Topic 1: Introduction to aerospace materials II.

Introduction to Aerospace Materials II

José Manuel Torralba

torralba@ing.uc3m.es

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Outline

Course Outline and Objectives

Classification: Engineering Metals

General Properties of Metals

Metallic Materials Today

Milestones in Metallic Materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2

Aerospace Materials

II

Topic 1: Introduction to aerospace materials II.

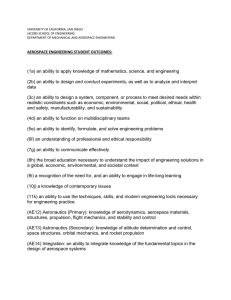

Aims and Objectives

• Understand: structure, composition,

processing, properties and performance

of different families of metallic materials

used in aerospace and relationship among

them.

• To know the more adequate standardized

tests to evaluate properties and

performance of metallic materials, and to

analyze the results.

• To be able to select metallic materials for

applications in different aerospace

engineering fields.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

3

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Course Outline

I.- Metallic Materials

1.

2.

3.

4.

Solidification of Metals

Processing I : Casting

Processing II: Metal Forming Fundamentals

Heat Treatments

II.- Materials Behaviour In-Service

5.

6.

7.

8.

Mechanisms of deformation and fracture I: Fracture

Mechanisms of deformation and fracture II: Fatigue

Thermomechanical behaviour: Creep

Corrosion and Wear

III.- Applications

9. Special Steels

10.Al-alloys

11.Ti-Alloys

12.Alloys for High Temperature Applications: Intermetallics

and Superalloys

13.Surface Treatments

14.Joining Methods

15.Non-destructive Testing Methods

4

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Classification of Materials

Aerospace Materials I

Aerospace Materials II

5

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Stages of manufacturing process

Raw materials

Casting methods

(gravity casting, die

casting etc.)

Deformation

processing

(rolling forging

extruding etc.)

Part 1. Metallic Materials

Molding (polymer

Powder methods

(pressing and sintering, hot

pressing, hot isostatic

pressing etc)

Material removal

molding, glass

molding)

Special methods

(composite layup,

chemical vapor

deposition,

electroforming etc.)

Aerospace materials I

(milling, grinding machining

etc)

Heat treating

(quenching and tempering,

age-hardening etc)

Joining

Part 3. Joining processes

and Surface Treatments

(welding, brazing,

fastening, adhesive

bonding etc.)

Finishing

(Cleaning, polishing,

painting etc)

Part 2. Behaviour inservice conditions

FAILURE IN

Part 3. Applications

Dpt. Materials Sci. and Eng. and Chem. Eng.

APPLICATIONS

UC3M

Useful life

SERVICE

CONDITIONS

6

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Evaluation

•

•

Continuous evaluation assessment:

- Exercises, tests, laboratory: 40%

End-of-term-examination: 60%

Continuous evaluation will consist of three parts:

•

•

•

•

•

•

(i) exercises and tests to be solved individually, during classes (3

activities 10% each) that will count 30% of the total mark

(ii) Presentations performed by students on the selected topics of the

course. Grade of the presentation will count 10% (it can replace one

mark of the tests)

(iii) Laboratory practices, that will be assessed with a questionnaire that

will be handed in at the end of each laboratory session, and that will count

10% of the total mark.

Help sessions and tutorial classes will be held prior to the final exam.

In order to pass, the final mark of the exam and the continuous evaluation

must be at least 5. (Minimum final-exam mark:4)

3 questions with a mark of 2 or less, transform the final exam mark

into 3.9

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

7

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Evaluation

Percentage of

final mark

Activity

Description

LABORATORY SESSIONS (10%)

10%

Laboratory Reports

Assessment of the methodology and

realization of the laboratory session as well

as the written report

CONTINIOUS EVALUATION (30%)

30%

10%

3 Exercises and Tests (10% each)

Presentations and reports

(= 1 test)

Exercises and test will be performed

individually during class and will be marked

Students will present in groups one of the

selected topics of the lecture course and

prepare a short handout with lecture notes

DEADLINE FOR SIGNING UP: 27/02/2023

FINAL EXAM (60%)

60%

Final exam for the lecture course. It will

contain problems and questions from the

whole lecture course.

Minimum mark to pass exam (in order

to count for the final grade with

continuous evaluation): 4

In order to pass the lecture course the total grade must be at least 5

Final Exam

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

8

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

https://doodle.com/meeting/

participate/id/egZR2Zrd

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

9

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Evaluation

Percentage of

final mark

Activity

Description

LABORATORY SESSIONS (10%)

10%

Laboratory Reports

Assessment of the methodology and

realization of the laboratory session as well

as the written report

CONTINIOUS EVALUATION (30%)

30%

10%

3 Exercises and Tests (10% each)

Presentations and reports

(= 1 test)

Exercises and test will be performed

individually during class and will be marked

Students will present in groups one of the

selected topics of the lecture course and

prepare a short handout with lecture notes

DEADLINE FOR SIGNING UP: 27/02/2023

FINAL EXAM (60%)

60%

Final exam for the lecture course. It will

contain problems and questions from the

whole lecture course.

Minimum mark to pass exam (in order

to count for the final grade with

continuous evaluation): 4

3 questions with a mark of 2 or less,

transform the final exam mark into 3.9

In order to pass the lecture course the total grade must be at least 5

Final Exam

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

10

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Evaluation

(ii) Presentations and reports:

OBJECTIVE: to develop soft-skills.

• Groups of 5-6 students

• Select one of the topics from the course marked for “presentation”

• Use the slides of the lecture course to give the presentation

• Each group will prepare either concept maps, mind maps, conceptual

diagrams, visual metaphors or comparison charts on all the topics

presented by their classmates. These works will count as reports.

• Reports will be corrected and used as studying material for all

students.

• Presentation and reports will be marked and the grade will

count 10% of the total mark. (self-evaluation, peerevaluation and evaluation by the teacher)

• Deadline for signing up for students presentation :

27/02/2023

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

11

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

(ii) Presentations Topics

Date

16 Mar

TOPIC

DESCRIPTION

Corrosion

23 Mar

Wear

13 Apr

Ti alloys

Corrosion. Basic electrochemical corrosion. Types of

corrosion. Corrosion control and prevention. High

temperature corrosion

Friction. Wear. Friction and wear tests. Lubricants. Wear

and friction in metal-working processes. Materials

selection for tribological system.

Production processes and manufacturing. Phase

transformations in Ti alloys.

Characteristics of Ti alloys. Heat Treatments for Ti alloys.

Applications of Ti in aerospace

20 Apr

Al- alloys

27 Apr

Surface Treatments

4 May

Non-detructive

testing

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Non Heat treatable Wrought Aluminium Alloys

Heat treatable Wrought Aluminium Alloys. Cast Aluminium

alloys. Applications in aerospace. Aluminium Processing

and Joining

Main surface treatments: Galvanizing; Electrodeposition;

Organic Coatings; CVD; PVD: Thermal Spraying.

Thermochemical Treatments. Thermal Barrier Coatings

Common NDT method. Visual Inspection. Liquid

Penetrants Magnetic Particle. Eddy Current.

Radiographic. Ultrasonic Acoustic Emissions. Nondestructive testing. Method comparison.

12

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

IMPORTANT

INFORMATION

ABOUT THE

LABORATORY

SESSIONS

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

AEROSPACE MATERIALS II

LABORATORY SESSIONS

• 4 Laboratory sessions.

✓

✓

✓

✓

Cold working of metals

Heat treatments

Metal casting

Non-destructive techniques

¡¡¡COMPULSORY ATTENDANCE!!!

Absence at laboratory practices without any justification

implies that the student cannot attend the ordinary

exam.

Communication with the laboratory coordination by email: ALWAYS indicate in SUBJECT: SUBJECT_NAMEGROUP- REASON

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

LABORATORY COORDINATION:

Manuel Torres

(matorres@ing.uc3m.es)

Office: 1.1J08

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

AEROSPACE MATERIALS II

LABORATORY SESSIONS

•

In the Master Group section of Aula Global you will find the

lists of students and schedules corresponding to each

laboratory group :

- 8-10 students aprox. per group

- There are groups A, B and C. VERIFY your group and

whether

you have any schedule compatibility issues.

•

The laboratory guide can be found in Aula Global

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

AEROSPACE MATERIALS II

LABORATORY SESSIONS

SAFETY IN LABORATORIES

•

Safety videos uploaded in the Small Group section of

Aula Global should be watched.

- GENERAL SECURITY VIDEO

- CHEMISTRY LAB SECURITY VIDEO

•

You must correctly answer all the questions of the

SECURITY TESTS (One test for each video). The

deadline closes the 17th of MARCH. You can

perform the tests as many times as necessary to

answer all the questions correctly.

ANSWERING ALL THE QUESTIONS OF THE TESTS

CORRECTLY ENABLES YOU TO ENTER THE LABORATORY!!!

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

ENTRANCE TO THE

LABORATORY WILL NOT

BE ALLOWED TO THOSE

WHO DO NOT CARRY OUT

THE TESTS CORRECTLY

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

AEROSPACE MATERIALS II

SAFETY IN LABORATORIES - COVID-19

TO BE ALLOWED INTO THE LABORATORY IT

IS MANDATORY:

• Bringing: mask, safety glasses and lab

coat

• Washing your hands before and after the

lab session

• Cleaning the workplace at the end of the

practice

• You will be provided with gloves

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

AEROSPACE MATERIALS II

LABORATORY SESSIONS

VIDEOS

In Aula Global, you can find the videos corresponding to

each laboratory session. It is mandatory to watch these

videos before to go to the laboratory.

Session 1: Cold working of metal

Session 2: Heat treatments

Session 3: Metal Casting

Session 4: Non-destructive techniques

•

During the practice you must make a report in pairs that you must deliver

one week after the day of the practice, as your teacher will indicate that

day.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Outline

Course Outline and Objectives

Classification: Engineering Metals

General Properties of Metals

Metallic Materials Today

Milestones in Metallic Materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

19

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

CLASSIFICATION OF METALS

METALLIC MATERIALS

Ferrous Alloys

Dpt. Materials Sci. and Eng. and Chem. Eng.

(90%)

UC3M

NON-Ferrous Alloys

(10 %)

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

CLASSIFICATION OF METALS

METALLIC MATERIALS

Ferrous Alloys

(90%)

Steels

Cast Irons

< 2 %C

Low alloy

<5% alloying elements

Low C (< 0,25 %)

• plain

• HSLA

Medium C (0,25 – 0,6 %)

• plain

• Heat Treatable

High C (0,6 – 1,4 %)

• plain

• Tool

Dpt. Materials Sci. and Eng. and Chem. Eng.

> 2 %C

High alloy

>5% alloying

elements

Tool steels

Grey Iron

Stainless steels

Ductile or

Nodular Iron

White Iron

Malleable Iron

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

CLASSIFICATION OF METALS

METALLIC MATERIALS

NON-Ferrous Alloys (10 %)

Light alloys

Cu alloys

Super alloys

and

Intermetallics

Refractory

metals

Precious

metals

Au, Ag, Pl

Al alloys

Bronzes

Co based

W, Mo, Ta, Nb

Ti alloys

Brasses

Ni based

Mg alloys

Alpaca

Fe based

W: 19,3 g/cm3

Mo: 10,3 g/cm3

Ta: 16,7 g/cm3

Nb: 8,57 g/cm3

Al: 2,7 g/cm3

Ti: 4,5 g/cm3

Mg: 1,7 g/cm3

Cu: 8,96 g/cm3

Dpt. Materials Sci. and Eng. and Chem. Eng.

Co: 8,86 g/cm3

Ni: 8,9 g/cm3

Fe: 7,87 g/cm3

UC3M

Au: 19,3 g/cm3

Ag: 10,5 g/cm3

Pl: 21,5 g/cm3

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Application examples

Metal

Iron alloys

Light alloys

Copper alloys

Application examples

Carbon steel

Stainless steel

Castings

Al alloys

Tools, construction, automotive

Naval construction, chemical material transport,

food industry, medical instruments

Cylinders, pistons, motor bodies, wear-resistant

materials.

Aerospace industry, construction, transport,

electrical conductors

Mg alloys

Automotive, sports equipment, aerospace

industry

Ti alloys

Aerospace industry, chemical industry, medical

industry, sports equipment

Electrical conductor

Heat exchange, chemical industry, naval industry

Copper

Bronze

Brass

Pressure container

Aerospace industry (turbines), coins

Nickel alloys

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

23

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Application examples

Metal

Iron alloys

Light alloys

Copper alloys

Application examples

Carbon steel

Stainless steel

Castings

Al alloys

Tools, construction, automotive

Naval construction, chemical material transport,

food industry, medical instruments

Cylinders, pistons, motor bodies, wearresistant materials.

Aerospace industry, construction, transport,

electrical conductors

Mg alloys

Automotive, sports equipment, aerospace

industry

Ti alloys

Aerospace industry, chemical industry, medical

industry, sports equipment

Electrical conductor

Heat exchange, chemical industry, naval industry

Copper

Bronze

Brass

Pressure container

Aerospace industry (turbines), coins

Nickel alloys

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

24

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Outline

Course Outline and Objectives

Classification: Engineering Metals

General Properties of Metals

Metallic Materials Today

Milestones in Metallic Materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

25

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties of materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

26

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties of metallic materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

27

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties of metallic materials

Relatively high Young Modulus (rigid)

Can achieve high strength

Normally ductile

High workability

Relatively high toughness

Electrically conductive

Magnetic properties (Iron)

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

28

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

30

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

32

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

34

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

• Metallic

– The

– The

– The

materials’ properties have their origin in:

nature of the metallic bond

crystal structure

presence of defects

Edge dislocation

Screw dislocation

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

35

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

• Metallic materials are normally POLYCRYSTALLINE

Unit cell

Crystal structure

Aggregate of single crystal grains

Microstructure revealed on material

surface

http://www.ebsd.com/12-ebsd-for-beginners

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

36

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

• Microstructure determines many of the physical properties of

materials

Scanning

electron

microscopy

Electron

Backscatter

Diffraction

SEM

EBSD

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

37

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties of metallic materials

• They can be composed of one or various phases, according to

their composition (alloys)

• Phases can have different sizes and shapes and can be distributed

in a different way, forming a MICROSTRUCTURE.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

38

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties

• Some properties of metals depend on their microstructure

and therefore can change when the microstructure is

altered.

Microstructure dependent

properties

Microstructure

independent properties

• Thermal expansion

• Thermal and electric conductivity

• Yield point

• Young modulus

• Resistance to fatigue

• Toughness

• Resistance to corrosion and wear

• Heat capacity

• Melting point

Dpt. Materials Sci. and Eng. and Chem. Eng.

• Hardness

• Ductility

• Tensile strength

UC3M

• Creep

• Density

39

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties

Microstructure

independent

properties

Microstructure

dependent properties

•

•

•

•

•

•

•

•

Yield point

Tensile strength

Ductility

Toughness

Creep

Resistance to fatigue

Hardness

Resistance to corrosion and

wear

• Thermal and electric

conductivity

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

•

•

•

•

•

Density

Young modulus

Thermal expansion

Heat capacity

Melting point

40

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

41

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General Properties

Other properties

• Diffusion: ability to form alloys –

solid solutions

• Phase diagrams

• Ability to modify its properties

• Thermal treatments

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

42

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

Nature of the bond<> properties <> types of materials <>

Processing and applications

• Metallic bond (>20-120 kcal/mol): Atomic nucleus surrounded by

a sea of e- (non-directional).

– Compact packing (density)

– Possibility to substitute atoms

(solid solutions) →alloys

– Conductivity

– Workability

Applied force

– High stiffness

• Band theory (conductivity)

conduction band

Antibonding orbitals

Bonding orbitals

Dpt. Materials Sci. and Eng. and Chem. Eng.

empty states

filled states

UC3M

valence band

43

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

CRYSTALLINE STRUCTURES

BCC

FCC

HCP

Fe (Tª<912 ºC)

Fe (912<Tª<1400 ºC)

Ti (Tª< 882ºC)

Ti (Tª>882ºC)

Al, Cu, Ni

Co, Mg, Zn

W, Mo

Nº Slip systems:

Dislocation motion

12

12

3

Closed packed planes and directions → easier slip/plastic deformation →

Ductility (FCC>BCC>HCP)

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

44

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

CRYSTALLINE STRUCTURES

SLIP SYSTEMS

FCC

BCC

HCP

Planes

{111}

{110}

{0001}

<110>

<111>

<2110>

4 x 3 = 12

6 x 2 = 12

1x3=3

Directions

Plastic deformation (slip) and

dislocation movement is more

difficult along a non-closed

packed (a) compared to a closedpacked plane (b)

Closed packed planes and directions → easier slip/plastic deformation →

Ductility (FCC>BCC>HCP)

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

45

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

CRYSTALLINE STRUCTURES : Interstitial sites

• TETRAHEDRAL (Coord. Nº 4)

• OCTAHEDRAL (Coord. Nº 6)

In compact structures:

• Nº of tetrahedral sites =2n

• Nº of octahedral sites =n

• n = Nº atoms in the cell

Importance of Interstices (example): SOLUBILITY OF C IN IRON

▪ Different packing factors: fbcc=0.68 and ffcc=0.74

Vinterstices(fcc)<Vinterstices(bcc),

but No.interstices(fcc)>No.interstice(bcc)

▪ Explains the solubility of C in Fe:

Troom. Feα(bcc) 0.02-0.05%C ferrite

High T (>910 ºC) Feγ(fcc) 2%C austenite

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Fe-

(fcc)

Fe-

(bcc)

Aerospace Materials46

II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

Defects in Crystalline Structures

Understanding crystalline defects is KEY in the

understanding of mechanical response to applied stress!!

Metals are NOT single crystals,

they have crystalline defects.

The presence of defects

determines the deformation of the

material under certain stress

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

The most common defect is the

presence of grain boundaries

47

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

Defects in Crystalline Structures

- Point defects: vacancies, interstitials, impurities

allow DIFFUSION → alloy formation

- Line defects: dislocations (insert an extra plain)

allow slip→ PLASTIC DEFORMATION

- Plane defects: grain boundaries,

interfaces, surfaces

control mechanical properties

high reactivity

- Volume defects: inclusions, pores, cracks

“Extra row of kernels between other rows”

they affect negatively conductivity

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

chem.libretexts.org

48

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

General properties and their origin

DEFORMATION

Dislocation movement (edge and screw) when a shear stress is applied

Vector de Burger’s = b

A.R. West. “Solid State Chemistry and its applications”. Wiley. Chichester,1992

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

https://youtu.be/kk2oOxSDQ7U

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Outline

Course Outline and Objectives

Classification: Engineering Metals

General Properties of Metals

Metallic Materials Today

Milestones in Metallic Materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

50

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

51

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

The ASHBY prediction

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

52

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Breakdown of materials in automotive industry

units: kg

Steel, iron

Light alloys

Lubricants, fuel

Other materials

Other metals

Electric/electronic Materials

Thermoplastics

Paint and Adhesives

Thermostable

Elastomers

Thermoplastic Elastomers

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Textiles and other composites

Ceramics and glasses

13-53

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Breackdown of materials used in aircrafts

BOEING 787

Mass breakdown of structural materials in the new Boeing 787

(http://seattlepi.nwsource.com/boeing/787/787primer.asp)

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Breackdown of materials used in aircrafts

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

55

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Breackdown of materials used in aircrafts

Figure 1. (a-left) Material usage and (bright) typical system cost distribution

trends for fighter aircraft

http://www.tms.org/pubs/journals/jom/0003/martin-0003.html

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

56

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Materials used in aircrafts

Cost-reduction opportunities by implementing metal-process technologies:

Low Cost Ti Plate

has Strong Cost

Impact

(a) Machined titanium frames

Al-Be Can Reduce

Cost and Survive

Higher Temps @

Equivalent Weight

(b) Composite pylon skins

http://www.tms.org/pubs/journals/jom/0003/martin-0003.html

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

57

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Materials used in aircrafts

Cost-reduction opportunities by implementing metal-process technologies:

Vacuum die casting of

Titanium is Lower Cost

than Complex

Machined Forging

(c) titanium hinge forgings

Laserforming of Flanges

Eliminates Material Waste

from Machining Ti Plate

(d) machined titanium support ribs.

http://www.tms.org/pubs/journals/jom/0003/martin-0003.html

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

58

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

The Gas Turbine

LPC: Low Pressure

Compressor

HPC: High Pressure

Compressor

HPT: High Pressure

Turbine

LPT: Low Pressure

Turbine

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

59

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

The Gas Turbine

The different materials used in a RollsRoyce jet engine.

Titanium

Nickel-based superalloys

Steel.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

60

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

The Gas Turbine

Evolution of materials used in aero gas turbines

• Civil aero-engine performance development has depended heavily

on advances in materials, not only by virtue of their properties but

also in their manufacturing and processing

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

61

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Historical evolution of the turbine blade surface temperature in

aeroengines

• New materials, such as molybdenum based superalloys are

necessary in order to achieve further technological gains

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

13-62

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Metallic materials today

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Outline

Course Outline and Objectives

Classification: Engineering Metals

General Properties of Metals

Metallic Materials Today

Milestones in Metallic Materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

64

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

STONE AGE - (200.000 BC - 2500 BC)

Mesolithic age (8000 BC – 4000 BC)

Starts of domestication of animals and cultivation of wild

varieties of crops. Small settlements. Fire

Needs:

o Tools for agriculture (hoe, sickle, quern) –

Stone+Wood

o Tools for cooking (pots, containers) – fired ceramics

Neolithic age (4000 BC – 2500 BC)

Development of agriculture, domestication of animals.

Large scale settled communities.

Needs:

o New textiles to replace animal skins – vegetable fibers

o Machines for weaving the threads into cloth

o Construction of buildings

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

65

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

BRONZE AGE - (3000 BC - 1200 BC)

•

10000 years ago: Gold, silver and copper mostly

used for jewellery, decorative items and pots and

pans for cooking, rather than tools.

•

3000 BC: Beginning of metallurgy. Discovery of

smelting led to alloying copper with tin → Bronze

BRONZE:

• Better malleability than stone

• Improve castability and hardness

→ Sophisticated tools, the first swords

Stronger and more durable tools.

Bronze age civilizations

→ TECHNOLOGICAL ADVANCE

Growth of commerce/Need for records

→ Development of the first writing

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Needs and challenges

o Organized system of production and division

of labor

o Higher degree of specialization and diversity

of skills

o Communication, coordination, trade and

transportation

66

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

IRON AGE - (1200 BC - 550 BC)**

**The transition happened at different times in different places

Metallic iron:

Occasional lumpy-by product from lead and

copper smelting. It was collected as a spongy

mass or bloom.

Intentional smelting of iron: Hittites (1500

BC).

• Hittite monopoly of ferrous knowledge

dispersed with the empire about (1200 BC).

• Small additions of carbon to iron + heat

treatments → massive increases in strength

Ferrous metallurgy:

• Tools or weapons that are equal or superior

to bronze.

• Mass production of tools and weapons made

from steel

• Damascus sword: Forged iron from sponge

iron.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

67

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

IRON AGE - (1200 BC - 550 BC)**

IRON AS THE DEMOCRATIC METAL:

• Rise in the living standards among larger

masses of population

• Applications of iron: Tools and

agricultural implements, precious

objects, weaponry (swords, shields,

armour).

• Increment in agriculture productivity →

surplus

Needs and challenges:

o New methods of working materials

o Organization arrangements

o Specialized craftsmen

o Decentralization of power → Democracy

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

**The transition happened at different times in

different places

68

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

STEEL

DATE

FACT

CONSEQUENCES

1709

Abrahan Darby I discovered that

carbon coke can replace

charcoal in the cast iron

manufacturing

1807

Sir Humphry Davy develops the

process known as electrolysis to

separate elemental metal salts

1827

Friedrich Wöhler isolated

elemental aluminum

1856

Henry Bessemer patents a low

cost process to manufacture

steel

1863

Emile and Pierre Martin develop

the Siemens-Martin furnace for

large production of steel

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

69

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

STEEL

DATE

FACT

CONSECUENCE

1709

Abrahan Darby I discovered that

carbon coke can replace

charcoal in the cast iron

manufacturing

Dramatically decreases the cost of casting (allowing

mass production) and saving huge tracts of

deforestation.

1807

Sir Humphry Davy develops the

process known as electrolysis to

separate elemental metal salts

New metals were discovered.

Electrometallurgy and electrochemistry were founded

1827

Friedrich Wöhler isolated

elemental aluminum

It opens the possibility of exploiting the most abundant

metallic element in Earth´s crust

1856

Henry Bessemer patents a low

cost process to manufacture

steel

It opens an era of massive use of cheap steel in

transportation, construction, and generally in the

industry.

1863

Emile and Pierre Martin develop

the Siemens-Martin furnace for

steel large production

Allowed the production of large amounts of steel, scrap

steel combining with iron ore, gas burners, making steel

the material most recycled metal.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

70

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Materials Science

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2000

1900

1800

1700

1000

0

-4000

-8600

-35000

-100000

-500000

-185000000

Leads to the

appearance of the

Metallography and

Physical

Metallurgy as a

result (and

Materials

Science).

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Materials Science

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2000

1900

1800

1700

1000

0

-4000

-8600

-35000

-100000

-500000

-185000000

Start using a

microscope to

identify and

correlate

esructuras crystal

observations with

the properties of

the material.

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Materials Science

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2000

1900

1800

1700

1000

0

-4000

-8600

-35000

-100000

-500000

-185000000

Initial work of the

phase diagram

more important in

metallurgy, laying

the foundation for

an indispensable

tool in many other

material systems.

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Materials Science

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2000

1900

1800

1700

1000

0

-4000

-8600

-35000

-100000

-500000

-185000000

Enacts the paradigm

"processingstructure-properties"

that guides the area

of Materials Science

and Engineering.

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Materials Science

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2000

1900

1800

1700

1000

0

-4000

-8600

-35000

-100000

-500000

-185000000

Lets understand

the mechanisms

of hardening

alloys capable

of being

hardened by

precipitation.

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Materials Science

DATE

FACT

CONSECUENCE

1863

Henry Clifton Sorby uses light

microscopy to reveal the

microstructure of steel

Leads to the appearance of the Metallography

and Physical Metallurgy as a result (and

Materials Science).

1890

Adolf Martens examines the

microstructure of a hard steel and

finds many varieties of patterns.

Start using a microscope to identify and

correlate crystal structure observations with

the properties of the material

1898

William Roberts-Austen develops

the phase diagram Fe-C

Initial work of the phase diagram more

important in metallurgy, laying the foundation

for an indispensable tool in many other

material systems.

1912

Albert Sauveur publishes

“Metallography and Heat

Treatment of iron and steel”

Enacts the paradigm "processing-structureproperties" that guides the area of Materials

Science and Engineering.

1937

André Guinier and G. D. Preston

independently report the strength

mechanism of Al-Cu alloys by

precipitation of intermetallic

Lets understand the mechanisms of

hardening alloys capable of being hardened

by precipitation

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

76

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials – Technology and new metals

DATE

FACT

CONSECUENCE

1878

William Siemens patents the electric

arc furnace

Ancestor of modern electric arc furnace, which

is the foundation of the modern steel and many

other alloys.

1886

Charles Martin Hall and Paul Heroult

discovered the reduction of alumina

into aluminum

It facilitates the beginning of the use of

aluminum for commercial purposes.

1904

Leon Guillet develops the first

stainless steel

Extend the versatility of the use of steel in

corrosive applications.

1906

Alfred Wilm discovers the

precipitation of aluminum

Appears first duralumin alloy, structural

aluminum.

1926

Paul Merica patents the addition of

small additions of Al to Ni-Cr alloy and

invents the first “super alloy”

Leads to commercialization of the propulsion

engine and improves the efficiency of power

turbines.

1940

Wilhelm Kroll develops an economic

process to extract titanium

Establishes the possibility of a necessary

material in the reactors, biomaterials, ...

1958

Frank VerSnyder develops a

directionally solidified turbine blade

Improves performance of aircraft engines,

saving airlines millions of dollars per year.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

77

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Milestones in metallic materials

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

2000

1900

1800

1700

1000

0

-4000

-8600

ALCOA

-35000

-100000

-500000

-185000000

It facilitates

the beginning

of the use of

aluminum for

commercial

purposes.

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Materials are the fundamental building blocks of culture

The material world is not just a

display of our technology and

culture, it is part of us, we

invented it, we made it and it

makes us who we are.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

79

Aerospace Materials II

Universidad

Carlos III de Madrid

www.uc3m.es

CLUSTER AEROSPACIAL DEL PAIS VASCO

Dpt. Materials Sci. and Eng. and Chemical Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

CLUSTER AEROSPACIAL ANDALUCÍA

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Universidad

Carlos III de Madrid

www.uc3m.es

CLUSTER AEROSPACIAL MADRID

Dpt. Materials Sci. and Eng. and Chemical Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

Aerospace Materials II

Topic 1: Introduction to aerospace materials II.

Next class

METALLIC MATERIALS

TOPIC 2. SOLIDIFICATION OF METALS

1.

2.

3.

4.

Solidification. Nucleation

Solidification. Growth

Cast structures

Defects in Castings

THANK YOU FOR YOUR ATTENTION!

Dpt. Materials Sci. and Eng. and Chem. Eng.

UC3M

85

Aerospace Materials II