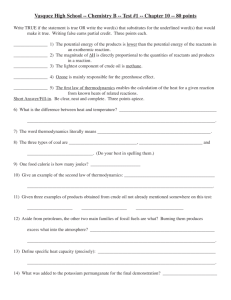

b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 Available online at www.sciencedirect.com http://www.elsevier.com/locate/biombioe Extractive fermentation with non-ionic surfactants to enhance butanol production Pradip B. Dhamole a,c, Zhilong Wang a,d, Yuanqin Liu a, Bin Wang a, Hao Feng a,b,* a Energy Biosciences Institute, University of Illinois at Urbana-Champaign, Urbana, IL 61801, USA Department of Food Science and Human Nutrition, University of Illinois at Urbana-Champaign, Urbana, IL 61801, USA c Department of Biotechnology, Sinhgad College of Engineering, Pune 411041, India d School of Pharmacy, Shanghai Jiao Tong University, Shanghai 200240, PR China b article info abstract Article history: One of the major limitations in butanol fermentation is the end product toxicity which Received 29 October 2011 limits the butanol yield and increases the downstream processing costs. In this work, Received in revised form a range of non-ionic surfactants (Triton X 114, L64, L62LF, L61, and L62) was tested to 6 February 2012 enhance the acetoneebutanol (AB) production, and to extract and separate butanol from Accepted 9 February 2012 the fermentation broth. In biocompatibility tests, a volume fraction of 3% L62, L62LF, and Available online 25 February 2012 L61 did not show inhibition to AB production in 72-h fermentation using Clostridium pasteurianum. Three-percent L64 reduced the AB yield whereas Triton X 114 (3%) inhibited the Keywords: AB production. Further optimization with L62 at 6% resulted in a butanol yield of 225% Butanol higher than the control. The partition coefficient of butanol in L62-water two phase Biofuel systems in cloud point extraction ranged from 3 to 4. A considerable enrichment of butanol Non-ionic surfactant (6 times) was achieved in the surfactant-rich phase over the control. In addition, the Extractive fermentation downstream process volume was reduced by 4e6 times. Butanol was separated from the Biocompatibility surfactant-rich phase (obtained from model system) by evaporation between 120 and 130 C. The butanol was enriched in the condensate reaching a concentration of 106.8 g l1, under which butanol automatically separated into two phases. The L62 was recovered by evaporation and reused for 3 times without affecting the partition coefficient, volume reduction, and butanol recovery in the surfactant-rich phase. The results demonstrated that the L62 not only significantly enhanced the butanol production but also functioned as a good extractant for separating butanol from the fermentation broth. ª 2012 Elsevier Ltd. All rights reserved. 1. Introduction In recent years, a renewed and growing interest in the production of acetone, butanol and ethanol (ABE) has been stimulated by the increasing demand for advanced biofuels. Butanol is the main product of ABE fermentation, and has some attractive properties. The advantages of butanol include 30% higher energy content (29.2 MJ L1) over ethanol (19.6 MJ L1), lower vapor pressure, less volatile, less flammable, and mixable with gasoline [1e4]. However, since the discovery of ABE fermentation a century ago, biobutanol production has faced numerous difficulties, preventing it from becoming a commercially viable process. There are two interrelated outstanding challenges facing the commercialization * Corresponding author. Department of Food Science and Human Nutrition, University of Illinois at Urbana-Champaign, 382F-AESB, 1304 West Pennsylvania Avenue, Urbana, IL 61801, USA. Tel.: þ1 217 244 2571; fax: þ1 217 333 9329. E-mail address: haofeng@illinois.edu (H. Feng). 0961-9534/$ e see front matter ª 2012 Elsevier Ltd. All rights reserved. doi:10.1016/j.biombioe.2012.02.007 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 of biobutanol today. The first is the end-product toxicity to the fermenting microorganisms. Butanol at low product concentrations (normally < 20 g L1) causes cell growth inhibition and premature termination of ABE fermentation [5]. The toxicity of butanol has been ascribed to passive proton flux by butanol causing membrane leaking [6], disruption of the lipid structure in cell membranes that alters membrane-bound enzyme activity [7], and membrane fluidity in the presence of butanol [8]. Newly developed strains, such as Clostridium beijerinckii P260, have shown improved butanol tolerance, but the maximum yield of butanol is still ca. 22.27 g L1 after hydrolysate detoxification [9]. The other challenge is the high energy cost of recovering butanol from the fermentation broth. Due to the low concentration (w20 g L1) in the broth and the high boiling point of butanol (117 C), removing water to obtain purified butanol is an expensive process [10e12]. To attack the low concentration butanol recovery problem, scientists have explored various techniques for butanol separation, including adsorption [13,14], pervaporation [15,16], perstraction [17,18], liquideliquid extraction [19,20], and gas stripping [21,22]. Extractive fermentation is a potential method to eliminate the product inhibition and thus increase the final product concentration. The concentrated product in the extraction phase during fermentation could save the cost in downstream process. Extractive fermentation of butanol has been conducted in organic solvent-aqueous solution two-phase systems [23e26] and in aqueous solution-polymer two-phase systems formed by polymer polypropylene glycol (PPG) [27]. Kumn [28] carried out an extractive fermentation of ethanol in polyethylene glycol (PEG)-dextrin aqueous two-phase system. The key challenge of extractive fermentation in aqueous solution-organic solvent two-phase systems is the biocompatibility of the organic solvent to the bacteria [29] whereas that of the PEG-dextrin aqueous two-phase system it is the high price of the polymer dextrin. A number of non-ionic surfactant aqueous solution forming cloud point systems at above a certain temperature have been developed as a novel medium for extractive microbial fermentation [30e33]. The main advantages of extractive fermentation in a cloud point system include that the biocompatibility to the bacteria is improved in comparison to that of organic solvent-aqueous solution two-phase systems, and the cost of PEOePPOePEO block copolymers is lower than that of dextrin in an aqueous two-phase system. Aqueous solution of a non-ionic surfactant at a temperature above the cloud point (the temperature at which the copolymer solution starts to separate) forms a surfactant rich phase (coacervate) and surfactant diluted phase. An organic compound presenting in the non-ionic surfactant aqueous solution should unevenly partitioned into those two phases. Such a scheme is called cloud point extraction (CPE). CPE has many advantages which include mild environment, simplicity, effectiveness of operation and easy scale up. Surfactants are amphiphilic in nature i.e. having a polar part and an apolar part which interact with interfaces. Amphiphilic characteristics are critically dependent on the molecular properties, such as total molecular weight, relative block size and block sequence as well as thermodynamic parameters, such as temperature and pressure. Water solubility of the surfactant is due to hydrophilic group which is an ionic or highly polar group. Above critical 113 micelle concentration and/or cloud point, surfactant molecules usually assemble themselves into many kinds of structures i.e. micelles, lamellar, hexagonal, etc. These nano-sized micellar assemblies formed facilitate removal of targeted compound (depending on its properties). Hence, in this work, we have explored a non-ionic surfactant aqueous solution system for overcoming the end product (butanol) toxicity and separation of butanol from the nonioninc surfactant micelle aqueous solution by cloud point extraction. The same hypothesis is used to relieve butanol toxicity during fermentation in non-ionic surfactant micelle aqueous solution, resulting in a significant increase in butanol yield. Experiments were carried out with non-ionic surfactants to find its butanol capturing capacity and those with high butanol capturing capacity were tested further for its biocompatibility. The surfactant resulting in high butanol production than control (i.e., without surfactant) was used for concentrating and separating butanol. The separation was carried out after fermentation by incubating the broth at a fixed temperature. A model system was used to study further downstream processing of butanol and recovery of surfactant. Recovered surfactant was reused to capture butanol. 2. Materials and methods 2.1. Chemicals Glucose, yeast extract, K2HPO4, KH2PO4, ammonium acetate, para-amino benzoic acid, thiamine, biotin, MgSO4.7H2O, MnSO4.H2O, FeSO4.7H2O, and NaCl of analytical grade were purchased. Non-ionic Pluronic surfactants L61, L62, L62LF, and L64 were provided by BASF, USA as a gift sample. The letter ‘L’ in the nomenclature denotes that the surfactant is liquid. The first number in the surfactant name indicates the molecular weight range of the hydrophobe (i.e., PPO) whereas the second number signifies the weight percentage of hydrophile (i.e., PEO). Thus, L61 has a weight to volume fraction of 10% hydrophile whereas L62 and L64 have 20% and 40% hydrophile, respectively. 2.2. Culture and cell propagation Acetoneebutanol producing strain Clostridium pasteurianum (NRRL B-598) obtained from the ARS culture collection centre (NRRL, Peoria, IL, USA) was used as a model organism because a high yield strain was not available. The strain was activated following the procedure provided by the supplier. Stock solutions were prepared before starting the fermentation. The buffer stock solution consisted of K2HPO4 (50 g L1), KH2PO4 (50 g L1), and ammonium acetate (220 g L1). The vitamin stock solution contained 0.19 g L1 para-amino benzoic acid, 0.19 g L1 thiamine, and 0.19 g L1 biotin whereas the composition of minerals stock solution was 20 g L1 MgSO4.7H2O, 1 g L1 MnSO4.H2O, 1 g L1 FeSO4.7H2O, and 1 g L1 NaCl. Before fermentation the strain was reactivated by incubating 1 ml of refrigerated strain into 25 mL of Difco Infusion broth (35 g L1). 0.25 mL of the buffer stock solution was added to the infusion broth before inoculation. The flasks 114 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 were incubated at 32 C for 36 h and the cells thus obtained were used for fermentation. 2.3. micelle diameters were measured by dynamic light scattering at a fixed scattering angle of 90 at 23 C with a NICOMP 380 ZLS Particle Sizer. Butanol capturing capacity (BCC) of surfactants 2.7. A dialysis cell (Scienceware, Bel-Art Products, NJ) and UF membrane was used in determining the relative butanol capturing capacity of a variety of surfactants. Total volume of the cell was 18 mL which was divided into two compartments by a membrane, with each compartment of 9 mL. One side of the cell was filled with distilled water whereas the other side was filled with a solution containing surfactant (30 g L1), butanol (50 g L1), and glucose (60 g L1). The dialysis cells were kept at 30 C throughout the study. Samples were collected from the water side on a periodic basis till the steady concentration of butanol was observed (data not shown). The butanol capturing capacity was defined as amount of butanol captured per unit amount of surfactant. After the fermentation, cells were separated from the fermentation broth by centrifugation at 13,130 g for 5 min to obtain a clear fermentation broth. It was then incubated in a water bath (Poly Science Digital Temperature Controller, Niles, IL) at different temperatures between 35 and 70 C to obtain a phase separation. The clear phase separation was observed at 70 C on incubation for 30 min when a volume fraction of 6% L62 was present. This resulted in a two phase formation with lower phase rich in surfactant and the upper phase being the aqueous phase. Samples were collected from the separated phases and analyzed for butanol concentration. 2.8. 2.4. Analysis Acetone and butanol in fermentation was determined by a gas chromatograph unit (GC Hewlett Packard 5890 Series II, Avondale, PA) equipped with an auto sample injector (HP 7673A Automatic Injector) and a flame ionization detector (FID). The column used was DB-WAX 30 m 0.250 mm 0.25 mm fused silica capillary column (J & W scientific, Agilent Technologies, Germany). The oven temperature was programmed from 40 C to 190 C at 20 C min1. The injector and detector temperature was set to 220 C and 250 C, respectively. The carrier gas was He at 0.72 mL min1 flow rate and acetonitrile was used as an internal standard. Peaks, areas and percentages were calculated using Agilent Technologies GC Chemstation software (Agilent Technologies, Germany). Glucose was estimated using HPLC system (Waters Corporation, Milford, MA) e2695 separation module and a Waters 2414 refractive index detector monitored by an Empower pro software version 6.2. Aminex column (HPX-87P 300 mm 7.8 mm) equipped with Microguard Carbo-P cartridge (30 mm 4.6 mm) from Biorad (Hercules, CA) was used. 2.6. 1 Separation of butanol from surfactant rich phase Fermentation A fermentation medium consisting of glucose (60 g L1), yeast extract (1 g L1), buffer stock solution (1 ml L1), mineral stock solution (1 ml L1), and vitamin stock solution (1 ml L1) was used. Nitrogen was purged after the inoculation and every time the sample was withdrawn to maintain the anaerobic conditions. Flasks were incubated at 32 C for butanol fermentation. Fermentation was carried out with and without surfactant (control). Surfactant addition was carried out after autoclaving the fermentation medium and before inoculation. 2.5. Extraction of butanol from fermentation broth C. pasteurianum produces very low amount of butanol (6e8 g L1) [34]. Due to unavailability of a high yielding strain to the authors, fermentation was carried out with C. pasteurianum and separation studies were conducted with model systems. A model system consisting 50 g L1 butanol and 6% L62 (optimum for fermentation) was chosen to resemble the process with high butanol producing strains. The model solution (containing 50 g L1 butanol and a volume fraction of 6% L62) was incubated at 38 C to obtain the surfactant rich phase [35]. The surfactant rich phase thus obtained was used for further downstream processing. Butanol and water from the surfactant rich phase was separated by evaporation between 120 and 130 C and the vapor phase was condensed in a condenser using tap water. The feed, condensate and concentrate were analyzed for butanol concentration, and their volumes were recorded for material balance calculations. 2.9. Reuse of L62 The L62 used in extraction of butanol (50 g L1) was separated following the above mentioned process. The concentrate containing L62 was reused for butanol extraction. The L62 concentrate was added into a solution having a total butanol concentration of 50 g L1 and the solution was incubated at 38 C to obtain a surfactant-rich phase and an aqueous phase. Samples were collected from both phases for butanol analysis. The surfactant-rich phase was again processed to recover L62 following the above procedure and was reused for butanol extraction for the third time. 3. Results and discussion 3.1. Screening of surfactant Characterization of surfactant in the model system H NMR spectra of the L62 solutions were recorded with a Varian Unity 400 MHz NMR spectrometer using D2O as the solvent in 5 mm NMR tubes. The residual signal of the solvent was used as a reference in all the spectra (D2O, d 4.8). The L62 The relative butanol capturing capacity of the selected surfactants (non-ionic and triblock co-polymer) (Triton X 114, L61, L62, L64, L62LF) was first examined with the dialysis cell method at 30 C. As shown in Table 1, 1 kg of Triton X 114 and co-polymer L62LF can capture 0.6 and 0.52 kg of butanol, 115 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 Table 1 e Butanol capturing capacity of some selected surfactants at 30 C. A 7 Butanol capturing capacity, (kg kg1) Cloud point temperature ( C) 6 Triton X 114 L62LF L62 L64 L61 0.6 0.52 0.32 0.06 Insoluble in water 25 28 32 58 24 5 -1 Control L62LF Triton X114 L43 L64 L61 L62 4 3 2 1 0 0 10 20 30 40 50 60 70 80 60 70 80 Time (hour) B 2.0 Control L62LF Triton X114 L43 L64 L61 L62 1.5 -1 Acetone (g L ) respectively; much higher than that of the other 3 polymers. Butanol captured and the cloud point of the surfactant is also included in Table 1. It can be seen that non-ionic surfactants having a low cloud point (than 30 C) captured high amount of butanol at 30 C. It is assumed that micelle formation (for Triton X 114 and L62LF) is better above cloud point. Hence, Triton X 114 entrapped the highest amount of butanol whereas L64 just captured very little butanol since the operating temperature (30 C) is lower than the cloud point (58 C) of L64. In control fermentation (i.e. without surfactant) maximum butanol produced was 4.75 g L1 after 120 h. Fermentation was continued till 168 h, however butanol concentration remained unchanged. Corresponding unutilized glucose concentration was observed to be 42.7 g L1 (Initial glucose ¼ 60 g L1) which clearly indicated that butanol fermentation was inhibited at 4.75 g L1 of butanol. Similar studies with C. pasteurianum (NRRL B-598) are reported in the literature however in those studies higher inhibition levels (6e7.5 g L1) were observed which could be attributed to different medium composition [34]. The biocompatibility of the surfactants was evaluated with an AB fermentation test with C. pasteurianum where 3% L62 was added in a fermentor and the butanol yield over a 72-h period was monitored (Fig. 1). Among the 5 surfactants examined, Triton X 114 totally inhibited AB production while a significant reduction in butanol yield when compared to the control (without surfactant) was observed for L64. L61 and L62LF produced nearly the same amount of butanol as the control. In the case of L64, the acetone and butanol produced were about 50% of the control, respectively. Notably, the fermentation with L62 enhanced the AB fermentation. Addition of 3% L62 increased the acetone as well as butanol production by little over 70% (Fig. 1A and B). The toxicity of surfactants follows the order: ionic surfactant > non-ionic surfactant > polymeric non-ionic surfactant [30]. All the pluronic surfactants studied in this work are polyoxypropylene (PPO) epolyoxyethylene (PEO) block copolymers. The toxicity of a surfactant can be correlated with its hydrophileelipophile balance (HLB) value. Generally, an increase in HLB is accompanied by an increase in the toxicity of the surfactant to microbes. For Triton X 114 and L64 the HLB values are 12.3 and 12 to 18, respectively and hence were toxic to the microbes. Other three surfactants (L61, L62 and L62LF) have HLB values in the range of 1e7 and hence are non-toxic to the microorganisms. L61 is insoluble in water and does not extract butanol from the fermentation; hence no relief to the microbes from butanol. Further, the butanol yield during fermentation with a surfactant is related to both the surfactant toxicity and its butanol capturing Butanol (g L ) Surfactant 1.0 0.5 0.0 0 10 20 30 40 50 Time (hour) Fig. 1 e Biocompatiblity of different surfactants for AB fermentation. (A) Butanol production and (B) Acetone production. Concentration of surfactant [ 3%, volume fraction. Temperature [ 32 C. capacity. Therefore, for Triton X 114 having a high butanol capturing ability, because of its high HLB values, is toxic to the microbes. Only the L62, which had a moderate butanol capturing capacity but a low HLB, enhanced the butanol production (0.32 kg kg1 of surfactant). Therefore, L62 was used in all the subsequent AB fermentation tests. 3.2. Effect of surfactant concentration Screening of surfactants showed that a volume fraction of 3% of L62 enhanced the acetone and butanol production (Fig. 1). It was desirable to find out the optimum amount of L62 which will further increase the AB production. Since the AB yield remained increasing at the end of 72-h fermentation, showing the potential to further increase the AB production, if the fermentation is continued over an extended period. It was 116 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 3.3. Concentration of butanol from fermentation broth by phase separation Butanol produced during the fermentation needs to be separated from the fermentation broth. The L62 added during the 12 -1 Butanol Produced (g L ) 10 12 -1 Acetone/Butanol Produced (g L ) thus decided to study the effect of surfactant concentration on fermentation over a period of 5 days. As can be seen from Fig. 2, an increase in surfactant concentration from 3% to 6% improved the acetone and butanol production by 25%. However, a further increase in surfactant concentration (9%) did not enhance AB production. The results suggested that 6% L62 was the optimum for fermentation. Fig. 3 shows the time course of AB fermentation in presence of 6% L62. It can be seen that the AB production was higher from day 3 onwards. At the end of 120 h, the AB produced in the presence of L62 was 225% higher than that of the control. The fermentation was continued till 8 days but no further increase in AB was observed (data not shown). It was assumed that L62 might have formed micelles and entrapped butanol resulting in high butanol production during fermentation. To confirm this, studies were carried out to check the micelle formation by the surfactant in a model system at fermentation temperature (32 C) with NMR and dynamic light scattering. The 1H NMR spectrum (Fig. 4) clearly shows the methyl proton signal of both L62 (d 1.1) and butanol (d 0.8). If L62 formed micelles and entrapped butanol, the NMR signal of butanol should decrease or disappear. However, from the integral of the peaks the ratio of L62/butanol was similar to the theoretical ratio (1: 0.5). The NMR data thus indicated that butanol was free and in an un-trapped form in the model system. The particle size measurement results (Table 2) also demonstrated that there were no micelles detected in the model system (L62 (6.0%) þ butanol (3 or 30 g L1)) because the measured particle sizes (10e11 nm) were similar to that of single L62 molecule (L62 (0.001%), 8 nm) and much smaller than the size of L62 micelles (L62 (6%), 130 nm). It can be concluded that no micelles formed in the model system and the increase in AB production might be attributed to the attachment of butanol to the monomers of L62. Butanol (control) Butanol (6% L62) Acetone (control) Acetone (6% L62) 10 8 6 4 2 0 0 20 40 60 80 100 120 Time (hour) Fig. 3 e Time course of AB fermentation in the presence of a volume fraction of 6% L62. fermentation process was used to separate and concentrate butanol from the fermentation broth. An increase in temperature above the cloud point resulted in two phases with upper phase being aqueous and the lower one rich in L62. The butanol was concentrated in surfactant rich phase. To separate the surfactant rich phase and to enrich butanol in the surfactant rich phase, the entire broth was first incubated at different temperatures to find out the phase separation conditions. It was noted that the presence of cells increased the turbidity and no clear phase separation was observed. Therefore, cells were separated from the fermentation broth by centrifugation to obtain a clear fermentation broth. The clear supernatant was then incubated at different temperatures to separate the surfactant-rich phase from the aqueous phase. Two phase formation was observed at 70 C after incubating the supernatant for 30 min Table 3 shows the partition of butanol in aqueous phase and surfactant rich phase. The butanol was enriched in the surfactant-rich phase, as shown by a partitioning coefficient of 3.5. Furthermore, the volume was reduced by a factor of 6 (i.e. the initial volume/ surfactant rich phase volume ¼ 6), resulted in a significant 8 6 4 2 0 0 2 4 6 8 10 L62 Added in the Medium (%) Fig. 2 e Effect of amount of L62 (in volume fraction) on AB fermentation (Data after 120 h of fermentation). Fig. 4 e 1H NMR spectrum of a model system (L62 (6.0%, volume fraction) D butanol (3 g LL1)). 117 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 Table 2 e Particle size of co-polymer L62 in the solution. % (v/v) L62 L62 L62 L62 (0.001%) (6%) (6%) þ butanol (0.3 g L1) (6%) þ butanol (3 g L1) Diameter at 32 C (nm) 8 130 10 11 4 38 4 3 reduction in downstream process volume and hence energy usage in butanol recovery. It needs to be emphasized here that in the control system (without L62) only 5 g L1 of butanol was produced by C. pasteurianum whereas with the surfactant system the surfactant rich phase contained 30 g L1 butanol representing a 6 times enrichment. Therefore, the addition of L62 during the fermentation not only increased the fermentation yield, it also reduced the process volume and enriched the surfactant rich phase significantly. Since C. pasteurianum used in this study produces very low amount of butanol, to represent the butanol fermentation with high yield strains (such as C. beijerinckii BA101), downstream processing was carried with a model system containing higher butanol concentration (50 g L1) and 6% L62 (optimum for fermentation). In the presence of 6% L62 C. pasteurianum produced 10.71 g L1 of butanol which is 225% higher than control. It is anticipated that high butanol producing strains will produce butanol in presence of biocompatible L62 (6%) in a similar manner. Thus a strain producing 20e22 g L1 butanol may produce 45e50 g L1 butanol. The phase diagram of L62 with 50 g L1 butanol was reported in our earlier work [35]. It was observed that the butanol concentration had a significant effect on phase separation. Butanol lowers the cloud point. In the presence of 50 g L1 butanol and 6% L62, the phase separation took place at 38 C (model system). When the fermentation broth contained 10 g L1 butanol, a clear phase separation was observed at 70 C whereas with 50 g L1 butanol the phase separation occurred at 38 C (model system) [35]. Consequently, for a high butanol producing strain, the temperature required for phase separation will be close to fermentation temperature. If a phase separation takes place during fermentation, a continuous extraction of the produced butanol can be Fig. 5 e Separation of butanol from the surfactant rich phase by evaporation (temperature [ 120e130 C). achieved; this will further increase the production and reduce the downstream separation costs. 3.4. Separation of butanol from surfactant rich phase and reuse of surfactant The surfactant rich phase obtained after incubating the aqueous solution containing butanol (50 g L1) and L62 (6%) was used for further studies. Fig. 5 shows the material balance over the evaporation unit and composition of the feed, condensate and concentrate. Water and butanol were obtained in the condensate and the high butanol concentration (106.8 g L1) resulted in two phase formation with the upper phase being butanol. Over 95% butanol was recovered from the surfactant rich phase. Very little butanol remained in the surfactant (2.1 g L1). Since the entire separation system is closed, the high boiling point L62 is retained in the concentrate. Further, the minimum amount of butanol that remained in the L62 implies that surfactant can be reused for butanol extraction. Hence, tests were conducted to examine the reuse of L62 for butanol extraction. The results are included in Table 4. The basic parameters of extractive fermentation, i.e., the volume ratio of non-ionic surfactant-rich phase to aqueous phase, partitioning coefficient of 1-butanol and 1-butanol concentration, were unchanged in the second and Table 3 e Separation of L62 from the aqueous phase. Initial concentration of butanol, g L1 Concentration of butanol in surfactant rich phase, g L1 Concentration of butanol in aqueous phase, g L1 Concentration factor Initial volume, mL Volume of surfactant rich phase, mL Phase volume ratio (Aqueous phase : Surfactant rich phase) Partition coefficient (Butanol in surfactant rich phase/Butanol in aqueous phase) Fermentation broth (after fermentation) Model system containing 50 g L1 butanol and 6% L62 11.8 30.1 8.71 2.55 12 2 6: 1 50 95 35.18 1.9 12 3 4: 1 3.5 2.7 118 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 Table 4 e Repeated utilization of recovered polymer non-ionic surfactant in the L62-rich phase (Butanol [ 50 g LL1, L62 [ 6%, Incubation temperature [ 38 C). Run Volume ratio Partitioning coefficient Butanol in surfactant phase, g L1 Butanol in aqueous phase, g L1 4 4 4 2.6 2.7 2.87 94.82 93.3 95.8 36.47 34.55 33.38 First Second Third third runs in comparison to that of first run. Therefore, the recovered L62 can be reused to reduce the cost of butanol enrichment in fermentation and butanol recovery in the downstream process. 4. [7] Conclusions In the present work, the effect of addition of conventional non-ionic surfactant Triton X-114 and triblock copolymer Pluronic surfactants on butanol fermentation and separation has been explored. A novel L62 cloud point system has been developed for extractive fermentation of 1-butanol. The L62 cloud point system fulfilled the basic demands of biocompatibility and doubled the butanol yield in a fermentation test. More importantly, the product 1-butanol was concentrated in the surfactant-rich phase after the fermentation, which is advantageous for downstream processing. In addition, the process volume was reduced by 4e6 times. Both would contribute to reduce the bio-butanol production costs. 95% of butanol was recovered from the surfactant-rich phase and the reuse of L62 had no effect on its performance as an extractant. The extractive fermentation with L62 is a promising method for relieving the butanol toxicity and enhancing the butanol production. [8] [9] [10] [11] [12] [13] Acknowledgments The project was funded by Energy Biosciences Institute grant No. 555794-231000. We are grateful to Mr. John Jerrell for his assistance in GC analysis. [14] [15] references [16] [1] Qureshi N, Blaschek HP. Evaluation of recent advances in butanol fermentation, upstream and downstream processing. Bioproc Biosyst Eng 2001;24(4):219e26. [2] DAquino R. Biobutanol on the horizon. Chem Eng Prog 2007; 103(3):1e10. [3] Qureshi N, Ezeji TC. Butanol, ‘a superior biofuel’ production from agricultural residues (renewable biomass): recent progress in technology. Biofuel Bioprod Bior 2008;2(4):319e30. [4] Lee SY, Park JH, Jang SH, Nielsen LK, Kim J, Jung KS. Fermentative butanol production by Clostridia. Biotechnol Bioeng 2008;101(2):209e28. [5] Awang GM, Jones GA, Ingledew WM. The acetone-butanolethanol fermentation. Crit Rev Microbiol 1988;15(1):S33e67. [6] Moreira AR, Ulmer DC, Linden JC. Butanol toxicity in the butylic fermentation. Third Symposium on Biotechnology in [17] [18] [19] [20] energy production and Conservation: proceedings, Gatlinburg, Tenn., May 12e15, 1981. New York (USA): Wiley; 1981. 567e579. Kuhn H, Linden JC. Effects of temperature and membrane fatty acid composition on butanol tolerance of Clostridium acetobutylicum. In: Scott CD, editor. Biotechnology and bioengineering symposium. Proceedings of the 8th symposium on biotechnology for fuels and chemicals; May 1986. Gatlinburg, TN; New York (USA): John Wiley and Sons; 1986. p. 197e207. Baer SH, Bryant DL, Blaschek HP. Electron spin resonance analysis of the effect of butanol on the membrane fluidity of intact cells of Clostridium acetobutylicum. Appl Environ Microbiol 1989;55(10):2729e31. Qureshi N, Saha BC, Dien B, Hector RE, Cotta MA. Production of butanol (a biofuel) from agricultural residues: part I - use of barley straw hydrolysate. Biomass Bioenerg 2010;34(4): 559e65. Qureshi N, Maddox IS. Integration of continuous production and recovery of solvents from whey permeate: use of immobilized cells of Clostridium acetobutylicum in a fluidized bed reactor coupled with gas stripping. Bioprocess Biosystems Eng 1991;6(1e2):63e9. Ezeji TC, Qureshi N, Blaschek HP. Bioproduction of butanol from biomass: from genes to bioreactors. Curr Opin Biotech 2007;18:220e7. April. Vane LM. Separation technologies for the recovery and dehydration of alcohols from fermentation broths. Biofuel Bioprod Bior 2008;2(6):553e88. Qureshi N, Hughes S, Maddox IS, Cotta MA. Energyefficient recovery of butanol from model solutions and fermentation broth by adsorption. Bioproc Biosyst Eng 2005;27(4):215e22. Nielsen DR, Prather KJ. In situ product recovery of n-butanol using polymeric resins. Biotechnol Bioeng 2009;102(3): 811e21. Qureshi N, Blaschek HP. Production of acetone butanol ethanol (ABE) by a hyper-producing mutant of strain Clostridium beijerinckii BA101 and recovery by pervaporation. Biotechnol Progr 1999;15(4):594e602. Ezeji TC, Qureshi N, Blaschek HP. Butanol fermentation research: upstream and downstream manipulations. Chem Rec 2004;4(4):305e14. Qureshi N, Maddox IS, Friedl A. Application of continuous substrate feeding to the ABE fermentation: relief of product inhibition using extraction, perstraction, stripping, and pervaporation. Biotechnol Progr 1992;8(5):382e90. Qureshi N, Maddox IS. Reduction in butanol inhibition by perstraction: utilization of concentrated lactose/whey permeate by Clostridium acetobutylicum to enhance butanol fermentation economics. Food Bioprod Process 2005;83(C1): 43e52. Adhami L, Griggs B, Himebrook P, Taconi K. Liquideliquid extraction of butanol from dilute aqueous solutions using soybean-derived biodiesel. JAOC 2009;86(11):1123e8. Taconi K, Venkataramanan K, Johnson D. Growth and solvent production by Clostridium pasteurianum ATCC 6013 b i o m a s s a n d b i o e n e r g y 4 0 ( 2 0 1 2 ) 1 1 2 e1 1 9 [21] [22] [23] [24] [25] [26] utilizing biodiesel-derived crude glycerol as the sole carbon source. Environ Prog Sust Energ 2009;28(1):100e10. Ezeji TC, Qureshi N, Blaschek HP. Acetone butanol ethanol (ABE) production from concentrated substrate: reduction in substrate inhibition by fed-batch technique and product inhibition by gas stripping. Appl Microbiol Biot 2004;63(6): 653e8. Ezeji TC, Qureshi N, Blaschek HP. Industrially relevant fermentations. In: Durre P, editor. Handbook on clostridia. Boca Raton, Florida: CRC Press, Taylor & Francis Group; 2005. p. 797e812. Shimizu K, Matsubara MA. Solvent screening criterion for multicomponent extractive fermentation. Chem Eng Sci 1987;42(3):499e504. Ishizaki A, Michwaki S, Crabbe E, Kobayashi G, Sonomoto K, Yoshino S. Extractive acetone-butanol-ethanol fermentation using methylated crude palm oil as extractant in batch culture of Clostridium saccharoperbutylacetonicum Nl-4 (ATCC 13564). J Biosci Bioeng 1999;87(3):352e6. Qureshi N, Maddox LS. Continuous production of acetonebutanol-ethanol using immobilized cells of Clostridium acetobutylicum and integration with product removal by liquid-liquid extraction. J Ferment Bioeng 1995;80(2):185e9. Roffler SR, Blanch HW, Wilke CR. In-situ recovery of butanol during fermentation, part 2: fed-batch extractive fermentation. Bioprocess Eng 1987;2(4):181e90. 119 [27] Barton WE, Daugulis AJ. Evaluation of solvents for extractive butanol, fermentation with CIostridium acetobutylicum and the use of polypropylene glycol 1200. Appl Microbiol Biot 1992; 36(5):632e9. [28] Kumn I. Alcoholic fermentation in an aqueous two-phase system. Biotechnol Bioeng 1980;12(11):2393e8. [29] Shukla R, Kang W, Sirkar KK. Toxicity of organic solvents to Clostridium acetobutylicum for extractive ABE fermentation. Appl Biochem Biotech 1988;18(1):315e24. [30] Wang Z, Dai Z. Extractive microbial fermentation in cloud point system. Enzyme Microb Tech 2010;46(6):407e18. [31] Wang Z, Xu JH, Chen D. Whole cell microbial transformation in cloud point system. J Ind Microbiol Biot 2008;35(7):645e56. [32] Wang Z, Xu JH, Zhang W, Zhuang B, Qi H. In situ extraction of polar product of whole cell microbial transformation with polyethylene glycol induced cloud point system. Biotechnol Progr 2008;24(5):1090e5. [33] Wang Z, Zhao F, Hao X, Chen D, Li D. Microbial transformation of hydrophobic compound in cloud point system. J Mol Catal B Enzym 2004;27(4e6):147e53. [34] Patakova P, Lipovsky J, Cizkova H, Fortova J, Rychtera MK. Exploitation of food feedstock and waste for production of biobutanol. Czech J Food Sci 2009;27(4):276e83. [35] Wang Z, Feng H. Double cloud point of ethylene oxidepropylene oxide triblock copolymer in an aqueous solution. Colloid Surf A 2010;362(1e3):110e6.