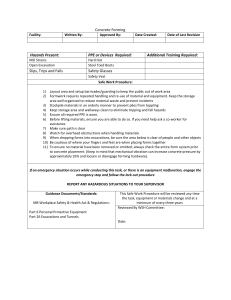

REPORT 108 Concrete pressure on formwork C.A. CLEAR BSc T.A. HARRISON PhD BSc CEng MICE MlCT Thc project leading to this Report was carried out under contract to CIRIA at the Ccmcrit and Concrete Association where M r Clear is a Research Engineer and Dr Harrison is Manager of the Civil Engineering Group in the Technical Applications Directorate. This Report was prepared with the help and guidance of the Project Steering Group. In addition to Dr Harrison and Mr Clear, the Group comprised: R.M. Hand BSc(Eng) CEng MICE (Chairman) John Mowlem and Company PLC C . M. Recves MlCT MlnstSMM Frodingham Cement Company Limited J . M . Dransfield BSc P. M. Follett BEng CEng MICE Cement Admixtures Association Pozzolanic Lytag Limited M. Grant BSc CEng FICE Kyle Stewart (Contractors) Limited P.G.K. Knight BSc(Eng) CEng MICE MIStructE CEGB, Ash Marketing Rapid Metal Development Limited P. F. Pallctt BSc CEng MICE MBIM K. Ward BSc CEng MICE Sir Robert McAlpine & Sons Limited A . R. McAvoy BSc CEng MICE was CIRIA's Research Managcr for thc project. This project was financially supported by the Cement and Concrete Association, Civil and Marine Limited, Department of the Environment, Frodingham Cement Company Limited, and Blue Circle Industries PLC. L CIKlA Report 108 Contents LIST OF ILLUSTRATIONS 4 LIST OF TABLES 4 ABBREVIATIONS USED 5 NOTATlON 5 SUMMARY 6 INTRODUCTION 6 1. DESIGN METHOD 9 2. NOTES FOR GUIDANCE 2.1 Cementitious materials and admixtures 2.2 Aggregates 2.3 Mix proportions 2.4 No-fines concrete 2.5 Workability 2.6 Concrete temperature at placing 2.7 Weight density Vertical form height 2.8 2.9 Shape and plan area of the cast section 2.1 0 Formwork permeability 2.1 1 Formwork stiffness and roughness 2.1 2 Slope of the form 2.1 3 Placing method 2.1 4 Rate of rise 2.1 5 Impact of concrete discharge 2.1 6 Vibration 2.1 7 Underwater concreting 13 13 13 13 13 14 14 14 15 15 16 16 17 17 17 18 18 EXAMPLES 3.1 Bridge abutment 3.2 Partition wall 3.3 Lift sh.aft 3.4 Mass concrete retaining wall 3.5 Bridge column 3.6 ‘V’ column 20 21 22 23 25 29 ACKNOWLEDGEMENTS 31 REFERENCES 31 3. ClRlA Report 108 ... .._, 3 ... .I List of illustrations Figure 1 Comparison of the ClRlA methods Figure 2 Cornparison between measured and calculated pressures on vertical formwork Figure 3 Design pressure envelope Figure 4 Example of formwork pressures and deflection measurements Figure 5 Height value to be used in the formulae Figure 6 Plan dimensions, showing sections defined as ‘columns’ or ‘walls and bases’ Figure 7 Pressure envelopes on the formwork of a wall with a sloping face where the fluid head is fully developed Figure 8 Relationship between rate of rise and pressure Figure 9 Pressure measurements on an underwater trdmie pour List of tables Table 1 Value of coefficients C, and C2 Table 2 Design formwork pressures 4 ClRlA Report 108 Abbreviations used OPC LHPBFC PBFC PPFAC RHPC SRPC ggbfs Pfa ordinary Portland cemeni low heat Portland-blastfurnace cement Portland-blastfurnace cement Portland pulverised-fuel ash cement rapid-hardening Portland cement sulphate-resisting Portland cement ground granulated blastfurnace slag pu!verised-fuel ash ’ Notation A R c, c* D H I1 K pma. Q R T I\’ ClRlA Report 108 plan area of mass concrete wall, m2 breadth of mass concrete wall, m coeffcient dependent on the size and shape of formwork, fi coeffcient dependent on the constituent materials of the concrete, weight density of concrete, kN/m’ (kg/m’ x 0.00981 ) vertical form height, m vertical pour height, m temperature coeffcient taken as (216 maximum concrete pressure on forniwork, kN/m’ volume supply rate, m’/h the rate at which the concrcte rises vertically up the form, m/h concrete temperature at placing, “C width of mass concrete wall, m fi -l2 c Summary The Report extends and improves the method used in CIRIA Report I to cover concretes using admixtures and blends or blended cements. Use of the method is demonstrated in six examples: bridge atutment, partition wall, lift shaft, mass concrete retaining wall, bridge column, and V column. Int roduction The method given in CERA (now CIRIA) Report for calculating concrete pressures on formwork has served the construction industry well since 1965. However, the design charts were limited to plain ordinary Portland cement concretes, and recent trends are towards the wider use of admixtures and blends or blended cements.' In addition, the commercitil need for faster construction has resulted in a general increase in lift heights and rates of concrete placing. New theories backed up with site data were being developed'2.3), and it was decided to review the 19G5 design method and to extend it to cover concretes which contain admixtures and/or blends or blended cements. CIRIA instigated a further programme of site formwork pressure measurements and the compilation of a comprehensive data file to contain both the new site measurements and previously obtained data. This file on formwork pressures contains over 350 sets of data. Using this data file in conjunction with recent advances in the understanding of the mechanisms, an improved method of estimating the concrete pressi're on formwork was formulated. Many factors affect the formwork pressure, some of which are unknown at the design stage. There are also other random site effects such as impact on discharge. Because many of the factors are inter-related, different interpretations of the data are possible, and there are several safe potential methods for estimating the pressure. The revised method is based on a model using only factors which should be known or which can be reasonably estimated at the design stage. The method is sufficiently conservative to envelop the spread of results for the factors not taken into account. Figure 1 shows a comparison of measured pressures against calculated pressures using the calculation methods given in Report 1 and this Report. This illustration only includes data which are strictly applicable to the Report 1 method (i.e. the concrete does not contain admixtures, pfa or ggbfs), and where all the data necessary for the calculation were recorded. Figure I (a) and (b) shows that the new method is as safe as the previous method. Figure 2 includes the data for concrete containing admixtures, pfa and ggbfs. Data better handled by hand calculation (because of non-regular section or other special conditions) were not included in Figures 1 and 2. Hand calculations showed that a few tall tapering columns gave measured pressures in excess of the calculated values. The Steering Group considered all the data, including those not presented in these illustrations, and concluded that it would be uneconomic to recommend a method which erivcloped all results irrespective of the exceptional conditions under which some of the results were recorded. The calculated pressures in Figures 1 and 2 are based on the recorded placing conditions. In practice, the placing conditions art: estimated. Assuming that these are normally 'safe' estimates, this has the effect of introducing an additional factor of safety not shown in Figures I and 2. A hlend is a ccmenl where ;I Portland cement has bccn combined with a latenl hydraulic binder. usually ggbfs or pfa. a1 the hatching plant. A hlcnded cenicnt is a c o m b i n n l h of Portland ccmenl with a lalent hydraulic binder (usually ggbfs or pfa). purchased direcl from a ccment company. 6 ClRlA Report !08 120 0 - 1 c 90 - O 0f 3 60 -. 00 8 , 1 0 30 60 90 120 150 I 1 1 180 210 Calculated pressures (kN/mz) (a) 1965 method 1501 120 0 0 90 0 0 60 0 nn 0 0 0 2 - 0 30 60 90 120 150 180 Calculated pressures (kN/m2) (b) 7985 method Figure 1 ClRlA Rcport 108 Comparison of the ClRlA methods 1 21 0 NOTES 1. This illlustration includes the data for Internally-vibrated concrete placed In nominaib vertical formwork 2. Data which contained estimated values of concrete temperature are excluded 3. Data for sloping and irrequial' zbaped formwork are excluded 150 "\ E 120 2 0 v) I3 U) ln 90 I Q 0 U I3 U) m E" 60 0 5 E .-X r" 30 0 Calculated pressures (kN/m2) Figure 2 x Comparison between measured and calculated pressures on vertical formwork (all relevant data are included) ClRlA Rcpori 108 1. Design method Freshly placed concrete comprises a gradation of particles from coarse aggregate down to fine cement particles. all of which are suspended to a greater or lesser extent in water. This is not a stable condition. The loss or displacement of a mere fraction of the total mix water (by settlement, leakage or hydration) can change the structure of the fresh concrete from a quasi liquid to a relatively stiff framework of touching particles with the water contained within the voids. This change in structure is important. While the aggregates and cement are suspended in water, the concrete exerts a fluid pressure ( D h ) on the formwork, but once a stable particle structure has been created, further increments of vertical load have an insignificant effect on the lateral pressure. Therefore the maximum lateral pressure is generally below the fluid head, and it is controlled by this change of structure (which can take from a few minutes to a few hours). The following factors affect this change of state (and hence the maximum formwork pressurc): Concrete admixtures aggregate shape, size, grading and density cementitious materials mix proportions temperature at placing weight density workability Formwork permeability/watertightness plan area of the cast section plan shape of the cast section roughness of the sheeting material slope of the form stiffness of the form vertical form height Placing impact of concrete discharge in air or underwater placing method (e.g. in lifts or continuous vertical rate of rise) vibration The complex inter-relationships of these factors are not described in this Report. A rationalised design equation is presented, together with a description of how the variables should be treated under design conditions. Using concepts developed at the Cement and Copcrete Association and during recent research 01the mechanisms creating formwork pressures(*”, the data for OPC concrete were analysed to quantify the relationships between maximum pressure, vertical form height, rate of rise, and concrete temperature at placing. Modifications to these basic relationships were then developed For concrete containing admixtures, ggbfs or pfa. This analysis led to the following expression for the maximum concrete pressure on formwork: ~~ * ClRlA Rcpori 108 ~~ The rcrcarch hy Clcar will be puhlirhcd in a Ccmcnl and Concrclc Arscxiatiim H c w r l during 1986 Y = 11 [ f,,, where C I Dt CzK ~ m f i or] Dh kN/m2, whichever is the smaller. C, coefficient de endent on the size and shape of formwork (see Table I for values), C, coefficient dependent on the constituent materials of the concrete (see Table 1 for values), fi D weight density of concrete, kN/m' H vertical form height, m It vertical pour height. m K temperature coeflicient taken as T1616 R the rate at which the concrete rises vertically up the form, m/h T concrete temperature at placing, "C d ( >' > H , tlie fluid pressure ( D h ) should be taken When C , f i as the design pressure. ,& incorporates the effects of vibration and workability, because these The term C factors are largely dcpendent on size, shape and rate of rise. All the effects of the height of discharge, cement type, admixtures, and concrete temperature at placing are incorporated in the term: C2 K J m - The design chart, Table 2, quantifies these equations for normal U K conditions where the concrete placing temperature is between 5 and 15°C. Pressure values shown in bold on the chart are for placing conditions broadly covered by pressure measurements on site, where the highest recorded pressures were 90 kN/m for walls and 166 kN/m- for columns. Values not in bold are outside recorded experience. They are in accord with the general trend, but may be somewhat conservative. No change is proposed in the design pressure envelope from that given in the ClRIA Report 1 design method. The envelope (see Figure 3) comprises fluid pressure to the depth where the maximum pressure obtained from the design equation or chart occurs and then remains at this value. Figure 4 is an example of measurements of formwork pressure and deflection taken on a site. This illustration shows that once a form deflects, it remains in that state until the tic bolts are released. In theory, a rigid form would experience a reduction in pressure aftcr the maximum. In practice, forms are not rigid, and some stress remains between thc form and concrete. For this reason, no reduction in pressure after the maximum is givcn in the design pressure envelope. Table 1 Values of coefficients C, and 1 C, I Value of C, Concrctc OPC. RHPC or SRPC without admixtures OPC. RHPC or SRPC with any admixture, except a retarder* OPC. RHPC or SRPC with a retarder LHPBFC. PBFC. PPFAC or blends containing less than 70 % ggbfs or 40 9h pfa ui!hout admixtures LHPBFC, PBFC. PPFAC or blends containing less than 70 % ggbfs or 40 '%pfn with any admixtures, except a retarder* LHPBFC. PBFC. PPFAC or blends containing less than 70 % ggbfs or 40 90 pfa with a rctardcr t Blcnds containing more than 70 96 ggbfs or 40 96 pfa t I ' \cc sc.clN,n 0.3 0.3 0.45 0.45 0.45 0.6 0.6 2 I ClRlA Rcport 108 = I 5 .- 3 W kW C l K l A Kcport 108 2 r Typical envelope of pressure on formwork Design pressure envelope Height of concrete h (m) Envelope of pressure if acted as a fluid \'\ /concrete '\\ '\ / Figure 3 Design pressure envelope I I '\ I 4 - \ 6 Pressure (kN/mz) Section: 0.8 x 5 x 6 m long Concrete: Normal-weight OPC Concrete temperature at placir-g: 13°C Slump: 40 mm Rate of rise: 3.2 m/h Pressure (kN/m2) 10.00 0 20 40 I I Deflection (mm) 60 80 100 120 140 I I I I 0 2.0 4.0 6.0 I 10.30 Calculated vertical 11.00 11.30 0 0 h 5 12.00 F 0 12.30 Porewater pressure on the form 13.00 13.30 14.00 Figure 4 I2 No reinforcement in the vicinity of the gauge Deflection measure on the back of the gauge I Example of formwork pressures and deflection measurements ClRlA Report 108 2. Notes for guidance 2.1 CEMENTITIOUS MATERIALS AND ADMIXTURES Coefficient C2 (see Table 1) takes into account the effects of different cementitious materials and admixtures. The term 'admixture' in Table I covers the range of products commercially available in 1985. Within the grouping 'retarder' fall retarders, retarding water-reducers, and retarding superplasticisers, also any admixlure which is used above the recommended dosage such that it effectively acts as a retarder. A major change from existing prac:ke is the recommendation that L iperplasticised concrete should be included within the gcneral grouping, and that it does not necessarily require design pressure equal to the fluid head. 2.2 AGGREGATES While quantifying the design equation, the effects of the aggregate shape and grading could not be isolated from the other mix parameters, so these factors are not included in thc design method. With the exception of no-fines concrete (see Section 2.4), the formula and tables apply !o all graded natural aggregates. The design equations apply to concrete mixes containing maximum aggregate sizes up to 40 mm. Pressures with larger maximum sized aggregates iirc likely to be controlled by the impact on discharge and the heavy vibration required. The design procedures for light- and heavyweight aggregate concretes are described in Section 2.7. 2.3 MIX PROPORTIONS The formula and design tables apply to !he whole range of normal mix proportions. 2.4 NO-FINES CONCRETE Because no-fines omcrete has a particle structure from :,e moment of placing, it results in a low formwork pressure. Typical design values are of the order of 2 to 2.5 kN/m2, so that handling stresses are likely to control the design of the form. 2,5 WORKABI LlTY Slump is not included as a variable in the dcsign chart for the following rsasons: I . The problems with placing low workability concrete around reinforcr.ment lead to prolonged vibration and formwork pressures similar to those obtain2d with more workable concretes. 2. The site data show no consistent direrence in formwork pressure between low. medium and high slump concretes. 3. Slump is not a good measure of the factors which affect formwork prcssure. Formwork pressures with flowing concretes are covcred in Section 2.1. ClRlA Rcport 108 13 2.6 CONCRETE TEMPERATURE AT PIACING At low rates of concrete placing, hydration effects become a significant factor in determining the maximum formwork pressure. Because these effects depend on the concrete temperature at placing, the design equation includes a temperature factor Although this only strictly applies to OPC and RHPC concretes, it is sufficiently accurate for all types of concrete when used in conjunction with coefficient C2.The K factor represents 8 d o of stiffening effects, which are dependent on temperature at placing. Data for concrete temperatures at placing in excess of 30°C or below 5 ° C are rare, and it is prudent not to extrapolate the design equation beyond these values. (Out of the 352 sets of data recorded over a number of years, on only 17 occasions were the temperatures at placing below 8°C.) 2.7 WEIGHT DENSITY The design chart (Table 2: assumes a weight density of 25 kN/m’. This is a safe value for normal-weight concretes. The procedure for calculating the maximum formwork pressure with light- or heavyweight concretes is to use the.appropriate weight density in the design equation (see Example 2). Thc design charts can be used to obtain the pressure with light- and heavyweight concrete by taking the chart value and then adjusting pro ruia by weight density. 2.8 VERTICAL FORM HEIGHT The vertical form height is important for two reasons: I . It limits the potcntial maximum pressure which can develop (in general, the maximum design pressure is not greater than Dh). 2. Height of discharge affects the magnitude of the impact forces. Both these factors affect the maximum formwork pressure, and they have been incorporated in the design equation as a function of the form height. Sometimes, the form can be substantially higher than the height of section cast (see Figure 5). In these cases, the limiting pressure might be the fluid pressure (which is obtained from the weight density times the actsial pour height). This should be checked with a separate calculation. T Depth of concrete h H 7 5 Figure 5 14 Height value to be used in the formulae ClRlA Report 108 2.9 SHAPE AND PLAN AREA OF THE CAST SECTION !n a section of small plan area, vibration can be sufficient to mobilise all the concrete in il layer and to transmit a relatively high amount of energy to t.he form. This has the effect of increasing the depth over which vibration is effective, and consequently the pressure on the form. In a larger section, all the concrete in a layer is not mobilised at the same time, and less energy is transmitted into the formwork. The point of concrete discharge and vibration is normally moved along the section, which allows the concrete a period of rest before the next layer is placed. The net effect is that in ‘walls’ the maximum pressures are lower than in ‘columns’. In fundamental terms, a wall is where the concrete is placed in layers with the point of discharge and vibration moving along the wall, while, for columns, the point of discharge and vibration is raised vertically. These conditions can be conservatively defined using the following simple definitions : wall or base - section where either the width or breadth exceeds 2 m column - section where boththe width and breadth are 2 m or less. These definitions are shown diagrammatically in Figure 6. The few site data recorded for small, single-storcy columns indicated B fluid pressure distribution. The formula generally predicts fluid head for small columns. This is reasonable, because small columns can be placed very quickly and vibrated such that the full fluid head is mobilised. However, an analysis of the forces on column clamps indicates that they would fail if concrete in columns develops full fluid pressure. It is therefore widespread practice to design small ply and timber column forms assuming less than the fluid head. The possible explanation of this anomaly has not been expcrimentally verified. 2.10 FORMWORK PERMEABILITY Formwork pressure decreases as the formwork permeability increases, if all other conditions are equal. This reflects the extent to which excess porewater pressure can dissipate through the formwork. The pressures are substantial!S lower with extremely permeable form materials such as expanded metal or fabric. In theory, the design equation should contain a factor for form permeability. Effects such as reduction of permeability through previous usage and the use of sealers and coatings, throw doubt on the ‘practicality’ of such a factor. Because the design equation does not includc a factor for form pcrmeability, the estimated pressures are not applicable to form materials such as expanded metal, where they effectively act as frce surfaces and prevent the build up of porewater pressure. t 3 Figure 6 Plan dimensions, showing Jections dofined as ‘columns’ or ‘walls and bases’ ClRlA Report 108 0 Walls and bases 1 2 3 Breadth (m) 15 2.1 1 FORMWORK STIFFNESS AND ROUGHNESS Study of the data suggests that the use of stiffer forms results in high pressures. Conversely, independent research work shows that the fonnwork pressure decreases substantially if a stiff form is moved slightly outwards. In most practical situations, the stiffness of a form varies from point to point, and it is difficult to quantify. Formwork stiffness was not, therefore, included in the design equation. While the concrete is acting as a fluid, the formwork roughness is immaterial, until a particle structure forms and the concrete starts to develop internal fricc.ion. Compared with other factors, its influence on the maximum pressure is small, and it has not been isolated in the design equation. 2.12 SLOPE OF THE FORM The pressure on sloping forms was not specifically examined in the research, and only a few experimental results were available. However, the CIRIA method described in this Report can be used conservatively with non-parallel sided walls with and without a uniform ratc of rise. If the volume supply rate is varied so that the rate of vertical rise is constant, the equation or tables can be directly used. The pressure at any level in the pour is the same on both faces, and the direction of action is perpendicular to the form (see Figure 7). The following method is suggested for calculating the pressure envelope with a constant volume supply rate: Split the pour into horizontal levels with the vertical distance between each level I in or less. 2. Calculate the plan area at each level. I. Figure 7 Pressure envelopes on the formwork of a wall with sloping face where the fluid head is fully developed ClRlA Rcpori 108 I I 1.. . . 3. Calculate the instantaneous rate of rise at each level from uniform volume supply rate (m'/h) Rlevcl = plan area at the level considered (m2) 4. Calculate the pressure at each level using the full height of the form, H, with either the equation or tables; 5 . Produce the design pressure envelope acting at right angles to the form. This procedure is illustrated in Examples 4, 5 and 6 (pages 23 to 30). 2.13 PLACING METHOD The difference between placing in lifts and con;iwous vertical placing has been described in Section 2.9. The design equations do not apply to conditions where the concrete is being pumped from below or where pre-placed large aggregate is grouted frqm below. In both these cases, the formwork pressures are likely to be higher than those given in this Report. American experience"' suggests that the formwork should be designed to withstand fluid pressure plus 50% for pump surge. 2.14 RATE OF RISE The rate at which the concrete rises vertically up the formwork is an important factor, and it is included in the design equation. In practice;this is never constant, but, the use of an average rate of rise is normally adequate for vertical formwork. The average rate of rise might not be applicable when a considerable lift is placed rapidly, followed by a long delay before the subsequent lift. As the rate of rise increases, the maximum pressure increases, but the relationship is not linear. At high rates of rise, changes in the rate of rise have less effect on the maximum pressure than changes at lower rates of rise (see Figure 8). 2.15 IMPACT OF CONCRETE DISCHARGE The effects of impact on discharge are incorporated into the design equation. Attention is drawn to the comments in Section 1.8. Figure 8 Relationship between rate of rise and pressure ClRlA Repon 108 Rate of vertical rise 17 ..-. . ... 2.16 VIBRATION The design method assumes normal internal vibration. Deep revibration can substantially increase the formwork pressure above the calculated value. If this technique is to be used, the form should be designed to withstand the fluid pressure at the depth of poker immersion if this is greater than the normal design value. This design method does not apply to externally-vibrated concrete. The action of vibrating the form induces stress additional to that created by the concrete pressure. 2.1 7 UNDERWATER CONCRETING When formwork is designed for use underwater, the buoyant weight density (Density of concrete - Density of water = 25 - 9.81 3 15 kN/m’) is normally used to calculate the effective formwork pressure. For fully-submerged sections, the formwork pressure can be calculated using either I . the design equation (see page 9) with D = 15 kN/m’ or 2. 0.6 times the value obtained from Table 2 (page 11). The procedures are based on the assumption that the static water pressure is equal on both sides of the formwork, and that it does not result in stresses in the formwork. This is a reasonable basis for design when the water level is not changing, but it can underestimate the pressures where there is a rapid drop in water level during concreting. This latter situation is analogous to an earth dam subjected to ‘rapid drawdown’. A change in water level produces an instantaneous change in pressure on the outside of a form, but a much slower change in the water pressure within the concrete, because that depends upon the permeability and hydraulic gradient within the concrete. When the water level is falling rapidly, this effect can result in the horizontal pressure exceeding the vertical pressure (see Figure 9). On the other hand, a rising water level reduces the formwork pressure. In these circurnstances, the formwork should be designed to resist the effective formwork pressure plus a surcharge proportional to the maximum tidal fall. ClRlA Report 108 _.... , ~ 7301 \. pressure \ \ \ 1400 \ 1 Pressure reduction on the outside of the form as a result of the fall in tide level I L Figure 9 Pressure measurements on an underwater tremie pour ClRlA Report 108 19 3. Examples The following examples illustrate the procedure for calculating the design pressure distribution. 3.1 BRIDGE ABUTMENT Section Concrete 0.8 x 6 x 5 m high Abutment details OPC normal-weight concrete Concrete temperature at placing 10°C :. K = (_?”>’ = 1-92 10+ 16 c, = 1.0 H=h=5m C2 = 0.3 D = 25 kN/m’ K = 1.92 R = 5 m/h Rate of placement 24 m’lh pumped Ratc of rise 24 - 5 m/h 0.8 x 6 From tables Pmax .‘. H 75 kN/m’ 85 kN/m’ = 80 kN/m’ 4 m) = Pmax (at H = 6 m) = pmax (at H = 5 m) PO kN/m’ < Dh = 125 kN/m’ From formula P,,, From tables 80 kN/m’ Pmax = = 25 ( 1. O d+ 0.3 x 19.2-/,) = 80 kN/m’ From formula f,,, = 80 kN/m’ < Dh Pressure envelope for formwork design : 5 80 kN/m2 20 ClRlA Report 108 3.2 PARTITION WALL Section Concrete 0.2 x 5 x 4 m high Wall details OPC lightweight concrete c, = 1.0 Concrete temperature at placing 15°C K= (m6) 36 = 1.35 Rate o f rise 10 m/h H=h=4m C, = 0.3 D = 19 kN/m3 K = 1.35 R = 10 m/h From tables P, = 70 kN/m* = 67.1 kN/m2 < 76 kN/m2 From formula = 65 kN/m2 f'ma, Pressure envelope for formwork design P CIRIA Report 108 65 kN/m2 21 3.3 LIFTSHAFT Section 0250 mm - Plan view (6m high) Continuous vertical placing and constant vibration unlikely. Therefore treat as a wall with breadth = 4 x 1.75 m Equivalent section 0.25 x 7 x 6 m high Concrete OPC normal-weight concrete Concrete temperature at placing 15°C :. K = ( 1 = 1.35 ... 15 + 16 36 2 Rate of rise 5 m/h From tables P,,, Shaft details c , = 1.0 H=h=6m C, = 0.3 D 25 kN/m’ K = 1.35 R = 75 kN/m’ = 5 m/h < Dh = 150 kN/m2 Pressure envelope for formwork design 22 ClRlA Rcpori 108 .._ .i 3.4 MASS CONCRETE RETAINING WALL Section I * End elevation ( 1 0 m long) Wall details c, = 1.0 Concrete OPC normal-weight concrete with retarder Concrete temperature a t placing 10°C .‘. K = (1036 2 = 1.92 ) + 16 Uniform volume supply rate (Q) One 6 m’ truck every 20 min = 18 m3/h Rate of rise H=5m C2 = 0.45 D = 25 kN/m’ K = 1.92 Q = 18 m’/h The rate of rise increases as the pour progresses because the section narrows. Therefore the pressures are calculated for instantaneous rates of rise at specific levels. The full height of the formwork is used in the formula, irrespective of the level for which it is calculated. R = Uniform volume supply rate (m’/h) Plan area at level considered (m2/h) Using formula Pmax = D (C,&+ = 25 = 25 CIRIA Rcport 105 C, K,/H-) C f i + 0.45 x I . 9 2 d m ) (fl+ 0.864,/5-) 23 Area, A = Breadth (8)X width ( w ) h (m) 0 T 0.5 1.o 1.5 2 .o 2.5 h 3.0 Calculation o f rate o f rise and pressure A R (m2) (m/h) -T-pr 12.5 2.00 2.50 50.0 62.5 3.50 4.00 4.50 5.00 87.5 112.5 1.25 10.0 12.5 15.0 17.5 20.0 22.5 25.0 11.5 30.0 32.5 35.0 1.80 1.44 1.20 1.03 0.90 0.80 0.72 0.65 0.60 0.55 0.51 66 65 64 64 63 63 0 12.5 25 .O 37.5 50.0 62.5 65.0 64.0 64.0 63.0 63.0 Pressure envelope for formwork design Note: Pressurc acts at right angles to face. and the stability of the forms has to be considered. 24 ClRlA Report IU8 3.5 BRIDGE COLUMN Section 5r 5n 5m P!-i End elevation 2.5 m Front view Section cast Although one plan dimension is greater than 2 m, the section should he considered a column, because the vibration and vertical placing are likely to be continuous. Concrete OPC normal-weight concrete with air entraining agent Column details c, = 1.5 H = 16m C, = 0.3 = 25 kN/m3 D ClRlA Report I08 I i. 25 . Concrete temperature at placing 1O’C K = 1.92 Uniform volume supply rate 20 m’/h Variable. Has to be calculated at specific depths. Pressure calculated using this rate and the full height of the form. Rate of rise Using formula P = D ( C , a t C2x K x)-/, = 25 ( I . 5 f i = 25 ( 1 . 5 4 + 0.576J16 - 1.5t/B) t 0.3 x 1 . 9 2 J m ) Calculation of rate of rise and pressure at a uniform volume supply rate of 20 m’/h h DIt ( k N (m 1 - /mz) I 25 2 3 4 5 6 7 8 9 10 II 12 13 14 15 -.- 16 26 50 75 100 125 I50 I75 200 225 250 275 300 325 350 375 400 B (m) 1.5 1.5 1.5 1.5 1.5 I .7 1.9 2.1 2.3 2.5 2.5 2.5 2.5 2.5 2.5 2.5 Pressure at h (kN/m2) P (kN/m’) 1 .o 1 .o 1 .o 1 .o 1 .o I .o 1 .o 1 .o 1 .o I .o 1.2 1.4 I .6 1.8 2.0 2.5 1.5 1 .5 1.5 1.5 1.5 I .7 1.9 2.1 2.3 2.5 3.0 3.5 4.0 4.5 5.O 5.O 13.3 13.3 13.3 13.3 13.3 11.8 10.5 9.5 8.7 8.0 6.7 5.7 5 .o 4.4 4.0 4.0 170 164 I60 I55 147 I40 135 130 127 127 25 50 75 100 125 150 170 164 160 155 a 147 140 135 130 127 127 ClRlA Rcport 108 - .._, w . . Pressure envelope for formwork design Front view I i. ClRlA Report 108 21 Pressure envelope for formwork design Pressure (kN/mZ) %I9 I* I I 1 1 1 2 1 3 1 - 4 1 5 Z 6 T 7 164E I 160 155 1 4 , h l 9 T10 x 1 1 P 1 2 x 1 3 1-14 Y15 1 1 6 End elevation 28 ClRlA Rcpori 108 , ! 3.6 ‘V’ COLUMN i 5b 31 2m -- 2m 2m I d F r m t view 4 End elevation Section llthough the breadth exceeds 2m, the possibility of continuous vertical placing and vibration cannot be discounted Concrete OPC normal-weight concrete with superplasticiser Concrete temperature at placing Very cold winter conditions, so taken as 5‘C K .‘. = [5%) Column details c, = 1.5 H=8m C, = 0.3 D = 25 kN/m2 2 = 2.94 K = 2.94 Uniform volume supply rate Two 6 m3 trucks per hour = 12 m’/h Using formula P = D C C , a + C, = 25 ( 1 . 5 f l + = 25 ( IS@ ClKlA Rcport 198 x K x drfl-) 0.3 x 2 . 9 4 d 8 T A ) +0 . 8 8 d t - m ) 29 Calculation of rate of rise and pressure at a uniform volume supply rate of 12 m’/h h (m) Dh (kN/m*) e W (m) (m) 1 25 50 75 100 125 150 I75 200 2.5 2.5 2.5 2.5 2.5 3.0 2.5 2.0 1 1 2 3 4 5 6 7 8 I 1 I 1 I 1 A (m’) (dh) 2.5 2.5 2.5 2.5 2.5 3.O 2.5 2.0 4.8 4.8 4.8 4.8 4.8 4.0 4.8 6.0 R P (kN/m’ 124 130 138 Pressure at h (kN/m’) 25 50 75 100 125 124 130 138 Half pressure envelope for formwork design Pressure (kN/mZ) I h (m) 125 I End elevation 30 CIRIA Report 108 _.... , Acknowledgements P. A. G. Andrews D. A. Biddlecombe P. E. Le i3ihan D. P. Burrage A. I. L. Byers R. P. Cannon J. R. Champion J . Csllins A. T. Cornish J. Dallaway R. M. Edmeads P. J. Egan A. J. Goldsmith P. S. Goodall J . Harrington-Lynn J . E. Harris J. R. lllingworth G. S. Kirk F. Lane P. R. Luckett D.Maher W. E. Murphy P. L. Owens K. R. Pook S. M. Rao P. L. Rawlinson B. G . Richardson P. Rogerson P. Rowdon B. M . Sadgrove M. F. Taylor C. F. Turner R. T. Ward P. F. Watson R. V. Watsoii A. S. White P. Williams C. J. Wilshere Taylor Woodrow Construction Limited GKN Kwikform Limited Ralfour Beatty Construction Limited Steveland Products Limitcd Balfour Rentty Construction Limited Frodingham Cement Company Limited Sir Alfred McAlpine & Son 1.imited Mabey Hire Company Limited Blue Circle Industries PLC/Cement Manufacturers Federation Ove Arup & Partners Cementation Research Limited/Cement Admixtures Association Fosroc Technology LimitedKement Admixtures Association Wimpey Construction ( U K ) Limited Pozament Cement Limited Department of the Environment Mabey Hire Company Limited Wimpey Construction ( U K ) Limited Blue Circle Industries PLCKement Manufacturers Federation Sir Robert McAlpine & Sons Limited Chart Formwork Limited MB Formwork Limited/National Association of Formwork Constructors Cement an i Concrete Association Consultant Property Services Agency Propcrty Services Agency Stelmo Limited CIRIA Taylor Woodrow Constructiop Limited Cementation Construction Limited CIRIA Acrow (Engineers) Limited Rapid Metal Developments Limited Tarmac Construction Limited Stelmo Limited Cement and Concrete Association Scaffolding (Grcat Britain) Limited John Mowlem & Company PLC John Laing Construction Limited References KINNEAR, R.G. ef a / . The pressure of concrete on formwork CERA (now CIRIA) Rcport I . April 1965 HARRISON, T.A. The pressure on vertical formwork when concrete is placed in wide sections Cement and Concrete Association, Research Report 22, March 1983 HABGOOD, M.G. Site formwork pressure measurements in wide sections recorded durine the period of March 1980 to June 198 I Cement and Concrete Association Departmental Note 2058. 1982 FORD. J . H . Consolidation of concrete using plastic form liners and plastic coated plywoods Conference paper, Second International Conferencc on Forming Economical Concrete Buildings, Chicago, November 1984 ClRlA Kcport 108 i ! . ., ,.. 31