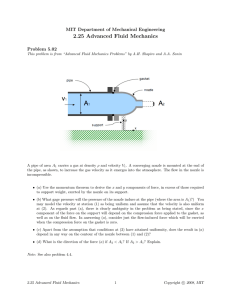

Graduate School ETD Form 9 (Revised 12/07) PURDUE UNIVERSITY GRADUATE SCHOOL Thesis/Dissertation Acceptance This is to certify that the thesis/dissertation prepared By DEEPAK THIRUMURTHY Entitled DESIGN AND ANALYSIS OF NOISE SUPPRESSION EXHAUST NOZZLE SYSTEMS For the degree of MASTER OF SCIENCE IN AERONAUTICS AND ASTRONAUTICS Is approved by the final examining committee: W Dr. ANASTASIOS S. LYRINTZIS Chair PR EV Dr. JOHN P. SULLIVAN IE Dr. GREGORY A. BLAISDELL To the best of my knowledge and as understood by the student in the Research Integrity and Copyright Disclaimer (Graduate School Form 20), this thesis/dissertation adheres to the provisions of Purdue University’s “Policy on Integrity in Research” and the use of copyrighted material. Dr. ANASTASIOS S. LYRINTZIS Approved by Major Professor(s): ____________________________________ ____________________________________ Approved by: Dr. ANASTASIOS S. LYRINTZIS Head of the Graduate Program JANUARY 14TH, 2010 Date Graduate School Form 20 (Revised 6/09) PURDUE UNIVERSITY GRADUATE SCHOOL Research Integrity and Copyright Disclaimer Title of Thesis/Dissertation: DESIGN AND ANALYSIS OF NOISE SUPPRESSION EXHAUST NOZZLE SYSTEMS W MASTER OF SCIENCE IN AERONAUTICS AND ASTRONAUTICS For the degree of ________________________________________________________________ IE I certify that in the preparation of this thesis, I have observed the provisions of Purdue University Executive Memorandum No. C-22, September 6, 1991, Policy on Integrity in Research.* Further, I certify that this work is free of plagiarism and all materials appearing in this thesis/dissertation have been properly quoted and attributed. PR EV I certify that all copyrighted material incorporated into this thesis/dissertation is in compliance with the United States’ copyright law and that I have received written permission from the copyright owners for my use of their work, which is beyond the scope of the law. I agree to indemnify and save harmless Purdue University from any and all claims that may be asserted or that may arise from any copyright violation. DEEPAK THIRUMURTHY ______________________________________ Printed Name and Signature of Candidate 02/22/2010 ______________________________________ Date (month/day/year) *Located at http://www.purdue.edu/policies/pages/teach_res_outreach/c_22.html DESIGN AND ANALYSIS OF NOISE SUPPRESSION EXHAUST NOZZLE SYSTEMS A Thesis of W Submitted to the Faculty IE Purdue University by PR EV Deepak Thirumurthy In Partial Fulfillment of the Requirements for the Degree of Master of Science in Aeronautics and Astronautics May 2010 Purdue University West Lafayette, Indiana UMI Number: 1479646 All rights reserved INFORMATION TO ALL USERS The quality of this reproduction is dependent upon the quality of the copy submitted. PR EV IE W In the unlikely event that the author did not send a complete manuscript and there are missing pages, these will be noted. Also, if material had to be removed, a note will indicate the deletion. UMI 1479646 Copyright 2010 by ProQuest LLC. All rights reserved. This edition of the work is protected against unauthorized copying under Title 17, United States Code. ProQuest LLC 789 East Eisenhower Parkway P.O. Box 1346 Ann Arbor, MI 48106-1346 PR EV IE W ii To my Parents and dear Sister, who enabled me to pursue my dreams. iii ACKNOWLEDGMENTS I would like to express my gratitude towards my major professors, Dr. Anastasios S. Lyrintzis and Dr. Gregory A. Blaisdell for their support, encouragement and instruction. My sincere appreciation goes to Dr. John P. Sullivan and his design team for their constant suggestions on the nozzle design and support in the form of experimen- W tal results. I would also like to thank Dr. Stephen D. Heister, director, Rolls-Royce University Technology Center in High Mach Propulsion, Dr. Jack S. Sokhey, senior engineering consultant, Rolls-Royce, Indianapolis, USA and Mr. John R. Whurr, senior IE project engineer, Rolls-Royce, Derby, UK for their support. I am grateful to Dr. John Matlik, Dr. Loren Garrison and Patricia A. Ellis, Rolls- PR EV Royce, Indianapolis, USA for being instrumental in liaisoning the Purdue University - Rolls-Royce University Technology Center activities and helping in obtaining publication approval. The work summarized in this thesis was part of Task 8, nozzle acoustics analysis, of the supersonic business jet program, sponsored by Rolls-Royce and the Gulfstream Aerospace Corporation. iv TABLE OF CONTENTS Page vi LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii ABSTRACT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix W LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2 4 5 6 2 Noise Suppression and Design Methodology . . 2.1 Jet Noise - A Classical Problem . . . . . . 2.2 Noise Suppression Exhaust Nozzles . . . . 2.2.1 Ejector Nozzle . . . . . . . . . . . . 2.2.2 Chevrons - Passive Mixers . . . . . 2.3 Computational Techniques . . . . . . . . . 2.3.1 Numerical Methods . . . . . . . . . 2.3.2 Turbulence Modeling for Jet Flows 2.4 Design Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 8 10 12 15 18 19 20 26 3 Chevron Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3 Three-Stream Separate-Flow Axisymmetric Plug Nozzle (3BB) 3.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 3.3.2 Geometry and Mesh Generation . . . . . . . . . . . . . 3.3.3 Boundary Conditions and CFD Methodology . . . . . . 3.3.4 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4 Three-Stream Separate-Flow Chevron Nozzle (3A12B) . . . . 3.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 3.4.2 Geometry and Mesh Generation . . . . . . . . . . . . . 3.4.3 Boundary Conditions and CFD Methodology . . . . . . 3.4.4 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 28 29 29 29 30 31 33 42 42 42 45 46 PR EV IE 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 1.1 Supersonic Civil Transport . . . . . . . . . . . . . 1.2 Challenges Associated with Supersonic Transport 1.3 Noise Suppression Propulsion System . . . . . . . 1.4 Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v 3.5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 59 59 60 60 60 62 64 68 68 68 69 71 74 76 79 106 5 3-D Ejector Nozzles with Clamshell Doors and Chevrons . . . . . . . . 5.1 Introduction . . . . . . . . . . . . . . . . . . 5.2 Objectives . . . . . . . . . . . . . . . . . . . 5.3 Ejector Flow with Chevrons . . . . . . . . . 5.4 Nozzle Design and CAD Geometry . . . . . 5.5 Computational Mesh . . . . . . . . . . . . . 5.6 Boundary Conditions . . . . . . . . . . . . . 5.7 Numerical Computation . . . . . . . . . . . 5.8 Results . . . . . . . . . . . . . . . . . . . . . 5.8.1 Design I . . . . . . . . . . . . . . . . 5.8.2 Design II . . . . . . . . . . . . . . . . 5.8.3 Discussion on the centerline statistics 5.8.4 Effect on the ejector mass flow . . . . 5.9 Conclusion . . . . . . . . . . . . . . . . . . . 5.10 Future Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 108 109 109 110 114 116 117 118 118 119 120 120 128 128 6 Conclusions and Recommendations . . . . . . . . . . . . . . . . . . . . . 129 LIST OF REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 PR EV IE W 4 Ejector Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 4.2 Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 2-D Ejector Nozzle Test Case . . . . . . . . . . . . . . . . 4.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . 4.3.2 Geometry and Mesh Generation . . . . . . . . . . . 4.3.3 Boundary Conditions and Numerical Computation 4.3.4 Results . . . . . . . . . . . . . . . . . . . . . . . . . 4.4 3-D Ejector Nozzle with Clamshell Doors . . . . . . . . . . 4.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . 4.4.2 Experimental Investigation . . . . . . . . . . . . . . 4.4.3 Nozzle Design and CAD Geometry . . . . . . . . . 4.4.4 Grid Generation . . . . . . . . . . . . . . . . . . . . 4.4.5 Boundary Conditions . . . . . . . . . . . . . . . . . 4.4.6 Numerical Computation . . . . . . . . . . . . . . . 4.4.7 Results . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi LIST OF TABLES Table Page Thies and Tam’s k- turbulence model constants [39]. . . . . . . . . . . 24 3.1 Boundary conditions for the CFD simulation of the three-stream separateflow axisymmetric plug nozzle (3BB) [20]. . . . . . . . . . . . . . . . . 32 Boundary conditions for the CFD simulation of the three-stream separateflow chevron nozzle (3A12B) [24]. . . . . . . . . . . . . . . . . . . . . . 45 4.1 2-D ejector nozzle boundary conditions [46]. . . . . . . . . . . . . . . . 62 4.2 Calculation of the corrected inlet axial velocity magnitude for the CFD simulations using the minimization of the RMS difference. . . . . . . . 77 Dimensions of the chevron on the 3-D ejector nozzle with clamshell doors for Design I and Design II. . . . . . . . . . . . . . . . . . . . . . . . . . 111 Boundary conditions for the CFD simulation of the ejector nozzle with clamshell doors and chevrons. . . . . . . . . . . . . . . . . . . . . . . . 116 The effect of chevrons on the ejector mass flow. . . . . . . . . . . . . . 121 5.2 5.3 IE 5.1 PR EV 3.2 W 2.1 vii LIST OF FIGURES Figure 1.1 1.2 Page History of the commercial and military supersonic transport aircraft and its progress. (Reproduced courtesy of P. Henne [3].) . . . . . . . . . . . 2 The noise distribution from the individual components of the airbreathing jet engine propulsion system [6]. . . . . . . . . . . . . . . . . . . . . . . 4 A schematic representation of the 3-D ejector nozzle with clamshell doors [7]. 2.1 Jet noise as a result of the shear layer mixing phenomenon. . . . . . . . 2.2 Requirements for the pressure ratio and the area ratio as Mach number increases [16]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Operational modes of the ejector nozzle with clamshell doors (1) Subsonic take-off, (2) Supersonic cruise and (3) Subsonic approach. . . . . . . . 14 LS /∆ = Optimum attached free mixing layer. (Reproduced courtesy of J. Der Jr. [17].) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Three-stream separate-flow nozzle with chevrons on the core and fan nozzle [18]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Mixing of two streams of the chevron nozzle and streamwise vortex formation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 2.7 Methodology for the jet engine exhaust nozzle design and analysis. . . 27 3.1 The CAD geometry of the three-stream separate-flow axisymmetric plug nozzle [20]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 The computational mesh for the three-stream separate-flow axisymmetric plug nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 3BB axial velocity magnitude contour plot corresponding to PIV experiments on the Z=0 plane [20]. . . . . . . . . . . . . . . . . . . . . . . . 37 3BB axial velocity magnitude contour plot corresponding to the standard k- turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . . 37 3BB axial velocity magnitude contour plot corresponding to the realizable k- turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . . 37 2.5 2.6 3.2 3.3 3.4 3.5 IE 2.4 PR EV 2.3 W 1.3 5 9 viii Figure 3.6 Page 3BB axial velocity magnitude contour plot corresponding to the standard k-ω turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . . 38 3BB axial velocity magnitude contour plot corresponding to the k-ω shear stress transport turbulence model on the Z=0 plane. . . . . . . . . . . 38 3BB axial velocity magnitude contour plot corresponding to the Reynolds stress turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . 38 3BB turbulent kinetic energy contour plot corresponding to PIV experiments on the Z=0 plane [20]. . . . . . . . . . . . . . . . . . . . . . . . 39 3.10 3BB turbulent kinetic energy contour plot corresponding to the standard k- turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . . 39 3.11 3BB turbulent kinetic energy contour plot corresponding to the realizable k- turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . . 39 3.12 3BB turbulent kinetic energy contour plot corresponding to the standard k-ω turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . . 40 3.7 3.8 IE W 3.9 40 3.14 3BB turbulent kinetic energy contour plot corresponding to the Reynolds stress turbulence model on the Z=0 plane. . . . . . . . . . . . . . . . . 40 3.15 Centerline axial velocity profiles for different turbulence models and comparison with the experimental result. . . . . . . . . . . . . . . . . . . . 41 3.16 Centerline total temperature profiles for different turbulence models and comparison with the experimental result. . . . . . . . . . . . . . . . . . 41 3.17 Dimensions for the design of alternating chevrons [21]. . . . . . . . . . 43 3.18 The CAD geometry of the three-stream separate-flow chevron nozzle [24]. 44 3.19 The computational mesh for the three-stream separate-flow chevron nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 3.20 3A12B axial velocity magnitude contour plot corresponding to PIV experiments on the Z=0 and inward-facing chevron mid-plane [24]. . . . . . 49 3.21 3A12B axial velocity magnitude contour plot corresponding to WINDCFD results on the Z=0 and inward-facing chevron mid-plane [24]. . . 49 3.22 3A12B axial velocity magnitude contour plot corresponding to the k-ω SST turbulence model on the Z=0 and inward-facing chevron mid-plane. 49 PR EV 3.13 3BB turbulent kinetic energy contour plot corresponding to the k-ω shear stress transport turbulence model on the Z=0 plane. . . . . . . . . . . ix Figure Page 50 3.24 3A12B axial velocity magnitude contour plot corresponding to the realizable k- turbulence model on the Z=0 and inward-facing chevron midplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 3.25 3A12B axial velocity magnitude contour plot corresponding to Thies and Tam’s k- turbulence model on the Z=0 and inward-facing chevron midplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 3.26 3A12B axial velocity magnitude contour plot corresponding to PIV experiments on the outward-facing chevron mid-plane [24]. . . . . . . . . . . 51 3.27 3A12B axial velocity magnitude contour plot corresponding to WINDCFD results on the outward-facing chevron mid-plane [24]. . . . . . . . 51 3.28 3A12B axial velocity magnitude contour plot corresponding to the k-ω SST turbulence model on the outward-facing chevron mid-plane. . . . . 51 3.29 3A12B axial velocity magnitude contour plot corresponding to the standard k- turbulence model on the outward-facing chevron mid-plane. . 52 PR EV IE W 3.23 3A12B axial velocity magnitude contour plot corresponding to the standard k- turbulence model on the Z=0 and inward-facing chevron midplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.30 3A12B axial velocity magnitude contour plot corresponding to the realizable k- turbulence model on the outward-facing chevron mid-plane. . . 52 3.31 3A12B axial velocity magnitude contour plot corresponding to Thies and Tam’s k- turbulence model on the outward-facing chevron mid plane. . 52 3.32 3A12B turbulent kinetic energy contour plot corresponding to PIV experiments on the Z=0 and inward-facing chevron mid-plane [24]. . . . . . 53 3.33 3A12B turbulent kinetic energy contour plot corresponding to WIND-CFD results on the Z=0 and inward-facing chevron mid-plane [24]. . . . . . 53 3.34 3A12B turbulent kinetic energy contour plot corresponding to the k-ω SST turbulence model on the Z=0 and inward-facing chevron mid-plane. . . 53 3.35 3A12B turbulent kinetic energy contour plot corresponding to the standard k- turbulence model on the Z=0 and inward-facing chevron mid-plane. 54 3.36 3A12B turbulent kinetic energy contour plot corresponding to the realizable k- turbulence model on the Z=0 and inward-facing chevron midplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 3.37 3A12B turbulent kinetic energy contour plot corresponding to Thies and Tam’s k- turbulence model on the Z=0 and inward-facing chevron midplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 x Figure Page 55 3.39 3A12B turbulent kinetic energy contour plot corresponding to WIND-CFD results on the outward-facing chevron mid-plane [24]. . . . . . . . . . . 55 3.40 3A12B turbulent kinetic energy contour plot corresponding to the k-ω SST turbulence model on the outward-facing chevron mid-plane. . . . . . . 55 3.41 3A12B turbulent kinetic energy contour plot corresponding to the standard k- turbulence model on the outward-facing chevron mid-plane. . . . . 56 3.42 3A12B turbulent kinetic energy contour plot corresponding to the realizable k- turbulence model on the outward-facing chevron mid-plane. . . 56 3.43 3A12B turbulent kinetic energy contour plot corresponding to Thies and Tam’s k- turbulence model on the outward-facing chevron mid-plane. . 56 3.44 Centerline axial velocity profiles for different turbulence models and comparison with the experimental result. . . . . . . . . . . . . . . . . . . . 57 IE W 3.38 3A12B turbulent kinetic energy contour plot corresponding to PIV experiments on the outward-facing chevron mid-plane [24]. . . . . . . . . . . 3.45 Centerline total temperature profiles for different turbulence models and comparison with the experimental result. . . . . . . . . . . . . . . . . . Experimental setup for the 2-D ejector nozzle. (Reproduced courtesy of [46].) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 4.2 Computational mesh for the 2-D ejector nozzle. . . . . . . . . . . . . . 62 4.3 Mach number contour plot of the 2-D ejector nozzle corresponding to the k-ω SST turbulence model. . . . . . . . . . . . . . . . . . . . . . . . . 63 Mach number contour plot of the 2-D ejector nozzle corresponding to the Spalart-Allmaras turbulence model. . . . . . . . . . . . . . . . . . . . . 63 4.5 2-D ejector nozzle axial velocity profile at X=3.0 in. . . . . . . . . . . 65 4.6 2-D ejector nozzle axial velocity profile at X=5.0 in. . . . . . . . . . . 65 4.7 2-D ejector nozzle axial velocity profile at X=7.0 in. . . . . . . . . . . 66 4.8 2-D ejector nozzle axial velocity profile at X=10.5 in. . . . . . . . . . . 66 4.9 2-D ejector nozzle total temperature profile at X=3.0 in. . . . . . . . . 67 4.10 2-D ejector nozzle total temperature profile at X=10.5 in. . . . . . . . 67 4.11 CAD model of the 3-D ejector nozzle without clamshell doors [44]. . . . 69 4.12 CAD model of the 3-D ejector nozzle with clamshell doors [44]. . . . . 69 4.4 PR EV 4.1 57 xi Figure Page 4.13 Computational mesh for nozzle walls (a) 3-D ejector nozzle without clamshell doors (Grid I), and (b) 3-D ejector nozzle with clamshell doors (Grid II). 70 4.14 Computational mesh (Grid II) for the entire flow domain of the 3-D ejector nozzle with clamshell doors for the CFD simulation at experimental conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 4.15 Computational mesh (Grid III) for the entire flow domain of the 3-D ejector nozzle with clamshell doors for the CFD simulation at take-off conditions (higher NPR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 4.16 Extent of the computational domain for the 3-D ejector nozzle with clamshell doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 74 4.18 Schematic representation of take-off boundary conditions (Simulation II) and their numerical values. . . . . . . . . . . . . . . . . . . . . . . . . . 75 4.19 Experimental survey of the plenum chamber in the absence of the nozzle showing the nonuniformity involved in the axial velocity magnitude distribution [44]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 PR EV IE W 4.17 Schematic representation of experimental boundary conditions (Simulation I) and their numerical values. . . . . . . . . . . . . . . . . . . . . . 4.20 RMS difference distribution in the axial velocity magnitude at X/DEQ =1.0 downstream of the nozzle throat. . . . . . . . . . . . . . . . . . . . . . 77 4.21 Contour plot of the normalized axial velocity magnitude on the Z=0 plane for the 3-D ejector nozzle with clamshell doors corresponding to the k-ω shear stress transport turbulence model. . . . . . . . . . . . . . . . . . 80 4.22 Contour plot of the normalized axial velocity magnitude on the Z=0 plane for the 3-D ejector nozzle with clamshell doors corresponding to the realizable k- turbulence model with Thies and Tam’s model constants for jet flows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 4.23 Experimental U/UP L contour plot at X/DEQ =1.0 from the throat [44]. 82 4.24 Computational U/UP L contour plot at X/DEQ =1.0 from the throat. . 82 4.25 Experimental U/UP L contour plot at X/DEQ =1.5 from the throat [44]. 83 4.26 Computational U/UP L contour plot at X/DEQ =1.5 from the throat. . 83 4.27 Experimental U/UP L contour plot at X/DEQ =2.0 from the throat [44]. 84 4.28 Computational U/UP L contour plot at X/DEQ =2.0 from the throat. . 84 4.29 Experimental U/UP L contour plot at X/DEQ =3.0 from the throat [44]. 85 xii Figure Page . 85 4.31 Normalized axial velocity profile at X/DEQ =1.0 and on the Z=0 plane. 86 4.32 Normalized axial velocity profile at X/DEQ =1.0 and on the Y =0 plane. 86 4.33 Normalized axial velocity profile at X/DEQ =1.5 and on the Z=0 plane. 87 4.34 Normalized axial velocity profile at X/DEQ =1.5 and on the Y =0 plane. 87 4.35 Normalized axial velocity profile at X/DEQ =2.0 and on the Z=0 plane. 88 4.36 Normalized axial velocity profile at X/DEQ =2.0 and on the Y =0 plane. 88 4.37 Normalized axial velocity profile at X/DEQ =3.0 and on the Z=0 plane. 89 4.38 Normalized axial velocity profile at X/DEQ =3.0 and on the Y =0 plane. 89 4.39 Computational U/UP L contour plot at X/DEQ =3.0 downstream of the nozzle throat corresponding to the realizable k- turbulence model. . . 90 4.40 Computational U/UP L contour plot at X/DEQ =3.0 downstream of the nozzle throat corresponding to the standard k- turbulence model. . . . 90 4.41 Comparison of centerline axial velocity profiles among experiments, the k-ω SST, the realizable k- and the standard k- turbulence models. . . 91 PR EV IE W 4.30 Computational U/UP L contour plot at X/DEQ =3.0 from the throat. 4.42 Comparison of axial velocity profiles at X/DEQ =3.0 and on the Z=0 plane between the k-ω SST and the realizable k- turbulence model. . . . . . 92 4.43 Comparison of axial velocity profiles at X/DEQ =3.0 and on the Y =0 plane between the k-ω SST and the realizable k- turbulence model. . . . . . 92 4.44 Contour plot of the normalized axial velocity magnitude of the 3-D ejector nozzle with clamshell doors on the Z=0 plane with streamlines showing the flow separation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 4.45 Experimental U/UP L contour plot at X/DEQ =0.42 from the throat [44]. 95 4.46 Computational U/UP L contour plot at X/DEQ =0.42 from the throat. . 95 4.47 Experimental U/UP L contour plot at X/DEQ =1.0 from the throat [44]. 96 4.48 Computational U/UP L contour plot at X/DEQ =1.0 from the throat. . 96 4.49 Experimental U/UP L contour plot at X/DEQ =1.5 from the throat [44]. 97 4.50 Computational U/UP L contour plot at X/DEQ =1.5 from the throat. . 97 4.51 Experimental U/UP L contour plot at X/DEQ =2.0 from the throat [44]. 98 4.52 Computational U/UP L contour plot at X/DEQ =2.0 from the throat. 98 . xiii Figure Page 4.53 Experimental U/UP L contour plot at X/DEQ =3.0 from the throat [44]. 99 4.54 Computational U/UP L contour plot at X/DEQ =3.0 from the throat. 99 . 100 4.56 Normalized axial velocity profile at X/DEQ =0.42 and on the Y =0 plane. 100 4.57 Normalized axial velocity profile at X/DEQ =1.0 and on the Z=0 plane. 101 4.58 Normalized axial velocity profile at X/DEQ =1.0 and on the Y =0 plane. 101 4.59 Normalized axial velocity profile at X/DEQ =1.5 and on the Z=0 plane. 102 4.60 Normalized axial velocity profile at X/DEQ =1.5 and on the Y =0 plane. 102 4.61 Normalized axial velocity profile at X/DEQ =2.0 and on the Z=0 plane. 103 4.62 Normalized axial velocity profile at X/DEQ =2.0 and on the Y =0 plane. 103 4.63 Normalized axial velocity profile at X/DEQ =3.0 and on the Z=0 plane. 104 4.64 Normalized axial velocity profile at X/DEQ =3.0 and on the Y =0 plane. 104 4.65 Mach number contour plot on the Z=0 symmetry plane of the 3-D ejector nozzle with clamshell doors at take-off conditions. . . . . . . . . . . . . 105 PR EV IE W 4.55 Normalized axial velocity profile at X/DEQ =0.42 and on the Z=0 plane. 4.66 Mach number contour plot at X/DEQ =0.5 plane downstream of the 3-D ejector nozzle throat at take-off conditions. . . . . . . . . . . . . . . . . 106 5.1 The phenomenon of the ejector flow with chevrons. . . . . . . . . . . . 109 5.2 CAD geometry of the ejector nozzle with clamshells and chevrons, Design I - X-section at the throat. . . . . . . . . . . . . . . . . . . . . . . . . . 112 CAD geometry of the ejector nozzle with clamshells and chevrons, Design II - X-section at the throat. . . . . . . . . . . . . . . . . . . . . . . . . 112 CAD geometry of the ejector nozzle with clamshells and chevrons, Design I - Isometric view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 CAD geometry of the ejector nozzle with clamshells and chevrons, Design II - Isometric view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 5.6 Computational mesh for ejector nozzle walls and chevrons - Design I. . 114 5.7 Computational mesh for ejector nozzle walls and chevrons - Design II. . 115 5.8 Contours of Mach number and turbulent kinetic energy corresponding to the CFD simulation of the baseline nozzle. . . . . . . . . . . . . . . . . 122 Contours of Mach number and turbulent kinetic energy corresponding to the CFD simulation of the chevron nozzle (Design II). . . . . . . . . . 122 5.3 5.4 5.5 5.9 xiv Figure Page 123 5.11 Mach number contours on Y Z-plane at X/DEQ = 0.5 for the ejector nozzle without chevrons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 5.12 Mach number contours on the plane in between two chevrons for the ejector nozzle with chevrons - Design I. . . . . . . . . . . . . . . . . . . . . . . 124 5.13 Mach number contours on Z=0 symmetry plane for the ejector nozzle with chevrons - Design I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 5.14 Mach number contours on Y Z-plane at X/DEQ = 0.5 for the ejector nozzle with chevrons - Design I. . . . . . . . . . . . . . . . . . . . . . . . . . . 125 5.15 Mach number contours on Z=0 symmetry plane for the ejector nozzle with chevrons - Design II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 5.16 Mach number contours on the plane in between two chevrons for the ejector nozzle with chevrons - Design II. . . . . . . . . . . . . . . . . . . . . . 126 IE W 5.10 Mach number contour plot Z=0 symmetry plane for the ejector nozzle without chevrons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 5.18 Centerline axial velocity profiles corresponding to the ejector nozzle with and without chevrons. . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 5.19 Centerline total temperature profiles corresponding to the ejector nozzle with and without chevrons. . . . . . . . . . . . . . . . . . . . . . . . . 127 PR EV 5.17 Mach number contours on Y Z-plane at X/DEQ = 0.5 for the ejector nozzle with chevrons - Design II. . . . . . . . . . . . . . . . . . . . . . . . . . xv ABBREVIATIONS Algebraic multigrid AST Advanced subsonic transport program BBSAN Broadband shock-associated noise BC Boundary conditions BPR Bypass ratio of the jet engine CAA Computational aeroacoustics CAD Computer-aided-design CFD Computational fluid dynamics CFL Courant-Friedrichs-Lewy number CRAFT Combustion Research and Flow Technology DARPA Defence Advanced Research Projects Agency EPS Encapsulated post script file format FA Fundamental aeronautics program PR EV IE W AMG GRC Glenn Research Center HSR High speed research program ICAO International Civil Aviation Organization JAXA Japanese aeronautical research agency LES Large eddy simulation NASA National Aeronautics and Space Administration NPR Nozzle pressure ratio PIV Particle image velocimetry QST Quiet supersonic transport program QSJ Quiet supersonic jet RANS Reynolds-averaged Navier-Stokes RMS Root mean square xvi Reynolds stress turbulence model SA Spalart-Allmaras turbulence model SCAR Supersonic cruise aircraft research program (1972-1985) SSBJ Supersonic business jet program SST Supersonic transport program (1963-1971) SST Shear stress transport turbulence model STEP Standard for the exchange of product model data file format TKE Turbulent kinetic energy URANS Unsteady Reynolds-averaged Navier-Stokes PR EV IE W RSM xvii NOMENCLATURE Area m2 A∗ Nozzle throat area m2 Ae Nozzle exit area m2 D Diameter m DC Control diameter of the nozzle m DEQ Equivalent diameter of the nozzle throat m Df an Diameter of the fan nozzle m H Semi-height of the 2-D ejector nozzle m I Turbulent intensity LS Length of the mixing duct in ejectors m M Mach number IE PR EV Me Exit Mach number Mthroat Throat Mach number P◦ Total pressure P a or atm Ps W A Static pressure P a or atm ReD Reynolds number based on the nozzle diameter T◦ Total temperature K or R Ts Static temperature K or R U Axial velocity m/s or f t/sec UP L Axial velocity inside the plenum chamber m/s or f t/sec V Velocity magnitude m/s or f t/sec k Turbulent kinetic energy m2 /s2 ṁej Secondary mass flow entrained through the ejector slot kg/m3 ṁin Primary nozzle mass flow kg/m3 y Wall normal distance m xviii y+ Normalized wall distance Greek Alphabets Ratio of specific heats ∆ Dimension of the secondary nozzle m β Turbulent viscosity ratio Dissipation rate of the turbulent kinetic energy m2 /s3 µ Dynamic viscosity kg/m/s µt Turbulent eddy viscosity kg/m/s ν Kinematic viscosity m2 /s νt Spalart-Allmaras variable m2 /s ρ Density kg/m3 ω Specific dissipation rate of turbulent kinetic energy 1/s PR EV IE W γ xix ABSTRACT Thirumurthy, Deepak M.S.A.A., Purdue University, May 2010. Design and Analysis of Noise Suppression Exhaust Nozzle Systems. Major Professors: Anastasios S. Lyrintzis and Gregory A. Blaisdell. The exhaust nozzle is an integral part of a jet engine and critical to its overall system performance. Challenges associated with the design and manufacturing of W an exhaust nozzle become greater as the cruise speed of the aircraft increases. The exhaust nozzle of a supersonic cruise aircraft requires additional capabilities such as variable throat and exit area, noise suppression, and reverse thrust. The present IE work is an effort to study the design and analysis of jet engine exhaust nozzle systems such as the axisymmetric plug nozzle, the chevron nozzle and the ejector nozzle with PR EV clamshells. High-bypass-ratio jet engines with two or more flow streams have superior noise suppressing and thrust characteristics. Much research has been done in the past to study and understand the flow physics of these engines. In the present work a computational fluid dynamics-based approach was used to study the jet engine exhaust nozzle systems. First, a computer-aided-design model of a three-stream separate-flow axisymmetric plug nozzle was created and axisymmetric flow simulations were performed to study the flow field. The mean flow and turbulent kinetic energy fields were compared with the particle image velocimetry results available in the literature. Next, computational fluid dynamics was used to study the performance of passive chevron mixers in enhancing the turbulent mixing. Three-dimensional calculations were carried out to study the effect of enhanced mixing on the mean velocity and turbulent kinetic energy flow fields. Different turbulence models were used to study their performance in predicting chevron-based jet flows. xx Gas turbine engine manufacturer Rolls-Royce, and business class aircraft manufacturer Gulfstream Aerospace Corporation, are collaborating on the development of technologies for a supersonic jet. As part of this collaborative research and development program, an ejector nozzle with clamshell doors, similar to that on an Olympus-593 engine, which powered the Concorde aircraft, was designed and tested. The ejector nozzle offers additional advantages such as thrust augmentation and noise suppression. Numerical simulations of this ejector nozzle with clamshell doors at 11.5◦ clamshell angle and without clamshell doors were performed as part of the validation task. Mean flow fields were predicted for low subsonic experimental conditions and compared with W the experimental data. Flow separation and recirculation zones were encountered near the inner surface of clamshell doors. Simulations at higher nozzle pressure ratios were condition as well. IE also performed to simulate actual flight conditions. Flow separation prevailed at this PR EV The existing new supersonic noise suppression exhaust nozzle design was improved by the addition of chevrons and its flow field was analyzed using computational fluid dynamics. The jet engine exhaust nozzle consisted of three-dimensional ejectors in the form of clamshell doors and chevrons as passive mixers. Chevrons were placed in the ejector slot to introduce streamwise vorticity and enhance mixing. It was observed that the flow separation zone was almost removed and an improvement in the ejector performance was obtained. Computational simulations corresponded to take-off conditions with a nozzle pressure ratio of 1.7 and freestream Mach number of 0.3. 1 1. Introduction Mankind has witnessed a remarkable change in the speed of transporting goods and people. During the 19th century the transportation method changed from horsepowered carts traveling at 10 kmph to high speed trains transporting passengers and cargo at 100 kmph. Speed has no limits as evidenced by the advent of subsonic airplanes of the 20th century capable of flying at 1000 kmph [1]. Mankind was W skeptical of flying at a speed greater than the speed of sound until October 1947, when United States Air Force Capt. Charles Yeager crossed the sound barrier and IE reached Mach 1.02 in his XS-1 experimental aircraft [2]. This fascinating and challenging supersonic flight motivated many aerospace organizations to start programs related to the design of supersonic cruise aircraft and PR EV develop related technologies. On November 29, 1962, the Concorde project, an AngloFrench partnership, was launched and remains one of two supersonic cruise passenger aircraft that traveled at speeds exceeding 2000 kmph, more than twice the speed of sound. As airport regulations became more stringent, the Concorde failed to meet requirements for performance, operating economics, development cost and environmental acceptance. British Airways and Air France ended their Concorde service in 2003. The Tupolev Tu-144 supersonic transport aircraft was a Soviet Union (now Russia) effort to make supersonic civil transport a viable option. The project started two years later than the Concorde. Although the Tu-144 was technically comparable to the Concorde with a cruise Mach number of 2.5, the Tu-144 lacked a passenger market within the Soviet Union and service was halted after only about 100 scheduled flights. Initial plane crashes and high maintenance cost led the Soviet Union to cease the program in 1983.