Double-Pipe Heat Exchanger Design: Thermal & Hydraulic Analysis

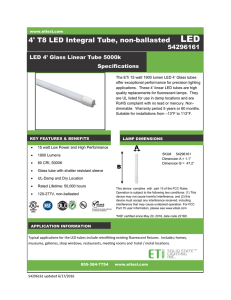

advertisement

Double-Pipe Heat Exchangers 1 2 3 The outer surface of the inner tube can be finned and then the tube can be placed concentrically inside a large pipe (Figures 1.8 and 7.2). In another type, there are multi tubes, finned or bare, inside a larger pipe (Figure 7.3). 4 5 6 7 8 Thermal and Hydraulic Design of Inner Tube Correlations available in the literature are used to calculate heat transfer coefficients inside the inner tube. Important correlations are given in Chapter 3. The frictional pressure drop for flow inside circular tube is calculated using the Fanning Equation (Equation 4.3): 9 Thermal and Hydraulic Analysis of Annulus Heat transfer and pressure calculations for flow inside the annulus shell are similar to those for the tube-side flow, provided that the hydraulic diameter of the annulus is used instead of the tube inner diameter. The hydraulic (equivalent) diameter is given by Equation 3.14. It should be noted that only a portion of the wetted perimeter is heated or cooled. Therefore, the hydraulic (equivalent) diameter for the heat transfer calculations is not the same as that used in pressure-drop calculations, given by Equation 3.18. 10 11 Hairpin Heat exchanger with Bare inner Tube 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Hairpin Heat exchangers with Multi-tube Finned inner Tubes The total wetted perimeter of the annulus with longitudinally finned inner tubes can be written as (see Figure 7.2) and the heat transfer perimeter of the annulus can be calculated from It is assumed that the outside of the annulus is insulated against heat losses and the heat transfer occurs through the wall and the fins of the inner tube. The net crosssectional free flow area in the annulus with longitudinal finned inner tubes is given by 26 Hairpin Heat exchangers with Multitube Finned inner Tubes From Equations 7.4, 7.5, 7.8, 7.9, and 7.10, the hydraulic diameter for the Reynolds number and the pressure drop is and the equivalent diameter based on heat transfer, For a double-pipe heat exchanger of length L, the unfinned (bare) and finned areas are, respectively, 27 The total outside heat transfer surface area of a hairpin is the sum of the unfinned and finned surfaces, given by Equations 7.11 and 7.12 (see Figure 7.2): The overall heat transfer coefficient based on the outside area of the inner tube is given by Equation 2.17. It should be noticed that Ao is replaced by At: where 28 which is defined by Equation 2.15. As can be seen from Equation 7.14, area ratios At /Ai and Af /At must be calculated to find the overall heat transfer coefficient based on the outside surface area of the inner tube. It should be noted that Rw is calculated for bare tubes using Equation 2.12b. The fin efficiency is given by Equation 2.18: where 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48