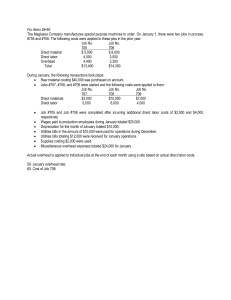

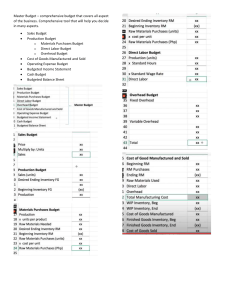

Cost Accounting and Control 2019 Edition Problem and Solutions CHAPTER 5 – Activity Based Costing EXERCISES Ex 5-1. ABC method The Sanka Company manufactures a variety of expensive furniture. Its job costing system was designed using an activity based approach/ There are two direct cost categories (direct materials and direct labor) and three indirect cost pools. These three cost pools represent three activity areas at the plant. Activity Area Materials handling Cutting Assembly Budgeted OH P200,000 P2,160,000 P2,000,000 Cost driver Parts Parts DLH Pool rate P2.5 P25.00 P250.00 Two styles of cabinets were produced in May, De Luxe and Standard. Their quantities, direct material costs and other data for May 2010 are as follows: Production 5,000 100 Standard De Luxe DM cost P3,500,000 P400,000 # of parts 100,000 3,500 DL Hours 7,500 1,500 The direct labor rate is P50 per hour. Assume no beginning inventory and ending inventory is 20% of total production. Required: Determine the total manufacturing cost for each product using ABC. Standard Overhead: Materials handling Cutting Assembly (100,000 x 2.5) (100,000 x 25) (7,500 x 250) Direct Materials: Direct Labor: 250,000 2,500,000 1,875,000 4,625,000 3,500,000 (7,500 x 50) DM DL OH TMC 375,000 Overhead: Materials handling Cutting Assembly Direct Materials: Direct Labor: 3,500,000 375,000 4,625,000 8,500,000 Standard Deluxe Ending Inventory De Luxe (3.500 x 2.5) (3,500 x 25) (1,500 x 250) 400,000 (1,500 x 50) DM DL OH TMC 8,500,000 946,250 9,446,250 x.20 1,889,250 8,750 87,500 375,000 471,250 75,000 400,000 75,000 471,250 946,250 Cost Accounting and Control 2019 Edition Problem and Solutions Ex 5-2. ABC and Conventional Method The Accountant of Camera Film Company has established the following activity cost of pools and cost drivers” Activity Machine set ups Materials hand Hazardous waste control Quality control Other overhead costs Budgeted OH P200,000 100,000 50,000 75,000 200,000 Cost driver No. of set ups Weight of Raw Materials Weight of Hazardous chemicals used Number of inspections Machine hours Budgeted level 100 50,000 lbs. 10,000 lbs 1,000 20,000 hrs. Pool rate P2,000 / set up P2 / lb. 5 / lb. P75 / inspection P10 / mhr. An order for 2,000 boxes of film development chemicals has the following production requirements: Machine set ups Raw materials Hazardous materials Inspections Machine hours 4 10,000 pounds 2,000 pounds 20 500 Direct manufacturing cost actually incurred to produce 2,000 boxes are Direct materials of P425,000 and direct labor of P400,000. Before the company adopts the ABC approach of costing, the traditional approach of allocating overhead, which is based on machine hours, is being used. Required: a. Determine the amount of overhead applied to each box of chemical under ABC and traditional costing b. Determine the manufacturing cost per box under ABC and traditional method a. Traditional Costing 620,000 / 20,000 = 31.25 31.25 x 500 = 15,625 / 2,000 = P7.81 per box Machine set ups Raw materials Hazardous materials Inspections Machine hours Total overhead ABC Costing 4 x 2,000 10,000 x 2 2,000 x 5 20 x 75 500 x 10 8,000 20,000 10,000 1,500 5,000 44,500 /2,000 P22.5 per box b. Traditional Costing Direct Materials Direct Labor Overhead Total Manufacturing Costs Divided by: Manufacturing cost per unit ABC Costing 425,000 400,000 15,625 840,625 /2,000 P420.31 per box Direct Materials Direct Labor Overhead Total Manufacturing Costs Divided by: Manufacturing cost per unit 425,000 400,000 44,500 869,500 /2,000 P434.75 per box Cost Accounting and Control 2019 Edition Problem and Solutions Ex. 5-3. Computing unit costs using ABC ABC Company has budgeted 84,000 machine hours in the production of 3 product lines for the coming year. Other budgeted information is summarized below: Machine related costs Materials receiving order costs Production orders / Engineering costs Production run / Set up costs Inspection costs P2,520,000 1,255,680 1,080,000 112,200 576,000 The following is a summary of actual data for the current year: Units produced Production costs per unit Materials Direct labor MH required per unit Activities per product line Receiving orders Production orders Set up Inspections P1 28,000 P2 18,000 P3 6,000 P60 36 1.5 P45 42 2 39 30 1 48 42 12 24 120 36 24 12 600 57 66 80 Required: Determine the following: 1. Overhead applied to each product line 2. Total manufacturing cost per product line Machine related costs Materials receiving order costs Production orders / Engineering costs Production run / Set up costs Inspection costs Overhead Machine related costs: P1: 560,000 x 1.5 P2: 560,000 x 2 P3: 560,000 x 1 Materials receiving order costs: P1: 1,635 x 48 P2: 1,635 x 120 P3: 1,635 x 600 Production orders / Engineering costs: P1: 8,000 x 42 P2: 8,000 x 36 P3: 8,000 x 57 Production run / Set up costs: P1: 1,100 x 12 P2: 1,100 x 24 P3: 1,100 x 66 Inspection costs: P1: 6,000 x 24 P2: 6,000 x 12 P3: 6,000 x 60 Total Overhead Divided by: units produced Applied OH to each product (2,520,000 / 4.5) (1,255,680 / 768) (1,080,000 / 135) (112,200 / 102) (576,000 / 96) P1 = = = = = P2 560,000 1,635 8,000 1,100 6,000 P3 840,000 1,120,000 560,000 78,480 196,200 981,000 336,000 288,000 456,000 13,200 26,400 72,600 144,000 72,000 1,411,680 /28,000 50.42 1,702,600 /18,000 94.59 360,000 2,429,600 /6,000 404.93 Cost Accounting and Control 2019 Edition Problem and Solutions Direct Labor Direct materials Overhead Total Manufacturing Costs Divided by units produced Manufacturing costs per product P1 1,680,000 1,008,000 1,411,680 4,099,680 /28,000 P146.42 P2 810,000 756,000 1,702,600 3,268,600 /18,000 P181.59 P3 234,000 180,000 2,429,600 2,843,600 /6,000 P473.93 Ex. 5-4. Traditional Costing Method Trinoma, Inc. provides the following information concerning its two product lines: Units produced Machine set up hours per product line Direct labor hours per unit Total budgeted machine set up related costs – P180,000 Product 1 2,500 150 10 Product 2 500 150 10 Required: Answer the following: 1. How much machine set up related cost id allocated to each product line if Trinoma Inc. uses a traditional cost allocation based on direct labor hours? 2. What is the conversion cost per unit of Product 1 and Product 2 180,000 =P 6 30,000 Product 1: 25,000 x 6 = P150,000 Product 2: 5,000 x 6 = 30,000 Cost Accounting and Control 2019 Edition Problem and Solutions TEST MATERIAL 1. MULTIPLE CHOICE 1. A costing system in which multiple overhead allocating using one or more non-volume related factors is called a. Normal Costing c. Backflush Costing b. Actual Costing d. Activity Based Costing 2. What is the normal effect on the numbers of cost of pools and allocation bases when an activity based cost (ABC) system replaces a traditional cost system? Cost Pools Allocation bases a. No effect No effect b. Increase No effect c. No effect Increase d. Increase Increase 3. In an activity-based costing system, what should be used to assign a department’s manufacturing overhead costs to products produced in varying lot sizes a. A single cause and effect relationship b. Multiple cause and effect relationships c. Relative net sales values of the products d. A product’s ability to bear cost allocations 4. In an activity-based costing system, cost reduction is accomplished by identifying and eliminating All cost drivers Non-value adding activities a. No No b. Yes Yes c. No Yes d. Yes No 5. Activity Based Costing a. Can be used only in a process cost system b. Focuses on units of production c. Focuses on activities performed to produce a product d. Uses only a single basis of allocation 6. Activity based costing: a. Is the initial phase of converting to a just in time operating environment b. Can be used only in a job order costing system c. Is a two-phased overhead cost allocation system that identifies activity cost pools and cost drivers d. Uses direct labor as its primary cost driver 7. Any activity that causes resources to be consumed is called: a. Just in time activity b. Facility level activity c. Cost driver d. No value added activity 8. HP Company manufactures products X and Y, applying overhead on the basis of direct labor hours. X requires a variety of complex manufacturing procedures and consumes significant productive resources. Y on the other hand is relatively simplistic in nature. What would an activity based costing system likely disclose about products X and Y as a result of HP’s current accounting process? Product X Product Y Product X Product Y a. Undercosted Undercosted Undercosted Overcosted b. Overcosted Overcosted Costed correctly Costed correctly 9. In the two-stage cost allocation process, costs are assigned: a. From jobs to service departments, to production departments b. From service departments, to jobs, to production departments c. From service departments, to production departments, to jobs d. From the balance sheet (when goods are produced) to the income statement (when goods are sold) Cost Accounting and Control 2019 Edition Problem and Solutions A newly established restaurant along Roxas Boulevard decided to adopt the ABC method of costing. The following are the budgeted figures for the coming year for the three major activities: Activity cost pool Serving party of diners Serving a dinner Serving drinks Activity cost driver No. of party served No. of dinners served No. of drinks served Budgeted costs P33,000 138,000 24,000 For the current period, the eatery had the following activities: Serving party of diners Serving a dinner Serving drinks 6,000 parties 15,000 diners 10,000 drinks The total costs for the month including organization-sustaining costs amounted to P240,000. 10. What is the total cost of serving a party of four diners who order three drinks? a. P49.50 b. P17.10 c. P68.40 d. P38.40 Diners Dinner Drinks (33,000 / 6,000) (2,400,000 / 10,000) (24,000 / 10,000) = = = 5.5 9.2 2.4 (5.5 x 1) (9.2 x 4) (2.4 x 3) = = = 5.5 36.8 7.20 P49.50 May flower Company uses Activity Based Costing in the manufacture of two models of furniture. Below are the Activity Based data together with the amounts of Cost Driver per Job: Activity driver Direct labor Machine set ups Number of parts Annual activity driver 600,000 10,000 900,000 Budgeted OH P9,600,000 2,400,000 1,800,000 Amount of Cost Driver per Job De Luxe Model 1,200 DLH 2 set ups 800 parts Standard Model 300 DLH 24 set ups 1,600 parts Actual data for the year ended December 31, 2019 Units produced Average cost per job: Materials Direct labor at P40 / hr De Luxe model 400 Standard model 60 P148,000 48,000 P140,800 12,000 11. The manufacturing cost per unit of De Luxe and Standard Model is a. P196,000, P152,800 b. P217,280, P166,560 c. P490, P2,547 d. P543.20, P2,776 Cost Accounting and Control 2019 Edition Problem and Solutions 9,600,000 / 600,000 = 16 2,400,000 / 10,000 = 240 1,800,000 / 900,000 = 2 Deluxe OH: Direct labor Machine set ups Number of parts OH DM DL TMC Divided by: MC per unit (16 x 1,200) (240 x 2) (2 x 800) Standard 19,200 480 1,600 21,280 148,000 48,000 217,280 /400 543.20 per unit OH: Direct labor Machine set ups Number of parts OH DM DL TMC Divided by: MC per unit (16 x 300) (240 x 24) (2 x 1,600) 4,800 5,760 3,200 13,760 140,800 12,000 166,560 /60 2,776 per unit The Robinson Company produces two products, Alpha and Beta, and uses the conventional method of allocating overhead based on direct labor cost. The management decided to adopt the ABC System of costing. The number of setups and the number of design hours were selected as the activity drivers for the two new cost pools, and direct labor cost will continue as the base for allocating the remaining overhead. Information on the other page is available. Units produced DM cost per unit Direct labor cost Setups Design hours Overhead: Setup related Design related Others Total overhead Alpha 73,500 P12 P2,910,000 30 12,000 Beta 125 P100 P90,000 30 3,000 P3,000,000 60 15,000 P 300,000 900,000 3,300,000 P4,500,000 12. The amount of overhead applied to the job beta under: ABC System Conventional system a. P135,000 P429,000 b. P429,000 P135,000 c. P3,300,000 P270,000 d. P4,500,000 P429,000 Beta ABC System Set ups: 300,000 / 60 = 5,000 Design: 900,000 / 15,000 = 60 Others: 3,300,000 / 3,000,000 = 1.1 Set ups: (5,000 x 30) Design: (60 x 3,000) Others: (1.1 x 90,000) Total 73,625 Conventional System 4,500,000 / 3,00,000 = 1.5 90,000 x 1.5 = P135,000 150,000 180,000 99,000 P429,000 Cost Accounting and Control 2019 Edition Problem and Solutions Mozarella Company had the following activities, traceable costs, and physical flow of driver units: Activities Account inquiry (hours) Account billing (lines) Account verification (accts) Correspondence (letters) Traceable costs P400,000 P280,000 P150,000 P50,000 Cost driver 10,000 4,000,000 lines 40,000 accounts 4,000 letters Departments A and B use the above activities as follows: A Account inquiry (hours) 2,000 hours Account billing (lines) 400,000 lines Account verification (accts) 10,000 accounts Correspondence (letters) 1,000 letters B 4,000 hours 200,000 lines 8,000 accts 1,600 letters 13. The amount of inquiry cost assigned to Dept. A is a. P80,000 b. P400,000 c. P160,000 d. P133,333 14. The amount of billing cost assigned to Dept. B is a. P28,000 b. P14,000 c. P93,333 d. P280,000 Account inquiry (hours) Account billing (lines) Department A inquiry cost Department B billing (cost (400,000 / 10,000) (280,000 / 4,000,000) (2,000 x 40) (200,000 x 0.07) = = = = 40 0.07 P80,000 P14,000 Kia Company is a manufacturer of remote controls. The company has always used a plant wide rate for allocating manufacturing overhead to its product. The plant manager believes it is time to change to a better method of cost allocation. The manager provided the following data: Activity Material handling Assembly Inspection Cost driver Number of parts Labor hours Time item at inspection station Allocation Rate P2 per part P20 per hour P3 per minute The traditional allocation method is based upon direct manufacturing labor hours, and if that method is used the rate is P200 per labor hour. 15. Using the traditional method of costing, assuming in a batch, 1,000 remote controls are produced, requiring 2,000 parts, 20 direct manufacturing labor hours, and 30 minutes inspection rime, the indirect manufacturing costs per remote control is a. P0.40 b. P4.00 c. P400 d. P4,000 20 x 200=4,000 4,000 =P 4.00 1,000 Cost Accounting and Control 2019 Edition Problem and Solutions 16. Using an ABC System, assuming the same data above, the manufacturing overhead costs per remote control is a. P0.449 b. P4.49 c. P449 d. P4,490 Material handling Assembly Inspection (2,000 x 2) (20 x 20) (30 x 3) = = 4,000 400 90 4,490 /1,000 P4.49 Nicfur Furniture Corporation has identified activity centers to which overhead costs are assigned. The cost pol amounts for these centers and their selected activity drivers for 2019 are as follows. Activity Centers Utilities Scheduling and setup Material handling Costs P300,000 273,000 640,000 Activity Drivers 60,000 machine hours 780 set ups 1,600,000 lbs of material Before it installed an ABC System, the company used a conventional costing system and allocated factory overhead to products using direct labor hours. The firm operates in a competitive market and product prices were set at cost plus 20 percent markup. The company’s products and other operating statistics follow: Product A P80,000 30,000 130 500,000 40,000 32,000 Prime costs Machine hours Number of set ups Pound of materials Units produced Direct labor hours Product B P80,000 10,000 380 300,000 20,000 18,000 Product C P90,000 20,000 270 800,000 60,000 50,000 17. The selling price for Product A, B and C based on costs for conventional costing is a. P561, 792, P358,008, P835,800 b. P570,600, P459,600, P725,400 c. P475,500, P383,000, P604,500 d. P468,160, P298,340, P696,500 1,213,000 =12.13 100,000 Product A Prime cost Overhead: (32,000 x 12.13) Total factory cost Markup Selling Price 80,000 388,160 468,160 1.20 P561,792 Product B Prime cost Overhead (18,000 x 12.13) Total factory cost Markup Selling Price 80,000 218,340 298,340 1.20 P358,008 Product C Prime cost Overhead (50,000 x 12.13) Total factory cost Markup Selling Price 90,000 606,500 696,500 1.20 P835,800 Cost Accounting and Control 2019 Edition Problem and Solutions 18. The unit cost for product A, B and C using the ABC system is a. P11.89, P19.15, P10.075 b. P11.704, P14.917, P11.608 c. P2.00, P4.00, P1.50 d. Answer not given Utilities (300,000 / 60,000) Scheduling and setup (273,000 / 780) Material handling (640,000 / 1,600,000) Product A Prime cost Overhead: Utilities (30,000 x 5) Scheduling and setup (130 x 350) Material handling (500,000 x 0.4) Total factory cost Divided by: Unit cost 80,000 150,000 45,500 200,000 475,500 /40,000 P11.89 5 / MH 350 / set up 04 / lb. Product B Prime cost Overhead: Utilities (10,000 x 5) Scheduling and setup (380 x 350) Material handling (300,000 x 0.4) Total factory cost Divided by: Unit cost Product C Prime cost Overhead: Utilities (20,000 x 5) Scheduling and setup (270 x 350) Material handling (800,000 x 0.4) Total factory cost Divided by: Unit cost 80,000 50,000 133,000 120,000 383,000 /20,000 P19.15 90,000 100,000 94,500 320,000 604,500 /60,000 P10.075 Olivia Enterprise is an exporter of souvenir items. The following overhead costs data have been accumulated: Activity Center Material handling Painting Assembly Cost driver Grams handled Units painted Labor hours Actual Activity 100,000 50,000 4,000 Costs P 50,000 200,000 120,000 Job 1234 contains 3,000 units. It weighs 10,000 grams and uses 300 hours of labor. Prime costs incurred amounts to P180,000. 19. The overhead costs that should be assigned to Job 1234 is a. P12,000 b. P14,000 c. P9,000 d. P26,000 Material handling Painting Assembly (50,000 / 100,000) (200,000 / 50,000) (120,000 / 4,000) 20. The cost to produce a unit of Job 1234 is a. P60.00 b. P64.00 c. P64.67 d. P68.67 = = = 0.5 4 30 (0.5 x 10,000) (4 x 3,000) (30 x 300) = = = 5,000 12,000 9,000 P26,000 Cost Accounting and Control 2019 Edition Problem and Solutions Prime costs + Overhead = TMC / units = Cost to produce unit 180,000 + 26,000 = 206,000 / 3,000 = P68.67 TEST MATERIAL 2 In manufacturing Roller blades, Super Store Company ‘s plant used 400 direct labor hours, 500 machine hours and 20 setups. The following overhead costs were taken from the factory accounts: Overhead expenses P120,000 40,000 160,000 Machine center Set up center Direct labor hours Volume activities 20,000 machine hrs 100 set ups 4,000 hours The plant was using a factory wide overhead rate based on direct labor hours. A new ABC system will use machine hours in the Machining Department and number of set ups in the Setup Department as cost drivers. 1. The overhead costs assigned to roller blades under: Based on direct labors ABC System a. P16,000 P11,000 b. P12,000 P12,000 c. P11,000 P16,000 d. P120,000 P120,000 Based on Direct Labors ABC System 120,000 / 20,000 = 6 6 x 500 40,000 / 100 = 400 400 x 20 Machine center 160,000 =40 x 400=P 16,000 Set up center 4,000 3,000 8,000 P11,000 Amend Instrument, Inc. manufactures two products: missile instruments and pressure gauges. During January, 50 missile instruments and 300 pressure gauges were produced, Direct cost of P54,000 and P85,000 are incurred for Instruments and Gauge, respectively and overhead costs of P81,000 were incurred. An analysis of overhead costs reveals the following activities: Activity Materials handling Machine set ups Quality inspections Cost Driver Number of acquisitions Number of set ups Number of inspections Total Activity costs P30,000 27,000 24,000 The cost driver volume for each product was as follows: Cost driver Number of acquisitions Number of setups Number of inspections Instruments 400 150 200 Gauges 600 300 400 Total 1,000 450 600 2. Determine the following for product Instrument: Overhead applied Total production costs a. P27,000 P54,000 b. P29,000 P83,000 c. P30,000 P85,000 d. P40,500 P135,000 Materials handling Machine set ups Quality inspections Applied Overhead Direct Costs (30,000 / 1,000) x 400 (27,000 / 450) x 150 (24,000 / 600) x 200 12,000 9,000 8,000 P29,000 54,000 Cost Accounting and Control 2019 Edition Problem and Solutions Total Production Costs P83,000 The following data are available for Everlasting Company. Units produced Direct material cost: Per unit Direct labor cost Direct labor hours Setups Design hours AA 2,000 BB 160,000 Total 162,000 P300 P280,000 2,800 45 3,000 P10 P560,000 5,600 45 5,000 8,000 Overhead: Set up related Design related Others P1,350,000 1,400,000 778,000 At present, Everlasting Company is using direct labor hours to allocate overhead. The management of Everlasting is considering the use of ABC for more accurate allocation of overhead. The number of set ups and number of design hours are used to allocate the new cost pools while direct labor hours will continue as the base for allocating all remaining overhead. 3. Determine the following: Unit costs of BB – present method a. P13.50 b. P28.20 c. P35.50 d. P55.00 Unit costs of BB – present method OH: 3,528,000 / 8,400 = 420 x 5,600 = 2,352,000 DM DL OH TMC Divided by: Unit cost 1,600,000 560,000 2,352,000 4,512,000 /160,000 P28.20 Production costs of AA-ABC System P2,056,000 P2,339,333 P1,731,833 P4,408,000 Production costs of AA-ABC System Set up related (1,350,000 / 90) x 45 Design related (1,400,000 / 8,000) x 3,000 Others (778,000 / 8,400) x 2,800) DM DL OH TMC 600,000 280,000 1,459,333 P2,339,333 675,000 525,000 259,333 1,459,333 Cost Accounting and Control 2019 Edition Problem and Solutions The Chromosome Manufacturing Company produces two products, X and Y and it uses direct labor hours to allocate overhead costs. X is selling at P65.00 per unit while Y is selling at P80.00 per unit. The company is considering to adopt ABS System using the most appropriate cost driver for each cost pool. The following data are obtained for the current period. Product X 11,000 P12.50 10,000 P20,000 1,600 80 12 Number of units produced & sold DM cost per unit Direct labor hours Direct labor cost per unit Machine hours Inspection hours Purchase orders Product Y 3,000 P25.00 2,500 P22.00 2,400 20 3 Overhead costs: Inspection costs Purchasing costs Machine costs Amount P56,200 80,000 50,000 4. Determine the following using ABC System: Gross margin per unit of Y a. P47.61 b. P17.59 c. P17.39 d. P13.92 Inspection costs Purchasing costs Machine costs Overhead costs Direct Materials Direct Labor Total MC Selling Price Gross Margin Divided by: GM per unit Product X (56,200 / 100) x 80 (80,000 / 15) x 12 (50,000 / 4,000) x 1,600 (12.50 x 11,000) (20 x 11,000) (65 x 11,000) Total gross margin for the period P715,000 P52,770 P191,290 P270,300 44,960 64,000 20,000 128,960 137,500 220,000 486,460 715,000 228,540 /11,000 P20.78 Inspection costs Purchasing costs Machine costs Overhead costs Direct Materials Direct Labor Total MC Selling Price Gross Margin Divided by: GM per unit Product Y (56,200 / 100) x 20 (80,000 / 15) x 3 (50,000 / 4,000) x 2,400 Total Gross Margin: 228,540 + 41,760 = P270,300 (25 x 3,000) (22 x 3,000) (80 x 3,000) 11,240 16,000 30,000 57,240 75,000 66,000 198,240 240,000 41,760 /3,000 P13.92 Cost Accounting and Control 2019 Edition Problem and Solutions ASEAN Manufacturing Company makes variety of products. The activity centers and budgeted information for factory overhead for the year are: Activity Center Overhead Costs Cost Driver Pool Rate Materials Handling P3,000,000 Weight of materials P3 per pound Cutting P13,000,000 No. of shapes P30 per shape Assembly 46,000,000 Direct labor hours P120 per DL Sewing 12,000,000 Machine hours P80 per MH Two types of products were produced in July, Product A and Product B which is being sold at 50% above cost. The quantities and other operating data for the month are: Product A P150,000 300,000 50,000 35,000 7,500 12,500 5,000 Direct materials Direct labor costs Direct materials – weight in pounds Number of shapes Assembly direct labor hours Sewing machine hours Units produced Product B P200,000 50,000 15,000 15,000 1,200 1,800 1,000 5. The gross profit for Product A is: a. P620 b. P710 c. P783 d. P1,232 e. P355 6. The gross profit for Product B is: a. P516.50 b. P688.87 c. P783 d. P1,033 Product A Materials Handling (50,000 x 3) Cutting (35,000 x 30) Assembly (7,500 x 120) Sewing (12,500 x 80) OH DM DL TMC Markup Sales TMC Gross Profit Divided by units Gross Profit per unit 150,000 1,050,000 900,000 1,000,000 3,100,000 150,000 300,000 3,550,000 1.50 5,325,000 3,550,000 1,775,000 /5,000 P355 Product B Materials Handling (15,000 x 3) Cutting (15,000 x 30) Assembly (1,200 x 120) Sewing (1,800 x 80) OH DM DL TMC Markup Sales TMC Gross Profit Divided by units Gross Profit per unit 45,000 450,000 144,000 144,000 783,000 200,000 50,000 1,033,000 1.50 1,549,500 1,033,000 516,500 /1,000 P516.50 PSP Company manufacturers two types of Electronic Toy, The Regular and Super Pro. The following data have been obtained: Regular Super Pro DM cost per unit P33 P38 DL cost per unit 32 44 Direct labor hours 12,000 3,000 Machine hours 2,000 4,000 Engineering hours 450 450 Cost Accounting and Control 2019 Edition Problem and Solutions Number of set ups 5 20 Number of units 8,000 2,200 Currently, overhead costs are assigned to products on the basis of direct labor hours, but the company decided to adopt the ABC method of cost allocation. The overhead consists of the following items: Overhead item Set up Engineering Machine costs Cost Driver Number of set ups Number of engineering hours Number of machine hours OH costs P240,000 180,000 900,000 7. Using direct labor hours to allocate overhead costs, the total cost of product regular is a. P520,000 b. P1,056,000 c. P1,312,000 d. P1,576,000 Regular: 1,320,000 / 15,000 = 88 x 12,000 = P1,056,000 8. Using ABC, determine the following: Overhead cost-Super Pro a. P882,000 b. P1,056,000 c. P1,402,000 d. P1,576,000 Per unit cost-Super Pro P482.91 P562.00 P682.22 P82.00 Set up (240,000 / 25) x 20 Engineering (180,000 / 900) x 450 Machine costs (900,000 / 6,000) x 4,000 OH DM DL TMC Divided by units Cost per unit 192,000 90,000 600,000 P882,000 83,600 96,800 1,062,400 /2,200 P482.91 Forever 21 Company is using traditional method of applying overhead at 20% of direct labor costs. Monthly direct labor costs for its main products is P30,000. In an attempt to distribute quality control costs more equitably, Forever 21 is considering activity-based costing. The monthly data shown below have been gathered for the main product. The three activities are (1) inspection of incoming materials; (2) inspection of in process; and (3) certification of completed products costs are to be allocated to each activity on the basis of cost drivers. Activity (1) (2) (3) Cost driver No. of types of materials No. of units No. of orders Cost rate P15 per type P0.15 per unit P77 per order Quantity for main products 12 types 17,500 units 30 orders 9. Using ABC, the monthly quality control cost assigned to the main product using ABC is: a. b. c. d. P5,115 Lower by P885 than the traditional method P6,000 Higher by 404 than the traditional method Inspection of incoming materials p (12 x 15) Inspection of in process Engineering (17,500 x 0.15) Certification of completed products costs (30 x 77)\ 180 2,625 2,310 P5,115 Cost Accounting and Control 2019 Edition Problem and Solutions TEST MATERIAL 3 Stop N Shop Supermarket has three main areas within its store: Beverage, Foods and Non-food items. The following information pertains to the last quarter of the current year, when store overhead was allocated based on cost of sales: Beverage Foods Non-Foods P677,500 275,000 110,000 P954,500 345,000 138,000 P559,000 240,000 96,000 600 400,000 3,600 1,550 250 350,000 2,950 1,750 175 150,000 2,575 1,875 Financial data: Sales Cost of sales Store overhead Activity usage & cost driver Ordering (No. of orders) Customer support (sold) Stocking shelves (hrs worked) Delivery (no. of deliveries) An activity analysis revealed that, of total store overhead, 30% related to ordering, 20% related to customer support, 40% related to stocking shelves and 10% to delivery. 1. Using the traditional method of allocating overhead, the amount of overhead allocated to Beverage is ___________ (275,000 / 860,000) x 344,000 = P110,000 2. If ABC costing is used, the amount of overhead allocated to Food section is ___________ Ordering Customer support Stocking shelves Delivery 344,000 x 30% 344,000 x 20% 344,000 x 40% 344,000 x 10% = = = = 103,200 x (250 / 1,025) 68,800 x (350,000 / 900,000) 137,600 x (2,950 / 9,125) 34,400 x (1,750 / 5,175) = = = = 25,171 26,756 44,484 11,633 P108,044 Rapide Company manufactures three products, gears, shafts and chassis. The Cost Accountant of Rapide Manufacturing Company has prepared the following budgeted activity for the year: Activity Center Materials Handling Production Scheduling Set ups Manual Machinery Automated machinery Finishing Packaging & Shipping Units produced DM cost per unit Number of orders Number of set ups Direct labor hours Labor rate per hour Machine hours Number of orders shipped Budgeted Costs P624,800 232,000 289,200 1,972,000 6,424,000 3,596,000 468,000 Gears 20,000 P120 80 40 40,000 P20 60,000 2,000 Answer 3-4 using labor hours as the basis of allocating overhead. Cost Driver Direct material costs Number of orders Number of set ups Direct labor hours Machine hours Direct labor hours Number of orders shipped Shafts 4,000 P160 40 20 20,000 P25 30,000 3,000 Chassis 1,400 P200 20 28 16,800 P30 5,600 140 Cost Accounting and Control 2019 Edition Problem and Solutions 3. The budgeted overhead applied to the three jobs will amount to ___________ 13,606,000 / 76,800 = 177.16 Gears Shafts Chassis 40,000 x 177.16 20,000 x 177.16 16,800 x 177.16 = = = 7,086,400 3,543,200 2,976,288 P13,605,800 4. The manufacturing cost per unit of gear is ____________ Direct Materials (120 x 120,000) Direct Labor (40,000 x 20) Overhead Total Manufacturing Costs Divided by units Manufacturing cost per unit 2,400,000 800,000 7,086,400 10,286,400 / 20,000 P514.32 Answer 5-6 using ABC method. 5. The total overhead applied to the three jobs will amount to ___________ Materials Handling Production Scheduling Set ups Manual Machinery Automated machinery Finishing Packaging & Shipping Gears (624,800 / 3,320,000) x 2,400,000 (232,000 / 140) x 80 (289,200 / 88) x 40 (1,972,000 / 76,800) x 40,000 (6,424,000 / 95,600) x 60,000 (3,596,000 / 76,800) x 40,000 (468,000 / 5,140) x 2,000 Materials Handling Production Scheduling Set ups Manual Machinery Automated machinery Finishing Packaging & Shipping Shafts (624,800 / 3,320,000) x 640,000 (232,000 / 140) x 40 (289,200 / 88) x 20 (1,972,000 / 76,800) x 20,000 (6,424,000 / 95,600) x 30,000 (3,596,000 / 76,800) x 20,000 (468,000 / 5,140) x 3,000 Materials Handling Production Scheduling Set ups Manual Machinery Automated machinery Finishing Packaging & Shipping Chassis (624,800 / 3,320,000) x 280,000 (232,000 / 140) x 20 (289,200 / 88) x 28 (1,972,000 / 76,800) x 16,800 (6,424,000 / 95,600) x 5,600 (3,596,000 / 76,800) x 16,800 (468,000 / 5,140) x 140 Gears Shafts Chassis Total Overhead P7,829,589 3,991,508 1,784,903 P13,606,000 P 451,663 132,571 131,455 1,027,083 4,031,799 1,872,917 182,101 P7,829,589 P 120,443 66,286 65,727 513,542 2,015,900 936,458 273,152 P3,991,508 P 52,694 33,143 92,018 431,375 376,301 786,625 12,747 P1,784,903 Cost Accounting and Control 2019 Edition Problem and Solutions 6. The budgeted manufacturing cost of product shaft is _____________ Direct Materials (160 x 4,000) Direct Labor (20,000 x 25) Overhead Total Manufacturing Costs Divided by units Manufacturing cost per unit 640,000 500,000 3,991,508 5,131,508 / 4,000 P1,282.88 The following budgeted activity data and costs are from Peninsula Hotel. Activity center Service Centers: Administration Building maintenance Production Centers: Accommodation Food section Direct costs P1,230,000 690,000 Support costs % of space used Number of employees P640,000 750,000 20% 15 10 450,000 880,000 60% 20% 30 20 Administration use number of employees as its cost driver. Building and maintenance uses percentage of space used as its cost driver. Accommodation uses labor hours as its cost driver and has budgeted 45,000 hours for the month of June. Food section also uses labor hours as its deriver and has budgeted 35,000 hours for this month. Peninsula Hotel uses direct method to allocate the service costs. 7. The total support costs allocated to Accommodation and Food section is ______________ and _____________ DIRECT METHOD Allocation to Accommodation: From Administration – 640,000 x (30 / 50) From Building maintenance – 750,000 x (60 / 80) Allocation to Food Section From Administration – 640,000 x (20 / 50) From Building maintenance – 750,000 x (20 / 80) 384,000 562,500 P946,500 256,000 187,500 P443,500 8. The cost rates used by Accommodation and Food Section in calculating overhead costs is ____________ and _______________ Accommodation: (1,396,500 / 80,000) = P17.46 Food Section: (1,323,500 / 80,000) = P16.54 Cost Accounting and Control 2019 Edition Problem and Solutions A new cost system has been implemented in Megaworld Center. The old system applied overhead to customer jobs using labor costs as the basis. The new cost system uses cost drivers for each activity center to cost customer jobs. Pre-selling tasks and Post selling services are preliminary activity centers. The activity center and their information are as follows: Activity Centers Pre-selling tasks Post-selling tasks Installation Renovation & Repair Labor costs P600,000 400,000 Overhead costs P500,000 500,000 400,000 600,000 Cost driver % of space Labor costs Material cost Repair hours Occupancy % Other activity 20% 40% 40% 1M material costs 9,000 hours One large commercial contract for Camella Prestige Corporation, used P540,000 of installation materials and P280,000 of labor costs. The job also used P120,000 and 950 hours of renovation and repairs labor. 9. The total costs for Camella Prestige Corporation under the new cost system is _____________ Allocation to Installation: From Pre-selling tasks – 500,000 x (40 / 80) From Post-selling tasks – 500,000 x (600 / 1000) 250,000 300,000 P550,000 Allocation to Renovation & Repair: From Pre-selling tasks – 500,000 x (40 / 80) From Post-selling tasks – 500,000 x (400 / 1000) Installation Renovation & Repair Total Overhead Direct Materials Direct Labor Total Costs (950,000 / 1,000,000) x 540,000 (1,050,000 / 9,00) x 950 250,000 200,000 P450,000 513,000 110,833 623,833 540,000 280,000 P1,443,833 The following cost data have been accumulated for Avis Car Rentals: Activity Center Selling Alterations Cleaning & Preparation General overhead Cost Driver Labor hours Times altered Number rented Labor hours Amount of activity 900 hours 200 units 750 units 900 hours Center Costs P45,000 12,000 60,000 43,650 Gerry Punch, a customer, necessitated two hours of selling time. He rented 10 cars for his company team building activity and 6 of them required alterations. 10. The total costs assigned to Gerry Punch is ______________ Selling Alterations Cleaning & Preparation General overhead (45,000 / 900) x 2 (12,000 513,000 110,833 623,833 540,000 280,000 P1,443,833 Cost Accounting and Control 2019 Edition Problem and Solutions