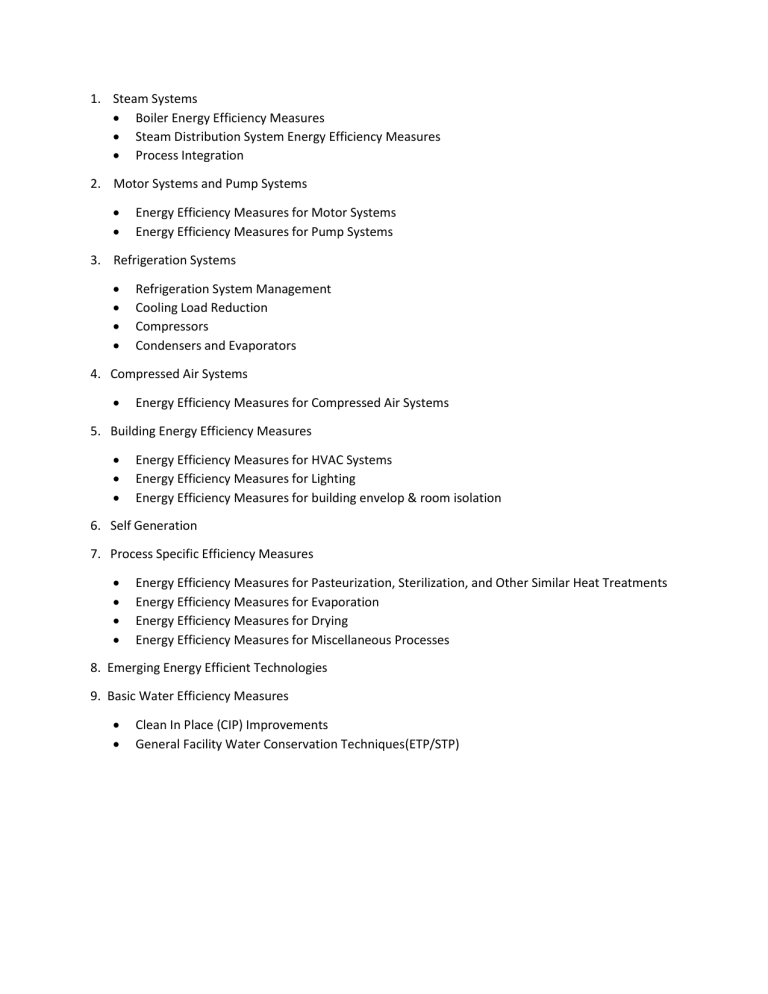

1. Steam Systems Boiler Energy Efficiency Measures Steam Distribution System Energy Efficiency Measures Process Integration 2. Motor Systems and Pump Systems Energy Efficiency Measures for Motor Systems Energy Efficiency Measures for Pump Systems 3. Refrigeration Systems Refrigeration System Management Cooling Load Reduction Compressors Condensers and Evaporators 4. Compressed Air Systems Energy Efficiency Measures for Compressed Air Systems 5. Building Energy Efficiency Measures Energy Efficiency Measures for HVAC Systems Energy Efficiency Measures for Lighting Energy Efficiency Measures for building envelop & room isolation 6. Self Generation 7. Process Specific Efficiency Measures Energy Efficiency Measures for Pasteurization, Sterilization, and Other Similar Heat Treatments Energy Efficiency Measures for Evaporation Energy Efficiency Measures for Drying Energy Efficiency Measures for Miscellaneous Processes 8. Emerging Energy Efficient Technologies 9. Basic Water Efficiency Measures Clean In Place (CIP) Improvements General Facility Water Conservation Techniques(ETP/STP) Boilers Boiler process control Boiler replacement Reduction of flue gas quantities Direct contact with water heating Reduction of excess air Condensing economizer Properly sized boiler systems Segregate hot water system according to temperature Improved boiler insulation Boiler maintenance Condensate return Flue gas heat recovery Blow down steam recovery Steam Distribution Systems Improved distribution system insulation Steam trap monitoring Insulation maintenance Leak repair Steam trap improvement Flash steam recovery Steam trap maintenance Process Integration Process integration Motor Systems Motor management plan Strategic motor selection Maintenance Properly sized motors Pumps Pump system maintenance Pump system monitoring Pump demand reduction Controls High-efficiency pumps Properly sized pumps Refrigeration Systems Refrigeration System Management Good housekeeping Monitoring system performance Ensuring proper refrigerant charge Refrigeration system controls Cooling Load Reduction Piping insulation Pinch analysis Adjustable-speed drives Power factor correction Minimizing voltage imbalances Multiple pumps for variable loads Impeller trimming Avoiding throttling valves Replacement of belt drives Proper pipe sizing Adjustable-speed drives Efficient piping design Thermal storage Checking for refrigerant contamination Segregation of refrigeration systems Geothermal cooling Minimizing heat sources in cold storage areas Reducing heat infiltration in cold storage areas Reducing building heating loads Free cooling Cooling towers Compressors Compressor control systems and scheduling Floating head pressure control Indirect lubricant cooling Raising system suction pressure Condensers and Evaporators Keeping condensers clean Automatic purging of condensers Reducing condenser fan use Reducing condensing pressure Use of axial condenser fans Compressed Air Systems System improvements Maintenance Monitoring Leak reduction Turning off unnecessary compressed air Modification of system in lieu of increased pressure Replacement of compressed air by other sources Improved load management Building Energy Efficiency Measures HVAC systems Energy-efficient system design Recomissioning Energy monitoring and control systems Non-production hours set-back temperatures Duct leakage repair Variable-air-volume systems Adjustable-speed drives Heat recovery systems Fan modification Lighting Turning off lights in unoccupied areas Lighting controls Tank Insulation for storage tanks Mixing in storage tanks Properly sized motors Optimized air flow pattern Compressor heat recovery Dedicating a compressor to defrosting Adjustable-speed drives Using an economizer with a single stage, low temperature compressor Adjustable-speed drives on condenser fans Cycling of evaporator fans in cold storage Adjustable-speed drives on evaporator fans Demand defrost Water defrosting Pressure drop minimization Inlet air temperature reduction Controls Properly sized pipe diameters Heat recovery from compressors Natural gas engine-drive compressors Buffer tank to regulate compressor duty cycle Efficient exhaust fans Use of ventilation fans Infrared heating Solar air heating Building reflection Building insulation Low-emittance windows Air curtains Replacement of T-12 tubes with T-8 tubes High-intensity discharge voltage reduction LED Exit signs Electronic ballasts High-intensity florescent lights Daylighting Self-Generation Combined heat and power Tri-generation Photovoltaic panels Solar thermal water preheating Process Specific Energy Efficiency Measures Pasteurization/Sterilization/Heat Treatment Reclamation/adding plates Compact immersion tube heat exchangers Helical heat exchangers Evaporation Maintenance Multiple effect evaporators Thermal vapor recompression Spray Drying Operating temperature optimization Strategic placement of air intake Inlet air monitoring Heat recovery from product Miscellaneous measures Good mixing in cooking tanks Cave aging (with use of heat pumps) Emerging Technologies Heat pumps for waste heat recovery Pulsed electric field pasteurization Geothermal heat pumps Advanced rotary burners Water Efficiency Measures (Chapter 15) CIP Improvements Reuse or recovery distribution systems Single phase cleaning Over-ride procedure Optimization of phase separation General Techniques Good housekeeping Wastewater treatment Recycling of milk waste as fertilizer Use of water efficient building fixtures Use of small diameter hoses Use of automated start/stop controls Induction heating of liquids Heat exchanger enhancement techniques Mechanical vapor recompression Concentration using membrane filtration Exhaust heat recovery Use of multiple stage drying Use of crystallization (dry whey only) Using other concentration techniques Creating 80% whey instead of powdered whey Use whey permeate to feed biogas reactor High hydrostatic pressure pasteurization UV pasteurization Microfiltration LED Lighting Pulse rinse on tanks RO or evaporative water use in CIP Air blows Reducing cooling tower bleed-off High pressure low volume sprays Low pressure foam cleaning Pre-soaking of floors and equipment Membrane filtration Malfunctioning