Page 401 Feb 27/02 0201KTU SERIES (1) If the values recorded in the capacitance check are outside the tolerances specified (or are very close to the limits of tolerance) it is probable that deposits on the cross pins are the cause, and that internal cleaning is required in accordance with the following procedure: (a) Completely immerse the tank unit in cleanser and soak for at least one hour. If the tank unit is too long for complete immersion, soak it one end at a time. (b) After soaking, shake the tank unit vigorously in the cleanser to remove any loose foreign matter and thoroughly clean the outer tube using a soft brush. (c) Dry the unit thoroughly in a clean low-pressure air-jet. (d) Repeat the Initial Capacitance check to ensure that the tank unit is now within the specified tolerances. NOTE: Uncontrolled when reproduced If the capacitance is marginally outside the specified limits, repeat the cleaning procedure. 28-47-05 Page 402 Feb 27/02 0201KTU SERIES CHECK ALL CHECKS THAT INVOLVE THE HANDLING AND TRANSPORTATION OF ESDs (ELECTROSTATIC SENSITIVE DEVICES) MUST BE CARRIED OUT IN ACCORDANCE WITH INTRODUCTION, PARA 3. CAUTION: 1. General The detailed procedures in this page block are applied to a tank unit as an aid to FAULT ISOLATION. Where applicable, the procedures are also relevant to any new components being fitted to a tank unit. 2. Detailed Procedures The equipment required is listed in Table 501. Equivalent substitutes may be used. Table 501 Equipment Description Reference/Part No. Vendor Insulation Resistance Tester, (500v d.c.) - Commercially available Capacitance Fuel Gauge Test Set 3. Test Cable 0601KQC-02 or 0602KQC-03 3684LMT Test Cable 3711LMT Smiths Procedures A. Visual Check (1) Ensure that all components of the unit are clean. (2) Check the general condition of the tubes, reject the unit if the tubes are corroded, distorted, split or dented. NOTE: Loss of an Anodic film on the tube does not require rejection of the unit. (3) Examine all other components for corrosion. Any parts showing signs of corrosion must be rejected. (4) Ensure that all cross-pins are secure. Reject a unit where the cross-pins are found to be loose. (5) Inspect for signs of breakdown of electrical insulation. Reject a unit where this defect is observed. (6) Inspect the cover ring and terminal block assembly for damage or deterioration. If required, renew these components. (7) Check the mounting clamps for security and damage. Damaged components are to be renewed. (8) Check the support ring, tank units fitted to pannier tanks only, for security and damage. Damaged components are to be renewed. Uncontrolled when reproduced 28-47-05 Page 501 Feb 27/02 0201KTU SERIES B. Insulation Resistance Test Check the insulation resistance between the drive terminal and the inner electrode. The reading obtained should not be less than 20Mohm when measured with a 500V d.c. potential applied for not less than 10 seconds. C. Diode Functioning Check (1) Using the Capacitance Fuel Gauge test set, proceed as follows: (a) Connect the test set to an external power source via the ‘POWER’ connector 2, using test cable 3711LMT. The supply should be 115V, 400Hz or 28V d.c. (b) Connect the tank unit to the test set connector (3) as shown in Fig.501 using test cable 3684LMT. Fig.501 Test Connections (c) Turn on the power source and move the test set switches to the positions indicated: Switch 14 to Position1 Switch 16 to USE Switch 17 to USE Switch 18 to USE Switch 23 to 30k. Switch 24 to -D.C. Switch 29 to MEG Uncontrolled when reproduced 28-47-05 Page 502 Feb 27/02 0201KTU SERIES (d) Select switch 14 to the positions detailed in Table 502 and note the reading on panel meter (15) is as detailed in the table. Table 502 Diode Functioning Check readings Switch 14 Position Panel Meter (15) Reading 1 > 30Mohm 2 > 30Mohm 3 > 30Mohm 7 10kohm ± 5kohm 8 25kohm ± 10kohm Uncontrolled when reproduced Travelling decimal point Temperature compensated tank units only 28-47-05 Page 503/504 Feb 27/02 0201KTU SERIES REPAIR Repair procedures are not directly applicable to the tank units covered in this manual. Repair is limited to the renewal of components as necessary and is covered in the disassembly and assembly procedures detailed in DISASSEMBLY and ASSEMBLY. Uncontrolled when reproduced 28-47-05 Page 601/602 Feb 27/02 0201KTU SERIES ASSEMBLY ALL ASSEMBLY OPERATIONS THAT INVOLVE THE HANDLING AND TRANSPORTATION OF ESDs (ELECTROSTATIC SENSITIVE DEVICES) MUST BE CARRIED OUT IN ACCORDANCE WITH INTRODUCTION, PARA 3. CAUTION: 1. General Make sure that the workbench, tools and parts are fully clean. Approved spares only should replace faulty parts, after inspection for serviceability. The detailed procedures provide the complete assembly of the tank unit but may be modified to suit the renewal of specific components. Following the assembly of the tank unit, carry out the full testing procedure detailed in TESTING AND FAULT ISOLATION. During ASSEMBLY, the ILLUSTRATED PARTS LIST (IPL) is referred to. The numbers in brackets after the components referred to in ASSEMBLY refer to the figure and item numbers in the IPL. All spring washers removed in DISASSEMBLY must be discarded and new items fitted in ASSEMBLY. 2. Tools The tools written in Table 701 will be required. Equivalent tools may be used. Table 701 Tools 3. Description Reference/Part No Riveting pliers, crank handle Type TT55 or similar Torque spanner, set at 3.5lb in. - Vendor Tucker Fasteners Ltd., Wasall Road, Birmingham, B42 1BP, U.K. Commercially available Procedure A. B. Assembling the Tank Unit Tubes (1) Insert the inner cross pins into the holes in the inner tube. (2) Slide the inner tube, complete with inner cross pins, into the outer tube. (3) Align the holes in the inner and outer tubes and insert the two cross pins to hold the tubes together. Assembling the Cover Ring and Terminal Block Assemblies (1) Insert a washer, internal lock, in the recess under the drive terminal of the terminal block and fit the terminal block into position by passing it over the stud on the outer tube of the tank unit. Ensure that the central pin of the terminal block locates with the socket in the inner tube. (2) Secure the terminal block by fitting a washer and nut to the stud. Tighten the nut to 3.5lb in torque. Uncontrolled when reproduced 28-47-05 Page 701 Feb 27/02 0201KTU SERIES (3) C. Fit a spring clip into the recess on either side of the terminal block assembly. Slide a cover ring assembly over the end of the tank unit outer tube and onto the terminal block until it is secured into position by the spring clips. Assembling the Mounting Clamps on Tank Units fitted to Wing, Centre and Collector Tanks Refer to Figures 1 and 2 of DESCRIPTION AND OPERATION for mounting clamp orientation. (1) (2) Top Mounting Clamp (a) Fit the mounting clamp by sliding it over the end of the tank unit outer tube. (b) Fit a 2.38mm (3/32in.) diameter fiat head rivet to the top of the outer tube. Bottom Mounting Clamp Fit the mounting clamp by sliding it over the end of the tank unit outer tube. Secure the clamp into position with two 2.38mm (3/32in.) diameter break head rivets using the riveting pliers. Remove and recover the broken heads of the rivet mandrels. D. Assembling the Support Ring Sleeve, Support Ring and Mounting Clamp on Tank Units fitted to Pannier Tanks (1) Suport Ring Sleeve Fit the support ring sleeve by sliding it over the end of the tank unit outer tube. Secure the sleeve into position with two 2.38mm (3/32in.) diameter break head rivets using the riveting pliers. Remove and recover the broken heads of the rivet mandrels. (2) Support Ring Assemble the support ring to its sleeve by sliding it over the outer tube and up the bevelled edge of the sleeve which is provided for this purpose; ensure that the ring is seating correctly. (3) Mounting Clamp Fit the mounting clamp by sliding it over the end of the tank unit outer tube. Secure the clamp into position with two 2.38mm (3/32in.) diameter break head rivets using the riveting pliers. Remove and recover the broken heads of the rivet mandrels. Uncontrolled when reproduced 28-47-05 Page 702 Feb 27/02 0201KTU SERIES 4. Storage After Component Maintenance A. General The following instructions cover both storage and transit of the units concerned and are applicable to all climatic conditions. B. Detailed Requirements (1) Materials Equivalent substitutes may be used for listed items. Description C. Nomenclature and Specification or Vendor’s Trade Name Vendor Paper Paper waxed to DEF 1242 (1621-401) Smiths Paper Paper corrugated to DEF 1253 As available Wadding Cellulose wadding to DEF 1248 As available Envelope Envelope, polythene to DEF 1317 Smiths Box Box, fibreboard (rigid) to DEF STAN. 81-15 Smiths Tape Tape, transparent adhesive DEF 1313 (1756-451) Smiths Tape Tape, paper Kraft DEF 1299 (1756-111) Smiths Packaging Procedure (1) Wrap the unit in waxed paper ensuring that covering is complete and that any sharp corners do not pierce the wrapping material. Further wrap the unit in cellulose wadding and secure with transparent adhesive tape. (2) Prepare two labels detailing the following information: (a) Code and serial number of the unit. (b) Modification state. (c) Date of last overhaul. (d) Note and date of any component change. (e) Reason for return,if applicable. Attach one label to the wrapped unit with transparent adhesive tape, so that all the information on the label is visible. (3) Insert the package in a polythene bag and partially heat seal the end, leaving an opening of approximately one inch. Ensure that the information label is visible. (4) Squeeze as much air as possible from the bag and complete the seal. (5) Place the package in the appropriate shock resistant moulds of the storage and transit container. Use corrugated paper as necessary to provide additional support. (6) Close and secure the container lid with Kraft paper tape. (7) Attach the second label to the outside of the container. Uncontrolled when reproduced 28-47-05 Page 703 Feb 27/02 0201KTU SERIES D. Storage Conditions Details of Storage Conditions are contained in Publication SAV/OH/SPA, issued by Smiths Industries. E. Storage Limiting Period Details of storage limiting period are contained in Publication SAV/OH/SPA, issued by Smiths Industries. Re -certification and re-storage after this period is dependent upon satisfactory completion of the following procedure: (1) Remove the unit from its packing. (2) Examine the unit visually for evidence of corrosion or damage. (3) Carry out the complete procedure described in TESTING AND FAULT ISOLATION. (4) Repack the unit as described in para.C. Uncontrolled when reproduced 28-47-05 Page 704 Feb 27/02 0201KTU SERIES FITS AND CLEARANCES Not applicable to these units. Uncontrolled when reproduced 28-47-05 Page 801/802 Feb 27/02 0201KTU SERIES SPECIAL TOOLS, FIXTURES AND EQUIPMENT 1. Tools, Fixtures and Equipment NOTE: Equivalent items can be used. Item Description 1 2 Insulation Resistance Tester, 500V d.c. Capacitance Fuel Gauge Test Set 3 4 5 6 7 Test Cable Test Cable End Plates (2 off) Wooden Vee Blocks (2 off) Riveting pliers, crank handle 8 Torque spanner, set at 3.5lb in. Uncontrolled when reproduced Specification or Code Number 0601KQC-02 or 0601KQC-03 3684LMT 3711LMT 6030LMT Vendor Commercially available Smiths Type TT55 or similar - Commercially available Tucker Fasteners Ltd., Wasall Road, Birmingham, B42 1BP, U.K. Commercially available 28-47-05 Page 901/902 Feb 27/02 0201KTU SERIES ILLUSTRATED PARTS LIST WARNING: ONLY SPARES AND COMPONENTS SPECIFIED BY THE SMITHS GROUP SHOULD BE USED. ELECTROSTATIC SENSITIVE DEVICES (ESDS) AND MODULES THAT CONTAIN ESDS MUST STAY IN THEIR INITIAL PACKAGE UNTIL REQUIRED FOR USE. REFER TO THE INFORMATION GIVEN IN INTRODUCTION, PARA 3 BEFORE YOU TOUCH OR MOVE ESDS. 1. Ordering A. Certain spares parts listed in the IPL are manufactured by other contractors and have the manufacturer’s number or British Standards Reference quoted in addition to the part number under which Smiths Group plc supply. B. When ordering from the Smiths Group, please quote the Smiths Group part number, the other manufacturer’s number or British Standards Reference and the code number of the LRU on all orders or enquiries. C. When ordering from other manufacturer’s please quote the manufacturer’s and/or British Standards Reference only. D. All Brisch codes Reflected in the Nomenclature field are Smiths Group assigned part numbers and carry K5294. E. 2. Part numbers and unit nameplates containing a hyphen/oblique, either between the alpha and numeric characters or between numeric and alpha characters, will have the hyphen/oblique removed from the part number listed in the IPL. Introduction A. General (1) B. The Illustrated Parts List is a list of all the parts in the unit. Use it to identify parts and to help with provisioning. Vendors Codes, Names and Addresses (1) The Vendors Code List specifies, by Federal Manufacturer’s Code Number, the name and address from which non-standard parts not manufactured by Smiths may be purchased. C. Equipment Designator Index (1) The Equipment Designator Index provides cross-reference of electrical/electronic parts to the IPL listing. Items are listed alpha/numerically. D. Alpha/Numeric Index (1) The Alpha/Numeric Index is used to help find part numbers in the Detailed Parts list. (2) The Total Required column (TTL REQ.) shows the total necessary each time the part number is shown in the Detailed Parts List. Uncontrolled when reproduced 28-47-05 Page 1001 Apr 17/06 0201KTU SERIES E. Detailed Parts List (1) The Detailed Parts List includes illustrations and all parts listings. When applicable, equipment variants are designated by usage codes A, B, C, etc in the usage code column. (2) The INDENT column is used to show the indent. Each assembly and part is indented under the Next Higher Assembly (NHA) of which it is part, for example: I N D E N T NOMENCLATURE 1 Assembly 1 Attaching Parts for assembly 2 Detail Parts for assembly 2 Sub-assembly 3 Detail parts for Sub-assembly 3 Sub-Sub Assembly 4 Detail Parts for Sub-Sub assembly (3) A hyphen (-) preceding an item number signifies that the item is not illustrated. (4) Next higher assembly relationships are references (NHA) or signified by indentures within the list. (5) The effectivity code, Reference letters ‘A’ through to ‘Z’ (does not include ‘I’ or ‘O’) are given to the EFF CODE column to each top assembly in each IPL figure. The Reference letter of each top assembly is also given in the EFF CODE column for each detail part and subassembly except that no Reference letter is given for details parts and subassemblies that are used on all top assemblies. (6) The UNITS PER ASSY column gives the total number of items that are necessary for each assembly, for each subassembly, and for each sub-subassembly as applicable. ‘As Required’ is written as ‘AR’. Parts that are written for Reference purposes are written as ‘RF’ or ‘REF’. (7) The interchangeability relationship between parts is identified in the NOMENCLATURE column of the Detailed Parts List. The table below describes the terms that are used to show interchangeability: Uncontrolled when reproduced 28-47-05 Page 1002 Apr 17/06 0201KTU SERIES Term Parts List Abbreviation Description Optional OPT This part is optional to and interchangeable with other parts in the same number variant group or other item number as given. Superseded SUPSD BY The part in the part number column is replaced by and is not interchangeable with the item number given in the notation. Supersedes SUPSDS The part in the part number column replaces and is not interchangeable with the item number given in the notation. Replaced by REPLD BY The part number in the part number column is replaced by and interchangeable with the item number given in the notation. Replaces REPLS The part number in the part number column replaces and is interchangeable with the item number given in the notation. The list below provides a description of the abbreviations that is used in the NOMENCLATURE column in the Detailed Parts List. Abbreviation Description Abbreviation Description ASSY Assembly RECEPT Receptacle AL Aluminum RECEIV Receiver CD Cadmium REF Reference CAPT Captive RES Resistor CER Ceramic SKT Socket CHRM Chromium CRS Stainless steel CIR Circuit SUB ASSY Sub-Assembly CSK Countersunk TANT Tantalum DIA Diameter TRANSMIT Transmitter IC Integrated Circuit TS Tri-State MICRO Microprocessor VAR Variable MUX Multiplexer VOL Voltage NET Network WW Wirewound Uncontrolled when reproduced 28-47-05 Page 1003 Apr 17/06 0201KTU SERIES Uncontrolled when reproduced 28-47-05 Page 1004 Apr 17/06 0201KTU SERIES 3. VENDOR CODES, NAMES AND ADDRESSES Uncontrolled when reproduced 28-47-05 Page 1005 Apr 17/06 0201KTU SERIES VENDOR CODE VENDOR K0017 EMHART FASTENING TEKNOLOGIES 177 WALSALL ROAD BIRMINGHAM W.MIDLANDS B42 1BP UK K7766 BRITISH STANDARDS INSTITUTION UK Uncontrolled when reproduced 28-47-05 Page 1006 Apr 17/06 0201KTU SERIES 4. EQUIPMENT DESIGNATOR INDEX Uncontrolled when reproduced 28-47-05 Page 1007 Apr 17/06 0201KTU SERIES EQUIPMENT DESIGNATOR FIG. ITEM EQUIPMENT DESIGNATOR FIG. ITEM Not Applicable Uncontrolled when reproduced 28-47-05 Page 1008 Apr 17/06 0201KTU SERIES 5. ALPHA/NUMERIC INDEX Uncontrolled when reproduced 28-47-05 Page 1009 Apr 17/06 0201KTU SERIES PART NUMBER R R R R AIRLINE STOCK NUMBER FIG. ITEM TTL REQ AGS2035A SEE 30-283-011-25 1 60A 1 AGS2035A SEE 30-283-011-25 1A 45A 1 A210AT SEE 30-297-634-03 1 50A 1 A210AT SEE 30-297-634-03 1A 35A 1 BCP1645 1 100 1 BCP1645 1A 85 1 KTUA124 1 45 1 KTUA125 1 45A 1 KTUA126 1A 60F 1 KTUA127 1 70 1 KTUA128 1 70A 1 KTUA129 1 70R 1 KTUA130 1 70B 1 KTUA131 1 70S 1 KTUA132 1 70T 1 KTUA133 1 70C 1 KTUA134 1 70D 1 KTUA135 1 70E 1 KTUA136 1 70U 1 KTUA137 1 70F 1 KTUA138 1 70G 1 KTUA139 1 70H 1 KTUA140 1 70J 1 KTUA141 1 70K 1 KTUA142 1 70L 1 KTUA143 1 70M 1 Uncontrolled when reproduced 28-47-05 Page 1010 Apr 17/06 0201KTU SERIES PART NUMBER AIRLINE STOCK NUMBER FIG. ITEM TTL REQ KTUA144 1 70V 1 KTUA147 1 75 1 R KTUA148 1A 60D 1 R KTUA149 1A 60E 1 KTUA150 1 75E 1 KTUA151 1A 60 1 KTUA152 1 75B 1 KTUA153 1 75A 1 R KTUA154 1A 60B 1 R KTUA155 1A 60A 1 KTUA156 1 75C 1 KTUA157 1 75D 1 KTUA159 1 75H 1 KTUA160 1A 60C 1 KTUA162 1 75F 1 KTUA163 1 75G 1 KTUA164 1 75J 1 KTUA165 1 75K 1 KTUA166 1 75M 1 KTUA167 1 75L 1 KTUA180 1 35 1 KTUA180 1A 20 1 KTUA183 1 75N 1 KTUA184 1 75P 1 KTUA185 1 75Q 1 KTUA186 1 70N 1 KTUA187 1 70P 1 KTUA188 1 70Q 1 R R R Uncontrolled when reproduced 28-47-05 Page 1011 Apr 17/06 0201KTU SERIES PART NUMBER R R R R AIRLINE STOCK NUMBER FIG. ITEM TTL REQ KTUA220 1 75R 1 KTUA221 1 75S 1 KTUA222 1 75T 1 KTUA223 1 75U 1 KTUA227 1 70W 1 KTUA228 1 70X 1 KTUA229 1 75V 1 KTUA230 1 75W 1 KTUA231 1 75X 1 KTUA943 1 45B 1 KTUA944 1 45C 1 KTUA945 1 71 1 KTUA946 1 71A 1 KTUA947 1 71R 1 KTUA947 1A 55 1 KTUA948 1 71B 1 KTUA949 1 71S 1 KTUA949 1A 55A 1 KTUA950 1 71T 1 KTUA950 1A 55B 1 KTUA951 1 71C 1 KTUA952 1 71D 1 KTUA953 1 71E 1 KTUA954 1 71U 1 KTUA954 1A 55C 1 KTUA955 1 71F 1 KTUA956 1 71G 1 KTUA957 1 71H 1 Uncontrolled when reproduced 28-47-05 Page 1012 Apr 17/06 0201KTU SERIES PART NUMBER AIRLINE STOCK NUMBER FIG. ITEM TTL REQ KTUA958 1 71J 1 KTUA959 1 71K 1 KTUA960 1 71L 1 KTUA961 1 71M 1 KTUA962 1 71V 1 R KTUA962 1A 55D 1 R KTUA963 1A 55E 1 R KTUA964 1A 55F 1 KTUA965 1 71N 1 KTUA966 1 71P 1 KTUA967 1 71Q 1 KTUA968 1 71W 1 KTUA969 1 71X 1 KTUA986 1 45D 1 KTUA986 1A 30 1 KTUA987 1 45E 1 KTUA987 1A 30A 1 KTU1128 1 65 2 KTU1128 1A 50 2 KTU1129 1 80 6 KTU1129 1 80C 4 KTU1129 1 80E 5 KTU1129 1 80F 8 R KTU1129 1A 65 6 R KTU1129 1A 65A 4 R KTU1129 1A 65B 2 KTU1130 1 80A 4 KTU1130 1 80B 3 R R R Uncontrolled when reproduced 28-47-05 Page 1013 Apr 17/06 0201KTU SERIES PART NUMBER AIRLINE STOCK NUMBER FIG. ITEM TTL REQ KTU1130 1 80D 1 R KTU1130 1A 65C 4 R KTU1130 1A 65D 2 KTU1140 1 90 1 R KTU1140 1A 75 1 R KTU1141 1A 70 1 KTU1146 1 65A 2 KTU1179 1 40 2 KTU1179 1A 25 2 KTU1344 1 85 1 KTU1353 1 10 2 KTU1353 1 10A 1 KTU1353 1A 10 2 SP47A SEE 30-298-211-01 1 55A 1 SP47A SEE 30-298-211-01 1A 40A 1 TAPD31BS SEE 30-227-236-01 1 15A 2 TAPD31BS SEE 30-227-236-01 1 30A 2 TAPD31BS SEE 30-227-236-01 1 95A 2 TAPD31BS SEE 30-227-236-01 1 105A 2 R TAPD31BS SEE 30-227-236-01 1A 15A 2 R TAPD31BS SEE 30-227-236-01 1A 80A 2 R TAPD31BS SEE 30-227-236-01 1A 90A 2 0201KTU10 1 1D RF 0201KTU11 1 1E RF R R R Uncontrolled when reproduced 28-47-05 Page 1014 Apr 17/06 0201KTU SERIES PART NUMBER R AIRLINE STOCK NUMBER FIG. ITEM TTL REQ 0201KTU12 1A 1C RF 0201KTU13 1 1F RF 0201KTU14 1 1G RF 0201KTU15 1 1H RF 0201KTU16 1 1J RF 0201KTU17 1 1K RF 0201KTU18 1 1L RF 0201KTU19 1 1M RF R 0201KTU20 1A 1D RF R 0201KTU21 1A 1E RF R 0201KTU22 1A 1F RF 0201KTU23 1 1N RF 0201KTU24 1 1P RF 0201KTU25 1 1Q RF 0201KTU29 1 1R RF 0201KTU3 1 1 RF 0201KTU30 1 1S RF 0201KTU31 1 1T RF 0201KTU32 1 1U RF 0201KTU33 1 1V RF 0201KTU34 1 1W RF 0201KTU35 1 1X RF 0201KTU4 1 1A RF 0201KTU5 1A 1 RF 0201KTU6 1 1B RF R 0201KTU7 1A 1A RF R 0201KTU8 1A 1B RF 0201KTU9 1 1C RF R Uncontrolled when reproduced 28-47-05 Page 1015 Apr 17/06 0201KTU SERIES PART NUMBER AIRLINE STOCK NUMBER FIG. ITEM TTL REQ 30-222-658-01 1 5 1 30-222-658-01 1A 5 1 30-227-236-01 1 15 2 30-227-236-01 SEE TAPD31BS 1 15A 2 30-227-236-01 1 30 2 30-227-236-01 SEE TAPD31BS 1 30A 2 30-227-236-01 1 95 2 30-227-236-01 SEE TAPD31BS 1 95A 2 30-227-236-01 1 105 2 30-227-236-01 SEE TAPD31BS 1 105A 2 R 30-227-236-01 1A 15 2 R 30-227-236-01 SEE TAPD31BS 1A 15A 2 R 30-227-236-01 1A 80 2 R 30-227-236-01 SEE TAPD31BS 1A 80A 2 R 30-227-236-01 1A 90 2 R 30-227-236-01 SEE TAPD31BS 1A 90A 2 30-283-011-25 1 60 1 30-283-011-25 SEE AGS2035A 1 60A 1 R 30-283-011-25 1A 45 1 R 30-283-011-25 SEE AGS2035A 1A 45A 1 30-297-634-03 1 50 1 30-297-634-03 SEE A210AT 1 50A 1 30-297-634-03 1A 35 1 R R Uncontrolled when reproduced 28-47-05 Page 1016 Apr 17/06 0201KTU SERIES PART NUMBER R AIRLINE STOCK NUMBER FIG. ITEM TTL REQ 30-297-634-03 SEE A210AT 1A 35A 1 30-298-211-01 1 55 1 30-298-211-01 SEE SP47A 1 55A 1 R 30-298-211-01 1A 40 1 R 30-298-211-01 SEE SP47A 1A 40A 1 37-714-124-01 1 20 1 37-714-127-01 1 25 1 Uncontrolled when reproduced 28-47-05 Page 1017 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page 1018 Apr 17/06 0201KTU SERIES 6. DETAILED PARTS LIST Uncontrolled when reproduced 28-47-05 Page 1019 Apr 17/06 0201KTU SERIES IPL Fig. 1 Tank Unit Uncontrolled when reproduced 28-47-05 Page 1020 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -1 0201KTU3 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) A RF -1A 0201KTU4 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) B RF -1B 0201KTU6 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) C RF -1C 0201KTU9 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) D RF -1D 0201KTU10 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) E RF -1E 0201KTU11 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) F RF -1F 0201KTU13 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) G RF -1G 0201KTU14 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) H RF -1H 0201KTU15 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) J RF -1J 0201KTU16 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) K RF - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1021 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -1K 0201KTU17 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) L RF -1L 0201KTU18 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) M RF -1M 0201KTU19 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) N RF -1N 0201KTU23 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) P RF -1P 0201KTU24 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) Q RF -1Q 0201KTU25 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) R RF -1R 0201KTU29 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) S RF -1S 0201KTU30 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) T RF -1T 0201KTU31 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) U RF -1U 0201KTU32 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) V RF - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1022 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -1V 0201KTU33 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) W RF -1W 0201KTU34 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) X RF -1X 0201KTU35 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) Y RF 5 30-222-658-01 2 RIVET 3/32IN DIA X 1/8IN LG FLAT HD ALUM A,B, 1 C,D, E,F, G,H, J,K, L,M, N,S, T,U, V,W, Y 10 KTU1353 2 CLAMP MOUNTING A,B, 2 C,D, E,F, G,H, J,K, L,M, N,S, T,U, V,W, X,Y 10A KTU1353 2 CLAMP MOUNTING P,Q, 1 R ATTACHING PARTS 15 -15A 30-227-236-01 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 15A) 2 TAPD31BS 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (30-227-236-01) VK0017 (REPLS ITEM 15) 2 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1023 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 20 37-714-124-01 2 RING SUPPORT P,Q, 1 R 25 37-714-127-01 2 SLEEVE RING SUPPORT P,Q, 1 R 30 30-227-236-01 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 30A) P,Q, 2 R TAPD31BS 2 RIVET P,Q, 2 3/32IN DIA X 0.14IN LG R FLAT HD ALUM (30-227-236-01) VK0017 (REPLS ITEM 30) 35 KTUA180 2 COVER ASSY RING 1 40 KTU1179 2 SPRING RETAINING 2 -30A * * * 45 KTUA124 2 TERMINAL ASSY BLOCK (PRE SB28-326) A,B, 1 C,D, E,F, G,H, J,K, L,M, N,P, Q,R, S,U, V,W, Y -45A KTUA125 2 TERMINAL ASSY BLOCK (PRE SB28-326) T,X -45B KTUA943 2 TERMINAL ASSY BLOCK (SB28-326) (PRE SB28-318) A,B, 1 C,D, E,F, G,H, J,K, L,M, N,P, Q,R, S,U, V,W, Y - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 1 Page 1024 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T EFF CODE NOMENCLATURE UNITS PER ASSY. 1 -45C KTUA944 2 TERMINAL ASSY BLOCK (SB28-326) (PRE SB28-318) T,X 1 -45D KTUA986 2 TERMINAL ASSY BLOCK (SB28-318) A,B, 1 C,D, E,F, G,H, J,K, L,M, N,P, Q,R, S,U, V,W, Y -45E KTUA987 2 TERMINAL ASSY BLOCK (SB28-318) T,X 1 ATTACHING PARTS 50 -50A 55 -55A 60 -60A 30-297-634-03 2 NUT 4-40UNC THIN BRASS (REPLD BY ITEM 50A) 1 A210AT 2 NUT 4-40UNC THIN BRASS (30-297-634-03) (REPLS ITEM 50) 1 30-298-211-01 2 SP47A VK7766 WASHER NO.4 SPRING STL (REPLD BY ITEM 55A WASHER NO.4 SPRING STL (30-298-211-01) (REPLS ITEM 55) 1 1 VK7766 30-283-011-25 2 WASHER NO.4 SHAKEPROOF STL (REPLD BY ITEM 60A) 1 AGS2035A 2 WASHER 6BA SHAKEPROOF STL VK7766 (30-283-011-25) (REPLS ITEM 60) 1 * - ITEM NOT ILLUSTRATED Uncontrolled when reproduced * * 28-47-05 Page 1025 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 65 KTU1128 2 PIN CROSS A,B, 2 C,D, H,K, L,M, N,R, S,T, U,V, W,X, Y -65A KTU1146 2 PIN CROSS E,F, 2 G,J, P,Q 70 KTUA127 2 TUBE ASSY OUTER (PRE SB28-326) A 1 -70A KTUA128 2 TUBE ASSY OUTER (PRE SB28-326) B 1 -70B KTUA130 2 TUBE ASSY OUTER (PRE SB28-326) C 1 -70C KTUA133 2 TUBE ASSY OUTER (PRE SB28-326) D 1 -70D KTUA134 2 TUBE ASSY OUTER (PRE SB28-326) E 1 -70E KTUA135 2 TUBE ASSY OUTER (PRE SB28-326) F 1 -70F KTUA137 2 TUBE ASSY OUTER (PRE SB28-326) G 1 -70G KTUA138 2 TUBE ASSY OUTER (PRE SB28-326) H 1 -70H KTUA139 2 TUBE ASSY OUTER (PRE SB28-326) J 1 -70J KTUA140 2 TUBE ASSY OUTER (PRE SB28-326) K 1 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1026 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -70K KTUA141 2 TUBE ASSY OUTER (PRE SB28-326) L 1 -70L KTUA142 2 TUBE ASSY OUTER (PRE SB28-326) M 1 -70M KTUA143 2 TUBE ASSY OUTER (PRE SB28-326) N 1 -70N KTUA186 2 TUBE ASSY OUTER (PRE SB28-326) P 1 -70P KTUA187 2 TUBE ASSY OUTER (PRE SB28-326) Q 1 -70Q KTUA188 2 TUBE ASSY OUTER (PRE SB28-326) R 1 -70R KTUA129 2 TUBE ASSY OUTER (PRE SB28-326) S 1 -70S KTUA131 2 TUBE ASSY OUTER (PRE SB28-326) T 1 -70T KTUA132 2 TUBE ASSY OUTER (PRE SB28-326) U 1 -70U KTUA136 2 TUBE ASSY OUTER (PRE SB28-326) V 1 -70V KTUA144 2 TUBE ASSY OUTER (PRE SB28-326) W 1 -70W KTUA227 2 TUBE ASSY OUTER (PRE SB28-326) X 1 -70X KTUA228 2 TUBE ASSY OUTER (PRE SB28-326) Y 1 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1027 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 71 KTUA945 2 TUBE ASSY OUTER (SB28-326) A 1 -71A KTUA946 2 TUBE ASSY OUTER (SB28-326) B 1 -71B KTUA948 2 TUBE ASSY OUTER (SB28-326) C 1 -71C KTUA951 2 TUBE ASSY OUTER (SB28-326) D 1 -71D KTUA952 2 TUBE ASSY OUTER (SB28-326) E 1 -71E KTUA953 2 TUBE ASSY OUTER (SB28-326) F 1 -71F KTUA955 2 TUBE ASSY OUTER (SB28-326) G 1 -71G KTUA956 2 TUBE ASSY OUTER (SB28-326) H 1 -71H KTUA957 2 TUBE ASSY OUTER (SB28-326) J 1 -71J KTUA958 2 TUBE ASSY OUTER (SB28-326) K 1 -71K KTUA959 2 TUBE ASSY OUTER (SB28-326) L 1 -71L KTUA960 2 TUBE ASSY OUTER (SB28-326) M 1 -71M KTUA961 2 TUBE ASSY OUTER (SB28-326) N 1 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1028 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -71N KTUA965 2 TUBE ASSY OUTER (SB28-326) P 1 -71P KTUA966 2 TUBE ASSY OUTER (SB28-326) Q 1 -71Q KTUA967 2 TUBE ASSY OUTER (SB28-326) R 1 -71R KTUA947 2 TUBE ASSY OUTER (SB28-326) S 1 -71S KTUA949 2 TUBE ASSY OUTER (SB28-326) T 1 -71T KTUA950 2 TUBE ASSY OUTER (SB28-326) U 1 -71U KTUA954 2 TUBE ASSY OUTER (SB28-326) V 1 -71V KTUA962 2 TUBE ASSY OUTER (SB28-326) W 1 -71W KTUA968 2 TUBE ASSY OUTER (SB28-326) X 1 -71X KTUA969 2 TUBE ASSY OUTER (SB28-326) Y 1 75 KTUA147 2 TUBE ASSY INNER A 1 -75A KTUA153 2 TUBE ASSY INNER B 1 -75B KTUA152 2 TUBE ASSY INNER C 1 -75C KTUA156 2 TUBE ASSY INNER D 1 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1029 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -75D KTUA157 2 TUBE ASSY INNER E 1 -75E KTUA150 2 TUBE ASSY INNER F 1 -75F KTUA162 2 TUBE ASSY INNER G 1 -75G KTUA163 2 TUBE ASSY INNER H 1 -75H KTUA159 2 TUBE ASSY INNER J 1 -75J KTUA164 2 TUBE ASSY INNER K 1 -75K KTUA165 2 TUBE ASSY INNER L 1 -75L KTUA167 2 TUBE ASSY INNER M 1 -75M KTUA166 2 TUBE ASSY INNER N 1 -75N KTUA183 2 TUBE ASSY INNER P 1 -75P KTUA184 2 TUBE ASSY INNER Q 1 -75Q KTUA185 2 TUBE ASSY INNER R 1 -75R KTUA220 2 TUBE ASSY INNER S 1 -75S KTUA221 2 TUBE ASSY INNER T 1 -75T KTUA222 2 TUBE ASSY INNER U 1 -75U KTUA223 2 TUBE ASSY INNER V 1 -75V KTUA229 2 TUBE ASSY INNER W 1 -75W KTUA230 2 TUBE ASSY INNER X 1 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1030 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 -75X KTUA231 2 TUBE ASSY INNER Y 1 80 KTU1129 2 PIN INNER CROSS A,B, 6 C,D, Q,S, -80A KTU1130 2 PIN INNER CROSS E,G, 4 J,V, X,Y -80B KTU1130 2 PIN INNER CROSS F -80C KTU1129 2 PIN INNER CROSS H,K, 4 L,M, N,P, T,U, Y -80D KTU1130 2 PIN INNER CROSS Q 1 -80E KTU1129 2 PIN INNER CROSS R 5 -80F KTU1129 2 PIN INNER CROSS W 8 85 KTU1344 2 TUBE X 1 90 KTU1140 2 LINK CONNECTING X 1 3 ATTACHING PARTS 95 -95A 30-227-236-01 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 95A) X 2 TAPD31BS 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM VK0017 (30-227-236-01) (REPLS ITEM 95) X 2 * - ITEM NOT ILLUSTRATED Uncontrolled when reproduced * * 28-47-05 Page 1031 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1 100 BCP1645 2 LABEL 1 ATTACHING PARTS 105 30-227-236-01 -105A TAPD31BS 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 105A) 2 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM VK0017 (30-227-236-01) (REPLS ITEM 105) 2 * - ITEM NOT ILLUSTRATED Uncontrolled when reproduced * * 28-47-05 Page 1032 Apr 17/06 0201KTU SERIES THIS PAGE IS NOT USED Uncontrolled when reproduced 28-47-05 Page 1033 Apr 17/06 0201KTU SERIES IPL Fig. 1A Tank Unit Uncontrolled when reproduced 28-47-05 Page 1034 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1A R -1 0201KTU5 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) A RF R -1A 0201KTU7 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) B RF R -1B 0201KTU8 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) C RF R -1C 0201KTU12 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) D RF R -1D 0201KTU20 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) E RF R -1E 0201KTU21 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) F RF R -1F 0201KTU22 1 UNIT TANK (SB28-326 MOD.01) (SB28-318 MOD.02) G RF R 5 30-222-658-01 2 RIVET 3/32IN DIA X 1/8IN LG FLAT HD ALUM 1 R 10 KTU1353 2 CLAMP MOUNTING 2 ATTACHING PARTS R 15 R -15A 30-227-236-01 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 15A) 2 TAPD31BS 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (30-227-236-01) VK0017 (REPLS ITEM 15) 2 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1035 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T EFF CODE NOMENCLATURE UNITS PER ASSY. 1A R 20 KTUA180 2 COVER ASSY RING 1 R 25 KTU1179 2 SPRING RETAINING 2 * * * R -30 KTUA986 2 TERMINAL ASSY BLOCK (SB28-318) A,C, 1 D,E, G R -30A KTUA987 2 TERMINAL ASSY BLOCK (SB28-318) B,F 1 ATTACHING PARTS R 35 R -35A R 40 R -40A R 45 R -45A 30-297-634-03 2 NUT 4-40UNC THIN BRASS (REPLD BY ITEM 50A) 1 A210AT 2 NUT 4-40UNC THIN BRASS (30-297-634-03) (REPLS ITEM 50) 1 30-298-211-01 2 SP47A WASHER NO.4 SPRING STL (REPLD BY ITEM 55A WASHER NO.4 SPRING STL (30-298-211-01) (REPLS ITEM 55) 50 1 1 VK7766 30-283-011-25 2 WASHER NO.4 SHAKEPROOF STL (REPLD BY ITEM 60A) 1 AGS2035A 2 WASHER 6BA SHAKEPROOF STL VK7766 (30-283-011-25) (REPLS ITEM 60) 1 * R VK7766 KTU1128 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 2 * * PIN CROSS 28-47-05 2 Page 1036 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1A R 55 KTUA947 2 TUBE ASSY OUTER (SB28-326) TUBE ASSY OUTER (SB28-326) A 1 R -55A KTUA949 2 B 1 R -55B KTUA950 2 TUBE ASSY OUTER (SB28-326) C 1 R -55C KTUA954 2 TUBE ASSY OUTER (SB28-326) D 1 R -55D KTUA962 2 TUBE ASSY OUTER (SB28-326) E 1 R -55E KTUA963 2 TUBE ASSY OUTER (SB28-326) F 1 R -55F KTUA964 2 TUBE ASSY OUTER (SB28-326) G 1 R KTUA151 2 TUBE ASSY INNER A 1 R -60A KTUA155 2 TUBE ASSY INNER B 1 R -60B KTUA154 2 TUBE ASSY INNER C 1 R -60C KTUA160 2 TUBE ASSY INNER D 1 R -60D KTUA148 2 TUBE ASSY INNER E 1 R -60E KTUA149 2 TUBE ASSY INNER F 1 R -60F KTUA126 2 TUBE ASSY INNER G 1 R KTU1129 2 PIN INNER CROSS A,E, 6 G 60 65 - ITEM NOT ILLUSTRATED Uncontrolled when reproduced 28-47-05 Page 1037 Apr 17/06 0201KTU SERIES FIG. & INDEX NO. PART NUMBER AIRLINE STOCK NUMBER I N D E N T NOMENCLATURE EFF CODE UNITS PER ASSY. 1A R -65A KTU1129 2 PIN INNER CROSS B,C 4 R -65B KTU1129 2 F 2 R -65C KTU1130 2 PIN INNER CROSS PIN INNER CROSS D,F 4 R -65D KTU1130 2 PIN INNER CROSS E,G 2 R 70 KTU1141 2 TUBE F 1 R 75 KTU1140 2 TUBE F 1 ATTACHING PARTS R 80 R -80A 30-227-236-01 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 95A) F 2 TAPD31BS 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM VK0017 (30-227-236-01) (REPLS ITEM 95) F 2 * R 85 BCP1645 2 * * LABEL 1 ATTACHING PARTS R 90 R -90A 30-227-236-01 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM (REPLD BY ITEM 105A) 2 TAPD31BS 2 RIVET 3/32IN DIA X 0.14IN LG FLAT HD ALUM VK0017 (30-227-236-01) (REPLS ITEM 105) 2 * - ITEM NOT ILLUSTRATED Uncontrolled when reproduced * * 28-47-05 Page 1038 Apr 17/06