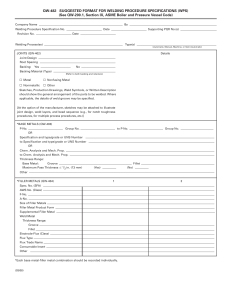

Chemical Composition Variations in Shielded Metal Arc Welds Metal transfer droplet size, which changes with heating temperature, is discovered to be a factor varying chemical composition BY A. Q . BRACARENSE A N D S. LIU ABSTRACT. The use of shielded metal arc (SMA) welding can result in chemical composition variations along the weld length. Manganese and silicon, c o m m o n l y found in low-carbon steel welds, change in composition with weld position. This research was performed to better characterize the composition variations observed in structural steel welds and to understand the controlling factors that determine the extent of these composition changes. Single bead-on-plate and multipass welds were performed and analyzed. Manganese, silicon, and oxygen contents showed significant variation along the weld length. Hardness measurements and microstructure confirmed the strong effect of the composition change. To determine the cause of such composition variations, additional experiments were carried out w i t h the w e l d ing arc established between the electrode and a water-cooled copper pipe. The individual metal droplets were collected in water and processed using standard particulate materials processing techniques to remove the slag covering. The droplet size distribution was determined and related to the composition variation and position along the weld length. The results indicated that electrode preheating caused a change in the size of the droplets transferred during welding. At the beginning of welding, the electrodes were not heated as much and small size droplets predominated. The fine droplets, with large surface areato-volume ratio, experienced more complete deoxidation reactions and large losses in manganese and silicon. As elecA. Q. BRACARENSE and S. LIU are with the Center for Welding and Joining Research, Colorado School of Mines, Golden, Colo. trade preheating becomes more intense, globular transfer with large droplets replaced the small droplets. Chemical analysis showed that more manganese and silicon were transferred across the arc to the weld pool. Introduction The shielded metal arc (SMA) welding process is probably one of the most versatile methods for joining steels. It is inexpensive, simple, and requires minimum welding skills in most applications. An SMA electrode consists of a metal core rod and a "clay-like" covering of powdered minerals such as fluorides, carbonates, oxides, organic materials, and alloying additions. A silicate binder is used to help extrude the flux ingredients onto the metal core rod. Subsequent baking of the electrode removes the moisture from the covering and forms a hard covering over the metal rod. During welding, both base metal and electrode are melted by the heat gener- KEY WORDS SMAW Chemical Comp. Varies Covered Electrodes Structural Steel Electrode Heating Chemical Analysis Metal Transfer Mode Weld Metal Manganese Weld Metal Silicon Arc Physics ated from the arc. The transfer mode of liquid metal from the electrode tip to the weld pool in SMA welding is often difficult to establish without special experimental techniques because of the fume and slag present (Ref. 1). However, it has been shown that globular transfer occurs in SMA w e l d i n g . Large droplets of l i q uid metal, at the size of the electrode diameter or bigger, grow at the tip of the electrode, detach and fall to the molten weld pool. Explosive transfer, before or after short circuiting of the metal droplet with the weld pool, was also observed in SMA welding. A showery spray of small droplets of liquid metal and slag fly across the arc including many projected outside the weld zone (Refs. 1, 2). Many factors are responsible for the transfer mode in SMA welding. The major ones are current, voltage, electrode diameter, melting temperature of the core material, coating thickness, and temperature of the electrode (Ref. 3). Few studies (Refs. 3-6), however, provide insights on the effect of electrode temperature on metal transfer and weld deposit properties. During welding, an electric current (I) passes from the electrode holder to the electrode and through the electrode to the arc column. As a result of the electrical resistance of the electrode, heating of the electrode occurs. Joule heating, which is given by the product of the square of the current (I2) and the electrical resistance (R), causes the electrode to heat up. Additionally, part of the heat of the plasma, w h i c h is given by the product of the electric current (I) and the arc voltage (V 0 ), also raises the temperature of the electrode. However, this contribution is minimum, because part of the arc energy is used to melt the tip of the elec- W E L D I N G RESEARCH SUPPLEMENT I 529-s TR = HEAT FROM JOULE EFFECT HEAT FLOW . THROUGH TIP FLUX COATING- I POWER I SOURCE I V0 Q, LIQUID = DROPLET. V0 Fig. I — Schematic illustration HEAT FLOW TO FLUX THE of the thermal conditions t r a d e a n d the base m e t a l , a n d part is lost b y r a d i a t i o n a n d by e v a p o r a t i o n of m a terial f r o m the surface of the electrode (Ref. 6). Figure 1 is a s c h e m a t i c illustration of the t h e r m a l c o n d i t i o n s e x p e r i e n c e d b y an S M A w e l d i n g e l e c t r o d e . From the e s t a b l i s h m e n t of the arc, the t e m p e r a t u r e of the e l e c t r o d e is e x p e c t e d t o increase as s h o w n in Fig. 2 . It is clear that d u r i n g n o r m a l w e l d i n g t h e t e m p e r ature of an e l e c t r o d e at a p o i n t r e m o v e d f r o m the arc c a n vary s i g n i f i c a n t l y , f r o m r o o m temperature to over 1000°C (1 832°F) (Ref. 3). C o n s e q u e n t l y , the m e l t rate of e l e c t r o d e a n d t h e m e t a l transfer are e x p e c t e d to c h a n g e w i t h w e l d i n g t i m e and position along the w e l d length. D u r i n g w e l d i n g , the length of the e l e c t r o d e , £, also d i m i n i s h e s , w h i c h d e - =: ARC FUSION = HEAT FROM PLASMA NEAR BOUNDARY VOLTAGE in a covered electrode (Ref. 6). creases t h e J o u l e e f f e c t . H o w e v e r , t h e increase in t e m p e r a t u r e of t h e c o r e r o d m a t e r i a l leads t o an i n c r e a s e o f t h e res i s t i v i t y , p (Ref. 7), w h i c h d e s p i t e t h e e l e c t r o d e length decrease, the Joule h e a t i n g c o n t i n u e s to be s i g n i f i c a n t . Figure 3 s h o w s the increase of resistivity of s o m e c o m m o n steels w i t h t e m p e r a t u r e . Based o n this fact, Fig. 4 s h o w s s c h e m a t i c a l l y t h e d i s t r i b u t i o n o f the t e m p e r a t u r e of the metal c o r e rod a l o n g its l e n g t h , as p r o p o s e d b y W a s z i n k , ef al. (Ref. 6). Next to the electrode holder, the t e m perature of the c o r e r o d increases r a p i d l y t o a steady t e m p e r a t u r e . A t a s h o r t d i s tance f r o m the arc, the t e m p e r a t u r e of t h e e l e c t r o d e t i p increases r a p i d l y t o t h e m e l t i n g t e m p e r a t u r e . W a s z i n k , et al. (Ref. 6), e s t i m a t e d that the r a p i d t e m p e r - Table 1 — Welding Conditions Used for the Three Electrodes Core rod diameter = 3.2 mm (% in.) Conditions Current (amperes) Voltage (volts) Travel speed (mm/s) Heat input (kj/mm) E6013 | iA 23 2.05 1.5 E7018 El 2018 134 25 2.05 1.5 130 27 2.5 1.4 Table 2 — W e l d i n g Conditions Used in the Experiment w i t h E7018 Electrodes to Verify the Composition Variation and Its Dependence of Welding Current Core rod diameter = 3.2 mm (% in.) Conditions Current (amperes) Voltage (volts) Travel speed (mm/s) Heat input (kj/mm) Lower Current 100 25 1.69 1.5 Higher Current 150 25 2.54 1.5 Table 3 — C h e m i c a l C o m p o s i t i o n in w t - % of t h e A 3 6 Plate a n d E 7 0 1 8 Electrode C o r e Rod Element Carbon Silicon Manganese 530-s I DECEMBER 1993 A36 Steel 0.1282 0.2637 0.9688 E7018Core Rod 0.1136 0.0094 0.4957 ature increase occurred at about 1 mm (0.039 in.) from the molten electrode tip. At the melting front, the core rod is much hotter than the surrounding covering. As the electrode heats up by Joule effect during welding, the portion of the electrode tip that experiences the transient temperature increase, A9, w i l l also increase. The electrode covering plays an important role by keeping the generated heat from the Joule effect and the heat conducted from the plasma inside the core rod. Since the electrical resistance of the electrode covering is several orders of magnitude higher than the metal core rod, Joule heating in the electrode covering is negligible because it can be considered that no current flows through the covering material (Ref. 6). In summary, with the melting of the electrode, more heat is generated and the electrode becomes hotter. The effects of electrode temperature increases during welding are various. It has been suggested (Ref. 3) that when an electrode is heated to high temperatures, the specific melting rate may experience a five-fold increase, w h i c h is the ratio between the latent heat of the hot metal and its heat of fusion. An extension of this observation may be the effect of electrode temperature on metal transfer mode, w h i c h may strongly influence the weld chemical composition. Additionally, it was found (Ref. 5) that oxygen content decreased w h i l e manganese and silicon contents increased as a function of the droplet growth time, as shown in Fig. 5. These observations seem to indicate that larger droplets will exhibit higher manganese and silicon content. This phenomenon must be associated with the deoxidation of the liquid metal droplet, w h i c h is controlled by kinetic factors such as temperature and droplet surface area. Experimental Procedure Bead-on-plate welds on A36 steel plates were conducted using E6013, E701 8, and E1 201 8 electrodes to verify the composition variations along the weld length. The welds were made with a linear heat input approximately equal to 1.5 kj/mm. The welding conditions for each electrode are shown in Table 1. Four additional sets of welding experiments were performed using E7018 electrodes to investigate the influence of Joule heating of the electrode on weld metal chemical composition. In the first one, bead-on-plate welds were prepared to verify the composition variation in the weld metal along the weld length at two levels of current. Composition changes were also correlated with d i l u t i o n , hardness and m i - O 115 AMP 1200 / O 1000 or: m o AMF / / / / / / . y < / o_ 5 / V y EL s,MP /j / / A A / /. SAE-1008 SAE-1025 SAE-1042 / '* A 0 20 40 60 80 TIME OF WELDING 100 120 (S) Fig. 2 — Increase in temperature in SMA electrodes with time for different welding currents (Ref. 3). Fig. 3 — Resistivity of low-carbon crostructure. The welds were performed using a constant current p o w e r source w i t h d i r e c t c u r r e n t e l e c t r o d e positive (reversed polarity). The w e l d i n g c o n d i t i o n s , s h o w n in T a b l e 2, w e r e kept c o n stant b y u s i n g an a u t o m a t i c v o l t a g e c o n trol apparatus. 2 . Samples w e r e p r e p a r e d for c h e m i c a l a n a l y s i s as s h o w n i n F i g . 9 . W i t h f o u r layers o f w e l d b e a d s , t h e effect of base m e t a l d i l u t i o n is c o m p l e t e l y r e m o v e d . T h e results of this set of e x p e r i m e n t s w i l l b e c o m p a r e d w i t h t h e results o f t h e metal droplet experiments. T o investigate the possible reactions b e t w e e n t h e e l e c t r o d e c o v e r i n g and the metal core r o d , the remaining electrode tips after w e l d i n g w e r e r e t a i n e d for further analysis. In t h e t h i r d set o f w e l d i n g e x p e r i ments, multipass welds w e r e prepared w i t h the h i g h c u r r e n t w e l d i n g c o n d i t i o n s s h o w n in T a b l e 2. The start of the w e l d s was staggered to p r o d u c e a long w e l d as in a c t u a l s t r u c t u r a l f a b r i c a t i o n . W i t h this p r e p a r a t i o n , it is e x p e c t e d that t h e o v e r l a p p i n g w e l d s w i l l m i n i m i z e t h e eff e c t of c o m p o s i t i o n c h a n g e s b y m i x i n g m a t e r i a l o f t h e e n d of w e l d s ( h i g h - a l l o y contents) w i t h material of the b e g i n n i n g of welds ( l o w - a l l o y contents). Samples w e r e p r e p a r e d f r o m the w e l d s as s h o w n in Fig. 1 0 for c h e m i c a l analysis. After the w e l d s w e r e m a d e , the s a m ples w e r e p r e p a r e d for c h e m i c a l a n a l y sis f r o m the w e l d length as s h o w n in Fig. 6. T h e m a n g a n e s e a n d s i l i c o n c o n t e n t s of t h e A 3 6 steel plate a n d t h e E 7 0 1 8 c o r e r o d are s h o w n in T a b l e 3. Special p r e p a ration was required to obtain the specim e n s for o x y g e n a n a l y s i s as s h o w n in Fig. 7. W e l d m o r p h o l o g y , hardness m e a surement, and microstructure evaluat i o n samples w e r e p r e p a r e d as s h o w n in Fig. 8. In t h e s e c o n d set of w e l d i n g e x p e r i ments, multipass bead-on-plate welds were prepared w i t h the same w e l d i n g c o n d i t i o n s as t h e h i g h c u r r e n t s i n g l e b e a d - o n - p l a t e w e l d s presented in T a b l e Fig. 4 — Temperature distribution in the core rod along the length of the electrode at different times (Ref. 6). T h e f o u r t h set of w e l d i n g e x p e r i m e n t s was performed on a water-cooled pure copper tube positioned over a metal d r o p l e t c o l l e c t i o n box. T h e b o x has f o u r c o m p a r t m e n t s that c o l l e c t e d metal d r o p l e t s at a s p e c i f i c l o c a t i o n a l o n g t h e w e l d . T h e b o x w a s f i l l e d w i t h w a t e r to q u e n c h the molten metal droplets and MELTING --> ERONT^ TEMPERATURE OF T H E ARC /I "ELECTRODE: TIP" J\ to p r e v e n t the d r o p l e t s f r o m fusing o n t o t h e b o x . A s c h e m a t i c d r a w i n g o f this a p paratus is presented in Fig. 1 1 . The w e l d ing c o n d i t i o n s used in this part of the e x p e r i m e n t are s h o w n in T a b l e 4 . The droplets were removed from the specific c o m p a r t m e n t s a n d processed in groups using particulate materials processing techniques. The droplets w e r e t h e n c l a s s i f i e d i n t o t h r e e size g r o u p s as s h o w n in T a b l e 5. D r o p l e t s o f d i a m e t e r less t h a n 1.5 m m ( 0 . 0 5 9 in.) w e r e c h a r a c t e r i z e d as s p r a y t r a n s f e r r e d , a n d m e d i u m a n d large droplets (d > 1.5 m m ) , as g l o b u l a r t r a n s f e r r e d . T h e a v e r a g e d i ameter and deviation of the droplets were d e t e r m i n e d for each size range Table 4 — Welding Conditions Used in the Droplet Generation and Collection Experiments 110 35 3.38 0.97 Current (amperes) Voltage (volts) Travel speed (mm/s) Heat input (k|/mm) Table 5 — Classification of the Droplets from 3.2mm (% in.) Diameter E7018 Electrodes Classification Small Medium Large Dimension (mm) 0.5 to 1.5 1.5 to 3.0 3.0 to 4.5 Table 6 — Percent Increase of Weld Metal Manganese and Silicon per 100mm (3.94 in.) of Weld Length for the Three Electrodes Tested ae J .r," \ ELECTRODE steels with temperature (Ref. 7). ARC f i r n e Z -J / ^ t 1250 500 750 1000 TEMPERATURE (°C) 140 LENGTH Elements E6013 Manganese 7.1 Silicon 10.7 E7018 E12018 6.3 14.5 8.1 21.8 W E L D I N G RESEARCH SUPPLEMENT I 531-s 0 100 200 300 400 500 600 700 CUT TO FIT IN THE TIME (ms) EMISSION SPECTROMETER Fig. 5 — Variation of weld metal oxygen, manganese and silicon contents as a function of droplet growth time for electrodes with lowoxygen-potential covering (marble: 14 wt-., fluorspar: 56 wt-%, mica: 2 wt-%, Na2C03: 1 wt-%, TiO,: 4 wt-%, Fe-Si: 5.5 wt-%, Fe-Mn: 5.5 wt-%, Fe-Ti: 13 wt-%) (Ref. 5). Fig. 6 — Sample preparation for weld metal chemical CHAMBER analysis. WIDTH REINFORCEMENT PENETRATION HARDNESS TEST INDENTATIONS POSITION POSITION OF EXTRACTED Fig. 7 — Sample preparation piece weighed approximately THE SAMPLES for weld metal oxygen analysis. 1 g (2.2 X 10~3 Ib). Each Fig. 8 — Sample preparation for bead morphology determination, hardness measurement and microstructural evaluation. I ..fcROII BECAUSE OF ARC INSTABILITY CUT TO FIT t i n TO FIT IN THE EMISSION IN THE EMISSION SPECTROMETER Fig. 9 — Sample preparation for multipass weld metal chemical ysis. 532-s I DECEMBER 1993 SPECTROMETER CHAMBER CHAMBER anal- Fig. 10 — Sample preparation analysis. for overlapping weld metal chemical 40.0 20.0 40.0 60.0 WELD POSITION FROM THE START (mm) Fig. 11 — Schematic illustration of the apparatus used for droplet generation and collection. (transfer mode) and each compartment. Results and Discussion Manganese and silicon were chosen to be analyzed in this study because they are the most common elements present in commercial electrodes for low-carbon and low-alloy steel weldments and that they have a strong effect on m i crostructure and mechanical properties of steel welds (Refs. 8-11). The manganese and silicon contents of the welds made using the E6013, E701 8 and E1 201 8 electrodes are plotted in Figs. 12 and 13, respectively, as a function of the weld position. As can be observed, variations occurred for all the electrodes. Table 6 summarizes the percent increase of each element per 100 mm (3.94 in.) of weld length from the beginning to the end of the w e l d . The relative increase was the greatest in the welds made using the E1 201 8 elec- Fig. 12 — Manganese variation along weld length for various electrodes. Total weld length: E6013, 90 mm (3.54 in.); E7018, 105 mm (4.13 in.); El2018, 73 mm (2.87 in.). trodes, indicating that significant changes in microstructure and mechanical properties along the weld length can be expected (Ref. 12). To further confirm these results, E7018 electrodes were used in four additional experiments as described previously. Figure 14 shows the manganese and silicon contents as a function of the weld length and welding current for the single bead-on-plate welds. Figure 15 shows the oxygen content along the length of the welds made with two current levels. These results again confirmed the composition variation trends noted previously. Manganese and silicon both increased, being the increase more significant for the higher current (150 A) welds. Oxygen, however, decreased along the weld length. It is important to notice that the results presented are independent of weld dilution, which was approximately constant at 38 vol-% for the two currents and along the weld length. Constant dilution precludes the effects of base metal preheating, which could also cause the weld metal composition variation. The results from the multipass welding further confirmed the results from the single bead-on-plate welding. Manganese and silicon contents increased in the last of 1 0 passes as shown in Fig. 1 6. Figure 1 7 shows the chemical composition along the overlapping w e l d . Manganese and silicon increased even when the end of a weld overlapped with the beginning of the subsequent w e l d . The "compensation" expected from a high- and low-alloy content (end of a weld and beginning of a weld) was minimum. The variation in manganese and silicon along a long weld joint can compromise the quality of the weld joint. All results reported indicate that the composition variation was caused mainly by the heating of the electrode during welding. Therefore, two possible 100.0 MANGANESE o D - 150 AMP o D - 100 AMP « 40.0 20.0 40.0 60.0 WELD POSITION FROM THE START (mm) Fig. 13 — Silicon variation along weld length for various electrodes. Total weld length: E6013, 90 mm (3.54 in.); E7018, 105 mm (4.13 in.); El2018, 73 mm (2.87 in.). 20.0 40 60 80 100 120 WELD LENGTH POSITION (mm) Fig. 14 — Weld metal manganese and silicon variation along the weld length for E7018 electrodes at the currents of 100 and 150 A. W E L D I N G RESEARCH SUPPLEMENT I 533-s 100.0 . 150 AMP 00 AMP 80.0 60.0 SILICON 40 50 60 70 80 WELD LENGTH POSITION (mm) 20.0 40 60 80 WELD LENGTH POSITION ( m m ) Fig. 15 — Weld metal oxygen variation along the weld length E7018 electrodes at the currents of 100 and 150 A. e x p l a n a t i o n s n e e d to be discussed. First, the metal core rod-electrode covering i n t e r a c t i o n j u s t b e f o r e m e l t i n g w i l l be c o n s i d e r e d . D i f f u s i o n o f e l e m e n t s (Ref. 5), s u c h as m a n g a n e s e a n d s i l i c o n f r o m t h e c o v e r i n g to t h e c o r e r o d , m a y o c c u r d u r i n g heating and increase their c o n c e n t r a t i o n in t h e w e l d m e t a l . T h e second explanation concerns the heating of the electrode, w h i c h changes the d r o p l e t s ' size a n d c o m p o s i t i o n . Small d r o p l e t s w i t h large surface area per u n i t v o l u m e can interact more efficiently for 120 100 Fig. 16 — Weld metal manganese and silicon variation along the tenth multipass weld length for E7018 electrodes at current of 150 A. w i t h t h e o x i d i z i n g s p e c i e s i n t h e arc l e a d i n g to t h e o x i d a t i o n o f t h e m e t a l l i c elements. O n the other h a n d , large d r o p l e t s w i t h s m a l l surface area per u n i t v o l u m e i n t e r a c t less w i t h o x y g e n resulting in l o w e r loss of the a l l o y i n g e l e m e n t s in the w e l d m e t a l . T o e v a l u a t e the first hypothesis, a n a l yses of t h e e l e c t r o d e tips w e r e p e r f o r m e d using the scanning electronic m i c r o s c o p e (SEM). Figure 1 8 s h o w s the c o n c e n t r a t i o n profiles o f m a n g a n e s e a n d s i l i c o n across t h e c o r e r o d . N o t i c e t h a t Mn manganese and silicon contents were a l m o s t c o n s t a n t in t h e c o r e r o d . S l i g h t deviations from the original manganese and silicon contents were observed but the magnitude of change cannot justify the transport of elements between flux c o v e r i n g a n d c o r e r o d . These results i n dicate that the c o m p o s i t i o n variations in the w e l d metal d i d not result f r o m a n y r e a c t i o n b e t w e e n the c o r e r o d a n d c o v e r i n g before m e l t i n g (Ref. 5). T h e r e f o r e , t h e o t h e r p o s s i b i l i t y is t h e i n t e r a c t i o n b e t w e e n the m o l t e n droplets Si (1 _ y NOMINAL ROD COMPOSITION (jmmmm^~z~imm o o o ° o °0 n ° 0 r ..: 0.0 NOMINAL ROD^ COMPOSITION 1.0 2.0 ELECTRODE DIAMETER ( m m D O " ,D 0.0 1.0 2.0 ELECTRODE DIAMETER ( m m ) i°n n DD : o D 0 50 100 150 200 WELD LENGTH POSITION (mm) Fig. 17 — Weld metal manganese and silicon overlapped weld length. 534-s I DECEMBER 1993 250 variation 300 along the Fig. 18 — SEM analysis of an E7018 electrode 150 A. tip after welding at WELDING DIRECTION 4.0 LARGE DROPLETS : [J [3 3.5 : M 11 : E £3.0: M fcj g2.0 : Q 1.5 MEDIUM DROPLETS i : : \ 1 1 : T t -L SMALL DROPLETS Z 1.0 _ x_ <tf- (J - X 1 £ ; 1 3 TANK 4 5 POSITION Fig. 19 — Droplet size variation (in mm) as a function of tank position. and the arc plasma during transfer. The results of droplet collection are presented in Fig. 19 as a function of the tank position. It can be seen that the average size of the large droplets increased while the smallest droplets decreased along the weld length. It is important to notice that the increase in large droplet size was at the expense of the small droplets since the melting rate remained approximately constant at 0.07 g/s (0.1 5 X 1 0~2 Ib/s). These results confirm that electrode heating actually changed the transfer mode and the chemical composition of the weld metal. At the beginning of w e l d i n g , the core rod is cold and the electric resistance of the electrode is low. When the current begins to pass through the electrode, the temperature starts to increase by Joule effect. At this point, the heat of the plasma contributes little to heating the electrode. As the electrode is being consumed, the temperature increases even with the decrease of electrode length, as described previously. It is believed that the more the electrode is consumed the more the heat of the plasma will contribute to the heating up of the electrode. Simultaneously, while the electrode heats up, the resistance increases due to the increase TEMPERATURE TEMPERATURE Fig. 20 — Arc voltage and electrode voltage during welding with the automatic arc voltage controller. in resistivity of the metal. The increase in resistance, at constant current, increases the voltage along the electrode. As the automatic voltage arc control apparatus keeps the total voltage constant, the arc voltage should decrease during welding, as shown in Fig. 20. At high arc voltage, such as at the beginning of welding using a new electrode, small droplets are expected to be predominant. At low voltage, after the electrode heats up, large droplets and short-circuit transfer are predominant (Ref. 1 3). The effect of metal transfer mode on chemical composition can be explained by Fig. 2 1 . The small droplets have large 2 <^Roo ^ ^ ^ f } ooo OXYGEN Mn AND Si OXIDIZE AND GO TO SUAG o Fig. 21 — Effect of the electrode heating during welding on metal droplet transfer mode and the chemical composition of the droplets. 40 60 WELD LENGTH POSITION (mm) Fig. 22 — Hardness variation along the length of welds made with E7018 electrodes at 150 A. WELDING RESEARCH SUPPLEMENT I 535-s Acknowledgments The authors gratefully acknowledge the support of the SP-7 W e l d i n g Panel of NSRP, the National Shipbuilding Research Program. A. Q. Bracarense also acknowledges the financial support received from CNPq. The assistance of David Fazzina in a part of the experimental program is also appreciated. References Fig. 23 — Microstructure of sections along the length of welds made with E7018 electrodes at 150 A. As the electrode gets hotter, toward the end of the weld, the amount of grain boundary ferrite in the weld metal de- surface area per unit volume and elements such as manganese and silicon can react easily with oxygen or oxidizing species in the arc. When the electrode heats up, the average size of the droplets increases reducing the surface area per unit volume. The interaction between oxygen and the elements on the surface of these droplets may still occur, but much of the alloying elements remain unoxidized inside the droplets. Oxygen decreases because less oxides are present in the weld metal. To evaluate the effect of composition variation along the weld length, hardness tests and metallography were performed in several sections of the welds. Figure 22 showed that hardness increased approximately 18% per 100 mm (3.94 in.) of weld length. This increase can be associated with the manganese and silicon increase and the oxygen decrease, Figs. 14 and 15, respectively. Both are in close agreement with the literature (Refs. 8-12). The increase in hardness corresponded to an increase of approximately 30 ksi (207 MPa) in ultimate tensile stress (o"uts), which can be significant in structural welds where uniform and constant mechanical properties along the weld length are essential. Metallographic analysis confirmed the hardness results. A slight decrease in the amount in grain boundary ferrite was observed along the weld length as shown in Fig. 23. These observations can also be associated with the increase in manganese and silicon contents, and are also in complete agreement with the literature (Refs. 8-12). 536-s I DECEMBER 1993 Conclusions This investigation of the SMA electrode heating during welding and its effects on weld metal mechanical properties and microstructure can be summarized with the following conclusions: 1) Using commercially available covered electrodes, a significant increase in weld metal manganese and silicon occurred along the weld length. This increase (for example, 8-21 wt-%, respectively, in welds prepared with E1 201 8 electrodes) can affect considerably the mechanical properties and microstructure of single and multipass welds. 2) Along with the increase of weld metal manganese and silicon, oxygen was observed to decrease. These changes affect considerably the weld metal microstructure and mechanical properties since an 18% increase in hardness (indirectly, ultimate tensile strength) in the E7018 welds was observed. 3) The composition variations can be explained as a result of electrode heating during welding since no significant variation in base metal dilution was observed. 4) The heating of the electrode changed the metal droplet transfer size across the arc. Alloying elements in the small droplets were easily oxidized to form oxide inclusions and/or removed from the weld pool as slag. Alloying elements in the large droplets were not as easily oxidized, resulting in higher content in the weld metal. 1. Brandi, S., Taniguchi, C , and Liu, S. 1991. Analysis of metal transfer in shielded metal arc welding. Welding Journal 70(10): 261-sto270-s. 2. IIW (1977) Classification des Divers Modes de Transfert du Metal en Soudage a I'Arc. IIW DOC XII-535-77. 3. ter Berg, J., and Larigaldie, A. 1952. Melting rate of coating electrodes. Welding Journal 32(5): 268-s to 271 -s. 4. Erokhin, A. A. 1 980. A study of electrode with alloying elements added to the covering and flux core. Paper 26, Weld Pool Chemistry and Metallurgy, International Conference, London, England, pp. 251-258. 5. Chen, J. H., and Hang, L. 1989. Investigation of the kinetic process of metal-oxygen reaction during shielded metal arc welding. Welding Journal 68(6): 245-s to 251-s. 6. Waszink, ). H., and Piena, M. |. 1985. Thermal process in covered electrode. Welding Journal 64(2): 37-s to 48-s. 7. Metals Handbook, Vol. 1, Properties and Selection: Irons and Steels. 1978. ASM International, Materials Park, Ohio. 8. Evans, G. M. 1977. Effect of manganese on the microstructure and properties of C-Mn all-weld-metal deposits. IIW DOC ll-A-43277. 9. Evans, G. M. 1 982. The Effect of heat input on the microstructure and properties of C-Mn all-weld metal deposits. Welding Journa/61(12): 125-sto 132-s. 10. Podkhonya, I. X., Xorsun, A. O , and Meshkov, Yu Ya. 1 986. Effects of the segregation of silicon and manganese on the formation of acicular ferrite in the structure of a weld. Automatic Welding, September, pp. 13-16. 11. Cochrane, R. C, and Kirkwood, P. R. 1 978. The effect of oxygen on the weld metal microstructure. Paper 35, Trends in Steels and Consumable for Welding, International Conference, London, England, pp. 13-16. 1 2. Dorschu, K. E., and Stout, R. D. 1961. Some factors affecting the notch toughness of steel meld metal. Welding Journal 40(3): 97-sto 105-s. 13. Liu, S., Siewert, T. A., and Lan, H. C. 1989. The transfer mode in gas metal arc welding. Proceedings of the 2nd International Conference on Trends in Welding Research, Gatlinburg, Tenn., pp. 14-18.