Problems on the Design of Machine Elements - Faires Solution Manual

advertisement

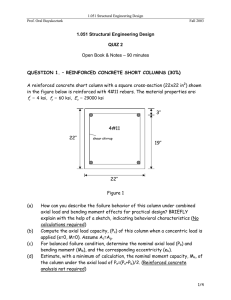

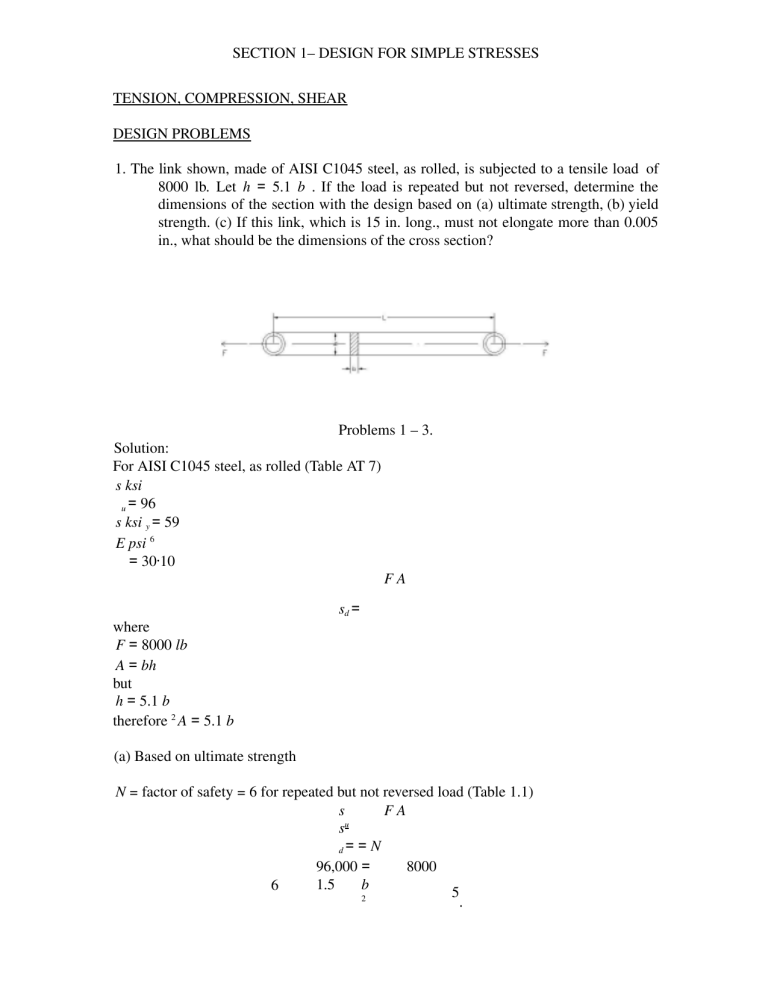

SECTION 1– DESIGN FOR SIMPLE STRESSES TENSION, COMPRESSION, SHEAR DESIGN PROBLEMS 1. The link shown, made of AISI C1045 steel, as rolled, is subjected to a tensile load of 8000 lb. Let h = 5.1 b . If the load is repeated but not reversed, determine the dimensions of the section with the design based on (a) ultimate strength, (b) yield strength. (c) If this link, which is 15 in. long., must not elongate more than 0.005 in., what should be the dimensions of the cross section? Problems 1 – 3. Solution: For AISI C1045 steel, as rolled (Table AT 7) s ksi u = 96 s ksi y = 59 E psi 6 = 30⋅10 FA sd = where F = 8000 lb A = bh but h = 5.1 b therefore 2 A = 5.1 b (a) Based on ultimate strength N = factor of safety = 6 for repeated but not reversed load (Table 1.1) FA s u s d= = N 96,000 = 8000 1.5 b 6 5 2 . b = .0 577 in say in 8 2 SECTION 1– DESIGN FOR SIMPLE STRESSES 15 = 5.1 = h b in 16 (b) Based on yield strength N = factor of safety = 3 for repeated but not reversed load (Table 1.1) FA s u s d= = N 59,000 = 8000 1.5 b 3 9 2 . b = .0 521in say in 16 27 h b in = 5.1 = 32 FL δ = (c) Elongation = AE where, δ = .0 005 in F = 8000 lb E psi 6 = 30⋅10 L =15 in 2 A = 5.1 b then, FL δ = AE ( )( ) 8000 15 .0 005 ⋅ = b ( )( ) 2 6 5.1 30 10 3 . b = .0 730 in say in 4 1 h b in = 5.1 8 =1 2. The same as 1 except that the material is malleable iron, ASTM A47-52, grade 35 018. Solution: For malleable iron, ASTM A47-52, grade 35 018(Table AT 6) s ksi u = 55 s ksi y = 36 5. E psi 6 = 25⋅10 3 SECTION 1– DESIGN FOR SIMPLE STRESSES FA sd = where F = 8000 lb A = bh but h = 5.1 b therefore 2 A = 5.1 b (a) Based on ultimate strength N = factor of safety = 6 for repeated but not reversed load (Table 1.1) FA s su d= = N 2 55,000 6 = 7 1.5 . 8000 b b = .0 763 in say in 8 5 h b in = 5.1 16 =1 (b) Based on yield strength N = factor of safety = 3 for repeated but not reversed load (Table 1.1) FA s u s d= = N 2 36,500 3 = 11 1.5 . 8000 b b = .0 622 in say in 16 1 h b in = 5.1 =1 32 FL δ = (c) Elongation = AE where, δ = .0 005 in F = 8000 lb E psi 6 = 25⋅10 L =15 in 2 A = 5.1 b then, 4 SECTION 1– DESIGN FOR SIMPLE STRESSES FL δ = AE( )( ) 8000 15 .0 005 ⋅ = b ( )( ) 2 6 5.1 25 10 7 . b = 8.0 in say in 8 5 h b in = 5.1 16 =1 3. The same as 1 except that the material is gray iron, ASTM 30. Solution: For ASTM 30 (Table AT 6) s ksi u = 30 , no y s E psi 6 =14 5. ⋅10 Note: since there is no y s for brittle materials. Solve only for (a) and (c) FA sd = where F = 8000 lb A = bh but h = 5.1 b therefore 2 A = 5.1 b (a) Based on ultimate strength N = factor of safety = 7 ~ 8 say 7.5 (Table 1.1) FA s su d= = N 30,000 = 8000 1.5 b 7.5 3 2 b = .1 1547 in say in 1. 16 25 h b in = 5.1 =1 32 FL δ = (c) Elongation = AE where, δ = .0 005 in F = 8000 lb E psi 6 =14 5. ⋅10 5 SECTION 1– DESIGN FOR SIMPLE STRESSES L =15 in A = 5.1 b then, 2 FL δ = ( )( ) AE 8000 15 .0 005 = ⋅ b ( )( ) 2 6 5.1 14 5. 10 1 b = .1 050 in say in 1. 16 19 h b in = 5.1 32 =1 4. A piston rod, made of AISI 3140 steel, OQT 1000 F (Fig. AF 2), is subjected to a repeated, reversed load. The rod is for a 20-in. air compressor, where the maximum pressure is 125 psig. Compute the diameter of the rod using a design factor based on (a) ultimate strength, (b) yield strength. Solution: From Fig. AF 2 for AISI 3140, OQT 1000 F s ksi u =152 5. s ksi y =132 5. π F force ( ) ( ) 20 125 39,270 lb 39 27. kips ==== 2 4 From Table 1.1, page 20 = 8 Nu Ny = 4 (a) Based on ultimate strength NFu A= 39 27. 2 u π s ( )( ) 8 152.5 5 1 4 d= d = 62.1 in say in 8 (b) Based on yield strength NF A= y y 4 ( )( ) 4 d = π s 39 27. 132.5 2 6 SECTION 1– DESIGN FOR SIMPLE STRESSES 1 1 d = 23.1 in say in 4 5. A hollow, short compression member, of normalized cast steel (ASTM A27-58, 65 ksi), is to support a load of 1500 kips with a factor of safety of 8 based on the ultimate strength. Determine the outside and inside diameters if Do Di = 2 . Solution: u = 65 s ksi = 8 Nu F =1500 kips 2 πππ 3 ( ) ( )4 2222 ADDDD = − = − = oiii 44 2 DNF 3 i 4 D π A = = = iu ( )( ) 8 1500 4 u s 65 7 D in i = 85.8 say in Do Diin = = 8 7 2 2 8 17 = 8 8 3 4 6. A short compression member with Do Di = 2 is to support a dead load of 25 tons. The material is to be 4130 steel, WQT 1100 F. Calculate the outside and inside diameters on the basis of (a) yield strength, (b) ultimate strength. Solution: From Table AT 7 for 4130, WQT 1100 F s ksi u =127 s ksi y =114 From Table 1.1 page 20, for dead load = 3 ~ 4 Nu, say 4 Ny = 5.1 ~ 2 , say 2 3 πππ Area, ( ) ( )4 2222 2 D i ADDDD =−=−= 4 oiii 44 F = 25 tons = 50 kips (a) Based on yield strength 2 DNF3 Aπ === iy ( )( ) 2 50 4 s y 114 7 SECTION 1– DESIGN FOR SIMPLE STRESSES 5 D in i = 61.0 say in 8 Do Diin = = 22= 8 (b) Based on ultimate strength = = = iu 32 DNF ( )( ) 4 50 π A 4 5 s u D in i = 82.0 say in 8 Do Diin = = 22= 8 7 1 1 4 7 127 3 1 4 7. A round, steel tension member, 55 in. long, is subjected to a maximum load of 7000 lb. (a) What should be its diameter if the total elongation is not to exceed 0.030 in? (b) Choose a steel that would be suitable on the basis of yield strength if the load is gradually applied and repeated (not reversed). Solution: FL δ = or E FL A (a) AE δ = where, F = 7000 lb L = 55 in δ = .0 030 in E psi 6 = 30⋅10 ( )( ) π 7000 55 2 A=d= ( )( ) 6 4⋅ .0 030 30 10 3 d = 74.0 in say in 4 (b) For gradually applied and repeated (not reversed) load Ny = 3 7000 NF y s ( )( ) 3 y 47,534 = = = psi A π () 2 75.0 4 s ksi y ≈ 48 say C1015 normalized condition (s ksi y = 48 ) 8. A centrifuge has a small bucket, weighing 0.332 lb. with contents, suspended on a manganese bronze pin (B138-A, ½ hard) at the end of a horizontal arm. If the pin is in double shear under the action of the centrifugal force, determine the diameter 8 SECTION 1– DESIGN FOR SIMPLE STRESSES needed for 10,000 rpm of the arm. The center of gravity of the bucket is 12 in. from the axis of rotation. Solution: From Table AT 3, for B138-A, ½ hard s ksi us = 48 W 2 F =ω g where r W = .0 332 lb 2 g = 32 2. fps ( )1047 sec ω 2 rad n ππ 60 60 r =12 in W 2 10,000 === F 1047 1 11,300 11 3. 2.0 332 2 r ( ) ( ) lb kips = ω = = = g 32 2. From Table 1.1, page 20 N = 3 ~ 4 , say 4 u A= ( )( ) N F u 4 11 3. s π for double shear d 22 = d = .0 774 in say in 32 4 48 25 CHECK PROBLEMS 3 9. The link shown is made of AISIC1020 annealed steel, with b in = and 4 1 =1 . (a) What force will cause breakage? (b) For a design factor of 4 based h in 2 on the ultimate strength, what is the maximum allowable load? (c) If N = 5.2 based on the yield strength, what is the allowable load? Problem 9. 9 SECTION 1– DESIGN FOR SIMPLE STRESSES Solution: For AISI C1020 annealed steel, from Table AT 7 s ksi u = 57 s ksi y = 42 (a) F = su A 3 1 1 A bh = in == 4 2 2 .1 125 F = (57)( .1 125) = 64 kips (b) F= s A = 4 Nu 1 1 3 A bh = in ( )( ) 57 .1 125 F 16 kips == 4 == 4 2 2 .1 125 u N u sA (c) F= y y N Ny = 5.2 11 3 A bh = in == 4 2 2 .1 125 ( )( ) 42 .1 125 F 18 9. kips == 2 10. A ¾-in.bolt, made of cold-finished B1113, has an effective stress area of 0.334 sq. in. and an effective grip length of 5 in. The bolt is to be loaded by tightening until the tensile stress is 80 % of the yield strength, as determined by measuring the total elongation. What should be the total elongation? Solution: sL δ= E from Table AT 7 for cold-finished B1113 s ksi y = 72 then, s s ( ) ksi = 80.0 y = 8.0 72 = 57 6. E 30 10 psi 30,000 ksi 6 =⋅= ( )( )in sL .0 0096 57 6. 5 δ=== E 30,000 10 SECTION 1– DESIGN FOR SIMPLE STRESSES 11. A 4-lb. weight is attached by a 3/8-in. bolt to a rotating arm 14-in. from the center of rotation. The axis of the bolts is normal to the plane in which the centrifugal force acts and the bolt is in double shear. At what speed will the bolt shear in two if it is made of AISI B1113, cold finish? Solution: From Table AT 7, s ksi psi us = 62 = 62,000 1 = in A2 ()2 8 =π4 .0 2209 W F = = us g 2 4 ω= 32.2 ( ) ( )( ) 14 2 3 2 ω rsA 62,000 .0 2209 ω = 88 74. rad sec 2 = = 60 88 74. ω πn n = 847 rpm 12. How many ¾-in. holes could be punched in one stroke in annealed steel plate of AISI C1040, 3/16-in. thick, by a force of 60 tons? Solution: For AISI C1040, from Figure AF 1 s ksi u = 80 s s ( ) ksi ksi us u = 75.0 = 75.0 80 = 60 A td = in 3 3 =π =π 4 16 .0 4418 2 F = 60 tons =120 kips n = number of holes F 120 n holes = = = 4415 60 Asus 5 ( )( ) .0 13. What is the length of a bearing for a 4-in. shaft if the load on the bearing is 6400 lb. and the allowable bearing pressure is 200 psi of the projected area? Solution: pDL =W where p = 200 psi D = 4 in 11 SECTION 1– DESIGN FOR SIMPLE STRESSES W = 6400 lb (200)(4)L = 6400 L = 8 in BENDING STRESSES DESIGN PROBLEMS 14. A lever keyed to a shaft is L =15 in long and has a rectangular cross section of h = 3t . A 2000-lb load is gradually applied and reversed at the end as shown; the material is AISI C1020, as rolled. Design for both ultimate and yield strengths. (a) What should be the dimensions of a section at a =13 in ? (b) at b = 4 in ? (c) What should be the size where the load is applied? Problem 14. Solution: For AISI C1020, as rolled, Table AT 7 s ksi u = 65 s ksi y = 49 Design factors for gradually applied and reversed load = 8 Nu Ny = 4 3 th I = , moment of inertial 12 but h = 3t 36 h 4 I= Moment Diagram (Load Upward) 12 SECTION 1– DESIGN FOR SIMPLE STRESSES Based on ultimate strength s s= u u N (a) IFac Mc s== I h2 c= F = 2000 lbs = 2 kips s 65 36 h = 86.3 in 86.3 in h t 29.1 = = = 3 say 3 1 == ( )( ) 2 13 h2 8 h 4 h in in = 5.4 = 2 41 t in in = 5.1 2 =1 (b) IFbc Mc s== I h2 c= F = 2000 lbs = 2 kips s 65 == ( )( ) 2 4 8 h2 3 3 h 4 36 h = 61.2 in in h 61.2 t 87.0 = = = say h=3 in t =1in (c) 13 SECTION 1– DESIGN FOR SIMPLE STRESSES 3 = − h 4 5.4 3 h = 33.2 in 1 −t4 t = 78.0 in say h = .2 625 in or h in − = 5.1 1 − 13 4 − =2 8 13 4 − 5 15. A simple beam 54 in. long with a load of 4 kips at the center is made of cast steel, SAE 080. The cross section is rectangular (let h ≈ 3b ). (a) Determine the dimensions for N = 3 based on the yield strength. (b) Compute the maximum deflection for these dimensions. (c) What size may be used if the maximum deflection is not to exceed 0.03 in.? Solution: For cast steel, SAE 080 (Table AT 6) s ksi y = 40 E psi 6 = 30⋅10 14 SECTION 1– DESIGN FOR SIMPLE STRESSES From Table AT 2 Max. ( )( )kips in FL M = = = 54 − 4 54 bh I= 4 4 3 12 but h = 3b h 4 s s == I= 36 (a) IMc y N y c= h2 ( ) 54 2 40 3 = h h 4 3 5.1 1 36 h = 18.4 in in h 18.4 b 39.1 = = = 3 3 = 4 , in in h 1 say h in b 21 5.4 ==== 2 3 (b) ( )( ) 33 FL .0 0384 δ== 4000 54 48 () ( )( )in = 3 48 30 EI 10 ⋅ 3 6 12 5.1 5.4 (c) = FL δ h 4 48 E 36 ( )( ) ( ) 3 4000 54 36 03.0 ⋅h 48 30 10 = ( )( ) 6 4 h = 79.4 in in h 79.4 b 60.1 = = = 3 3 = 25.5 = 5 , in in h 1 25.5 ==== say h in in b 43 4 3 3 75.1 1 15 SECTION 1– DESIGN FOR SIMPLE STRESSES 16. The same as 15, except that the beam is to have a circular cross section. Solution: s (a) IMc == s y y d N4 π I d 2 d = sπ π = = c= 64 2 M 43 d d 64 = 3 πd () 40 32 54 d = 46.3 i n 1 say d in =3 2 3 FL (b) EI δ= π I = 48 d 4 64 ( )( ) () 64 FL δ == 32 3 3 .0 0594 64 4000 54 48 ( )( )( ) Ed 4 in 64 = 3 M π π 48 30 10 5.3 ⋅ FL 64 3 (c) ()4 π δ= 48 Ed ( )( ) 3 64 4000 54 03.0 ⋅πd 48 30 10 = ( )( ) 6 4 d = 15.4 i n 1 say d in =4 4 17. A simple beam, 48 in. long, with a static load of 6000 lb. at the center, is made of C1020 structural steel. (a) Basing your calculations on the ultimate strength, determine the dimensions of the rectangular cross section for h = 2b . (b) Determine the dimensions based on yield strength. (c) Determine the dimensions using the principle of “limit design.” 16 SECTION 1– DESIGN FOR SIMPLE STRESSES Solution: From Table AT 7 and Table 1.1 s ksi u = 65 s ksi y = 48 = 3 ~ 4 Nu, say 4 Ny = 5.1 ~ 2 , say 2 ( )( )in kips FL M = = = 72 − 6 48 4 Mc I s=c= h 2 4 3 bh I= 12 but 2h b = h h 4 s= I= 24 2 = h M 43 12 M h 24 (a) Based on ultimate strength u u 12 M3 s s == = 4 h 65 N () 12 72 h 3 h = 76.3 in 17 SECTION 1– DESIGN FOR SIMPLE STRESSES 76.3 in h b 88.1 = = = 2 2 = 75.3 = 3 , in in h 3 say h in in b 87 75.3 ==== 4 2 2 (b) Based on yield strength .1 875 1 s 12 M s y 3 == N h () y 48 12 72 = 3 h 2 h = 30.3 in in h 30.3 b 65.1 = = = 2 2 = 5.3 = 3 , in in h 1 say h in in b 43 5.3 ==== 2 ( )42 72 48 = h = 29.2 in in h 29.2 2 2 (c) Limit design (Eq. 1.6) 75.1 1 = 4 bh Ms2 y h h 2 b .1 145 = = = 2 2 = 5.2 = 2 , in in h 1 5.2 ==== say h in in b 41 2 2 2 25.1 1 18. The bar shown is subjected to two vertical loads, F1 and F2, of 3000 lb. each, that are L =10 in apart and 3 in. ( a , d ) from the ends of the bar. The design factor is 4 based on the ultimate strength; h = 3b . Determine the dimensions h and b if the bar is made of (a) gray cast iron, SAE 111; (b) malleable cast iron, ASTM A4752, grade 35 018; (c) AISI C1040, as rolled (Fig. AF 1). Sketch the shear and moment diagrams approximately to scale. 18 SECTION 1– DESIGN FOR SIMPLE STRESSES Problems18, 19. Solution: F F R R 3000 lb 1 = 2 = 1 = 2 = Moment Diagram M = R a = (3000)(3) = 9000 lbs −in = 9 kips −in 1 N = factor of safety = 4 based on u s 1 bh I= 2 3 h 2 c= h h 3 4 3 I= = h 12 36 (a) For gray cast iron, SAE 111 s ksi u = 30 , Table AT 6 h M Mc s su = === 43 N 30 18 h 36 h 18 9 I () 4 2 s== h 3 h = 78.2 in in h 78.2 b 93.0 = = = say h = 5.3 in , b =1in 3 3 (b) For malleable cast iron, ASTM A47-52, grade 35 018 M 19 SECTION 1– DESIGN FOR SIMPLE STRESSES s ksi u = 55 , Table AT 6 M h Mc s 2 () h 36 h 18 9 18 M s = === u 43 N 55 I 4 s== h 3 3 1 3 3 h = 28.2 in in h 28.2 b 76.0 = = = = 2 , b in (c) For AISI C1040, as rolled s ksi u = 90 , Fig. AF 1 h M Mc s su = === say h in 4 = 4 2 () h 36 h 18 9 43 N 90 I s== 18 M 4 h h= 93.1 in 3 3 3 7 5 8 = in h 93.1 b 64.0 = = = say h in =1 , b in 8 19. The same as 18, except that F1 acts up ( F2 acts down). Solution: [ ]M ∑ =0 A R R 1875 lb 1 = 2 = 20 SECTION 1– DESIGN FOR SIMPLE STRESSES Shear Diagram Moment Diagram M =maximum moment = 5625 lb-in = 5.625 kips-in (a) For gray cast iron s su = = M 3 18 = N 18 .5 30 625 h () 4 h 3 3 1 3 4 = 3 h = 38.2 in in h 38.2 b 79.0 = = = say h in = 2 , b in (b) For malleable cast iron s 4 su = = M 3 18 = N 18 .5 55 625 h () 4 h 3 3 7 5 8 = 3 h = 95.1 in in h 95.1 b 65.0 = = = say h in =1 , b in 8 21 SECTION 1– DESIGN FOR SIMPLE STRESSES (c) For AISI C1040, as rolled s () N 90 h 4 su = = M 3 18 = 18 .5 h 625 3 h = 65.1 in in h 65.1 b 55.0 = = = =1 , b in 3 31 1 say h = in 2 2 20. The bar shown, supported at A and B , is subjected to a static load F of 2500 lb. at θ = 0 . Let d = 3 in , L =10 in and h = 3b . Determine the dimensions of the section if the bar is made of (a) gray iron, SAE 110; (b) malleable cast iron, ASTM A47-52, grade 32 510; (c) AISI C1035 steel, as rolled. (d) For economic reasons, the pins at A, B, and C are to be the same size. What should be their diameter if the material is AISI C1035, as rolled, and the mounting is such that each is in double shear? Use the basic dimensions from (c) as needed. (e) What sectional dimensions would be used for the C1035 steel if the principle of “limit design” governs in (c)? Problems 20, 21. Solution: 22 SECTION 1– DESIGN FOR SIMPLE STRESSES [ ]M ∑ =0 A 3 =13(2500) RB R lb B =10,833 [ ]M ∑ =0 B 3 =10(2500) RA R lb A = 8333 Shear Diagram Moment Diagram M = (2500 )(10) = 25,000 lb −in = 25 kips −in h = 3b bh 3 I= 12 4 Mc s= h I = c = 36 h h M 2 2 18 M == 43 I h 36 h (a) For gray cast iron, SAE 110 s ksi u = 20 , Table AT 6 N = 5 ~ 6 , say 6 for cast iron, dead load 18 M3 s su = = = N 18 25 20 h () h 6 3 23 SECTION 1– DESIGN FOR SIMPLE STRESSES h = 13.5 in 1 say h in in h b 71.1 3 == 3 = 5 , b in 4 4 =1 (b) For malleable cast iron, ASTM A47-32 grade 32510 s ksi u = 52 , s ksi y = 34 N = 3 ~ 4 , say 4 for ductile, dead load 18 M3 s su = = = N 18 25 52 h () 4 h = 26.3 in 3 3 say h in in h b 09.1 == h 3 1 = 3 , b in =1 4 4 (c) For AISI C1035, as rolled s ksi u = 85 , s ksi y = 55 N = 4 , based on ultimate strength 18 M3 s su = = = N 18 25 85 h () 3 h 4 h = 77.2 in in h b 92.0 == 3 say h = 3 in , b =1in (d) For AISI C1035, as rolled s ksi su = 64 N = 4 , R kips B =10.833 su B s s s R N A == 2 2 ππ A2DD = 42 = 64 10.833 == s 657 in s π 2 D = .0 D 4 2 24 SECTION 1– DESIGN FOR SIMPLE STRESSES 11 say D in = (e) Limit Design bh For AISI C1035 steel, s ksi y = 55 h3 b= 16 = y4 Ms2 h M == ( )43 8 = h 2 25 55 h = 76.1 in in h b 59.0 7 == 5 3 say h in in = .1 875 =1 , b in 8 21. The same as 20, except that o θ = 30 . Pin B takes all the horizontal thrust. Solution: FV = F cosθ [ ]M ∑ =0 [ A ]M ∑ =0 B RB FV 3 =13 3 =13(2500)cos30 RB R lb B = 9382 RA FV 3 =10 3 =10(2500)cos30 RA R lb A = 7217 Shear Diagram 25 SECTION 1– DESIGN FOR SIMPLE STRESSES Moment Diagram M = (2165 )(10) = 21,650 lb − in = 21 65. kips − in 18 M s= 3 h (a) For gray cast iron, SAE 110 s ksi u = 20 , Table AT 6 N = 5 ~ 6 , say 6 for cast iron, dead load 18 M3 s u s == N () 20 h 65. = 18 21 6 h 3 h = 89.4 in say h in in h b 63.1 == 3 3 1 = 5 , b in 4 4 =1 (b) For malleable cast iron, ASTM A47-32 grade 32510 s ksi u = 52 , s ksi y = 34 N = 3 ~ 4 , say 4 for ductile, dead load 18 M3 s u s == N () 52 h 65. = 18 21 3 h 4 h = 11.3 in in h b 04.1 == 3 say h = 3 in , b =1in (c) For AISI C1035, as rolled s ksi u = 85 , s ksi y = 55 N = 4 , based on ultimate strength 26 SECTION 1– DESIGN FOR SIMPLE STRESSES 18 s M3 su = = N 85 h () 4 h = 64.2 in 65. = 18 21 3 h in h b 88.0 == 3 7 5 = 2 , b in say h = in 8 8 (d) For AISI C1035, as rolled s ksi su = 64 N = 4 , R lb BV = 9382 R F F lb BH H = = sinθ = 2500sin 30 =1250 ( ) ( ) 2 2 = + = + 1250 RB RBV 9382 222 RBH R lb B = 9465 s su B s s= = R N A 2 2 ππ A2DD = 42 = 64 .9 465 s say D s π 2 D = .0 in == 614 in D 4 2 5 8 = (e) Limit Design bh For AISI C1035 steel, s ksi y = 55 h3 b= = y4 Ms2 h h 2 M == ( )43 8 = 21 65. 55 h = 68.1 in in h b 56.0 7 == 5 3 say h in in = .1 875 =1 , b in 8 27 SECTION 1– DESIGN FOR SIMPLE STRESSES 22. A cast-iron beam, ASTM 50, as shown, is 30 in. long and supports two gradually applied, repeated loads (in phase), one of 2000 lb. at e =10 in from the free end, and one of 1000 lb at the free end. (a) Determine the dimensions of the cross section if b = c ≈ 3a . (b) The same as (a) except that the top of the tee is below. Problem 22. Solution: For cast iron, ASTM 50 s ksi u = 50 , s ksi uc =164 For gradually applied, repeated load N = 7 ~ 8 , say 8 M = F d + F (d + e) 1 2 where: F 2000 lb 1 = F 1000 lb 2 = d = 30 −10 = 20 in d + e = 30 in M = (2000)(20)+ (1000)(30) = 70,000 lb −in = 70 kips − in c I s= M Solving for I , moment of inertia ( )( ) ( )( ) [ ] ( )( ) ( )( ) a a a a y 3 = + a 5 a 3 aa 2 aa33 2 2 + 3a y= 28 SECTION 1– DESIGN FOR SIMPLE STRESSES ( )( ) ( )( ) ( )( )( ) ( )( )( )2 3 a 3 4 3 aa 17 aa3 2 I=+++= 12 (a) 3 aaa 12 aaa 32 ct = cc 3a 2 5a 2 = Based on tension Mc s ut s t == N I 3 50 8 = a ( ) 70 2 17 a 4 2 a = .1 255 in Based on compression Mc s uc c s c == 8 ( ) 70 2 N 164 = 17 2 a = .1 001in Therefore a = .1 255 in 1 Or say a in And b = c = 3a = 3( 25.1 ) = 75.3 in =1 I5 a a 4 4 29 SECTION 1– DESIGN FOR SIMPLE STRESSES 3 Or b c in ==3 4 (b) If the top of the tee is below = c 5a 2 3a 2 17 4 a 2 t = c c = I M = 70 kips −in Based on tension s Mc su t t = = 8 ( ) 70 2 N 50 = 17 I5 a a 4 2 a = .1 488 in Based on compression Mc s uc c s c == 8 2 a = .0 845 in Therefore a = .1 488 ( ) 70 2 N 164 = 17 I3 a a 4 in 1 Or say a in =1 2 And b c a in 1 ==3 2 =4 CHECK PROBLEMS 30 SECTION 1– DESIGN FOR SIMPLE STRESSES 23. An I-beam is made of structural steel, AISI C1020, as rolled. It has a depth of 3 in. and is subjected to two loads; F1 and 2 1 F = 2F ; F1 is 5 in. from one end and F2 is 5 in. from the other ends. The beam is 25 in. long; flange width is b = .2 509 in ; 4 I 9.2 in x = . Determine (a) the approximate values of the load to cause elastic failure, (b) the safe loads for a factor of safety of 3 based on the yield strength, (c) the safe load allowing for flange buckling (i1.24), (f) the maximum deflection caused by the safe loads. Problems 23 – 25. Solution: [ ]M ∑ =0 ( ) F F RB A 5 20 2 25 1 + 1 = 1 [ RB = 8.1 F ]F ∑ =0 V F1 + F1 = RA + RB 2 RA = 3F − 8.1 F = 2.1 F Shear Diagram 111 Moment Diagram 31 SECTION 1– DESIGN FOR SIMPLE STRESSES M = 9F = maximum moment For AISI C1020, as rolled s ksi y = 48 1 (a) IMc s y= where in d 3 c 5.1 === ( )( ) 48 F1 2.9 s y= = 9 5.1 F 10 31. kips 1 = F 2F 20 62. kips 2 = 1 = s (b) IMc sy == N ( )( ) 48 F1 s = = 3 9 5.1 2 2 2.9 F 44.3 kips 1 = F 2F 88.6 kips 2 = 1 = L (page 34) 25 (c) 96.9 15 2.509 b ==< s ksi c = 20 ( page 34, i1.24) sc = Mc 1 20 F = 9 5.1 2.9 F 30.4 kips 1 = F 2F 60.8 kips 2 = 1 = (d) For maximum deflection, by method of superposition, Table AT 2 2 () ′ 3 +′ =a L b Fb max 3 3 y , a > b′ EIL or () 2 3 ′ + =b L a Fa max 3 3 y , b′ > aEIL I ( )( ) 32 SECTION 1– DESIGN FOR SIMPLE STRESSES =b L a max y caused by F a F1 1 () 2 3 ′ + y , 11 b′ > a 1111 max 33 EIL where E = 30,000 ksi a 5 in 1 = b 20 in 1′ = L = 25 in F ()5 + 5 ( )( )( ) 3 30,000 9.2 25 Fb 2 max y caused by F2 2 3 a > b′ +′ =a L b y , 22 2222 max 20 25 .0 0022 1F 1 ′ () 2 = () 4 3 y= max I = 9.2 in 33 EIL 3 1 where b 5 in 2′ = a 20 in 2 = () 25F () + 20 25 5 3 y= 2 max .0 0043 2F = 1 ( )( )( ) 1 3 30,000 9.2 25 3 Total deflection = δ δ = y + y = F + F = F max max 1 1 0065 1 12 .0 022 .0 0043 .0 Deflection caused by the safe loads in (a) ( ) in a δ = .0 0065 10 31. = .0 067 Deflection caused by the safe loads in (b) ( ) in b δ = .0 0065 44.3 = .0 022 Deflection caused by the safe loads in (c) ( ) in c δ = .0 0065 30.4 = .0 028 24. The same as 23, except that the material is aluminum alloy, 2024-T4, heat treated. Solution: For aluminum alloy, 2024-T4, heat treated s ksi y = 47 (a) IMc s y= 33 SECTION 1– DESIGN FOR SIMPLE STRESSES ( )( ) 47 F1 9 5.1 s y= = 2.9 F 10 10. kips 1 = F 2F 20 20. kips 2 = 1 = s (b) IMc sy == N ( )( ) 47 F1 2.9 s==3 9 5.1 F 36.3 kips 1 = F 2F 72.6 kips 2 = 1 = L (page 34) 25 (c) 96.9 15 2.509 b ==< s ksi c = 20 ( page 34, i1.24) sc = Mc I ( )( ) 1 20 F = 9 5.1 2.9 F 30.4 kips 1 = F 2F 60.8 kips 2 = 1 = (d) Total deflection = δ δ = y + y = F + F = F max max 1 1 0065 1 12 .0 022 .0 0043 .0 Deflection caused by the safe loads in (a) ( ) in a δ = .0 0065 10 10. = .0 066 Deflection caused by the safe loads in (b) ( ) in b δ = .0 0065 36.3 = .0 022 Deflection caused by the safe loads in (c) ( ) in c δ = .0 0065 30.4 = .0 028 25. A light I-beam is 80 in. long, simply supported, and carries a static load at the midpoint. The cross section has a depth of d = 4 in , a flange width of b = 66.2 in , and 4 I 0.6 in x = (see figure). (a) What load will the beam support if it is made of C1020, as-rolled steel, and flange buckling (i1.24) is considered? (b) Consider the stress owing to the weight of the beam, which is 7.7 lb/ft, and decide whether or not the safe load should be less. 34 SECTION 1– DESIGN FOR SIMPLE STRESSES Solution: (a) For C1020, as rolled, s ksi u = 65 Consider flange buckling 80 == Lb 2.66 30 L since 15 < < 22 5. 40 b 22 5. sc15 = 2 2= ksi 30 = () 1 L 1 1800 + + 1800 b s= Mc I in d 4 c2=== 2 2 From Table AT 2 ( )F FL F M 20 80 === 4 4 Mc ss=c = I ( )( ) 15 F = 20 2 6 F = 25.2 kips, safe load (b) Considering stress owing to the weight of the beam 2 wL M = (Table AT 2) add’l 8 where w = 7.7 lb ft 35 SECTION 1– DESIGN FOR SIMPLE STRESSES add’l ( )lb in kips in wL M = − = − 22 7.7 80 8 M = 20F + .0 513 = total moment 12 8 ss=c = Mc I = = 513 .0 513 ( )( ) =F 15 + 20 .0 513 2 6 F = .2 224 kips Therefore, the safe load should be less. 26. What is the stress in a band-saw blade due to being bent around a 13 ¾-in. pulley? The blade thickness is 0.0265 in. (Additional stresses arise from the initial tension and forces of sawing.) Solution: in t c .0 0265 .0 01325 === 2 r =13 75. + .0 01325 =13.76325 in Using Eq. (1.4) page 11 (Text) s= E c r where E psi 6 = 30⋅10 ( )( ) 30 10 .0 01325 6= ⋅ s 28,881 psi 25 = 13.763 27. A cantilever beam of rectangular cross section is tapered so that the depth varies uniformly from 4 in. at the fixed end to 1 in. at the free end. The width is 2 in. and the length 30 in. What safe load, acting repeated with minor shock, may be applied to the free end? The material is AISI C1020, as rolled. Solution: For AISI C1020, as rolled s ksi = 65 (Table AT 7) Designing based on ultimate strength, N = 6, for repeated, minor shock load u 36 SECTION 1– DESIGN FOR SIMPLE STRESSES 65 s s 10 8. = ksi u == 6 N Loading Diagram 41− − 30 h = 10.0 x wh +1 3 I= = h1x 12 c= == xFx Mc 2 s M = Fx( ) Fx h 6 Fx () I h2 3 3 Fx === 3 222 wh 12 2 h h 10.0 1 + Differentiating with respect to x then equate to zero to solve for x giving maximum stress. ( ) ( ) ( )( )( ) ds + 2 10.0 1 1 2 10.0 1 10.0 xxx +−+ = x dx 34 F 0 () h = 10.0 (10)+1 = 10.0 x +1− 2( = 2 in 10.0 x) = 0 x 10.0 1 =10 in 3 s su = = N h 3 10 10 8.F Fx 2 () = ( )2 2 F = 44.1 kips TORSIONAL STRESSES DESIGN PROBLEMS 37 SECTION 1– DESIGN FOR SIMPLE STRESSES 28. A centrifugal pump is to be driven by a 15-hp electric motor at 1750 rpm. What should be the diameter of the pump shaft if it is made of AISI C1045 as rolled? Consider the load as gradually repeated. Solution: For C1045 as rolled, s ksi y = 59 s ksi us = 72 Designing based on ultimate strength s us s = , N = 6 (Table 1.1) N 72 s 12 ksi == 6 Torque, ( ) hp T = = = 45 − = 540 − = .0 540 − 33,000 33,000 15 2 1750 2 ft lb in lb in kips () n ππ For diameter, 16 = d sπ 16 .0 540 12π d d = .0 612 in 5 say d in T () 3 = 3 = 8 29. A shaft in torsion only is to transmit 2500 hp at 570 rpm with medium shocks. Its material is AISI 1137 steel, annealed. (a) What should be the diameter of a solid shaft? (b) If the shaft is hollow, Do Di = 2 , what size is required? (c) What is the weight per foot of length of each of these shafts? Which is the lighter? By what percentage? (d) Which shaft is the more rigid? Compute the torsional deflection of each for a length of 10 ft. Solution: hp () T = = = 23,036 − = 276 − 33,000 2500 33,000 2 ft lb in kips () n 2 570 ππ For AISI 1137, annealed s ksi y = 50 (Table AT 8) s s ksi ys = 6.0 y = 30 Designing based on yield strength N = 3 for medium shock, one direction 38 SECTION 1– DESIGN FOR SIMPLE STRESSES Design stress s 30 N 3 sys 10 = = ksi = (a) Let D = shaft diameter 4 D = s= T c J π J c= 32 D 2 T = 16 D 3 sπ () 16 276 10π D = 3 =5 4 2 − D = 20.5 i n 1 say D in (b) ( ) [( ) ]32 4 4 4 4 4 Do Di Di Di Di − πππ J 15 = 32 = 32 = 2 TD 2 32 T DD 2 c=== oi D i sπ π = = i 43 15 D 15 i i D 32 () 32 276 10π Di = 3 15 D in i = 66.2 D D in o i = 2 = 32.5 say i D in 85 =2 o D in 41 =5 (c) Density, 3 ρ = .0 284 lb in (Table AT 7) 39 SECTION 1– DESIGN FOR SIMPLE STRESSES For solid shaft w = weight per foot of length w D 3 D 3 ( )( ) .0 284 25.5 73 8. lb ft 12 = πρ π ρ ===4 π 22 2 For hollow shaft π w( ) ( ) D D D D ( ) ( ) ( ) [ ] lb ft o i 3 o i 3 .0 284 25.5 .2 625 55 3. 12 2222 ρ 22 = πρ π −=−=−=4 Therefore hollow shaft is lighter − 73 8. 55 3. = Percentage lightness = ( ) 100% 33 5. % 55.3 (d) Torsional Deflection TL θ= JG where L =10 ft =120 in G ksi 3 =11 5. ⋅10 4 π J For solid shaft, 32 = 180 ( )( ) D .0 039 .0 039 276 120 ()o ()() θ rad =π π 4 3 2.2 == = ⋅ 32 For hollow shaft, ( 25.5 11 5. 10 ) 4 4 Do Di J− π = ( )( ) 276 120 180 .0 041 .0 041 ()o []()()() θ rad =π π 32 44 4.2 == = 3 −⋅ 32 5. 10 25.5 .2 625 11 Therefore, solid shaft is more rigid, o o 2.2 < 4.2 30. The same as 29, except that the material is AISI 4340, OQT 1200 F. Solution: hp () T = = = 23,036 − = 276 − 33,000 2500 33,000 2 ft lb in kips () n 2 570 ππ For AISI 4340, OQT 1200 F s ksi y =130 s s ( ) ksi ys = 6.0 y = 6.0 130 = 78 Designing based on yield strength 40 SECTION 1– DESIGN FOR SIMPLE STRESSES N = 3 for mild shock Design stress s 78 N 3 s 26 = = ksi ys = (a) Let D = shaft diameter s= T c J π J 4 D = c= 32 D = 16 T 16 276 26π D 2 () sπ D 3 = 3 =3 4 2 − D = 78.3 i n 3 say D in (b) ( ) [( ) ]32 4 4 4 4 4 Do Di Di Di Di − πππ J = 32 = 2 TD 2 32 T 15 = 32 DD 2 c=== oi D i = = sπ π i 43 15 D 15 i i D 32 () 32 276 26π Di D in i = 93.1 D D in o i = 2 = 86.3 say D in i = 2 D in o = 4 = 15 3 (c) Density, 3 ρ = .0 284 lb in (Table AT 7) 41 SECTION 1– DESIGN FOR SIMPLE STRESSES For solid shaft w = weight per foot of length w D 3 D 3 ( )( ) .0 284 75.3 37 6. lb ft 12 = πρ π ρ ===4 π 22 2 For hollow shaft π w( ) ( ) D D D D ( ) ( ) ( ) [ ] lb ft o i 3 o i 3 .0 284 4 2 32 1. 12 2222 22 = πρ π ρ −=−=−=4 Therefore hollow shaft is lighter 37 6. 32 1. = − Percentage lightness = ( ) 100% 17 1. % 32.1 (d) Torsional Deflection TL θ = JG where L =10 ft =120 in G ksi 3 =11 5. ⋅10 π J For solid shaft, 32 4 D = ( )( ) 276 120 180 .0 148 .0 148 () ()() o θ rad =π π 4 3 48.8 == = ⋅ 32 For hollow shaft, ( ) 4 4 Do Di J− π = 75.3 11 5. 10 ( )( ) 276 120 32 180 .0 122 .0 122 ()o []()()() θ rad =π π 44 3 −⋅ 32 4 2 11 5. 10 == = 99.6 Therefore, hollow shaft is more rigid, o o 99.6 < 48.8 . 31. A steel shaft is transmitting 40 hp at 500 rpm with minor shock. (a) What should be its diameter if the deflection is not to exceed 1o in 20D ? (b) If deflection is primary what kind of steel would be satisfactory? Solution: (a) ( ) hp T = = = 420 − = 04.5 − 33,000 33,000 40 2 ft lb in kips () n 2 500 ππ 3 G ksi =11 5. ⋅10 L = 20D 42 SECTION 1– DESIGN FOR SIMPLE STRESSES π 1 o θ = = JG 180 TL θ = rad = DD 04.5 π 20 ( )( ) 180⋅ π 32 4 ( ) 3 11 D = 72.1 i n 3 say D in =1 (b) ( ) 16 16 04.5 T s 8.4 = = = () ksi 4 5. 10 D 75.1 33 ππ Based on yield strength N=3 s Ns ( )( ) ksi ys = = 3 8.4 =14 4. s sys y 14 4. 24 = = = ksi 0.6 Use C1117 normalized steel s ksi y = 35 0.6 32. A square shaft of cold-finish AISI 1118 transmits a torsional moment of 1200 in lb. For medium shock, what should be its size? Solution: For AISI 1118 cold-finish s ksi y = 75 s s ksi ys = 6.0 y = 45 N = 3 for medium shock s T N Z 9 9 2 b == 4 sys′ = = where, h = b 22 3 bhb 2 Z′ = = (Table AT 1) T =1200 in − lb = 2.1 in − kips () 45 s = = 2.1 9 3 b = h = 71.0 in 3 say b h in 3 43 SECTION 1– DESIGN FOR SIMPLE STRESSES CHECK PROBLEMS 33. A punch press is designed to exert a force sufficient to shear a 15/16-in. hole in a ½-in. steel plate, AISI C1020, as rolled. This force is exerted on the shaft at a radius of ¾-in. (a) Compute the torsional stress in the 3.5-in. shaft (bending neglected). (b) What will be the corresponding design factor if the shaft is made of cold-rolled AISI 1035 steel (Table AT 10)? Considering the shock loading that is characteristics of this machine, do you thick the design is safe enough? Solution: For AISI C1020, as rolled s ksi us = 49 F s ( Dt) = us π 15 where D in = 16 1 = 2 t in 15 49 = F ( ) 72 2. kips =π where r in T() = in − kips 1 T = Fr = 4 16 3 3 = 54 2. 72 2. 4 16 T (a) 3 = sπ where d = 5.3 in d 2 () () 16 54 2. s 44.6 ksi == π 3 5.3 (b) For AISI 1035 steel, s ksi us= 64 for shock loading, traditional factor of safety, N =10 ~ 15 64 s Design factor , 94.9 Nus , the design is safe ( N ≈10) = = = s 6.44 34. The same as 33, except that the shaft diameter is 2 ¾ in. Solution: 44 SECTION 1– DESIGN FOR SIMPLE STRESSES d = 75.2 in 16 T (a) 3 sπ = d () 16 54 2. s 13 3. ksi () == π 75.2 3 (b) For AISI 1035 steel, s ksi us= 64 for shock loading, traditional factor of safety, N =10 ~ 15 64 s Design factor , 8.4 Nus , the design is not safe ( N <10 ) = = = s 13.3 35. A hollow annealed Monel propeller shaft has an external diameter of 13 ½ in. and an internal diameter of 6 ½ in.; it transmits 10,000 hp at 200 rpm. (a) Compute the torsional stress in the shaft (stress from bending and propeller thrust are not considered). (b) Compute the factor of safety. Does it look risky? Solution: For Monel shaft, us= 98 (Table AT 3) s ksi N = 3 ~ 4 , for dead load, based on ultimate strength (a) JTc s= ( ) [( ) ( ) ] 4 4444 32in D D − ππ = Jo i = = 13 5. 5.6 − 13 5. co75.6 = = = 32 3086 in D () 2 2 hp T = = = 262,606 − = 3152 − 33,000 10,000 33,000 2 ft lb in kips () n 2 200 ππ ( )( ) 3152 75.6 s 9.6 ksi == 3086 (b) Factor of safety, 98 s us N , not risky === 14 2. 6.9 s 45 SECTION 1– DESIGN FOR SIMPLE STRESSES STRESS ANALYSIS DESIGN PROBLEMS 36. A hook is attached to a plate as shown and supports a static load of 12,000 lb. The material is to be AISI C1020, as rolled. (a) Set up strength equations for dimensions d , D , h , and t . Assume that the bending in the plate is negligible. (b) Determine the minimum permissible value of these dimensions. In estimating the strength of the nut, let D 2.1 d 1 = . (c) Choose standard fractional dimensions which you think would be satisfactory. Problems 36 – 38. Solution: s = axial stress s = shear stress s (a) F 4 F sπ == 1 d 2 π 4 d 2 Equation (1) sF dπ4 = 46 SECTION 1– DESIGN FOR SIMPLE STRESSES 44F F F 4 F s − =π π π = = ()()[]()() 1 2 2 = 222 Dd 2 2 − 2.1 DD 2 44.1 D D Dd− 4 π − 1 4 d 1 Equation (2) 2 D = + 44.1 F dh s s π 1 2.1 π F == Dh Equation (3) h dss 2.1 π = F π s F F s sπ = Dt Equation (4) F Dss tπ = (b) Designing based on ultimate strength, Table AT 7, AISI C1020, as rolled u = 65 s ksi s ksi us = 49 N = 3 ~ 4 say 4, design factor for static load 65 s su16 = = ksi = sus 4 N s 12 = = = 49 ksi s N F =12,000 lb =12 kips From Equation (1) () 4 4 12 F d 98.0 = = = ππs () in 16 From Equation (2) () 4 22 F 4 12 44.1 () d ( ) in 4 D 44.1 98.0 53.1 = + = + = Equation (3) 16 s ππ From F 12 h = = = ( )( ) in 2.1 2.1 ds ππ 98.0 12 27.0 s From Equation (4) = = = ( )( ) Ds π πs 12 F t in 53.1 12 21.0 47 SECTION 1– DESIGN FOR SIMPLE STRESSES (c) Standard fractional dimensions d =1in 1 D in =1 1 2 = 4 1 = 4 h in t in 37. The same as 36, except that a shock load of 4000 lb. is repeatedly applied. Solution: (a) Same as 36. (b) N =10 ~ 15 for shock load, based on ultimate strength say N =15, others the same. 65 s su4 = = =ksi N s sus 15 49 N 15 3 = = = ksi s F = 4000 lb = 4 kips From Equation (1) () 444 F d 13.1 = = = ππs () in 4 From Equation (2) () 4 22 F () 44 d ( ) in D 44.1 13.1 76.1 = + = + = s ππ From Equation (3) h = = = ( )( ) 44.1 4 F 4 in 13.1 3 31.0 ds 2.1 2.1 ππ s From Equation (4) t F 4 = = = ( )( ) Ds π πs in 76.1 3 24.0 48 SECTION 1– DESIGN FOR SIMPLE STRESSES (c) Standard fractional dimensions 1 d in =1 8 3 =1 3 4 = 81 D in h in = t in 4 38. The connection between the plate and hook, as shown, is to support a load F . Determine the value of dimensions D , h , and t in terms of d if the connection is to be as strong as the rod of diameter d . Assume that D 2.1 d 1 = , us u s = 75.0 s , and that bending in the plate is negligible. Solution: s = F 1 d 4 π 2 1 F d s2 =π 4 = Ns 1π (1) F d2 u 4 49 SECTION 1– DESIGN FOR SIMPLE STRESSES = = F F s 1 Dd 1 ( ) ( ) 2 2 2 244.1 DD − ππ − 4 F (D d )s 2 2 1 1 4 = π − 444.1 =− Ns (2) ( 1π ) 22u FDd 4 F 44.1 == Dh sF = 2.1 π dhs F s s π1 dh 2.1 π = Ns s F dh us 75.0 u 2.1 π 2.1 π = dh N = Ns F dh 5 u (3) 9.0 π F s sπ = Dt = Dt F = π Dtss = us u F Dt 75.0 π π Ns = Ns (4) F Dt u 75.0 π s N Equate (2) and (1) =− Ns s 1π π () 1 22u2u FDd 4 22 Equate (3) and (1) 1 = Ns F dh u 2 u 9.0 π π D= 44.2 d 44.1 D = .1 N 562d = 4 d s d N = 4 d h .0 278 == () d 4 9.0 Equate (4) and (1) = Ns 1 s F Dt u 2 u d = 75.0 π π N 4 = Ns ( )( ) 1 s F d tu 2 u = d 75.0 π .1 562 π N d 4 t .0 214 = = d ( )( ) 4 75.0 .1 562 50 SECTION 1– DESIGN FOR SIMPLE STRESSES 39. (a) For the connection shown, set up strength equations representing the various methods by which it might fail. Neglect bending effects. (b) Design this connection for a load of 2500 lb. Both plates and rivets are of AISI C1020, as rolled. The load is repeated and reversed with mild shock. Make the connection equally strong on the basis of yield strengths in tension, shear, and compression. Problems 39, 40 Solution: (a) = 2 ss 5D 4 π D 5π4 Equatio F n (1) s −2 = Fs s = t( ) b D F Equation (2) D b=+2 F 1 ts F = s 5 Dt F Equation (3) Ds t 5 = (b) For AISI C1020, as rolled s ksi y = 48 (Table AT 7) s s ksi ys = 6.0 y = 28 N = 4 for repeated and reversed load (mild shock) based on yield strength 48 s 12 ksi == 4 28 s ksi s7 == 4 From Equation (1) 51 SECTION 1– DESIGN FOR SIMPLE STRESSES D 5π4 = Fs where F = 2500 lb = 5.2 kips ( ) 4 5.2 4 F s 5 π π say in D === () in 5 From Equation (3) s s 57 30.0 16 5.2 F = = say in t 13.0 5 in 5= Ds 5 5 16 ( ) 12 32 F 5.2 5 From Equation (2) = + = say 2 in b 96.1 2 = D in ts 5 32 ( ) 12 + 2 16 40. The same as 39, except that the material is 2024-T4, aluminum alloy. Solution: (a) Same as 39. (b) ) For 2024-T4, aluminum alloy s ksi y = 47 (Table AT 3) s s ksi ys = 55.0 y = 25 N = 4 for repeated and reversed load (mild shock) based on yield strength 47 s 12 ksi == 4 25 == s ksi s6 4 From Equation (1) D 5π4 Fs = where s F = 2500 lb = 5.2 kips ( ) 4 5.2 4 F π π say in 3 D === () in 5 56 s 33.0 s 8 From Equation (3) 52 SECTION 1– DESIGN FOR SIMPLE STRESSES 5.2 1 F = = say in t 11.0 in 5= Ds 5 From Equation (2) F 5.2 = + = say in b 42.2 2= D in ts 18 38 + ( ) 12 2 ( ) 12 8 3 8 1 2 2 41. (a) For the connection shown, set up strength equations representing the various methods by which it might fail. (b) Design this connection for a load of 8000 lb. Use AISI C1015, as rolled, for the rivets, and AISI C1020, as rolled, for the plates. Let the load be repeatedly applied with minor shock in one direction and make the connection equally strong on the basis of ultimate strengths in tension, shear, and compression. Problem 41. Solution: (a) P s − 34 F F P = or t( ) b D s 2 = Equation (1) − t( ) b D F 1 Equation (2) ssR = 42 4 D ()2 π 53 SECTION 1– DESIGN FOR SIMPLE STRESSES F Dt = Equation (3) R s 4 (b) For AISI C1015, as rolled s ksi uR = 61 , s s ksi usR uR = 75.0 = 45 For AISI C1020, as rolled s ksi uP = 65 N = 6, based on ultimate strength s suP 65 10 8. = = ksi P = N s suR 6 61 N s susR 6 45 N 6 2 5.7 .0 412 7 16 10 1. = = ksi R = sR 5.7 = = =ksi F = 8000 lb = 8 kips Solving for D F sR s π = 2 2DF 7 8 π π say in D === () in s 2 Solving for t F R s 4 = F Dt sR 16 1 8 = = say in t 4= .0 453 Ds R Solving for b F P s − = Using t( ) b D in 4 ( ) 10 1. 2 F 8 +=7 = + = say 2 in b D in ts P Using 12 ( ) 10 8. 34 F = − 16 92.1 P t( ) b D s 2 54 SECTION 1– DESIGN FOR SIMPLE STRESSES () 3 = = + = say 2 in b F 38 7 2 D in 4 ts P 1 4 2 ( ) 10 8. + 2 16 99.1 Therefore b = 2 in 7 D in = 16 = 2 1 t in 42. Give the strength equations for the connection shown, including that for the shear of the plate by the cotter. Problems 42 – 44. Solution: Axial Stresses 4 F F 2 s π = = Equation (1) 1 π D D 2 1 4 F 1 s −2 = Equation (2) ( ) L D e 55 SECTION 1– DESIGN FOR SIMPLE STRESSES F s = Equation (3) D e 2 4 F F s = − π = Equation (4) ()() π aD 2 − s 1 2 aD 2 2 2 F 2 4 4 F = π = 1 − π 2 DDe 2 DDe Equation (5) 4 − 2 2 2 2 4 Shear Stresses F eb = Equation (6) s s2 F s s −+ = 2 2 Equation (7) ( ) L D e t 56 SECTION 1– DESIGN FOR SIMPLE STRESSES F at s sπ = Equation (8) F Dm = Equation (9) s s π1 F Dh s s 22 = Equation (10) 43. A steel rod, as-rolled AISI C1035, is fastened to a 7/8-in., as-rolled C1020 plate by means of a cotter that is made of as-rolled C1020, in the manner shown. (a) Determine all dimensions of this joint if it is to withstand a reversed shock load F =10 kips , basing the design on yield strengths. (b) If all fits are free-running fits, decide upon tolerances and allowances. Solution: (See figure of Prob. 42) 7 = = , sy y t in .0 875 in 8 s = 6.0 s For steel rod, AISI C1035, as rolled s ksi y 55 1= s ksi sy 33 1= For plate and cotter, AISI C1020, as rolled s ksi y 48 2= s ksi sy 28 2= N = 5 ~ 7 based on yield strength say N = 7 From Equation (1) (Prob. 42) () N D s 41 F syπ == 4 10 7 πD 2 55 = 2 1 1 D 27.1 in 1 1 = 1 1= say D in 4 57 SECTION 1– DESIGN FOR SIMPLE STRESSES From Equation (9) s ssy == s 1 F 33 N 7 π 10 Dm1 = π m = 54.0 in 9 say m in 1 14 = m 16 From Equation (3) .1 273 D2e = From Equation (5) F s sy De2 1 ==N ==7 De2 s 10 55 sy 41 s == πN 2 F 4 DDe 2 D 80.1 in 2 = 3 1 2= say D in 4 and 273 .1 D2e 3 = 1= e e = 73.0 in 3 say e in By further adjustment 5 Say D 2 in 2 = , e in = 10 πD ()4 55 2 − 273 2− 7 2 4( ) .1 .1 273 4 = 4 = (8) From 8 Equation s ssy ==2 28 7 = πa F s πN at 10 ( ) .0 875 a = 91.0 in say a =1in 58 SECTION 1– DESIGN FOR SIMPLE STRESSES From Equation (4) sy− == () πN 4 10 ( ) 22 =π a 2 42 s F ( ) 22 aD 48 7 − a= 42.2 in 2 =2 21 =2 2 1 say a in use a in From Equation (7) s F sy s == 22 2 −+N ()LDet s 28 = 58 + 7 22L − L = 80.2 in 10 ( ) .0 875 say L = 3 in From Equation (6) 7 b = 2 in From Equation (10) s s 2N sy s 2 = = eb F 10 = 28 2 58 s ssy b == F 2 s 22 28 2( ) 2 D h 5 =7 h N 10 h in in = .0 8 625 = Summary of Dimensions L = 3 in 5 h in = 8 = 8 b=2 in 7 t in 59 SECTION 1– DESIGN FOR SIMPLE STRESSES 9 = m in 16 1 a in =2 2 = 8 1 1 1= D in 4 D 2 in 2 =5 e in (b) Tolerances and allowances, No fit, tolerance = ± .0 010 in L = 3 ± .0 010 in h = .0 625 ± .0 010 in t = .0 875 ± .0 010 in m = .0 5625 ± .0 010 in a = .2 500 ± .0 010 in D 25.1 .0 010 in 1 = ± For Free Running Fits (RC 7) Table 3.1 Female Male 0.2 .0 0030 0.2 .0 0040 −− −+ b in = b in = .0 0058 .0 0000 allowance = 0.0040 in .0 0030 .0 0040 0.2 0.2 2 2 −− −+ = D in = allowance = 0.0040 in D in .0 0058 .0 0000 .0 0016 .0 0020 .0 625 .0 625 + −− − e in = e in = .0 0030 .0 0000 allowance = 0.0020 in 44. A 1-in. ( D1) steel rod (as-rolled AISI C1035) is to be anchored to a 1-in. steel plate (as-rolled C1020) by means of a cotter (as rolled C1035) as shown. (a) Determine all the dimensions for this connection so that all parts have the same ultimate strength as the rod. The load F reverses direction. (b) Decide upon tolerances and allowances for loose-running fits. Solution: (Refer to Prob. 42) (a) For AISI C1035, as rolled s ksi u 85 1= s ksi us 64 1= For AISI C1020, as rolled 60 SECTION 1– DESIGN FOR SIMPLE STRESSES s ksi u 65 2= s ksi us 48 2= Ultimate strength Use Equation (1) 1 22 F s D ( ) ( ) kips u u 1 66 8. = π π 11 = 4 on (9) =π Fusus Equati D m 1 1 66 8. = (64)(π )(1)m m = 33.0 in 3 say m in 1 = 85 4 = 8 1 From Equation (3) F s D e uu21 = ( )D e2 66 8. = 85 .0 7859 D2e = From Equation (5) π F = s D − D e uu2 2 1 4 ( ) 66 8. 85 2 π D2 = − .0 7859 4 1 2 D 42.1 in 2 = 3 1 2= say D in 8 D e = e 2 1 .0 7859 3 = e = 57.0 8 = 16 in 9 say e in From Equation (4) 1 =− ( ) 2 2 Fusu π a D 2 () 2 2 4 1 66 8. 65 π a 2 = a= say a in 3 1 79.1 in − 8 3 4 =1 4 From Equation (8) 61 SECTION 1– DESIGN FOR SIMPLE STRESSES F s at u us π2 = 66 8. = (48)(π )(a)(1) a = 44.0 in 1 say a in = 2 3 use a in =1 4 From Equation (2) F s (L D )e u u 2 2 =− =− 169 3 ( ) 20.3 in 1 66 8. say L 65 L 1 in 8 L= 4 =3 From Equation (7) F s (L 3 D e)t 9 u = us − 2 − 2 2 66 8. 2 48 1 ()()1 =L−− 8 say L in L = 51.1 in 16 1 21 =1 use L in =3 4 From Equation (6) Fusus eb =2 = 169 b ( ) 66 8. 2 64 b = 93.0 in 1 say b =1in From Equation (10) Fusus D2h =2 1 = 83 h ( ) 66 8. 2 64 1 h = 38.0 in 3 say h in = 8 =3 4 Dimensions 1 L in 62 SECTION 1– DESIGN FOR SIMPLE STRESSES 3 = h in 8 b =1in t =1in 3 m in = 8 3 =1 4 = 16 a in D 1in 1 3 = 1 2= D in 8 9 e in (b) Tolerances and allowances, No fit, tolerance = ± .0 010 in L = 25.3 ± .0 010 in h = .0 375 ± .0 010 in t = .1 000 ± .0 010 in m = .0 375 ± .0 010 in a = 75.1 ± .0 010 in D .1 000 .0 010 in 1 = ± For Loose Running Fits (RC 8) Table 3.1 Female Male 0.1 0.1 .0 0035 .0 0045 −− −+ b in = b in = .0 0065 .0 0000 allowance = 0.0045 in .0 0040 .0 0050 .1 375 .1 375 2 2 −− −+ D in = D in = .0 0075 .0 0000 allowance = 0.0050 in .0 0028 .0 0035 .0 5625 .0 5625 −− −+ e in = e in = .0 0051 .0 0000 allowance = 0.0035 in 45. Give all the simple strength equations for the connection shown. (b) Determine the ratio of the dimensions a , b , c , d , m , and n to the dimension D so that the connection will be equally strong in tension, shear, and compression. Base the calculations on ultimate strengths and assume us u s = 75.0 s . 63 SECTION 1– DESIGN FOR SIMPLE STRESSES Problems 45 – 47. Solution: (a) Neglecting bending Equation (1): 1 =2 FsπD 4 Equation (2): =2 F s 2 c sπ 4 Equation (3): F = s(2bc) Equation (4): F = s(ac) Equation (5): F = s[2 (d − c)b] Equation (6): F s ( mb) s = 4 Equation (7): F s ( nb) s = 2 Equation (8): F = s(d − c)a (b) Ns su = and Ns sus s= Therefore s s s = 75.0 Equate (2) and (1) 1 = =2 2 F ss 2 π c s π D 1 4 1 1 4 2 = 4 1 2 2 75.0 s c s D c = .0 8165D Equate (3) and (1) 1 ( ) 2 == F s 2bc s π D 4 1 ()2 2b .0 8165D = π D 4 b = .0 4810D 64 SECTION 1– DESIGN FOR SIMPLE STRESSES Equate (4) and (1) = =2 F sac s π D 4 1 () 2 a .0 8165D = π D 4 a = .0 9619D Equate (5) and (1) 1 [ ] ( ) 1 = − =2 Fs2dcbsπD4 1 ( )( ) 2 2 d − .0 8165D .0 4810 = π D 4 d = .1 6329D Equate (6) and (1) 1 ( ) 2 == F ss 4mb s π D 4 1 ( )( ) 2 75.0 4m .0 4810D = π D 4 m = .0 5443D Equate (7) and (1) 1 ( ) 2 == F ss 2nb s π D 4 1 ( )( ) 2 75.0 2n .0 4810D = π D 4 n = .1 0886D Equate (8) and (1) 1 ( ) 2 =−= FsdcasπD 4 1 () 2 .1 6329 − D − .0 8165D a = π D4 a = .0 9620D Summary a = .0 9620D b = .0 4810D c = .0 8165D d = .1 6329D m = .0 5443D n = .1 0886D 65 SECTION 1– DESIGN FOR SIMPLE STRESSES 46. The same as 45, except that the calculations are to be based on yield strengths. Let s = 6.0 s . sy y Solution: (Refer to Prob. 45) (a) Neglecting bending Equation (1): 1 =2 FsπD 4 Equation (2): =2 F s 2 c sπ 4 Equation (3): F = s(2bc) Equation (4): F = s(ac) Equation (5): F = s[2 (d − c)b] Equation (6): F s ( mb) s = 4 Equation (7): F s ( nb) s = 2 Equation (8): F = s(d − c)a 1 (b) Ns = and y s Ns ssy s = Therefore s s s = 6.0 Equate (2) and (1) =2 2 F ss 2 π c s π D = 1 4 1 1 4 2 = 4 1 1 2 2 6.0 s c s D c = .0 9129D Equate (3) and (1) 1 ( ) 2 == F s 2bc s π D 4 1 ()2 2b .0 9129D = π D 4 b = .0 4302D Equate (4) and (1) = =2 F sac s π D 4 1 () 2 a .0 9129D = π D a = .0 8603D 4 66 SECTION 1– DESIGN FOR SIMPLE STRESSES Equate (5) and (1) 1 [ ] ( ) 2 =−= Fs2dcbsπD 4 ( )( ) 1 2 2 d − .0 9129D .0 4302 = π D 4 d = .1 8257D Equate (6) and (1) 1 ( ) 2 == F ss 4mb s π D 4 1 ( )( ) 2 6.0 4m .0 4302D = π D 4 m = .0 7607D Equate (7) and (1) 1 ( ) 2 == F ss 2nb s π D 4 1 ( )( ) 2 6.0 2n .0 4302D = π D 4 n = .1 5214D Equate (8) and (1) 1 ( ) = − =2 FsdcasπD 4 () 1 2 .1 8257 − D − .0 9129D a = π D 4 a = .0 8604D Summary a = .0 8604D b = .0 4302D c = .0 9129D d = .1 8257D m = .0 7607D n = .1 5214D 47. Design a connection similar to the one shown for a gradually applied and reversed load of 12 kips. Base design stresses on yield strengths and let the material be AISI C1040 steel, annealed. Examine the computed dimensions for proportion, making changes that you deem advisable. Solution: (See figure in Prob. 45 and refer to Prob. 46) 67 SECTION 1– DESIGN FOR SIMPLE STRESSES N = 4 based on yield strength for gradually applied and reversed load. For AISI C1040, annealed s ksi y = 47 (Fig. AF 7) s s ksi sy = 6.0 y = 28 47 s y s 11 75. = ksi == =2 FsπD4 N 4 1 =2 12 11 75. π D 4 D = 14.1 in 1 say D in a D 97.0 in = = =1 8 .0 8604 .0 8604 1 = 8 but a > D 1 say a in b 48.0 in = 1 .0 4302 say b in 1= 8 = 2 1 1 =1 4 1 say c =1in 81 d 05.2 in = say d = .1 8257 2 in 1= 8 = 1 c .1 030 in = 1= .0 9129 m 86.0 in = say m .0 7607 in 1= 8 7 8 1 1 n 71.1 in = 1= .1 5214 say n in 8 3 =1 4 =1 4 Dimension: 1 a in 68 SECTION 1– DESIGN FOR SIMPLE STRESSES 1 = b in 2 c =1in d=2 in 7 m in = 8 3 =1 4 1 =1 8 n in D in 48. Give all the strength equations for the union of rods shown. Problems 48 – 68. Solution: 1 =2 F s π d Equation (1) 4 F s ( ad ) = s π Equation (2) F s ( tc) s = 2 Equation (3) 69 SECTION 1– DESIGN FOR SIMPLE STRESSES F s [ (D e)b] = s2 Equation (4) − F = set Equation F = s(D − e)t Equation (6) (5) () 2 2 1 F s π k e Equation (7) =− 4 1 π Equation (8) ()() 22 F=sm−e−m−et4 F s ( ef ) s = 2 Equation (9) 70 SECTION 1– DESIGN FOR SIMPLE STRESSES 1 π Equation (10) F=se − et 2 4 49-68. Design a union-of-rods joint similar to that shown for a reversing load and material given in the accompanying table. The taper of cotter is to be ½ in. in 12 in. (see 172). (a) Using design stresses based on yield strengths determine all dimensions to satisfy the necessary strength equations. (b) Modify dimensions as necessary for good proportions, being careful not to weaken the joint. (c) Decide upon tolerances and allowances for loose fits. (d) Sketch to scale each part of the joint showing all dimensions needed for manufacture, with tolerances and allowances. Prob. No. Load, lb. AISI No., As Rolled 49 3000 1020 50 3500 1030 51 4000 1117 52 4500 1020 52 5000 1015 54 5500 1035 55 6000 1040 56 6500 1020 57 7000 1015 58 7500 1118 59 8000 1022 60 8500 1035 61 9000 1040 62 9500 1117 63 10,000 1035 64 10,500 1022 65 11,000 1137 66 11,500 1035 67 12,000 1045 68 12,500 1030 71 SECTION 1– DESIGN FOR SIMPLE STRESSES Solution: (For Prob. 49 only) (a) For AISI 1020, as rolled s ksi y = 48 s s ( ) ksi ys = 6.0 y = 6.0 48 = 28 8. For reversing load, N = 4 based on yield strength 48 s y s 12 = = ksi = s N s sys 4 28 8. N 4 2.7 = = = ksi F = 3000 lb = 3 kips Equation (1) =2 Fsπd4 =2 3 12 π d 4 d = .0 5642 in 9 say d in Equation (2) F s ( ad ) = s π = 169 ( ) a = .0 236 in 1 say a in Equation (5) F = set 3 =12et et = 25.0 Equation (10) 1 1 = 16 3 2.7 π a = 4 1 π F = s e − et 2 4 3 12 2 πe = − 25.0 4 e = .0 798 in 13 say e in 1 = 16 et = 25.0 72 SECTION 1– DESIGN FOR SIMPLE STRESSES 25.0 13 = 16 t t = ..0 308 in 5 say t in = Equation (6) F = s(D − e)t 13 3 12 D =− 165 16 D = .1 6125 in 5 say D in Equation (4) F s [ (D e)b] = s2 − =−b 8 =1 16 8 3 2.7 2 5 1 13 b = .0 say b in 256 in 1 16 4 = Equation (7) 1 ) 22 ( Fsπke =−4 1 3 12 π k = k = .0 989 in say k =1in Equation (9) F s ( ef ) s = 2 = 13 16 3 2.7 2 ()f f = .0 256 in 1 say f in Equation (8) 1 π 2 2 13 4 − 16 = 4 2 2 ()() F=sm−e−m−et 4 2 =− 165 1 2 3 12 πmm 4 16 13 −− 13 16 73 SECTION 1– DESIGN FOR SIMPLE STRESSES 25.0 .0 7854 .0 5185 .0 3125 .0 2539 2 =m−−m+ 2 m−m−= .0 7854 .0 3125 .0 5146 0 2 m−m−= .0 3979 .0 6552 0 m = .1 032 in say m =1in Equation (3) F s ( tc) s = 2 = 165 c ( ) 3 2.7 2 c = .0 667 in 11 say c in = 16 = 16 1 = 4 1 = 4 11 = 1 6 1 DIMENSIONS: 9 d in a in b in c in = f in 4 13 e in = 16 5 = 16 =1 8 = 16 1 = 4 3 = 4 11 = 16 t in k =1in 5 D in m =1in (b) Modified dimensions 9 d in a in b in c in 74 SECTION 1– DESIGN FOR SIMPLE STRESSES 1 = f in 2 13 e in = 16 5 = 16 =1 81 =1 4 t in k =1in 5 D in m in (c) Tolerances and allowances No fit, ± .0 010 in d = .0 5625 ± .0 010 in a = .0 250 ± .0 010 in f = .0 500 ± .0 010 in D = .1 625 ± .0 010 in k = .1 000 ± .0 010 in m = .1 250 ± .0 010 in Fits, Table 3.1, loose-running fits, say RC 8 Female Male .0 750 −+ .0 0035 b in = b in = .0 0000 allowance = 0.0045 in .0 0028 .0 6875 .0 6875 −− −+ c in = c in = .0 0000 allowance = 0.0035 in .0 0035 .0 8125 .0 8125 −− −+ = e in = e in .0 0000 .0 0022 .0 3125 .0 3125 −− −+ t in = t in = .0 0000 allowance = 0.0030 in .0 750 −− .0 0045 .0 0065 .0 0035 .0 0051 .0 0045 allowance = 0.0045 .0 0065 .0 0030 .0 0040 75 SECTION 1– DESIGN FOR SIMPLE STRESSES (d) ROD COTTER 76 SECTION 1– DESIGN FOR SIMPLE STRESSES SOCKET CHECK PROBLEMS 1 1 69. The connection shown has the following dimensions: d in 1 1 1 = , h in 5 D in = , t in 4 1 =2, 2 = 1 , D in = ; it supports a load of 15 kips. Compute the tensile, 2 8 2 compressive, and shear stresses induced in the connection. What is the corresponding design factor based on the yield strength if the rod and nut are made of AISI C1045, as rolled, and the plate is structural steel (1020)? 77 SECTION 1– DESIGN FOR SIMPLE STRESSES Problem 69. Solution: Tensile Stresses 15 F (1) ksi s 12 22. 1 = == 12 2 1 π 1 1 d 4 F 4 15 1 1 4 π (2) ksi s 4.8 2 = == 12 2 1 π πD 1 4 Compressive Stress F (3) s 78.4 3 = 4 2 15 = ksi () = 1 22 1 1 π 2 DD 2 1 1 4 − Shear 1 Stresse s F 4 π 15 2 − 2 2 (4) ksi ss82.3 4= π Dt π == 2 2 (5) ksi ss09.5 5= 1 1 2 F 15 == 2 π π Dh1 For AISI C1045, as rolled (rod and nut) s ksi y 59 1= s s ( ) ksi ys 6.0 y 6.0 59 35 4. 1= = = For structural steel plate (1020) s ksi y 48 2= s s ( ) ksi ys 6.0 y 6.0 48 28 8. 1= = = Solving for design factor 1 1 5 8 78 SECTION 1– DESIGN FOR SIMPLE STRESSES Ny 59 s (1) 83.4 1 ===1 12 22. 59 ss 1 Ny (2) 95.6 1 ===2 s s 2 s 78.4 s 49.8 48 Ny (3) 10 04. 2 ===3 3 ys 28 8. (4) 54.7 N 4= = = 2 s s 4 ys s 82.3 35 4. (5) 96.6 N 5= = = 1 s s 09.5 5 The corresponding design factor is N = 83.4 7 3 3 = , t in = , b in 70. In the figure, let D in 4 = 3 , and let the load, which is applied 16 4 centrally so that it tends to pull the plates apart, be 15 kips. (a) Compute the stresses in the various parts of the connection. (b) If the material is AISI C1020, as rolled, what is the design factor of the connection based on yield strengths? Problem 70. Solution: (a) Tensile stresses 15 F s 11 43. 1 = = () ksi t b D −= s 11 43. 2 = 34 F 16 7 − 434 4 3 ( ) 15 3 3 ksi = D ()tb = − 16 Compressive bearing stress − 2 7 3 3 4 2 3 4 F 15 4 16 s 11 43. 3 = == 3 ksi 7 4 Dt 4 79 SECTION 1– DESIGN FOR SIMPLE STRESSES Shearing stress F = 15 ss24.4 4 = () 4 π π 1 ()2 = 3 2 ksi 4 D 2 s Ny = or s N= ys 4 2 (b) For AISI C1020, as rolled s ksi y = 48 s s ksi ys = 6.0 y = 28 8. Ny s = Using s s ss Ny 48 s === 2.4 Using s N= 11.43 s ys s s N s === s 24.4 28 8. 8.6 Therefore the design factor is N = 2.4 s ys 15 9 3 1 71. For the connection shown, let a in = , b in 16 3 15 16 = , c in = , d in 4 =1 , 2 = , m n in D in 4 annealed (see Fig. AF 1). 16 = = . The material is AISI C1040, (a) For a load of 7500 lb., compute the various tensile, compressive, and shear stresses. Determine the factor of safety based on (b) ultimate strength, (c) yield strengths. Problem 71. Solution: (a) Tensile stresses 80 SECTION 1– DESIGN FOR SIMPLE STRESSES 5.7 F s 16 98. 1 = 12 ksi == 2 1 3 4 π D 4 F π 4 5.7 s 89.8 2 = = () ksi 2 bdc−= 2 16 − 9 1 1 5.7 2 4 F 3 s 10 67. 3 = = () ksi adc−= 15 − 16 1 1 3 2 4 Compressive Stresses (Bearing) F 5.7 9 16 3 ksi 4 s 89.8 4 = 2 bc 2 == 5.7 F s 10 67. 5 = = = ac 15 16 3 4 16 16 F 5.7 2 16 nb For AISI C1040, annealed,Fig. AF 1 s ksi y = 47 s ksi u = 79 s s ksi ys = 6.0 y = 28 16 ksi F Shearing 5.7 Stresses ss56.3 6= == 15 4 ksi 9 4 mb ss11.7 7= == 15 2 9 ksi s s ksi us u = 0.6 = 47.4 (b) Based on ultimate strength 79 s Nu === 65.4 1 s 16 98. (c) Based on yield strength 47 s Ny === 77.2 s 1 16 98. 72. The upper head of a 60,000-lb. tensile-testing machine is supported by two steel rods, one of which A is shown. These rods A are attached to the head B by split rings C. The test specimen is attached to the upper head B so that the tensile force 81