Steve Furnival

PVT Analysis for Compositional Simulation

Oxford

February 2000

PVT Analysis

2

Oxford

09/09/09

PVT Analysis

Table of Contents

Table of Contents.................................................................................................................3

Table of Figures...................................................................................................................6

1. Introduction......................................................................................................................7

2. Hydrocarbon Composition..............................................................................................9

2.1 The Atom....................................................................................................................9

2.1.1 The Carbon Atom...............................................................................................10

2.2 Basic Hydrocarbon Molecules – the Alkanes...........................................................10

2.2.1 Isomerism...........................................................................................................13

2.2.2 Alkenes and Alkynes..........................................................................................14

2.3 Cycloalkanes.............................................................................................................15

2.4 Aromatics.................................................................................................................16

2.5 Polyaromatics...........................................................................................................17

2.6 Other Compounds.....................................................................................................17

2.7 Single Carbon Number Groups................................................................................17

Generalized SCN Physical Properties.........................................................................18

2.8 The Plus Fraction......................................................................................................19

Phase Behaviour................................................................................................................21

3.1 Pure Component Phase Behaviour...........................................................................21

3.1.1 p-T Projection.....................................................................................................23

3.1.2 p-V Projection....................................................................................................24

3.2 Binary Mixture Phase Behaviour.............................................................................25

3.3 Multi-Component Base Behaviour...........................................................................27

3.3.1 Dry and Wet Gas................................................................................................28

3.3.2 Gas Condensates................................................................................................28

3.3.3 Volatile Oils.......................................................................................................30

3.3.4 Crude Oils..........................................................................................................30

3.4 The Corresponding States Theorem.........................................................................31

Z-Factor Correlations..................................................................................................33

Estimating Pseudo-Criticals.....................................................................................34

4. Sampling and Laboratory Analysis...............................................................................35

4.1 Sampling...................................................................................................................35

4.1.1 Well Testing.......................................................................................................35

Conditioning................................................................................................................36

4.1.3 Down Hole Sampling.........................................................................................36

4.1.4 Surface Sampling...............................................................................................38

4.1.4.1 Liquid Loading in Gas Wells.......................................................................38

4.1.4.2 Taking Samples............................................................................................39

4.1.4.3 Metering.......................................................................................................39

4.1.4.4 Checking the Data........................................................................................41

4.1.4.5 Recombination Example..............................................................................41

4.2 Laboratory Analysis.................................................................................................45

4.2.1 Compositional Determination............................................................................45

3

Oxford

09/09/09

PVT Analysis

4.2.2 Saturation Pressure (SAT)..................................................................................47

4.2.2.1 The PVT Cell...............................................................................................47

4.2.3 Constant Composition Expansion (CCE)...........................................................50

4.2.4 Separator Test (SEP)..........................................................................................51

4.2.5 Differential Liberation (DLE)............................................................................52

Constant Volume Depletion (CVD)............................................................................54

4.2.6.1 CVD Material Balance Check.....................................................................55

4.2.7 Other Experiments.............................................................................................56

5. Equations of State..........................................................................................................59

5.1 Development of the Ideal Gas Law..........................................................................59

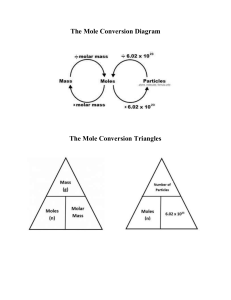

5.1.1 The Mole............................................................................................................60

5.1.2 Deficiencies in the Ideal Gas Law.....................................................................61

5.1.3 The Real Gas Law..............................................................................................61

5.2 Cubic EoS.................................................................................................................62

5.2.1 Van der Waals EoS............................................................................................62

5.2.2 Redlich-Kwong Family of EoS..........................................................................64

5.2.2.1 Zudkevitch Joffe RK EoS............................................................................64

5.2.2.2 Soave RK EoS.............................................................................................65

Peng-Robinson EoS....................................................................................................65

The Martin’s 2-Parameter EoS....................................................................................66

5.2.5 Other Cubic EoS................................................................................................66

5.3 Multi-Component Systems.......................................................................................67

5.4 Volume Translation..................................................................................................68

6. Flash Calculations..........................................................................................................69

6.1 Successive Substitution (SS) Method.......................................................................70

6.1.1 Rachford-Rice Equation.....................................................................................72

6.2 Stability Test.............................................................................................................72

6.3 Saturation Pressure...................................................................................................74

6.4 Composition versus Depth.......................................................................................75

7. Characterization.............................................................................................................77

7.1 Molar Distribution Models.......................................................................................77

7.1.1 Quadrature..........................................................................................................79

7.1.2 Modified Whitson Method.................................................................................80

7.2 Inspection Properties Estimation..............................................................................81

7.3 Critical Property Estimation.....................................................................................83

7.3.1 Normal Boiling Point Temperature....................................................................83

7.3.2 Critical Temperature, Critical Pressure..............................................................83

7.3.3 Critical Volume..................................................................................................83

7.3.4 Acentric Factor...................................................................................................84

8. Regression......................................................................................................................85

Objective Function.........................................................................................................85

8.2 Variable Choice........................................................................................................86

8.3 Constraints................................................................................................................87

9. Export for Simulation....................................................................................................89

9.1 Black Oil Modeling..................................................................................................89

9.2 Compositional Modeling..........................................................................................92

4

Oxford

09/09/09

PVT Analysis

9.2.1 Grouping............................................................................................................92

9.2.2 Mixing Rules......................................................................................................93

References..........................................................................................................................95

Appendix A: Classical Thermodynamics..........................................................................97

A.1 Abstractions.............................................................................................................97

A.2 Chemical Potential...................................................................................................98

A.2.1 Fugacity.............................................................................................................99

A.3 Equilibrium............................................................................................................100

5

Oxford

09/09/09

PVT Analysis

Table of Figures

Figure 1: The Total Production System...............................................................................8

Figure 2: Schematic of Methane Molecule showing four C-H Bonds..............................11

Figure 3: Schematic of Ethane Molecule...........................................................................12

Figure 4: Schematic of Propane Molecule.........................................................................12

Figure 5: Schematic Representations of Butane Isomers, nC4 and iC4............................14

Figure 6: Schematic Representation of Pentane Isomers..................................................14

Figure 7: Schematic of the Alkene Double Bond..............................................................17

Figure 8: Schematic of the Alkyne Triple Bond................................................................18

Figure 9: Schematic Representation of Cyclopentane and Cyclohexane..........................19

Figure 10: Alternate Schematic Representations for Benzene Molecule..........................19

Figure 11: The p-V-T Behaviour of a Pure Substance. [From Adkins]............................25

Figure 12: p-T and p-V projections from the 3D p-V-T Surface [from Adkins]..............26

Figure 13: p-T Projection for a Pure Component..............................................................26

Figure 14: p-V Projection for a Pure Component..............................................................28

Figure 15: Phase Envelopes of C2-C10 Binary Mixtures.................................................29

Figure 16: Multi-Component Phase Envelope..................................................................30

Figure 17: Schematic Phase Envelope of a Dry and Wet Gas...........................................31

Figure 18: Liquid Dropout Profile from Gas Condensate [at constant composition]........32

Figure 19: Standing Z-Factor Chart...................................................................................35

Figure 20: Schematic of the Venturi Tube Rate Measurement.........................................42

Figure 21: Schematic of an Orifice Plate Gas Rate Device...............................................42

Figure 22: Surface Separator Analysis..............................................................................45

Figure 23: Standing Analysis for the Separator Stage.......................................................47

Figure 24: Schematic of a GC System...............................................................................48

Figure 25: Schematic of the FID [from www.scimedia.com]...........................................49

Figure 26: Freezing point depression diagram [from Pedersen et al.]...............................50

Figure 27: Schematic of a Gas Condensate PVT cell........................................................51

Figure 28: Change in Slope of p-V curve around the Bubble Point..................................51

Figure 29: Liquid Dropout “Tail” Shown by Some Gas Condensates..............................52

Figure 30: Schematic of CCE applied to Gas Condensate Fluid.......................................53

Figure 31: Schematic of 2-Stage Separator Test...............................................................54

Figure 32: Schematic of Differential Liberation Experiment............................................56

Figure 33: Schematic of CVD Performed on Gas Condensate Fluid................................57

Figure 34: Schematic of the Swelling Test........................................................................60

Figure 35: Schematic of the Slim Tube Apparatus [ref. See Figure 27]...........................61

Figure 36: Charles’ Law Behaviour for Water Implying Zero Temperature....................62

Figure 37: p-V Behaviour for Pure Component with Cubic EoS Behaviour....................66

Figure 38: Flow Diagram for the Successive Substitution Flash......................................74

Figure 39: Gas-Oil Contact Figure 40: Critical Transition..............................................79

Figure 39: Gas-Oil Contact Figure 40: Critical Transition..............................................79

Figure 41: Whitson GDM for different values of α..........................................................81

Figure 42: Schematic of the Generalized BO Table Construction....................................93

6

Oxford

09/09/09

PVT Analysis

1. Introduction

In order to perform flow simulation in the reservoir and production system, we need to

know various physical properties of the fluid system. Firstly, what phases are present?

Gas? Oil? Water? What are the relative proportions of these phases? What are the bulk

phase properties, i.e. density, viscosity, thermal conductivity, etc.

In principle, we can and do take samples of the reservoir fluid and measure the quantities

of interest at certain pressures and temperature. However, these experiments are both

difficult and costly and cannot hope to cover the range of pressures, temperatures and

compositions we are likely to encounter. Consider the following schematic of the total

production system:

Figure 1: The Total Production System.

In mature areas such as the North Sea, petroleum accumulations are being sought at evergreater depths: it is now common to find reservoirs at 20000-ft [6100 m] or more. At

such depths, pressures can approach 16000 psia [1100 bars] and temperatures are close to

400 oF [205 oC]. Pressure can take any value between initial reservoir pressure and 1

7

Oxford

09/09/09

PVT Analysis

atmosphere in the stock tank, if one exists. Temperature will also vary between reservoir

temperature and standard temperature although lower temperatures are possible in subsea flow lines and cryogenic coolers.

If the fluid composition was fixed, a set of pre-defined look-up tables could handle

temperature and pressure variability. This is the black oil approach, which we will

review later in this course.

Generally, the fluid composition within the production system is not fixed for a variety of

reasons. Within the reservoir, the following changes can take place:

•

Composition varies with depth and areal location. The presence of high permeability

streaks can then allow different fluids to mix.

•

As fluid drops below saturation pressure, one phase – generally the gas – will flow in

preference to the oil so the produced well composition changes with time. This effect

is particularly important for Gas Condensates and Volatile Oils – near critical fluids.

•

Gas injection for pressure maintenance or miscibility processes.

Within the production system:

•

Fluids from different parts of the reservoir or reservoirs, can mix, i.e. Eastern Trough

Area Project (ETAP).

•

Gas injection for Gas-Lift.

•

Changes in surface separation.

•

Phase slippage in long pipe and flow lines can cause formation of liquid slugs.

All these cases, and more, point to the need for a compositional treatment of the fluid

system. These methods are computational expensive. However, with the rapid increase

in computer power at reducing cost, they are all now achievable on a high-end PC.

8

Oxford

09/09/09

PVT Analysis

2. Hydrocarbon Composition

Hydrocarbons are molecules1 composed principally of Hydrogen and Carbon but also

containing Sulphur, Nitrogen, Oxygen and various trace metals.

Carbon is unique amongst the elements in its ability to form not only strong CarbonCarbon bonds but strong Carbon-OtherElement bonds also. Because of this ability, the

number of naturally occurring molecules containing Carbon is vast. So much so that one

of the main sub-disciplines within Chemistry is devoted to the study of Carbon

compounds – Organic Chemistry. In order to appreciate the richness of Carbon

compounds, it is worth taking a short time to understand the nature of how atoms bind

within molecules.

2.1 The Atom

Consists of a central positively charged nucleus of +Z units, comprising the majority of

the atom’s mass, surrounded by Z electrons, each of charge –1. Electrons are forced to

occupy certain orbits or shells by the laws of quantum physics. The number of electrons

that can occupy each shell is limited. The first can hold two, the second eight, etc. As

the Z electrons are added to balance up the charge on the nucleus, they will fill the shells

from the inside out.

When the outermost shell is not complete then the atomic species will try to bond with

other atomic species to close the shell. Atomic species containing just one electron in

their outermost shell, such as the Group I Alkali metals 2 will donate their spare electron

to atoms that are missing one in their outermost shell. Similarly, atoms such as the Group

II Alkaline metals3 will donate their two spare electrons to atoms missing one or two

electrons. Atoms missing one or two electrons in their outermost shell include the Group

VII Halogens4 or Group VI atoms5. The exchange of electrons causes the donor become

positively charged and the recipient ions to become negatively charged. The electrostatic

attraction between the ions is what then provides the bonding mechanism. This is known

as ionic bonding.

The other way in which atoms can close their outermost shell is by sharing electrons with

other atomic species that have vacancies in the outermost shell. This is known as

covalent bonding and is the mechanism that dominates Carbon chemistry.

1

A molecule is the smallest sub-division of a chemical species which is representative of that species.

2

Lithium, Sodium, Potassium, etc.

3

Beryllium, Magnesium, Calcium, etc

4

Fluorine, Chlorine, Bromine, etc.

5

, Oxygen, Sulphur, etc.

9

Oxford

09/09/09

PVT Analysis

2.1.1 The Carbon Atom

The nucleus of the most commonly occurring Carbon consists, in part, of six positively

charged protons. Therefore, its six electrons are arranged in two shells; the inner shell of

two electrons is full and the outer shell of four electrons is four short of being complete.

Therefore, each Carbon atom requires other atomic species to share four electrons with it.

Note the four electrons required do not have to come from four other atoms. CarbonCarbon pairs can exchange one, 2 or 3 electrons with each other to form what are known

as single, double and triple bonds. Naturally occurring hydrocarbons usually only consist

of Carbon-Carbon pairs with single bonds.

These four other electrons can be donated by four other Carbon atoms in one of two

different ways. When combined in a 2D planar lattice structure, the result is graphite - a

soft powder that is used in pencils. When combined in a 3D tetrahedral structure, the

result is diamond – an ultra-hard crystal that is prized for its durability.

When Carbon combines with other atomic species, principally hydrogen, the result is the

series of chemical compounds found in petroleum.

2.2 Basic Hydrocarbon Molecules – the Alkanes

The most common hydrocarbon molecule by number is that of Methane. It consists of a

single Carbon atom surrounded by 4 hydrogen atoms each of which shares its single

electron thereby closing the Carbon outer shell of 8 and the single Hydrogen shell of 2.

The Hydrogen atoms arrange themselves at the apexes of a tetrahedron with the Carbon

atom at the centre of the structure. Symbolically Methane is represented by:

Figure 2: Schematic of Methane Molecule showing four C-H Bonds

The common shorthand representation is CH4: on PVT reports it will be denoted as C1.

If one of the C-H bonds is broken, the resulting Methyl radical is highly reactive and will

look to fill the missing electron hole as quickly as possible. If another Methyl radical is

close by, they will C-C bond to form Ethane, which is represented by:

10

Oxford

09/09/09

PVT Analysis

Figure 3: Schematic of Ethane Molecule

The common shorthand representation is CH3CH3 or C2H6: on PVT-reports it will be

denoted C2.

A Methane molecule can lose two electrons to generate a CH2 radical. Now if the Ethane

C-C bond is broken, the CH2 radical can be inserted between the 2 Methyl radicals and

the Propane molecule is created which is represented by:

Figure 4: Schematic of Propane Molecule

The common shorthand representation is CH3 CH2CH3 or C3H8: on PVT-reports it will be

denoted C3.

The process just described of inserting CH2 radicals can now be repeated ad-infinitum.

The next few molecules in the series are Butane [C4H10 or C4], Pentane [C5H12 or C5] and

Hexane [C6H14 or C6]. The generic formula for this series is CNH2N+2 where N is number

of Carbon atoms.

Organic molecules that have a similar structure and consequently graded physical

properties are known as a homologous series. This series is variously referred to as the

Alkanes or Paraffins. Some physical properties of the normal-Alkanes are shown in

Table 2.1 and its corresponding Chart.

Note the melting points of Methane and Ethane does not fit the trend; otherwise, a

remarkably smooth set of trends is evident. The first four Alkanes are gases at room

conditions: Alkanes with 18 Carbons or more are solids at room conditions.

Whether hydrocarbon molecules are found in gas, liquid or solid states depend on the

inter-molecular force called the van der Waals force. Fluctuations in the distribution of

the electron clouds gives rise to an electric field, which is the basis for the force. The

smallest molecules are highly symmetric and hence the generated fields are weak:

characteristics of a gas. The larger molecules are less symmetric and have a stronger

field: characteristic of a liquid or solid.

11

Oxford

09/09/09

PVT Analysis

N

1

2

3

4

5

6

7

8

9

10

11

12

15

20

30

Name

Methane

Ethane

Propane

Butane

Pentane

Hexane

Heptane

Octane

Nonane

Decane

Undecane

Dodecane

Pentadecane

Eicosane

Triacontane

Boil.Point Melt.Point Spec.Grav.

o

o

F

F

60o /60 o

-258.7

-269.4

-127.5

-297.0

-43.7

-305.7

0.507

31.1

-217.1

0.584

96.9

-201.5

0.631

155.7

-139.6

0.664

209.2

-131.1

0.688

258.2

-70.2

0.707

303.5

-64.3

0.722

345.5

-21.4

0.734

384.6

-15.0

0.740

421.3

14.0

0.749

519.1

50.0

0.769

648.9

99.0

835.5

151.0

Table/Chart 2.1: Physical Properties of Normal-Alkanes

Variation of Physical Properties with Carbon Number

500.0

0.900

400.0

0.850

0.800

300.0

Temperature/[degF]

0.700

100.0

0.650

0.0

0.600

-100.0

Specific Gravity

0.750

200.0

Boil.Point

Melt.Point

Spec.Grav.

0.550

-200.0

0.500

-300.0

0.450

-400.0

0.400

1

2

3

4

5

6

7

8

9

10

11

12

Carbon Number

12

Oxford

09/09/09

PVT Analysis

2.2.1 Isomerism

The structure of the Alkanes from C4 and above can vary from that implied above. In

Figure 3 showing Propane, one of the Hydrogen atoms bonded to the central Carbon

atom can be removed and replaced by a Methyl radical: this is known as iso-Butane or

iC4.

It has the same number of Carbon’s and Hydrogen’s as its straight-chained equivalent

that is generally known as normal-Butane or nC4 [or just C4].

Figure 5: Schematic Representations of Butane Isomers, nC4 and iC4.

Three possible structures are possible for Pentane. The straight-chained molecule called

normal-Pentane, nC5 [or just C5]. A Butane chain with a Methyl radical attached to the

2nd Carbon called iso-Pentane, iC5. Finally, a Propane chain with two Methyl radicals

attached to the central Carbon: the last structure called neo-Pentane is rarely found in

petroleum mixtures.

Figure 6: Schematic Representation of Pentane Isomers.

As the Carbon number rises, the number of Isomers increases rapidly.

Question:

How many isomers are there of Hexane [C6]? Estimate the number of isomers of

Decane [C10] and Triacontane [C30].

Branch-chained Isomers do not exhibit the smooth variation in physical properties seen

for the normal-Alkanes [see Table/Chart 2.1]. The physical properties of the Hexane

Isomers are shown in Table 2.2, below.

13

Oxford

09/09/09

PVT Analysis

Isomer

n-Hexane

Structure

Boil.Point

o

F

CH3CH2 CH2CH2CH2 CH3

Melt.Point

o

F

Spec.Grav.

o

o

60 /60

155.7

-139.6

0.664

145.9

-180.4

0.669

140.5

-244.6

0.658

136.4

-199.4

0.666

121.5

-147.7

0.654

CH3

3-MethylPentane

CH3 CH2CHCH2CH3

CH3

2-MethylPentane

CH3 CHCH2CH2CH3

CH3 CH3

2,3-DiMethylButane

CH3CH

CHCH 3

CH3

2,2-DiMethylButane

CH3 CCH2CH3

CH3

Table 2.2: Physical Properties of Hexane Isomers

Generally, an increase in the degree of branching causes a decrease in the inter-molecular

attraction with the consequent lowering in boiling point. The variation of melting point is

harder to predict. The way the different shapes can be slotted together is the main factor

affecting the formation of the solid lattice.

2.2.2 Alkenes and Alkynes

Chemically the Alkanes are unreactive: the name Paraffin means not enough affinity.

This is not true of straight-chained and branched hydrocarbons with double bonds – the

Alkenes: note each Carbon makes two conventional single bonds.

Figure 7: Schematic of the Alkene Double Bond.

Nor is it the case for triple bounds – the Alkynes: note each Carbon can make only one

conventional single bond.

14

Oxford

09/09/09

PVT Analysis

Figure 8: Schematic of the Alkyne Triple Bond.

These bonds are somewhat stretched compared with the equivalent single bond making

them much more likely to break. Therefore, these compounds are rarely found in

naturally occurring petroleum. That is not to ignore their importance in the

Petrochemical industry. In particular, the polymerization6 of Ethene, C2H4, [or to give it

its old name of Ethylene] gives rise to that most versatile of materials – polyethylene.

Similarly, polymerizing Ethyl Chloride gives PVC – poly-vinyl-chloride.

The presence of a Carbon-Carbon double bond in the Alkenes eliminates the need for two

Hydrogen atoms giving a generic formula of CNH2N. The corresponding Alkyne has the

formula CNH2N-2.

2.3 Cycloalkanes

The Alkanes [Alkenes and Alkynes] are all straight or branched chains; with 3 or more

Carbon atoms, other structures are possible. One of these alternatives is the homologous

series called the Cycloalkanes. In the petroleum industry, the names Cycloparaffins or

Napthenes are often used instead.

Although they have the same general formula as the Alkenes, CNH2N, because they have a

ring structure, their physical properties are very different. The two most common

Cycloalkanes are Cyclopentane, C5H10, and Cyclohexane, C6H12: see figures below.

The lighter Cycloparaffins of Cyclopropane, C3H6, and Cyclobutane, C4H8, are both

possible. However, they rarely occur in natural petroleum. The Carbon-Carbon bond

angles of 60o and 90o are both very sharp making these bonds much weaker than their

equivalents in the 5- and 6-Carbon ring structures. Ring structures with 7 or more

Carbon atoms are chemically stable but again occur rarely in natural petroleum. This is

probably because the probability a straight-chained molecule of 7 or more Carbons would

lose a Hydrogen atom from both ends simultaneously is very low.

6

In the case of polymerization of Ethene, one of the C=C double bonds is broken in each molecule. The

second Carbon in the first ethane-radical then bonds with the first Carbon in the second ethane-radical, etc.

to form the long-chain polyethylene.

The Polymerization Process of Ethene.

15

Oxford

09/09/09

PVT Analysis

Figure 9: Schematic Representation of Cyclopentane and Cyclohexane.

As with the Paraffins, one or more Hydrogen atoms can be removed from any point on

the ring to be replaced by Methyl, Ethyl, etc. radicals. Unlike the next series, the

Aromatics, the central ring is referred to as saturated.

2.4 Aromatics

A third main homologous series are the Aromatics. The basis for the Aromatics is the

Benzene molecule. Benzene contains six Carbons in a hexagonal ring with one

Hydrogen atom attached to each Carbon. Initially it was thought that there were three

single Carbon-Carbon bonds alternating with 3 double Carbon-Carbon bonds. However,

the double bonds would be much weaker than their single bond equivalents making

Benzene chemically reactive which is not the case. Clearly, the Carbon-Carbon bonds in

Benzene are unlike anything considered to date.

Current thinking has it that the electrons are delocalized over all six Carbon atoms thus

there are six hybrid bonds, or one-and-half bonds or benzene bonds.

The common symbols used to depict the Benzene molecule are shown below:

Figure 10: Alternate Schematic Representations for Benzene Molecule

In the figure above, it is assumed there is a single CH group at each vertex of the

hexagon. As with the Cycloalkanes, each of the Hydrogen atoms can be replaced by a

Methyl, Ethyl, etc. radical. Replacing one Hydrogen atom by a single Methyl radical

produces Toluene, C6H5.CH3. Replacing two Hydrogen atoms by Methyl radicals

produces Xylene, C6H4.CH3.CH3.

16

Oxford

09/09/09

PVT Analysis

2.5 Polyaromatics

Most of the large molecules found in petroleum are linked multi-ring structures that are

composed of Cycloalkanes and Aromatics, often with Sulphur, Oxygen and/or Nitrogen

atoms replacing one or more Hydrogen atoms. They are often sub-divided into two

classes called Resins and Asphaltenes.

Resins readily dissolve in petroleum and are either heavy liquids or sticky solids.

Asphaltenes are solids that are only weakly soluble in petroleum. An oil with a high

Asphaltene content is a production nightmare since when the near well bore pressure

drops, these molecules will precipitate, causing pore blocking and leading to a loss of

Productivity Index (PI).

2.6 Other Compounds

The four main non-hydrocarbon or inorganics components of naturally produced

petroleum are:

•

Nitrogen

N2

•

Carbon Dioxide

CO2

•

Hydrogen Sulphide

H2S

•

Water

H2O

Of these, it is generally assumed that water is mutually insoluble in hydrocarbon phases:

this may not be true at high temperatures or in the presence of large concentrations of

CO2 and/or H2S. However, we will not consider the effect of water other than as a standalone component during this course.

N2, CO2 and H2S are important constituents of most petroleum mixtures and are routinely

considered when laboratory analyses of reservoir fluids are undertaken. Chemically, N2

behaves most closely to Methane. CO2 is most similar to Ethane and H2S to Propane.

2.7 Single Carbon Number Groups

If the presence of Isomers were not bad enough, we now have to contend with the

different homologous series. Laboratory analysts could spend between now and eternity

trying to isolate every different molecular species. Clearly an impossible task!

For petroleum engineering purposes, standard practice is to check for and measure the

concentrations of the inorganics, N2, CO2 and H2S and the first few members of the

Alkane series, C1, C2, C3, iC4, nC4, iC5 and nC5. Thereafter, boiling point cuts called

Single Carbon Number (SCN) groups are used.

17

Oxford

09/09/09

PVT Analysis

SCN group N is taken to be all hydrocarbon molecules which boil at temperatures just

above that of the normal paraffin CN-1 up to and including the normal paraffin CN. For

example, consider some of the members of SCN group 7, denoted C7:

Name

Tboil/Kelvin

normal-Hexane

341.9

Benzene

353.2

Cyclohexane

353.8

2-Methylhexane

363.2

normal-Heptane

371.6

Table 2.3: Some Members of SCN group C7 – Shaded Area.

Clearly, the blend of Paraffins, Paraffin-Isomers, Cycloparaffins and Aromatics within

any given SCN group will vary from fluid to fluid. As the blend varies from highly

Paraffinic to highly aromatic, the average physical properties of the group can vary

considerably. This can in turn, have a considerable effect on the ability of our models to

predict fluid behaviour. We will reconsider this issue when we look at fluid

characterization and regression. For now, we either take some average of a reasonably

large set of test fluids or just use the paraffin properties.

Generalized SCN Physical Properties

The following table is re-produced from Whitson. Note the mole weights of the SCN

components are less than the mole weights of the normal-Paraffins with the same number

of Carbon atoms. This reflects the presence of Napthanic and Aromatic components

within the blend.

Key:

Tb

Normal Boiling Point Temperature

γ

Specific Gravity (60/60)

Kw

Watson Characterization Factor: see section 7.2

Mw

Molecular Weight

Tc

Critical Temperature

Pc

Critical Pressure

ω

Acentric Factor

18

Oxford

09/09/09

PVT Analysis

γ

Tb

Kw

Mw

Tc

o

SCN

K

R

K

6

337

607

0.690

12.27

84

7

366

658

0.727

11.96

8

390

702

0.749

9

416

748

10

439

11

ω

Pc

o

R

kPa

psia

512

923

3340

483

0.250

96

548

985

3110

453

0.280

11.87

107

575

1036

2880

419

0.312

0.768

11.82

121

603

1085

2630

383

0.348

791

0.782

11.83

134

626

1128

2420

351

0.385

461

829

0.793

11.85

147

648

1166

2230

325

0.419

12

482

867

0.804

11.86

161

668

1203

2080

302

0.454

13

501

901

0.815

11.85

175

687

1236

1960

286

0.484

14

520

936

0.826

11.84

190

706

1270

1860

270

0.516

15

539

971

0.836

11.84

206

724

1304

1760

255

0.550

16

557

1002

0.843

11.87

222

740

1332

1660

241

0.582

17

573

1032

0.851

11.87

237

756

1360

1590

230

0.613

18

586

1055

0.856

11.89

251

767

1380

1530

222

0.638

19

598

1077

0.861

11.91

263

778

1400

1480

214

0.662

20

612

1101

0.866

11.92

275

790

1421

1420

207

0.690

21

634

1124

0.871

11.94

291

801

1442

1380

200

0.717

22

637

1146

0.876

11.95

300

812

1461

1330

193

0.743

23

648

1167

0.881

11.95

312

822

1480

1300

188

0.768

24

659

1187

0.885

11.96

324

832

1497

1260

182

0.793

25

671

1207

0.888

11.99

337

842

1515

1220

177

0.819

26

681

1226

0.892

12.00

349

850

1531

1190

173

0.844

27

691

1244

0.896

12.00

360

859

1547

1160

169

0.868

28

701

1262

0.899

12.02

372

867

1562

1130

165

0.894

29

709

1277

0.902

12.03

382

874

1574

1110

161

0.915

30

719

1294

0.905

12.04

394

882

1589

1090

158

0.941

2.8 The Plus Fraction

Depending on the nature of the fluid, there comes a point in the allocation of SCN groups

where the law of diminishing returns takes over. That is, the error associated with

measuring the concentration of SCN group N is bigger than that concentration. At some

point before that, which usually depends on how much the owner of the fluid is prepared

to pay the service laboratory, a cut-off in the analysis is made. The residual or plus

19

Oxford

09/09/09

PVT Analysis

fraction is what is left. Usually, just the molecular weight 7 and sometimes the specific

gravity of this fraction are measured are reported. As laboratory techniques have

improved, so the typical Carbon number of the plus fraction has increased. In the 1960’s,

a plus fraction of C7+ was typical. During the 1970’s and 1980’s, C12+ was typical

whereas C20+ would be the norm now. Some typical reservoir fluid analyses are shown

below. Note the units are mole fractions. Moles and mole fractions will be discussed in

some detail in section 5.1.

Comp

N2

CO2

H2S

C1

C2

C3

iC4

nC4

iC5

nC5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

C17

C18

C19

C20

NS GC

0.60

3.34

0.00

74.16

7.90

4.15

0.71

1.44

0.53

0.66

0.81

1.20

1.15

0.63

0.50

0.29

0.27

0.28

0.22

0.17

0.15

0.14

0.09

0.13

0.47

Bah-GC

11.71

6.50

0.05

79.06

1.62

0.35

0.08

0.10

0.04

0.04

0.06

0.06

0.05

0.04

0.24

(+)

195

(+)

362

NS-VO

0.58

3.27

0.00

53.89

8.57

6.05

1.05

2.44

0.88

1.17

1.45

2.38

2.59

1.75

1.50

1.55

0.93

1.13

1.01

0.80

0.86

0.60

0.68

0.54

4.34

SWT-BO

0.00

0.00

0.00

52.00

3.81

2.37

0.76

0.96

0.69

0.51

2.06

2.63

2.34

2.35

29.52 (+)221

(+)

411

Table 2.4: Typical Fluid Analyses

Key:

NS – North Sea

SWT – South West Texas

GC- Gas Condensate VO

7

– Volatile Oil

Bah – Bahrain

BO – Black Oil

Molecular weight will be defined shortly. Note its measurement can be subject to an error of ±10 %.

20

Oxford

09/09/09

PVT Analysis

Phase Behaviour

One of the first questions to ask of a petroleum mixture of known composition is how

those components distribute themselves at some specified conditions. In particular, is the

fluid a gas, oil or a mixture of the two?

Generally we will limit our interest to hydrocarbon mixtures which can form up to 2phases which are usually denoted oil and gas, although it may be best to reserve those

names for the phases at surface conditions. Under reservoir or production conditions, the

names vapour and liquid will be used here.

Wherever we find hydrocarbons, we usually find water also. Strictly, we should consider

hydrocarbons and water together when we investigate fluid properties, however, their

mutual solubility is generally very low and for most purposes, we can consider water

independently. A notable exception is gas-water mixtures in production systems,

especially long sub-sea flow lines. At low flow rates or shut-ins, the gas-water mixture is

capable of forming a solid ice-like structure at temperatures above zero oC called a Gas

Hydrate. Once formed, they are very difficult to get rid of. So much so those operators

will add expensive Methanol at the earliest convenient point in the flow line to suppress

hydrate formation.

Other pure hydrocarbon solids can be found. We have already seen when discussing

petroleum composition that very heavy hydrocarbon molecules called resins and

Asphaltenes can be found. These materials cause most problems in the production

system but they can also be a problem in the near well bore region where they can drop

out as pressure falls and effectively reduce the porosity. Again, expensive chemical

treatments may be needed to remove them if they occur.

Carbon Dioxide injection is popular for many old oil fields in the Southern Continental

USA. Large CO2 reservoirs mean there is a plentiful supply of material for injection and

under the right conditions it can substantially enhance oil production. However, CO 2 and

to a lesser extent H2S are as soluble in water as they are in hydrocarbons. At relatively

low pressures and temperatures, say 150 oF and 1500 psia; a four-phase system is seen

consisting of an aqueous phase, a hydrocarbon vapour, a hydrocarbon liquid and a CO2

rich liquid. Given the narrow range of conditions under which this effect occurs, it is

generally not modeled in reservoir simulation although it is studied as a PVT problem.

3.1 Pure Component Phase Behaviour

Before we attempt to consider the phase behaviour of petroleum mixtures, let us first

consider a single pure component. The 3D image shown below shows axes for pressure

p, volume V and temperature T.

At high temperatures, the T5 isotherm approximates to Boyle’s Law, namely pV =

constant, which we see in Section 5.1. As temperature is reduced, the isotherm becomes

more distorted until at Tc – the Critical Temperature at point C– it becomes horizontal.

At temperatures less than Tc there is a region in which liquid and vapour can co-exist –

21

Oxford

09/09/09

PVT Analysis

region GCF. The point G is called the Triple Point, which is the unique point at which

this component can co-exist as solid, liquid and vapour.

Figure 11: The p-V-T Behaviour of a Pure Substance. [From Adkins]

Although most general, the 3D image is difficult to work around. It is more useful to

consider one of two possible projections take from this image, namely the p-T projection

at constant volume and p-V projection at constant temperature. These projections can be

seen on the next figure, below. Note that for a given temperature, liquefaction and

solidification take place at a constant pressure, therefore, the mixed phase regions shown

shaded project into lines on the p-T plot. Whereas on the p-V plane, the mixed phase

regions continue to be visible.

22

Oxford

09/09/09

PVT Analysis

Figure 12: p-T and p-V projections from the 3D p-V-T Surface [from Adkins].

Using the projections derived from this figure, we can now give a clearer description of

the fluid phase behaviour.

3.1.1 p-T Projection

Figure 13: p-T Projection for a Pure Component

23

Oxford

09/09/09

PVT Analysis

As described before, the two-mixed phase regions on the 3D-image project into two lines

on this representation, the Vapour-Liquid-Equilibrium (VLE) line and the SolidLiquid-Equilibrium (SLE) line. We will not consider the SLE any further except to

note the dashed line GH’ which is that of water – all other compounds behave like the

line GH. One consequence of line GH’ for water is a skater is actually sliding on a film

of water: the pressure caused by a skate causes the ice to melt [at constant temperature].

The VLE line GC defines the unique pressure versus temperature curve at which liquid

and vapour can co-exist. For water at atmospheric pressure, this is 100 oC or 212 oF. The

point C – the critical point – marks the highest temperature at variable pressure or the

highest pressure at variable temperature at which this compound can exist as liquid and

vapour. Furthermore, unlike other point along the VLE, the intensive properties of the

liquid and vapour at the critical point, such as density, viscosity, specific heat, etc. are

identical. At temperatures or pressures in excess of T c and pc, the fluid can only ever

exist as a single-phase of indeterminable type: some authors call this region

supercritical.

Previously in section 2.2, we saw how properties such as boiling point, melting point and

specific gravity vary with Carbon number. Not surprisingly, the critical properties,

including critical Volume, Vc, vary in a similar way:

Comp

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

Tc

R

343.0

549.8

665.7

765.3

845.4

913.4

972.5

1023.9

1070.3

1111.8

o

Pc

psia

667.8

707.8

616.3

550.7

488.6

436.9

396.8

360.6

332.0

304.0

Vc

ft3/lbmol

1.5899

2.3695

3.2499

4.0803

4.8702

5.9290

6.9242

7.8820

8.7729

9.6612

Table 3.1: Variation of Tc, pc and Vc with Carbon Number.

3.1.2 p-V Projection

In this projection, we have only highlighted the vapour-liquid two-phase region – shaded.

Consider the sub-critical isotherm defined by the points MNOP. At point P we have a

highly compressible vapour: small changes in pressure yield large changes in volume. At

point O – the Dew Point - the liquid phases appears. Now at constant pressure, the

proportion of liquid and vapour changes along the line NO until at point N – the Bubble

Point – all the vapour has disappeared and we have a single-phase liquid. Now along

24

Oxford

09/09/09

PVT Analysis

line MN we have the characteristic behaviour of a liquid in that large changes in pressure

only cause a small change in volume.

Figure 14: p-V Projection for a Pure Component

The loci of points traced out by the dew point and bubble point lines define the two-phase

region. As the temperature rises towards the critical temperatures, the [molar] volumes

and other intensive properties of the saturated vapour and liquid come together until they

are equal at the critical point, C. We will review this issue when we consider Cubic

Equations of State (EoS) in section 5.2.

3.2 Binary Mixture Phase Behaviour

Consider a mixture of two pure components, say Ethane and Decane, (C2, C10). From

Table 3.1, above, we can see that on a p-T plot, the critical points of Decane are displaced

down [in pressure] and to the right [in temperature]. Generally, with increasing Carbon

number, critical temperature increases and critical pressure decreases.

Now add a small amount of C10 to otherwise pure C2. The effect is to make the VLE line

of C2 into a narrow envelope – the two-phase region denoted 99/01. Note the critical

point of the 99/01 mixture denoted as a black circle has a critical pressure greater than

that of pure C2 whereas the critical temperature is intermediate between the Tc of C2 and

C10. As the percentage of C10 is increased and therefore that of C2 reduced, the envelope

initially broadens until as the percentage of C10 approaches 100%, it collapses onto the

VLE line of C10. The critical pressure of the binary mixtures exceeds that of C2 for the

25

Oxford

09/09/09

PVT Analysis

90/10, 75/25 and 50/50 mixtures. The critical temperature of these and the remaining

mixtures, 25/75 and 10/90 like their predecessors are intermediate between the T c of C2

and C10.

Figure 15: Phase Envelopes of C2-C10 Binary Mixtures.

As a rule of thumb, the critical temperature of an N-component mixture may be estimated

from:

(3.1)

Tcmix ≈

N

∑

i= 1

z i Tci

Tci is the critical temperature of the ith component and zi is that component’s mole

fraction: we will explain moles and mole fractions in the next two sections. This

expression is often referred to as Kay’s rule: experience has shown it is accurate to ±10%.

No such estimation technique is available for critical pressure.

Note that generally the critical point for a mixture is not the highest pressure and/or

highest temperature at which a two-phase system can exist. For a mixture, we call the

point corresponding to the highest saturation pressure [psat] the Cricondenbar [at which

dp sat dT = 0 ] and the highest temperature the Cricondentherm [at dp sat dT → ∞ ]

26

Oxford

09/09/09

PVT Analysis

3.3 Multi-Component Base Behaviour

Adding more components to a mixture generally has the effect of broadening and raising

the phase envelope. The extent of these changes depends primarily on the range of

components in the mixture and their relative proportions [measured in moles – see section

5.1]. The phase envelope for a hypothetical mixture is shown below.

Figure 16: Multi-Component Phase Envelope.

In addition to the Bubble point line [vapour fraction, V = 0%] and Dew point line [V =

100 %], we have plotted lines of constants vapour fraction for V = 10, 25, 50,75 and

90%. All these lines, including the Bubble and Dew point lines converge at the critical

point [approximately 4100 psia and 250 oF]. Using this plot, we can make sense of the

five standard fluid types:

•

Dry Gas

•

Wet Gas

•

Gas Condensate

•

Volatile Oil

•

Crude Oil

We will discuss each of these fluid types by looking at relationship between reservoir

temperature and phase envelope.

27

Oxford

09/09/09

PVT Analysis

3.3.1 Dry and Wet Gas

Although not marked explicitly, the Cricondentherm for this fluid is about Tcri ≈ 525 oF: it

is highly unlikely a hydrocarbon reservoir would be found at such a temperature. For a

lighter fluid mixture, the Tcrit will be lower and it is common to find Tres > Tcri.

If reservoir temperature is in excess of Tcri, under primary depletion where only pressure

changes, at no point would the phase envelope be crossed: denoted 1 → 2 in the figure

below. If surface conditions are at point 3d, still outside the two-phase region, the fluid

is called Dry Gas.

Figure 17: Schematic Phase Envelope of a Dry and Wet Gas.

On the other hand, if surface conditions are at point 3w inside the two-phase region, then

at some point in the production system liquid drop out will occur: this fluid is called Wet

Gas.

As a rough guide, it has been suggested that any fluid which produces more than 50

Mscf/STB [≈ 8900 sm3/sm3] may be considered a wet gas. This corresponds to the

Heptanes plus fraction being 1.0 mole percent or less. For most purposes, dry and wet

gases can be modeled using correlations: this will be discussed further when we look at

reduced properties and the Corresponding States theorem [see section 3.4].

3.3.2 Gas Condensates

Imagine the reservoir temperature for our multi-component mixture lies between T crit

[approximately 252 oF] and Tcri. Further, assume the initial reservoir pressure is 4500

psia - we have a single-phase fluid.

28

Oxford

09/09/09

PVT Analysis

Under primary depletion, pressure can fall to about 3675 psia whereupon we find the dew

point at which the first drop of liquid [heavier phase] appears from what we can now

assume to be the vapour [lighter phase].

Figure 18: Liquid Dropout Profile from Gas Condensate [at constant composition]

As the pressure continues to fall, the liquid fraction builds to a peak of about 19% [by

moles!] at about 3200 psia. As the pressure continues to fall, some of the dropped-out

liquid re-vapourizes so that as we approach abandonment pressure around 1000 psia, the

liquid fraction has fallen back to about 10%.

Note the behaviour just described is an idealized representation, which is only seen in the

laboratory. Within a reservoir, the dropped-out liquid will generally remain immobile

because of relative permeability effects [we will discuss this effect later in section 4.2.6].

The vapour however, will flow and therefore the fluid composition at a point will change

with time.

The effect where a heavier liquid phase is evolved from a lighter vapour phase goes

against our normal expectation of fluid behaviour under pressure reduction. Hence, the

name Retrograde Condensation was termed: some authors still prefer to call Gas

Condensates – Retrograde Gases.

As reservoir temperature approaches the critical temperature, we have already seen how

the vapour fraction lines on the multi-component phase envelope are packing together.

On the liquid dropout plot above, this would correspond to the slope of the curve

becoming more nearly vertical and the maximum dropout approaching 50%. If the

29

Oxford

09/09/09

PVT Analysis

reservoir temperature is equal to the critical temperature, then as the pressure falls to

equal the critical pressure, we immediately jump to a two-phase system [with 50% liquid

and 50% vapour]. The two-phases will be identical and therefore indistinguishable.

Gas Condensates typically have GOR’s between 3.3 Mscf/STB [590 sm 3/sm3] and 50

Mscf/STB [8900 sm3/sm3] although values up to 150 Mscf/STB have been reported. The

stock tank oil derived from a gas condensate is usually lighter in colour than that derived

from a crude oil. These rules are somewhat arbitrary. A more useful indicator is the

mole fraction of the Heptanes-plus will be less than 12.5%.

3.3.3 Volatile Oils

If the reservoir temperature is less than the critical temperature, we get the expected fluid

behaviour as pressure is reduced. An initially single-phase fluid, which we will

subsequently label as liquid, on reaching the bubble point pressure yields a lighter vapour

phase. The amount of vapour evolved depends on the proximity to the critical point. At

temperatures just below the critical temperature, the amount of vapour produced

approaches 50%. This vapour is rich in heavier hydrocarbons and will exhibit retrograde

condensation as it’s produced. In some volatile oil reservoirs, it is common to find that

half the produced stock tank oil entered the well bore as vapour. Because of this effect,

the classical reservoir engineering material balance equations attributed to Schilthuis [see

Dake, Chapter 3] will not work for a volatile oil.

GOR’s for volatile oils vary between 2.0 and 3.3 Mscf/STB. The Heptanes plus fraction

varies between 12.5 and 20.0 mole percent. The liquid formation volume factor, denoted

Bo [see section 4.2.5] will usually be greater than 2.0 RB/STB [2.0 m3/sm3].

3.3.4 Crude Oils

As the difference between reservoir temperature and critical temperature increases, with

Tres < Tcrit, so the lines of constant vapour fraction spread out. Therefore, as pressure falls

from the bubble point, the amount of vapour liberated falls. In addition, the liquid

content of the liberated vapour is reduced. If the assumption that the liberated vapour can

be treated as dry gas is acceptable, we can treat this fluid as a crude oil.

At pressures in excess of the bubble point, the crude will be referred to as being

undersaturated, that is more vapour could be dissolved if it were present. At the bubble

point, the crude is called saturated i.e. it holds as much vapour as it can. Strictly, at all

pressures less than the bubble point pressure the liquid will be saturated, as vapour will

continue to evolve.

Crude oils usually have GOR’s less than 2.0 Mscf/STB and their stock tank oil is often

very dark in colour, usually black hence the alternative name of black oil. The Heptanes

plus mole fraction will exceed 20%.

The relative simplicity of the crude oil phase behaviour has given rise to numerous

correlations to describe their behaviour. These consist of expressions to calculate:

30

Oxford

09/09/09

PVT Analysis

•

Bubble point pressure, pb,

•

Liquid [Oil] Formation Volume Factor (FVF), Bo,

•

Solution GOR, Rs, and

•

Oil and Gas Viscosity, µo and µg.

These correlations generally use the following set of parameters:

•

Oil API gravity8, γAPI,

•

Gas gravity9, γg,

•

Solution GOR at initial conditions, Rsi, and

•

Temperature, TR.

The correlations are therefore of the form:

(3.2)

p b = f (γ

API

, γ g , Rsi , TR )

The more commonly known correlations are due to Standing, Lasater, and Vasquez and

Beggs: for more details see Chapter 22 of Bradley.

3.4 The Corresponding States Theorem

As was evident from Table 3.1, the physical properties of hydrocarbons vary with

molecular weight [and shape]. Therefore, derived properties such as density, viscosity,

thermal conductivity, etc., cannot be easily be deduced for one species based on

measurements of those properties for another species. However, it was observed that if

we work in terms of reduced properties, such as reduced temperature, Tr, and reduced

pressure, pr, where:

(3.3)

Tr =

T

Tc

pr =

p

,

pc

then a more consistent picture emerges.

In particular, the Corresponding States theorem says all pure gases will have the same Zfactor10 at the same reduced temperature and reduced pressure: see the Real Gas Law in

section 5.1.3.

The following figure, usually known as the Standing Z-Factor chart, shows the variation

of Z-Factor with reduced pressure and reduced temperature.

8

API gravity is related to specific gravity, γo, [density relative to water] by

γ

API

= (141.5 γ o ) − 131.5

9

Gas gravity is density relative to that of air. Since they are both measured at standard conditions, we

assume the ideal gas law applies [see section 5.1] and therefore density is proportional to mole weight.

Therefore, gas gravity can be equally well represented as the gas mole weight relative to that of air where

Mair = 28.97.

10

We will define Z-factor in section 5.2.

31

Oxford

09/09/09

PVT Analysis

Figure 19: Standing Z-Factor Chart

All hydrocarbon gases [up to C6] and the inorganics N2, CO2 and H2S obey this chart to

within a few percent. Mixtures of these components can also have their Z-Factor

computed from this chart if instead of the pure component critical pressure and

temperature in (3.3), we use the pseudo-critical pressure, ppc, and pseudo-critical

temperature, Tpc, defined by:

(3.4)

p pc =

N

∑

i= 1

y i p ci

T pc =

N

∑

i= 1

y i Tci

Here yi is the mole fraction of the ith of the N components. In the absence of a

compositional analysis, the pseudo-criticals can be estimated from correlations based on

gas gravity: see Appendix B of McCain.

We will see later when we study Equations of State that both pressure and temperature

enter these expressions as reduced quantities. Other models utilize the Corresponding

States Theorem. Amongst them are the models for estimating viscosity and thermal

conductivity of hydrocarbon mixtures due to Pedersen et al., in Chapter 11 of Pedersen et

al.

32

Oxford

09/09/09

PVT Analysis

Z-Factor Correlations

One of simplest correlations for estimating Z-factors is due to Brill and Beggs [see Beggs

for details]:

D

Z = A + (1 − A) exp(− B ) + Cp pr

(3.5)

where:

A = 1.39(T pr − 0.92 )

0.5

− 0.36T pr − 0.101

0.066

B = p pr ( 0.62 − 0.23T pr ) + p 2pr

− 0.037 + 0.32 p 6pr exp − 20.723(T pr − 1)

(T − 0.86)

(3.6)

pr

C = 0.132 − 0.32 log T pr

[

(

D = exp 0.715 − 1.128T pr + 0.42T pr2

]

)

This correlation is adequate (±1-2%) provided the temperature is 80.0 < T (oF) < 340.0

and the pressure p < 10000.0 psia. The main advantage is the expression is explicit in Z.

A more accurate expression, which can be used over a wider range of pressure and

temperature, is credited to Hall and Yarborough. Here, the Z-factor is calculated from:

(3.7)

Z=

α p pr

y

where:

(3.8)

[

α = 0.06125t exp − 1.2(1 − t )

t = 1 T pr

2

]

In (3.7), y is the reduced density, which is found by solving the non-linear equation:

F ( y ) = − α p pr +

(3.9)

y + y2 + y3 + y4

(1 − y )

3

− (14.76t − 9.76t 2 + 4.58t 3 ) y 2

+ (90.7t − 242.2t 2 + 42.4t 3 ) y ( 2.18+ 2.82t )

= 0

The derivative of (3.9) is calculated from:

(3.10)

dF 1 + 4 y + 4 y 2 − 4 y 3 + y 4

=

− (29.52t − 19.52t 2 + 9.16t 3 ) y

4

dy

(1 − y )

(

)

+ ( 2.18 + 2.82t ) 90.7t − 242.2t 2 + 42.3t 3 y ( 1.18+ 2.82t )

An initial estimate of y=0.001 when used with the Newton procedure should achieve

convergence in 3 to 10 iterations for F(y) = 10-8.

33

Oxford

09/09/09

PVT Analysis

Estimating Pseudo-Criticals

In the absence of compositional information, the pressure and temperature pseudocriticals (ppc, Tpc), can be estimate by correlations dependent on the [reported] gas gravity.

Standing gives two sets of correlations, one for dry gases (γgHC < 0.75):

(3.10)

T pcHC = 168.0 + 325.0γ

p pHC = 667.0 +

gHC

15.0γ

gHC

− 12.5γ

− 37.5γ

2

gHC

2

gHC

and a second set for wet gas mixtures (γgHC ≥ 0.75):

(3.11)

T pcHC = 187.0 + 330.0γ

p pHC = 706.0 +

gHC

51.7γ

gHC

− 71.5γ

2

gHC

− 11.1γ

2

gHC

When significant quantities of the inorganics CO2 and H2S are present, the pseudocriticals should be corrected to account for the mole fractions of these components. In

particular,

T pc = T pcHC − ε

(3.12)

p pc =

p pcHC (T pcHC − ε

)

T pcHC + y H 2 S (1 − y H 2 S )ε

where the ε-correction factor is calculated from:

(3.13)

[

ε = 120 ( y CO2 + y H 2 S )

0.9

(

− y CO2 + y H 2 S

) ] + 15( y

1.6

0.5

H 2S

− y H4 2 S

)

34

Oxford

09/09/09

PVT Analysis

4. Sampling and Laboratory Analysis

Increasingly, we are using mathematical models encapsulated within software packages

to predict the behaviour of hydrocarbon reservoirs and their associated production

systems. The models require things:

1. Input and Initialisation

2. Calibration

For fluid property determination this necessitates we take samples of the fluids of

interest. Next, we determine their composition. Finally, we perform a set of standard

tests to produce data to calibrate our models.

4.1 Sampling

Before we can conduct any test, we have to acquire samples of the fluid of interest.

Samples should be taken as part of the initial well testing program. There are usually

conflicts in the well test program with the need to acquire reservoir parameters versus the

collection of representative samples. Proper design and careful planning are the key to

minimizing these conflicts.

A number of industry bodies have studied the problem of sampling, especially for more

complex fluids such as gas condensates. Their recommendations can be found the reports

from the API and UKOOA.

4.1.1 Well Testing

The main problems in well test design for sampling concern the producing interval and

tubing size.

In large hydrocarbon columns, a significant variation in composition with depth is

possible [we will discuss this effect in detail in section 6.4]. In this case, it is preferable

to sample only a limited interval by restricting the perforations: the UKOOA report

suggests intervals be restricted to 30-ft [10 m]. This then requires several tests be

performed over a large column: over a 300-ft column, the UKOOA report suggests a

minimum of three separate tests.

As we will see when we consider well conditioning, sample collection is best served by

low flow rates. Low flow rates should be produced using small diameter tubing since

low rate production in large diameter tubing gives rise to an unstable flow regime called

slugging. However, the rate must be high enough to ensure that liquids are produced to

surface: see Turner et al.: see section 4.1.4. If the flow rate of a condensate well being

surface sampled is too low such that some of the liquid phase is not produced then an

35

Oxford

09/09/09

PVT Analysis

unrepresentative sample will be taken. If all the liquid falls back, the well may choke and

die.

Technological advances in recent years have helped us here since it may be possible to

run small diameter coiled tubing during the sampling phase, reverting back to the large

diameter tubing for the other aspects of the well test.

Conditioning

As we shall discuss shortly, there are two ways of sampling:

•

Down Hole

•

Surface

In both cases, proper conditioning of well prior to taking the sample is essential.

Ideally, sampling should be done as soon as possible after the well is completed. The

process of drilling and completion usually results in near well bore damage and

contamination, which must be cleaned-up before the sample can be taken. This is best

achieved by a high flow rate. However, a high flow rate may cause in a large pressure

draw down that results in the bottom hole pressure falling below the saturation pressure.

Then, depending on relative permeability effects, the fluid flowing into the well may be

unrepresentative of the reservoir fluid.

Once the balance has been achieved between maximizing clean-up time and minimizing

draw down the main aim is to achieve:

•

Uniform flow rate,

•

Uniform GOR,

•

Stable Top Hole Pressure (THP)

•

Stable Bottom Hole Pressure (BHP)

•

Stable bottom hole density, ρBH [to ensure no liquid build up], and

•

Stable wellhead temperature, TWH.

The UKOOA report suggests these stability conditions be satisfied for 6 hours prior to the

sample being taken.

4.1.3 Down Hole Sampling

In this technique, a bottle is lowered down hole on a wire line and placed as close as

possible to the open interval. At some pre-arranged time or on a command from the

surface, the bottle is opened to the fluid flowing around it whereupon some of that fluid is

allowed to enter the bottle.

Unlike surface sampling, the volume of fluid that can be collected is relatively small:

typically 1 litre or so. Traditionally, this has precluded their use for gas condensate

36

Oxford

09/09/09

PVT Analysis

systems but with improving laboratory techniques requiring less fluid to perform the suite

of analysis tests, this is less of a problem.

The sample bottle is returned to the laboratory and the fluid is flashed to atmospheric

conditions. The volumes of stock tank gas and oil are measured (Vg, Vo). The normalized

weight fractions of the stock tank gas and oil samples are found by gas chromatography,

wgi and woi. The mole weight and density of the oil sample are measured, Mo and ρo. The

flash GOR, Rs, in consistent units, i.e. ft3/ft3 or m3/m3, tells us:

(4.xxx)

Rs =

Vg

n g V gm

=

Vo

noVom

Vgm and Vom are the molar volumes of gas and oil and ng and no are the corresponding

mole numbers: by definition, in field units, Vgm = 379.4 ft3/lbmole. If we assume 1.0

mole of feed then no = 1.0 – ng. The oil molar volume is calculated from:

(4.xxx)

Vom =

Mo

ρo

Combining these results allows us to calculate the gas moles as:

(4.xxx)

ng =

( M o ρ o ) Rs

V gm + ( M o ρ o ) Rs

Meanwhile, the oil and gas weight fractions are converted to mole fractions using the

component mole weights:

xi =

yi =

Mi )

M j ) + ( wo 7 + M o 7 +

∑ (w

j ≠ C7 +

(4.xxx)

( woi

oj

∑ (w

j ≠ C7 +

(w

gi

Mi )

M j ) + ( wg 7+ M g 7+

gj

)

)

The surface gas usually contains 1.0 mole percent or less of C7+ so Whitson has suggested

that a good estimate for the gas’ plus fraction mole weights is M g7+ = 105.0. The oil

sample plus fraction weight is calculated by material balance from:

(4.xxx)

M o7+ =

wo 7 +

1

−

Mo

∑

j ≠ C7 +

woj

Mj

Finally, with the gas and oil sample compositions and the gas moles, the feed

composition is calculated from:

(4.xxx)

z i = n g y i + (1 − n g ) xi

We will see in section 4.2.1 that the measurement of mole weight is extremely difficult

and can be subject to an error as large as ±10.0%: this will clearly feed through into the

determination of well stream composition. Whitson has suggested that the Watson

37

Oxford

09/09/09

PVT Analysis

characterization factor, Kw11, can be used to test the accuracy of the mole weight

measurement.

4.1.4 Surface Sampling

This remains the dominant technique for collecting samples. A well is allowed to flow to

surface where a fraction of the well stream fluid is re-directed to a test separator held at

some pre-determined pressure and temperature. After ensuring the stability conditions

outlined in section 4.1.2 are met, samples of the separator vapour and liquid are collected

in a number of bottles. These are then sent to regional laboratories for analysis.

The main advantage of this technique over down-hole sampling is the ability to collect

large volumes of fluid. However, there are a number of issues including:

•

Lifting all the produced fluids,

•

Ensuring a representative mix is taken from the flow line,

•

Accurate metering with the consequent problem of recombining the vapour and liquid

streams to reconstitute the well stream fluid.

4.1.4.1 Liquid Loading in Gas Wells

The first issue is particularly important for gas wells that also produce condensate or

water. The minimum [equivalent surface] rate for a given well head pressure and tubing

size was predicted by Turner et al. from:

(4.xxx)

Qmin = 3.06

v min Ap wh

TZ

The surface flow is expressed in MMscf/day, the tubing area, A, in ft2, the well head

pressure, pwh, in psia, the surface flowing temperature, T, is in degrees Rankine and Z is