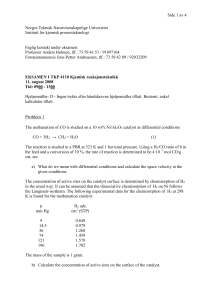

PENEX PROCESSES In worldwide production of automotive gasoline permanent tendency to the toughening of not only its operating but also its ecological characteristics is observed. So, international and domestic regulations to automotive gasoline considerably limit the content of benzene, aromatic hydrocarbons, olefin hydrocarbons and sulfur. In 1970s the variants of hydrogenation of the benzene, contained in the reformate, proceeding without the decrease of product octane number have been offered. However for decrease of the total aromatics content the dilution of reformate with high-octane nonaromatic components is required. This situation is complicated by refusal from tetraethyl lead (TEL) and deficit of butane-butylene fraction (because of the lack of FCC duty), which is used for the production of high-octane alkylate in the world practice. Thereby the development of isomerization process is one of the effective methods for solution of this problem. It allows the producing of commercial gasoline which corresponds to the current and perspective requirements to the fuels and provides necessary flexibility of processing. 1. TYPES OF ISOMERIZATION PROCESSES Three types of industrial isomerization processes are worked out currently: high-temperature isomerization process (360-440 °С) on fluorinated-alumina catalysts; medium-temperature isomerization process (250-300 °С) on zeolite catalysts; low-temperature isomerization process on chlorinated-alumina catalysts (120-180 °С) and sulfated metal oxides (180-210 °С ). 2. THERMODYNAMIC AND KINETIC LAWS OF ISOMERIZATION PROCESS The schemes of proposing processes are analogous generally. The differences are defines by performances of usable catalysts due to their type. Main parameter which is the octane number of produced isomerizate depends on process temperature. That‘s why we will dwell on the issue of thermodynamic of isomerization reaction. First of all hydrocarbons isomerization reaction is balanced reaction, and equilibrium yield of isoparaffins increases with temperature reducing, but it can be reached only after an ―infinite residence time‖ of the feed in reaction zone or an equivalent very small value for LHSV. On the other hand an increase in temperature always corresponds to an increase in reaction velocity. So that at low temperature the actual yield will be far below the equilibrium yield, because of low reaction velocity. On the contrary, at higher temperature, the equilibrium yield will be more easily reached, due to a high reaction rate. Consequently, at higher temperature the yield of isoparaffins is limited by the thermodynamic equilibrium, and at lower temperature it is limited by low reaction rate (kinetic limitation) (Figure3.1). The comparative estimation of isopentanes content in sum of pentanes for different types of isomerization catalysts is represented below (Figure 3.2). Figure 3.1. Dependence of n-paraffins conversion on reaction temperature Figure 3.2. Comparative estimation of isomerization catalysts The conversion level of n-paraffins on zeolite catalysts is low, as it is limited by thermodynamic equilibrium. In the case of chlorinated-alumina catalysts and sulfated metal oxides conversion of n-paraffins is higher because of high equilibrium content of isocomponents in product. 3. TECHNOLOGIES OF ISOMERIZATION PROCESS ON DIFFERENT CATALYSTS ZEOLITE CATALYSTS Zeolite catalysts are less active and used at higher operating temperature compared to another types of catalysts, and consequently the octane number of isomerizate is low. However they possess high resistance to impurities in the feed and capability for total regeneration in the reactor of the unit. The technological scheme of this process is provided with fire-heaters for heating hydrogen and feed mixture up to reaction temperature. It is necessary high ratio of hydrogen to hydrocarbon feed (along with isomerization, hydrogen is spent for hydrotreating and dearomatization of the feed); that‘s why compressor for supplying of recycle hydrogen-rich gas and separator for separation of hydrogen-rich gas are necessary . Hysopar catalyst should be marked out among zeolite catalysts; it is the most progressive in the world catalyst market, because it considerably exceeds all another catalysts by resistance to impurities in the feed (available sulfur content is 100 ppm permanently and 200 ppm during short periods of time) CHLORINATED-ALUMINA Chlorinated-alumina based catalysts are the most active and supply the highest isomerizate yield and isomerizate octane. It should be noted that during isomerization catalysts loose chlorine, consequently the activity is reduced. That‘s why chlorine compound injection to the feed (usually ССl4) is provided for keeping of high activity. As a result, caustic soda washing from organic chloride in special scrubbers is necessary. Considerable drawback is that this type of catalyst is very sensible to poisonous impurities (to the oxygen compounds including water, to nitrogen) and requires pretreatment and drying of the feed. In addition the problems occur at regeneration The first generation catalyst of UOP is I-8, which was improved later in more active I-80 type catalyst. The latest developments of UOP Company are high-performance I-8 Plus, I-82, I84 catalysts for Penex process and I-122, I-124 catalysts, which are used in Butamer process (nbutane isomerization process with purpose to produce isobutane, which is the feed for alkylation unit). In development of new catalysts UOP has the target to decrease its platinum content without losing the activity, thereby to reduce significantly its operating costs. It is not of small importance for present-day refinery. SULFATED METAL OXIDES BASED CATALYSTS Sulfated metal oxides based catalysts get heightened interest last years as they combine main advantages of medium-temperature and low-temperature catalysts. They are active, resistant to poisonous impurities and able for regeneration. The only drawback, as for zeolite catalysts, is necessity in compressor for recycling of hydrogen-rich gas. The CИ-2 catalyst has an activity, which is higher than activity of PI-242 [5] and characterized with unique sulfur resistance. If necessary, the process can be carried out without pretreatment of the feed. In this case the octane number of isomerizate is reduced by 2 points, but total lifetime (8-10 years) doesn‘t changes and service cycle is no less than 12 months. The feed may contain considerable quantity of benzene which is hydrogenated efficiently on the catalyst. The Pt/WO3-ZrO2 catalyst shows higher activity and selectivity in isomerization reaction of n-alkanes compared to sulfated-zirconia catalysts. The advantage of this type of catalyst is explained by rapid surface diffusion of hydrogen atoms, which are converted into protons and hydrides on the Lewes acid sites, thereby increasing catalyst activity and selectivity. TECHNOLOGIES SCHEMES OF ISOMERIZATION PROCESS Penex Process The Penex process has served as the primary isomerization technology for upgrading C5/C6 light straight-run naphtha feeds since UOP introduced it in 1958. This process has a wide range of operating configurations for optimum design flexibility and feedstock processing capabilities. The Penex process is a fixed-bed procedure that uses high activity chloridepromoted catalysts to isomerize C5/C6 paraffins to higher octane branched components. The reaction is conducted in the presence of a minor amount of hydrogen. Even though the chloride is converted to hydrogen chloride, carbon steel construction is used successfully because of the dry environment. For typical C5/C6 feeds, equilibrium will limit the product to 83 to 86 RON (Research Octane Number) on a single hydrocarbon pass basis. To achieve higher octane, UOP offers several schemes in which lower octane components are separated and recycled back to the reactors. These recycle modes of operation can lead to product octane as high as 93 RON. Hydrocarbon Once-Through Penex Process Hydrogen Once-Through Penex process flow scheme results in a substantial saving in capital equipment and utility costs by eliminating product separator and recycle gas compressor. The stabilizer separates the light gas from the reactor effluent (Fig3.3). Typically, two reactors in series are used to achieve high on-stream efficiency. The catalyst can be replaced in one reactor while operation continues in the other. One characteristic of the process is that catalyst deactivation begins at the inlet of the first reactor and proceeds slowly as a rather sharp front downward through the bed. The adverse effect that such deactivation can have on unit on-stream efficiency is avoided by installing two reactors in series. Each reactor contains 50% of the total required catalyst. Piping and valving are arranged to permit isolation of the reactor containing the spent catalyst while the second reactor remains in operation. After the spent catalyst has been replaced, the relative processing positions of the two reactors are reversed. During the short time when one reactor is off-line for catalyst replacement, the second reactor is fully capable of maintaining continuous operation at design throughput, yield, and conversion. Several factors are considered when choosing a process flow scheme. One of the most important aspects is desired product octane. The hydrocarbon once-through flow scheme is the most widely used isomerization process for producing moderate octane upgrades of light naphtha. Economically efficient ―onethrough‖ scheme without any recycle can be used with minimum investment in realization of isomerization process Figure (3.3). Figure (3.3) Block diagram of “one- through” process TABLE 3.2 Typical Estimated Yields for Once-through Processing Penex Process With Recycle And Fractionation Separation and recycle of unconverted normal C5 and C6 paraffins and low octane C6 isoparaffins back to the reactor, produce a higher octane product. The most common flow scheme uses a deisohexanizer (DIH) column to recycle methylpentanes, n-hexane, and some C6 cyclics. It is the lowest capital cost option of the recycle flow schemes and provides a higher octane isomerate product, especially on C6 rich feeds. In the Penex/DIH process the stabilized isomerate is charged to a DIH column producing an overhead product containing all the C5 and dimethylbutanes. Normal hexane and some of the ethylpentanes are taken as a side-cut and recycled back to the reactors. The small amount of bottoms (C7+ and some C6 cyclics) can be sent to gasoline blending or to a reformer. The addition of a deisopentanizer (DIP) or a super DIH will achieve the highest octane from a fractionation hydrocarbon recycle flow scheme. In this scheme, both low octane C5 and normal and isoparaffin C6 are recycled to the Penex reactors . The scheme with deisopentanizer (DIP) before the reactor section allows the producing of isomerizate with high octane number, increasing of conversion level of n-pentanes and reducing the reactor duty simultaneously. The technology is reasonable in the case of isopentanes content in the feed more than 13-15 % Figure (3.4) Figure (3.4) Block diagram of process with DIP The scheme with deisohexanizer (DIH) after the isomerization reactor is the simplest way to produce the isomerizate with higher octane number. In this case non-converted low-octane components (methylcyclopentane and n-hexane) are recycled into reactor. However the given scheme allows only increasing of hexanes conversion, but doesn‘t raise the content of isopentanes in the product (Figure 3.5). The scheme of the process may include both deisopentanizer and deisohexanizer (with DIP and DIH) Figure (3.5) Block diagram of process with DIH TABLE 3.3 Typical Estimated Yields for Deisohexanizer Processing Scheme with recycle of n-pentane (with DIP and DP) requires providing with depentanizer of isomerizate after the reaction section and deisopentanizer before the reactor. Schemes with recycle of n-pentane and n-hexane. For total conversion of all linear paraffins (not only n-С6 but also n-С5) into isomers, their total recycle is necessary which can be realized by set of distillation columns (with DIP, DIH and DP) or by adsorption on molecular sieves. The method of adsorption on molecular sieves (in liquid or vapor phase) is based on capability of pores with definite size to adsorb selectively the molecules of n-paraffins. The next stage is desorption of n-paraffins from pores and its recycle to the feed stock. Stages of adsorption and desorption are repeated in cycles or pseudo-continuously. Penex / Molex Process This flow scheme uses Molex technology for the economic separation and recycle of nparaffin from the reactor effluent. The Molex process is an adsorptive separation method that utilizes molecular sieves for the separation of n-paraffins from branched and cyclic hydrocarbons. The separation is effected in the liquid phase under isothermal conditions according to the principles of the UOP Sorbex separations technology. Because the separation takes place in the liquid phase, heating, cooling and power requirements are remarkably low. Sorbex is the name applied to a particular technique developed by UOP for separating a component or group of components from a mixture in the liquid phase by selective adsorption on a solid adsorbent. In broad outline, Sorbex is a simulated moving bed adsorption process operating with all process streams in the liquid phase and at constant temperature within the adsorbent bed. Feed is introduced and components are adsorbed and separated from each other within the bed. A separate liquid of different boiling point referred to as ‗desorbent‘ is used to displace the feed components from the pores of the adsorbent. Twoliquid streams emerge from the bed – an extract and a raffinate stream, both diluted with desorbent. The desorbent is removed from both product streams by fractionation and is recycled to the system. A simplified schematic flow diagram of a gasoline Molex unit is shown in Fig. 3.6. The adsorbent is fixed while the liquid streams flow down through the bed. A shift in the positions of liquid feed and withdrawal, in the direction of fluid flow through the bed, simulates the movement of solid in the opposite direction. It is, of course, impossible to move the liquid feed and withdrawal points continuously. However, approximately the same effect can be produced by providing multiple liquid access lines to the bed, and periodically switching each net stream to the next adjacent line. A liquid circulating pump is provided to pump liquid from the bottom outlet to the top inlet of the adsorbent chamber. A fluid-directing device, known as a ‗rotary valve‘, is also provided. The rotary valve functions on the same principle as a multiport stopcock. Figure (3.6) Block diagram of Penex/Molex process TABLE 3.4 Typical Estimated Yields for Molex Processing UOP offers the processes with adsorption systems on the molecular sieves in vapour phase (Penex/Iso Siv) and liquid phase (Penex/Molex (Figure 3.9)), and process, which combines adsorptive separation of unconverted n-paraffins from isomers and deisohexanizing Penex/DIH/PSA. Penex-Plus technology, which is for processing of the feed with high benzene content (from 7 up to 30 % vol. in the case of light straight-run gasoline fraction and light reformate blend), includes feed treatment section which is hydrogenation of benzene. TABLE 3.5 TYPICAL PENEX ESTIMATED INVESTMENT COST TABLE 3.6 TYPICAL PENEX ESTIMATED UTILITY REQUIRMENT TABLE 3.7 TYPICAL PENEX ESTIMATED OPERATING REQUIRMENTS PENEX FLOW DIAGRAM DISCRIPTION FEEDSTOCK REQUIREMENTS To maintain the high activity of the Penex catalyst, the feedstock must be hydrotreated. However, costly pre-fractionation to sharply limit the levels of C6 cyclic and C7 compounds is not required. In fact, the Penex process affords the refiner with remarkably good flexibility in the choice of feedstocks, both at the time of design and even after the unit has been constructed. The latter is important because changes in the overall refinery processing scheme may occur in response to changing market situations. These changes could require that the composition of the isomerization feed be modified to achieve optimal results for the entire refinery. The Penex system can be applied to the processing of feeds containing up to 15 percent C7 with minimal or no effect on design requirements or operating performance. Generally, the best choice is to operate with lower levels of C7+ material because these compounds are better suited for upgrading in a reforming process. Charge containing about 5.0 percent or even higher amounts of benzene is completely acceptable in the Penex chargestock and will not produce carbon on the catalyst. When the feed has extremely high levels of benzene, a Penex-Plus unit is recommended. (The ―Plus‖ section can be retrofitted to an existing Penex unit should the refiner want to process high-benzene feedstock in an existing Penex unit.) The low-octane C6 cut recovered from raffinate derived from aromatic extraction operations typically contains a few percent of olefins and is completely acceptable as Penex feed without pre-hydrogenation. Sulfur is an undesirable constituent of the Penex feed. However, it is easily removed by conventional hydrotreating. Sulfur reduces the rate of isomerization and, therefore, the product octane number. Its effect is only temporary, however, and once it has been removed from the plant, the catalyst regains its normal activity. Water, other oxygen-containing compounds, and nitrogen compounds are the only impurities normally found in the feedstock that will irreversibly poison the Penex catalyst and shorten its life. Fresh feed and makeup hydrogen are dried by a simple, commercially proven desiccant system. PROCESS FLOW DIAGRAM The UOP Penex Unit can be divided into ten sections. A. Sulfur Guard Bed B. Liquid Feed Driers C. Makeup Hydrogen Driers D. Feed Surge Drum E. Exchanger Circuit F. lsomerization Reactors G. Stabilizer H. Stabilizer Gas Scrubber I. Separator and Compressor Section (Recycle Gas Units Only) FIGURE 4.1 PENEX FLOW DIAGRAM A. SULFUR GUARD BED The purpose of the sulfur guard bed is to protect the Penex catalyst from sulfur in the liquid feed. The hydrotreater will remove most of the sulfur in the Penex feed. The guard bed reduces the sulfur to a safe level for H.O.T. Penex operation and serves as insurance against upsets in the NHT which could result in higher than normal levels of sulfur in the feed. The guard bed is loaded with UCP ADS-11 adsorbent, a nickel- containing extrudate designed to chemisorb sulfur from the liquid feed. The feedstock is heated to the required temperature for sulfur removal, usually 250°- (120°C) and passed down flow over the adsorbent. Once sulfur breakthrough occurs, normally after one year or so of operation, the guard bed is taken off line and reloaded with fresh adsorbent. The Penex Unit need not be shut down during the short period of time required to reload the guard bed so long as the NHT is performing properly. B. LIQUID FEED DRIERS The liquid feed driers are used to dry the Penex liquid feed to less than 0.1 ppm H20. The piping is designed so that either drier can be in the lead or the lag position in series flow operation. Either drier can be operated individually while the other is being regenerated. The driers are designed for a 48 hour cycle which includes 24 hours in the lead position, 7 hours regenerating, and 3 hours cooling and 14 hours in the lag position. Proper drier operations are essential in the Penex process since the catalyst is water intolerant. Typically, type 4A molecular sieves are employed within the driers. Charge to the liquid feed driers is hydrotreated LSR naphtha from the Naphtha hydrotreater stripper bottoms. Additional recycle feed from a Molex unit or deisohexanizer may be added in the future. Liquid feed is pumped to the driers on flow control at 100°F (38°C). The low temperature must be maintained for proper drying. Feed enters the lead drier, passes up flow through it, crosses over to the bottom of the lag drier, passes up flow through it and is routed to the cold combined feed exchanger in the reactor section. The lead drier removes water from the feed to less than 0.1 wppm. The lag drier acts as a guard bed. It reduces the water content even further but is essentially in standby until 1.0 wppm H20 breaks through the lead drier (or until the scheduled regeneration period arrives). The water content is continuously monitored with a Parametric moisture analyzer. This analyzer will always be used to monitor the lead drier effluent. If the lead drier effluent reaches 1.0 wppm H20 content, it must be taken off line and immediately regenerated. The previous lag drier then becomes the lead drier. On completion of the regeneration, series flow is re-established with the regenerated drier now in the lag position. See the liquid feed drier regeneration procedure for details of the regeneration. C. MAKEUP HYDROGEN DRIERS The makeup hydrogen driers are used to dry the Penex unit makeup hydrogen to less than 0.1 ppm H20. The function and design of these driers is very similar to the liquid feed driers. Again, two vessels with interconnecting piping are used. the piping is designed so that in series operation either drier can be in the lead or the lag position and so that either drier can be operated individually. while the other is being regenerated. The driers are designed for a 48 hour cycle with includes 24 hours in the lead position, 6 hours regenerating, 4 hours cooling and 14 hours in the lag position. These driers, too, are essential for good Penex operations since the I-8 catalyst is water intolerant. Type 4A molecular sieves are normally employed within the driers. Makeup hydrogen to the driers comes from the Platforming unit at 100°F. (38°F). The actual makeup rate will vary with chemical consumption due to benzene saturation, ring opening and hydrocracking. The makeup gas flow rate is controlled by the H2O/HCBN ratio controller on the fresh feedstock. The ratio is adjusted to maintain excess hydrogen at the reactor outlet. The incoming gas passes up flow through the lead driers, crosses over to the bottom of the lag drier and passes up flow through it to the cooler in the separator and compressor section. Like the liquid feed driers, the lead makeup gas drier removes water from the makeup hydrogen to less than 0.1 wppm The lag drier acts as a guard bed until 1.0 ppm H20 breaks through the lead drier. Water content is continuously monitored with a moisture analyzer. This analyzer will always be used to monitor the lead drier effluent. If the lead drier effluent reaches 1.0 ppm H20 contend it must be taken off line and regenerated. The previous lag drier becomes the lead drier. On completion of the regeneration, series flow is re-established with the regenerated drier now in the lag position. See the makeup hydrogen direr regeneration procedure. for the details of the regeneration. D. FEED SURGE DRUM The purpose of this drum is to provide liquid feed surge capacity for the Penex Unit. Dried feed from the liquid feed driers is routed to this drum. A The feed surge drum is blanketed with dry hydrogen gas originating from the outlet of the make-up gas driers with the feed surge drum pressure being controlled by a PRC. E. EXCHANGER CIRCUIT The dried liquid feed from the feed surge drum is pumped by either of the two reactor charge pumps through the reactor exchanger circuit on flow control. The reactor exchanger circuit consists of the cold combined feed exchanger, the hot combined feed exchanger, and the reactor charge heater. Prior to the entry of the liquid hydrocarbon into the cold combined feed exchanger, it combines with the makeup hydrogen stream. After combining, the mixed hydrocarbon-hydrogen stream passes through the exchanger circuit in the order previously mentioned.. After the makeup gas combines with the feed a small quantity of catalyst promoter (CCI4) is added. This promoter is pumped into the process either of the- two injection pumps. The catalyst promoter is stored in a nitrogen blanketed storage drum. The cold combined feed exchanger is equipped with a bypass which can be used to regulate the amount of combined feed preheat. The bypass is regulated with a board mounted control valve. The combined feed is finally brought up to the desired temperature in the reactor charge heater by a temperature controller which resets the exchangers heating medium flow. The charge heater is equipped with an automatic shutdown which is activated by low feed or low makeup gas flow. After exiting the reactor charge heater, the heated combined stream then flows to the first reactor. F. ISOMERIZATI ON REACTORS The reactors are the heart of the process. The operation of them is such that a reactor will be placed in series with the other reactor. At various times throughout the unit‘s history it will be possible to have either reactor in the lead or tail position. Thermocouples are inserted into the catalyst bed of each reactor to monitor the activity of the catalyst. After exiting the reactor charge heater, the heated combined stream then flows to the first reactor. Upon exiting the first reactor, the stream then passes to the hot combined feed exchanger where the first reactor‘s heat of reaction is partially removed. The degree of temperature removal can be achieved by adjusting the amount of exchanger bypassing with a temperature controller.The partially cooled stream is then routed to the second reactor where the final process reactions are completed. The reactors are equipped with hydrogen purge lines which are located at the inlet of each reactor. The hydrogen purge is used to remove hydrocarbon from a reactor which is to be unloaded or to cool a reactor during an emergency. Each purge is controlled by a board mounted flow controller. In case of a high reactor temperature emergency the reactors are equipped with depressuring lines to the flare system. The reactors are depressured from the outlet of the lag reactor. The depressuring line is equipped with two motorized valves which can be operated from the control room. After exiting the second reactor, the stream is then routed to the tube side of the cold combined feed exchanger. The cold combined feed exchanger tube side effluent is then routed to the stabilizer on pressure control. G. STABILIZER The purpose of this column is to separate any dissolved hydrogen, HCl and cracked gases (C1, C2, and C3‘s) from the isomerate.The feed to this column is routed hot directly from the cold before entering the stabilizer.The column is reboiled by either steam or hot oil. The reboiler heat input is controlled by a FRC on the heating medium. The stabilizer column overhead vapor, consisting of the light hydrocarbon components of the column‘s feed, is routed to an air or water cooled condenser and then to the stabilizer receiver. To maintain pressure control on the column, gas is vented on pressure control to the stabilizer gas scrubber. Liquid is pumped from the receiver on level control with the stabilizer reflux pump. All liquid from the stabilizer overhead receiver is refluxed to the column on tray No. 1. Bottoms product is routed to storage on level control after first being cooled in the stabilizer bottoms cooler. If the stabilizer bottoms is sent to a Deisohexanizer it is not cooled, but is charged hot to the column. Part of the stabilizer bottoms is used for regenerating the driers. H. STABILIZER GAS SCRILIBBER The stabilizer off gas flows up flow through the stabilizer gas scrubber to remove hydrogen chloride. The scrubbed gas leaves the top of the vessel and goes to fuel gas on backpressure control. The hydrogen purity is monitored on the scrubbed off gas to determine the moles of H2 leaving the system for the H2/C:H determination. Make-up caustic is pumped from the refinery to the reservoir section of the gas scrubber when caustic addition is required. The caustic in the reservoir section is pumped by the caustic recirculating pumps to the top of the scrubbing section of the scrubber where a counter current contact with the rising acidic gas is made. Caustic is also continuously circulated to the distributor under the packed section. The flow rate of the circulating caustic can be monitored by a local flow indicator. Periodically a portion of the caustic is withdrawn to the refinery spent caustic facilities as spent caustic. The caustic level in the scrubber is maintained about 1-2 feet below the distributor under the packed section. I. SEPARATOR AND COMPRESSOR SECTION (Recycle Gds Units Only) The separator and compressor section separates the reactor effluent into unstabilized liquid product and recycle gas. The separator pressure is controlled by regulating the makeup hydrogen flow rate. The equipment in this section is: the reactor product condenser, the product separator, the recycle gas compressor, and if required, the make-up gas compressor suction drum, and the make-up gas compressor. In a Hydrogen Once Through Unit the product condenser, product separator and recycle compressor are not used. In this unit the pressure in the reactor circuit is controlled using a back pressure value on the stabilizer feed line. Reactor effluent exits the reactor section and is partially condensed in the reactor product condenser. It cools the effluent to about 100°F. The cooled liquid and gas then separate in the product separator. Unstabilized liquid product is pressured out of the product separator on level control to the stabilizer section. Recycle gas exits from the separator and goes through the recycle gas compressor to the cold combined feed exchanger in the reactor section. Recycle gas flow is controlled by a flow indicating controller which spills back to the product separator (through the reactor product cooler), thereby controlling the amount sent forward. Recycle gas flow and purity are controlled to maintain hydrogen to hydrocarbon mole ratio of about 2:1. Dry make-up hydrogen, from the make-up hydrogen drier section, combines with spillback from the make-up gas compressor. These gases pass through the make-up gas cooler and into the makeup gas compressor suction drum. Any entrained hydrocarbons are knocked out and are manually drained to an appropriate location. The make-up gas is compressed and combined with the recycle gas to the reactor section. Make-up gas flow is controlled by the product separator pressure recorder controller. PROCESS CHEMISTRY REACTION MECHANISMS Paraffin isomerization catalysts fall mainly into either of two principal categories: (1) those based on Friedel-Crafts catalysts as classically typified by aluminum chloride/hydrogen chloride, or (2) dual-function hydro-isomerization catalysts. No attempt is made to present a discussion of mechanisms of a degree of sophistication acceptable to a chemist specializing in the area. The intention is simply to provide those practicing engineers who have not previously had reason to consider isomerization with a basic introduction to the subject. Isomerization by either Friedel-Crafts or duals function catalysts is generally thought to entail intramolecular rearrangements of carboniumions as illustrated - for pentane: (1) CH3-CH-CH2-CH2-CH3 CH3-C2H3-CH2-CH3 There appear to be two schools of thought regarding the Friedel-Crafts mechanism. Perhaps each mechanism is operative and the disagreement is merely over their relative importance under specific circumstances. Friedel-Crafts isomerization is believed by some to require the presence of traces of olefins or alkyl halides as carbonium ion initiators, with the reaction thereafter proceeding through chain propagation. The initiator ion, which needs to be present in small amounts only, may be formed by the addition of HCl or HAlCI4 to an olefin, which is present in the paraffin as an impurity or which is formed by cracking of the paraffin: (2) RCH=CH2 + HAlCl4 RCHCH3 + AlCl4 The initiator then forms a carbonium ion from the paraffin to be isomerized: (3) RCHCH3 + CH3-CH2-CH2-CH2- CH3 RCH2CH3 + CH3-CH-CH2CH2-CH3 Skeletal rearrangement then occurs: (4) CH3-CH-CH2CH2-CH3 CH3-C-CH3-CH2-CH3 Isopentane is then formed and the chain propagated by the generation of a New normal carbonium ion: (5) CH3-CCH3-CH2CH3 + CH3-CH2-CH2-CH2-CH3 CH3-CH-CH2-CH3 + CH3-CH-CH2CH2-CH3 Naturally, the same sequence could have been illustrated starting with Isopentane and ending with n-pentane and an iso-carbonium ion to propagate The chain, i.e. reactions (3), (4), and (5) are reversible, as are all of the Reactions to be shown later. The composition of the final mixture is, of course, that set by thermo-dynamic equilibrium, assuming that sufficient reaction time has been provided. Another Friedel-Crafts route which has been suggested is direct hydride ion abstraction: (6) CH3-CH2-CH2-CH2-CH3 + AlCl3 CH3-CH-CH2-CH2-CH3 + HAlCl3 The carbonium ion, as before, rearranges (7) CH3-CH-CH2-CH2-CH3 CH3-C -CH2-CH3 Finally, iso-pentane is formed: (8) CH3-C-CH2-CH3 + HAlCl3 CH3-CH-CH2-CH3 + AlCl3 Abstraction of the hydride ion is energetically favored by the fact that the aluminum atom can thereby complete its electron octet. Since there is always some hydrogen chloride present, either by design or from hydrolysis of aluminum chloride by traces of water, a Bronsted (protonic) acid could have been shown for Reactions (6) and (8) instead of a Lewis acid: CH3-CH-CH2-CH2-CH3 (AlCl4)- +H2 (9) CH3-CH2-CH2·CH2CH3 + H + AlCl4 Some chemists feel uncomfortable with the above because of the required postulation of hydrogen formation. The dual-function hydro-isomerization catalysts are thought by some to operate through an olefin intermediate whose formation is catalyzed by the metallic component, assumed for illustration purposes to be platinum: (10) CH3-CH2-CH2CH2CH3 CH3-CH2CH2CH=CH2 + H2 This reaction is, of course, reversible and, since these catalysts are employed under substantial hydrogen pressure, the equilibrium is far to the left. However, the acid function of the catalyst consumes the olefin by formation of a carbonium ion and thus permits more olefin to form despite the unfavorable equilibrium. This step is entirely analogous to Reaction (2) shown for Friedel- Crafts, except that it is better to denote the acid function by a more general. (11) CH3-CH2-CH2—CH=CH2 + H + A- CH3-CH2-CH2-CH-CH3 + A- The usual rearrangement ensues: (12) CH3-CH2-CH2-CH-CH2 CH3-CH2CCH3-CH3 The is olefin is then formed by the reverse analogue of (11): (13) CH3-CH2C CH3-CH3 + A- CH3-CH2-C=CH2 + H + A- The iso-paraffin is finally created by hydrogenation: (14) CH3-CH2-CCH3=CH2 + H2 CH3-CH2-CHCH3-CH3 Those dual—functi0nal hydro-isomerization catalysts which operate at very low temperatures have stronger acid sites than those which require higher temperatures. In this case it is possible that the necessary carbonium ion is formed by direct hydride ion abstraction from the paraffin by the acid function of the catalyst: (15) CH3-CH2-CH2CH2CH3 + H+A(16) CH3-CH-CH2-CH2-CH3 (17) CH3-CCH3-CH2·CH2 + A-+H2 CH3-CHCH2-CH2-CH3 + A- + H2 CH3-CCH3-CH2-CH3 CH3-CH-CH2-CH3 + H+A The last reaction is in lieu of the displacement type chain propagation step (Reaction 5) discussed earlier. Since the reaction with hydrogen is relatively fast, acid sites are readily liberated for further reaction. This may account, at least in part, for the higher activity of such dual functional catalysts. Equilibrium limits the maximum conversion possible at any given set of conditions. This maximum is a strong function of the temperature at which the conversion takes place. A more favorable equilibrium exists at lower temperatures. Figure 5.1 shows the equilibrium plot for the pentane system. The maximum isopentane content increases from 64 mol % at 260°C to 82 mol % at 120°C (248°F). Neopentane and cyclopentane have been ignored because they seem to occur only in small quantities and are not formed under isomerization conditions. The hexane equilibrium curve shown in Fig. 5.2 is somewhat more complex than that shown in Fig. 5.1. The methylpentanes have been combined because they have nearly the same octane rating. The methylpentane content in the C6-paraffin fraction remains nearly constant over the entire temperature range. Similarly, the fraction of 2,3-dimethylbutane is almost constant at about 9 mol % of the C6 paraffins. Theoretically, as the temperature is reduced, 2,2dimethylbutane can be formed at the expense of normal hexane. This reaction is highly desirable because nC6 has a RON of 30. The RON of 2,2-dimethylbutane is 93. Of course, the petroleum refiner is more interested in octane ratings than isomer distributions. Figure 5.3 shows the unleaded research octane ratings of equilibrium mixtures plotted against the temperature characteristic of that equilibrium for a typical Chargestock. Both the C5 and the C6 paraffins show an increase in octane ratings as the temperature isreduced. FIGURE 5.1. C5 Paraffin Equilibrium Plot. FIGURE 5.2. C6 Paraffin Equilibrium Plot. FIGURE 5.3 Unleaded RON Ratings Of Equilibrium Fractions. Because equilibrium imposes a definite upper limit on the amount of desirable branched isomers that can exist in the reactor product, operating temperatures are thought to provide a simple basis for catalyst comparison or classification. However, temperature is only an approximate comparison that at best can discard a catalyst whose activity is so low that it might be operated at an unfavorably high temperature. Further, two catalysts that operate in the same general low-temperature range may differ in the closeness with which they can approach equilibrium in the presence of reasonable amounts of catalyst. B. ALUMINIUM CHLORIDE The isomerization catalysts employed during World War Il were all of the Friedel-Crafts type. Those which contained aluminum chloride only were either a hydrocarbon/aluminum chloride complex (the so-called sludge process) or they were manufactured in deposition onto a support such as alumina or bauxite. They were intended to operate at very low temperatures (120-2650F) and to approach the very favorable equilibrium composition characteristic of these temperatures. The catalyst tended to consume itself by reaction with the feedstock and/or product. When temperature was raised a little in an effort to compensate for loss of catalyst and to speed the reaction to effect more isomerization, light fragments were formed by cracking and these, when vented, caused an excessive loss of the HCl promoter. Corrosion of downstream equipment was also commonplace, due to the solubility of aluminum chloride in hydrocarbon, to its relatively high volatility and to the difficulty of removing it from the product by caustic washing. Aluminum chloride deposition in and plugging of reboiler tubes was not uncommon. The process faced problems in sludge disposal which were considered onerous even before the present acute awareness of environmental factors developed, The fixed bed process sometimes experienced unpredictable amounts of isomerization. C. HYDRO-ISOMERIZATI ON CATALYSTS (ABOVE 390 0F) The operational problems which had characterized the wartime Friedel- Crafts type isomerization plants, the advent of catalytic reforming which not only made hydrogen generally available in refineries but also demonstrated the practicality of using noble metal containing catalysts on a large scale, and the octane number race which postwar high compression engines initiated all combined in the 1950‘s to spawn a spate of hydro-isomerization processes. These catalysts generally contained a noble metal and some halide, operated at temperatures between about 560°F and temperatures approaching those characteristic of catalytic reforming, employed recycle hydrogen to prevent catalyst carbonization and utilized either no promoter or traces at most. In general, they did not require an especially dry feedstock but did benefit from a low sulfur content feedstock. Most achieved a close approach to the equilibrium characteristic of their particular operating temperature. Because of their high operating temperatures and their necessarily low conversions to iso-paraffins, these high temperature catalysts were quickly replaced with the advent of the "third generation" low temperature catalysts. D. HYDRO·ISOMERIZATI ON CATALYSTS (BELOW 390 °F) ―Low temperature‖ is considered rather arbitrarily for catalyst classification purposes as anything below 390°F operating temperature. Typically these are fixed bed catalysts containing a supported noble metal and a component to provide acidity in the catalytic sense. They operate in a hydrogen atmosphere and may employ a catalyst promoter whose concentration in the reactor may range from parts per million to substantially higher levels. They generally all require a dry, low sulfur feedstock; however, they may differ importantly in their tolerance of certain types and molecular weights of hydrocarbons. Hydrocracking to light gases is generally slight, so liquid product yields are high. The type of catalyst used in the Penex unit is of this type. Apart from the paraffin isomerization reactions which were discussed in detail in the proceeding pages, there are several other important reactions including: 1. Naphthenes Ring Opening: Penex feeds can contain up to 30% naphthene rings. The three Naphthenes which are typically present in Penex feed are cyclopentane (CP), methyl cyclopentane (MCP) and cyclohexane (CH). The naphthene rings will hydrogenate to form paraffins. This ring opening reaction increases with increasing reactor temperature. At typical Penex reactor conditions, the conversion of naphthene rings to paraffins will be on the order of 20-40 percent. 2. Naphthenes Isomerization: The Naphthenes MCP and CH exist in equilibrium. Naphthene isomerization will shift towards MCP production as temperature is increased. 3. Benzene Saturation: Penex feeds can contain up to 4% benzene. The catalyst will saturate benzene to cyclohexane. The catalyst-will saturate benzene to cyclohexane. This reaction proceeds very quickly and is achieved at very low temperatures. Saturation of benzene is not equilibrium limited at Penex conditions and conversion will be 100%. The saturation of benzene produces heat. This heat generation limits the amount of benzene which can be tolerated in the Penex feed. The platinum function on the Penex catalyst is responsible for benzene saturation. . Hydrocracking; Hydrocracking occurs in the Penex reactor to a degree which depends on the feed quality and severity of operation. Large molecules such as C7‘s tend to hydrocrack more easily than smaller molecules. C5 and C5 paraffins will also hydrocrack to a certain extent. As C5/C7 paraffin isomerization approaches equilibrium, the extent of hydrocracking increases. If isomerization is pushed too hard, hydrocracking will reduce the liquid yield and increase heat production. Methane, ethane, propane and butane are produced as a result of hydrocracking. The various Penex Unit reactions are illustrated as under: PARAFFIN ISOMERIZATION NORMAL HEXAHE CH3-CH2-CH2-CH2-CH2-CH3 24.8 ron 2 METHYL PENTANE CH3 CH3-CH-CH2-CH2-CH3 0 73.4 ron 3 METHYL PENTANE CH3 CH3-CH2-CH2-CH2-CH2-CH3 24.8 ron CH3-CH2-CH-CH2-CH3 74.5 ron 2-2 DIMETHYL BUTANE CH3 CH3-CH2-CH2-CH2-CH2-CH3 24.8 ron CH3-C-CH2-CH3 CH3 91.8 ron 2-3 DIMETHYLBUTANE CH3 CH3-CH2-CH2-CH2-CH2-CH3 24.8 ron CH3-CH-CH-CH3 CH3 104.3 ron PARAFFIN ISOMERIZATION NORMAL PENTANE CH3-CH2-CH2-CH2-CH3 61.8 ron ISO PENTANE CH3-CH-CH2-CH3 CH3 93.0 ron HYDROCRACKING NORMAL HEPTANE PROPANE + BUTANE CH3 CH3-CH2-Ch2-CH2-CH2-CH2-CH3 + H2 CH3-CH2-CH3 + CH3-CHCH3 ACIDIZING Hydrogen Iron Iron Chloride + Oxide Chloride + Water 6HCl + Fe203 2FeCl3 + 3H2O CHLORIDE PROMOTER Carbon Tet. + Hydrogen Hydrogen Chloride + Methane CATALYST CCI4 + 4H2 HEAT 4HCl + CH4 Perchloroethylene + Hydrogen Ethane Hydrogen Chloride + CATALYST C2Cl4 + 5H2 HEAT 4HCl + C2H6 CAUSTIC SCRUBBING HCI + NaOH NaCl + H2O HZS + 2NaOH Na2S + 2H2O HZS + Na2S 2NaHS HCI + Na2S NaCl + NaHS HCl + NaHS NaCl + H2S PROCESS VARIABLES In the normal operation of a Penex unit having once set the operating pressure, fresh feed rate and the recycle hydrogen and makeup hydrogen flows, it is usually only necessary to adjust the reactor inlet temperatures. Nevertheless, it is to the operator‘s advantage that he has a thorough understanding of the influence process variables will have on performance of the unit and the life of the catalyst. Once the catalyst has been loaded into the unit, the manner in which the catalyst is placed in service and the treatment it receives when in service will to a large extent influence its effectiveness for making quality product as well as the length of service it will give. In making any changes to the operation, the welfare of the catalyst must be given prime consideration for it can be regarded as the heart of the operation on which the quality of the results obtained will depend. FEED FRACTIONATION The economics of operating an isomerization unit are impacted by the feedstock composition and the cut point between the Penex isomerization feedstock and the heavy naphtha which is usually processed in a catalytic reformer. The prime consideration in splitting the feedstock is to maximize the C5/C6 paraffins to the Penex unit keeping the C7+ material in the naphtha splitter bottoms which will be processed in the catalytic reformer. A complication arises, however, in the fact that the C6 cyclics (methylcyclopentane, cyclohexane and benzene) are also present in the splitter feed and adecision on which unit to send them to must be made. Ideally, the C6 cyclics which are high octane benzene precursors would be best processed in the reformer. Some insight can be obtained by reviewing the accompanying figures regarding the component boiling points and volatilities. It is observed that the benzene and normal hexane have essentially the same volatility and, hence, cannot be separated by fractionation. Therefore, the decision must be made whether to take both the normal hexane and benzene overhead in the naphtha splitter or to send both components out the splitter bottoms to the reformer. By observing the conversion of normal hexane in both processes, it is seen that a catalytic reformer leaves a significant level of normal hexane in the C6 product. The question then becomes which is better to leave, low octane n-C6 in the reformate or to sacrifice it to cyclohexane. In general, the best overall octane (Penexate plus reformate) can be obtained by including the n-C6 and benzene in the Penex feedstock., Most of the cyclohexane should be fractionated out of the Penex feed and sent to the reformer. Hence, the Penex feed should include all of the C6 paraffins plus benzene and some MCP and the reformer feed should contain most of the cyclohexane and C7+. This feed preparation philosophy may shift as the percentage levels of MCP plus benzene increase in the C6 fraction and as the reforming selectivity in converting n-C6 to benzene increases. For those operations that process reformates in an aromatics recovery unit such as Sulfolane or Udex, the C6 cyclics and n-C6 should be included in the reformer feedstock. The unconverted C6 paraffins may then be fractionated from the light raffinate and upgraded in the Penex unit. In the discussion which follows, the "product isomer ratio‖ refers to either the percentage ratio of isopentane to total C5 aliphatic paraffins, the percentage ratio of 2,3 dimethylbutane in the total C6 aliphatic paraffins, or the percentage .ratio of normal hexane in the C6 aliphatic paraffins in the stabilizer bottoms stream, The terms ―liquid feed," ―reactor charge" and "combined feed,‖ refer to the C5/C6 charge to the liquid feed dryers of the unit, the effluent from the liquid feed dryers and the reactor charge plus makeup hydrogen and recycle hydrogen gas, respectively. REACTOR TEMPERATURE In general, reactor temperature is the main process control. A definite upper limit exists for the amount of iso-paraffins which can exist in the reactor product at any given outlet temperature.This is the equilibrium imposed by thermodynamics, and it can be reached only after an infinite length of time, i.e. with an infinitely large reactor. in practice, therefore, the product will contain slightly less iso-paraffins than this equilibrium concentration. As the reactor temperature is raised to increase the rate of isomerization, the equilibrium composition will be approached more closely. At excessively high temperatures, the concentration of iso-paraffins in the product will actually decrease because of the downward shift in the equilibrium curve, even though the high temperature gives a higher reaction rate. In the case of the Hydrogen Once Through Penex designs, where the hydrogen content of the reactor charge is so much lower than for recycle gas Penex, the reactor feed will contain a considerable amount of liquid. The equilibrium concentration for isoparaffins in the liquid phase is lower than in the vapor phase. This is a thermodynamic phenomenon related to the lower Gibbs free energies for the components in the liquid phase. The attached figures illustrate the equilibrium for both the vapor and liquid phases for isopentane and 2,2 DMB. The use of temperatures higher than necessary to achieve a reasonable close approach to equilibrium accomplishes neither other than to increase the amount of hydrocracking. Extremely high, temperatures may lead to an increased rate of carbon laydown on the catalyst; however, the carbon forming propensity of the catalyst is inherently so low that excessive hydrocracking would normally be encountered before carbon formation problems would develop. It is recommended, however, that UOP be consulted before temperatures above about 380°F are employed. A typical C5/C6 Penex unit is provided with two reactors in series with provision for independent temperature control. in The first reactor system affects the bulk of the isomerization, so long as most of the catalyst therein is still active. All of the benzene in the feed is hydrogenated in the first reactor, even when the catalyst therein has lost its activity with respect to paraffin isomerization. Some conversion of cyclohexane and methyl cyclopentane to hexanes also occurs, as does some hydrocracking of C7 to C3 and C4. These three reactions (benzene hydrogenation, naphthene conversion to hexane, and C7 hydrocracking) are exothermic and, for a typical feedstock, contribute more to the temperature rise in the first reactor than does paraffin isomerization, which is also exothermic. Normally, the first reactor will be operated at such a temperature as to maximize the concentration of isopentane and 2,2 dimethyl butane in its effluent. The concentrations attainable and-the required outlet temperature will be influenced by the amount of active catalyst present and by the amount of C6 cyclic and C7 components present in the feed, higher temperatures being required with high concentrations of these components in the feed. By this procedure, the required operating temperature for the second reactor is reduced and it is possible to operate under conditions where the equilibrium is more favorable. The optimum reactor temperatures are determined in the field by establishing a "base‖ set of conditions and then varying the reactor temperatures, one at a time, from this base condition. The performance of the reactors is determined by calculating the ―iso·ratios‖ of each reactor effluent. Reactor effluent or product octane is not used for this determination since it is also dependent on the relative amounts of C5 and C6 in the feedstock. Another interaction may occur with feeds which are rich in C5 cyclics. Since these materials tend to reduce the rate of paraffin isomerization, it may be beneficial with very rich feed stocks to choose the first reactor system temperature to control the amount of` cyclics which enter the second reactor system. By raising the first reactor system temperature, more of the cyclics be converted to hexanes and the rate of isomerization in the second reactor system thereby increased. LIQUID HOURLY SPACE VELOCITY This term, commonly shortened to LHSV, is defined as the volumetric hourly flow of reactor charge divided by the volume of catalyst contained in the reactors in consistent units. The design LHSV for C5/C5 Penex operation is- normally 1 to 2 and increasing the LHSV beyond this could lead to lower product isomer ratios. HYDROGEN TO HYDROCARBON MOL RATIO For Hydrogen Once Through Penex units, this ratio is defined as the number of mols hydrogen at the reactor outlet per mol of reactor charge passing over the catalyst and is specified at 0.05 mols H2/mol H:C. The primary purpose of maintaining the ratio at or above the design is to avoid carbon deposition on the catalyst and maintain enough H2 for the reactions to proceed. lf necessary, the reactor charge rate is to be reduced to maintain the design hydrogen to hydrocarbon ratio. The H2/H:C ratio is determined by measuring the total moles of hydrogen in the stabilizer overhead gas and dividing by the total moles of fresh feedstock. For Recycle Gas Penex units, the hydrogen to hydrocarbon ratio is specified at 1 to 2. This ratio is defined as the moles of hydrogen per mole of reactor charge. Lower ratios will generally increase the amount of liquid phase material in the reactor and may lead to flow distribution. PRESSURE C5/C5 Penex units are normally designed to operate at 450 psig at the reactor outlet. Methylcyclopentane and cyclohexane appear to adsorb on the catalyst and reduce the rate of isomerization reactions. Higher pressure helps to offset this effect of the C6 cyclic compounds. Lowering the unit pressure or operating at a slightly lower level would not affect the catalyst life but the extent of isomerization would be influenced. CATALYST PROMOTER To sustain catalyst activity, the addition of chloride is necessary. At no time should the plant be operated for longer than six hours without the injection of chloride. Whenever there is-a catalyst chloride decency, the product isomer ratios will decrease (although not necessarily instantaneously), other things being equal. Restarting the injection of chloride will tend to return the activity of the catalyst to its previous level, but it is possible that full activity will not be restored if a decline in activity, as a result no chloride injection has been observed. Carbon tetrachloride and specific grades of perchloroethylene are the only approved sources of chloride. CATALYST: CATALYSTS OF HYDROISOMERIZATION PROCESS: The major advantage of this catalyst was its low temperature activity (T< 200°C) due to its high acidity. However the catalysts were sensitive towards water and oxygenates and in addition had corrosive properties. Furthermore, chlorine addition during the reaction is necessary to guarantee catalyst stability. In the Hysomer process zeolite based catalysts were used which had the major advantage of resistance to feed impurities. Industrially applied zeolites used today are Pt-containing, modified synthetic (large-port) mordernite e.g. HS10 of UOP, or HYSOPAR from Sud- Chemie. As higher hydrogen to hydrocarbon ratios are needed recycle compressors and separators are required for this technology. The isomerization of hydrocarbons < C6 is currently carried out very successfully using bifunctional supported platinum catalysts. However, difficulties are encountered with hydrocarbons larger than hexane since the cracking reactions become more significant over platinum catalysts as the chain length increases. Catalysts used in state of the art isomerizationcracking reactors are bifunctional. They have a metal function providing de-hydrogenation and hydrogen activation properties that are usually supplied by group VIII noble metals like Pt, Pd, Ni or Co. The acid function is the support itself and some examples include acid zeolites, chlorided alumina and amorphous silica alumina. Noble metals have a positive effect on the activity and stability of the catalyst. However they have a low resistance to poisoning by sulfur and nitrogen compounds present in the processed cuts. In order to prepare a suitable catalyst for hydroconversion of alkanes, good balance between the metal and acid functions must be obtained. Rapid molecular transfer between the metal and acid sites is necessary for selective conversion of alkanes into desirable products. Two of the attractive features of zeolite are that the catalysts are tolerant of contaminants and that they are regenerable. The chlorinated alumina catalysts are very sensitive to contaminants such as water, carbon oxides, oxygenate, and sulfur. Thus, feeds and hydrogen must be hydrotreated and dried to remove water and sulfur. Furthermore, the chlorinated alumina catalysts require the addition of organic chloride to the feed in order to maintain their activities. This causes contamination in the waste gas of hydrogen chloride, a scrubber is needed to remove such contamination. The UOP BenSat process uses a commercially proven noble metal catalyst, which has been used for many years for the production of petrochemical-grade cyclohexane. The catalyst is selective and has no measurable side reactions. Because no cracking occurs, no appreciable coke forms on the catalyst to reduce activity. Sulfur contamination in the feed reduces catalyst activity, but the effect is not permanent. Catalyst activity recovers when the sulfur is removed from the system. ALUMINA Alumina or aluminum oxide (Al2O3) is a chemical compound with melting point of about 2000°C and sp. gr. of about 4.0. It is insoluble in water and organic liquids and very slightly soluble in strong acids and alkalies. Alumina occurs in two crystalline forms. Alpha alumina is composed of colorless hexagonal crystals with the properties given above; gamma alumina is composed of minute colorless cubic crystals with sp. gr. of about 3.6 that are transformed to the alpha form at high temperatures. Figure 8.1 shows the shape of (Al2O3). FIGURE 8.1. The shape of aluminium oxide Identifiers Aluminium oxide The most common form of crystalline alumina, α-aluminium oxide, is known as corundum. If a trace of the element is present it appears red, it is known as ruby, but all other colorations fall under the designation sapphire. The primitive cell contains two formula units of aluminium oxide. The oxygen ions nearly form a hexagonal close-packed structure with aluminium ions filling two-thirds of the octahedral interstices. TYPICAL ALUMINA CHARACTERISTICS INCLUDE: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties (from DC to GHz frequencies) Low dielectric constant Low loss tangent ZEOLITE Zeolites are microporous crystalline solids with well-defined structures. Generally they contain silicon, aluminium and oxygen in their framework and cations, water and/or other molecules within their pores. Zeolites occur naturally as minerals or synthetic, Figure (2.6) shows the shape of different types of zeolites. Because of their unique porous properties, zeolites are used in a variety of applications with a global market of several million tonnes per annum. In the western world, major uses are in petrochemical cracking, ion-exchange (water softening and purification), and in the separation and removal of gases and solvents. Other applications are in agriculture, animal husbandry and construction. They are often also referred to as molecular sieves. Zeolites have the ability to act as catalysts for chemical reactions which take place within the internal cavities. An important class of reactions is that catalysed by hydrogen-exchanged zeolites, whose framework-bound protons give rise to very high acidity. This is exploited in many organic reactions, including crude oil cracking, isomerisation and fuel synthesis. FIGURE 8.2. Structures and dimensions of different types of zeolite Underpinning all these types of reaction is the unique microporous nature of zeolites, where the shape and size of a particular pore system exert a steric influence on the reaction, controlling the access of reactants and products. Thus zeolites are often said to act as shapeselective catalysts. Increasingly, attention has focused on fine-tuning the properties of zeolite catalysts in order to carry out very specific syntheses of high-value chemicals e.g. pharmaceuticals and cosmetics. The following properties make zeolites attractive as catalysts, sorbents, and ionexchangers: 1. 2. 3. 4. 5. 6. Well-defined crystalline structure. High internal surface areas (>600 m2/g). Uniform pores with one or more discrete sizes. Good thermal stability. Highly acidic sites when ion is exchanged with protons. Ability to sorb and concentrate hydrocarbons. The tetrahedral arrangements of [SiO4]-4 and [AlO4]-5 coordination polyhedra create numerous lattices where the oxygen atoms are shared with another unit cell. The net negative charge is then balanced by cations (e.g. K+ or NH4+). Small recurring units can be defined for zeolites named, ‗secondary building units. The primary building blocks of all zeolites are silicon Si+4 and aluminum Al+3 cations that are surrounded by four oxygen anions O-2. This occurs in a way that periodic three dimensional framework structures are formed, with net neutral SiO2 and negatively charged AlO2. The negative framework charge is compensated by cation (often Na+) or by proton (H+) that forms bond with negatively charged oxygen anion of zeolite. The secondary building blocks differ between different types of zeolites. In the top line of Figure (8.2) the structure of a faujasite type zeolite is shown. The secondary building block of this zeolite is a sodalite cage, which consists of 24 tetrahedral in the geometrical form of a cubooctahedron. The sodalite cages are linked to each other via a hexagonal prism. KINETIC ANALYSIS The main aim of the present study is to analyze the kinetics of hydroisomerization process by assessing the effect of reaction time and reaction temperature on the performance of the catalysts. The process feed involves light naphtha which contains many reactions. Therefore, the hydroisomerization reaction has three stages as follows: 1- Adsorption of n- paraffin molecule on dehydrogenation- hydrogenation site followed by dehydrogenation to n- olefins. 2- Desorption of n- olefin from the dehydrogenation sites and diffusion to a skeletal rearranged site, which converts n- olefin into iso- olefin. 3- Hydrogenation of iso- olefin into iso- paraffin molecule. In general, the hydroisomerization of n- paraffin can occur through the bifunctional scheme shown below: The hydroisomerization process of light naphtha is regarded as one of the complex chemical reactions network, where such types of reactions take on a metal and acid sites of catalysts. Therefore, the mathematical modeling of the hydroisomerization process is a very important tool in petroleum refining industries. It translates experimental data into parameters used as the basis of commercial reactor process optimization. In the hydroisomerization of alkanes it is supposed that the alkane is dehydrogenated to an alkene on the metal site. The alkene is then protonated on the acid site to a carbenium ion, which is subsequently isomerized to a branched carbenium ion. The branched carbenium ion gives the proton back to the acid site, the resulting branched alkene is hydrogenated on the metallic site. The branched alkane is formed, and can be desorbed from the catalyst surface. The reaction mechanism scheme is shown in Figure (4.1) The general reactions mechanism for isomerization of n-alkane ASSUMPTION: The catalytic hydroisomerization kinetic the following assumptions are taken into account: 1. The system is isothermal and in steady state operation with first order reactions. 2. The reaction is carried out in the gas phase with constant physical properties and without pressure drop. 3. The temperature and concentration gradients in the radial direction can be neglected. The objective of kinetic study is to construct from the experimental results of the process, a mathematical formulation that can be used to predict the kinetic parameters of the hydroisomerization process. Therefore, the main aim of the present work is to estimate the reaction parameters (reaction rate constant, activation energy and pre-exponential factor) depending on the experimental work results under real isomerization conditions. In present work, it is suggested kinetic model for the reactions of hydroisomerization for light naphtha (n-paraffin) can be considered by the following scheme depending on the present model assumptions which can be formulated to the following equations: The Suggested Reactions Of Light Naphtha Isomerization Let, CA denotes the mole fraction of n-paraffin present at any time t, CN the mole fraction of n-olefin, Ciso the mole fraction of i-paraffin. Then, The mole balance can be formulated mathematically as follows: Equation (1) Equation (2) By integration of equation (1) CA = CA° CA = CA°exp(- k1t) at t= 0 we get, Equation (3) Substituting the equation (3) in equation (2) yield: = k1CA°exp (- k1t) - k2CN Rearrangement of equation (4) gives: + k2CN = k1CA°exp (- k1t) Equation (4) This is a linear first order differential equation as follows: 𝑑𝑦 +Py = Q where P = k2 , 𝑑𝑥 where 𝜌 integration factor which can be calculated from: 𝜌=𝑒 𝑃𝑑𝑥 𝜌=𝑒 𝑘2𝑑𝑡 where integration factor is : exp ( k2t) now multiple equation (4) with integration factor 𝑑𝐶 N 𝑑𝑡 𝑑 exp ( k2t) + k2 exp ( k2t) CN = k1CA°exp (- k1t) exp ( k2t) ( k t) [C ] = k1CA°exp (k - k t) N exp 𝑑𝑡 2 2 1 Then by integrate of differential equation will give: Q = k1CA°exp (- k1t) 𝑑[CN exp ( k2t)] = k1CA° 𝑒𝑥𝑝(k2- k1t) dt [CN exp ( k2t)] = exp (k2-k1) t + A Equation (5) k2 - k1 where A is the integration constant, and it can be determined using the following conditions: t=0 , CN = 0 Thus : [(0) exp ( k2( 0))] - exp (k2-k1) (0) = A k2 - k1 Equation (6) CN exp (- k2t) = [exp (k2-k1) t - 1] Then, CN = [exp (- k1t) - exp (- k2t) ] Equation (7) But, all products come from initial n-paraffin in the light naphtha feed, then, CAO = CA+CN+Ciso Equation (8) Then substituting the equations (3) and (7) in equation (8), will give: CAO = CAO exp(- k1t) + [exp (- k1t) - exp (- k2t) ] + Ciso Equation (9) Rearrangement of equation (9) gives: Ciso = CAO- CAO exp(- k1t) - Ciso = CAO [1- exp(- k1t) - [exp (- k1t) - exp (- k2t) ] [exp (- k1t) - exp (- k2t) ] Equation (10) REACTOR MODEL To develop a reaction model for an integral reactor, a material balance is made over the cross section of a very short segment of the tubular catalyst bed, as shown in Figure (.2): SEGMENT OF PACKED BED REACTOR. The tubular-flow reactor is one in which there is no mixing in the direction of flow and complete mixing perpendicular to the direction of flow. Above figure represents such a reactor .Concentrations will vary along the length coordinate , z , but not radial coordinate ,r .We conclude that the rate of reaction will vary with reaction length. A steady- state mole balance on reactant gives: 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 – 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 + 𝑟𝑎𝑡𝑒 𝑜𝑓 𝑖𝑛 𝑜𝑢𝑡 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑖𝑜𝑛 = 𝑟𝑎𝑡𝑒 𝑜𝑓 𝑎𝑐𝑐𝑢𝑚𝑢𝑙𝑎𝑡𝑖𝑜𝑛 Therefore, the volume element in the mole balance must be differential in length, but extend across the entire diameter of the reactor. Tubular-flow reactors are normally operated at steady state so that properties at any position are constant with respect to time. For such steadystate operation applied to the volume element ∆V, becomes FA│V - FA│V+∆V + rA∆V = 0 FA│V - FA│V+∆V = - rA∆V Divide by ∆V both the sides FA│V - FA│V+∆V = - rA ∆V applying limit ∆V 0 lim ∆V 0 FA│V - FA│V+∆V = - rA ∆V dFA= - rA dV Equation (11) For a flow system, FA has previously been given in terms of the entering molar flow rate FA and the conversion X: Equation (12) FA = FAO - FAOX Now for amount of mole convert in differential form , FAO dX= - rA dV Equation (13) Integration with the limit V=0 when X=0 gives: FAO 𝑥 0 𝑑𝑋 = -rA FAO 𝑥 0 𝑑𝑋 = -rAV 𝑉 𝑑𝑉 0 But, the rate of reaction for first order is: - rA = k1 CA So, V = FA o 𝒙 𝒅𝑿 𝟎 - k1 CA Now the the concentration conversion is, Equation (14) CA(1+εX) T = CAo (1 - X) To ε = Voidage is the proportion of unoccupied volume (that is, gaps or empty spaces) in a volume of some material. The term voidage is normally used to refer to the tiny spaces between particles in a powder or granulated material like sand CA = CAo (1 − X) To Equation (15) (1+εX) T put CA into equation (14) from equation (15) V = FAo 𝒙 (1+εX) T 𝑑𝑋 𝟎 (1 − X)To - k1CAo V = FAo [ k1CAo V = FAo [ k1CAo V = FAo 𝑥 1 0 1−𝑥 𝑑𝑥 +ε 𝑥 1 𝑑𝑥 0 1−𝑥 +ε 𝑥 X 0 1−𝑥 𝑇 𝑑𝑥]𝑇𝑜 𝑥 x−1+1 𝑇 𝑑𝑥]𝑇𝑜 0 1−𝑥 𝑥 1 0 1−𝑥 𝑑𝑥 +ε 𝑥 x−1 𝑑𝑥 0 1−𝑥 V = FAo [ k1CAo 𝑥 1 0 1−𝑥 𝑑𝑥 - ε 𝑥 1−x 0 1−𝑥 V = FAo [ k1CAo 𝑥 1 0 1−𝑥 𝑑𝑥 - ε 𝑥 0 [ k1CAo +ε 𝑥 1 0 1−𝑥 𝑑𝑥 ]𝑇𝑜 𝑑𝑥 + ε 𝑥 1 0 1−𝑥 𝑑𝑥 ]𝑇𝑜 𝑥 1 0 1−𝑥 1 𝑑𝑥 + ε 𝑇 1 1 𝑇 1 𝑇 V = FAo [ ln (1−𝑥) (1 + ε) − ε x]𝑇𝑜 k1CAo 𝑇 𝑇 𝑑𝑥 ]𝑇𝑜 V = FAo [-ln(1 − 𝑥) – ε x − ε ln(1 − x)]𝑇𝑜 k1CAo V = FAo [ ln (1−𝑥) +ε ln (1−x) – ε x]𝑇𝑜 k1CAo 𝑇 K1 = FAo [ ln 1 (1 + ε) − ε x] 𝑇 (1−𝑥) 𝑇𝑜 V Equation (16) CAo From equation (16), the values of k1 are calculated for any component. From Arrhenius equation plot Ln k1 vs 1/T, the slope represents –E/RT to calculate the activity energy (E) and the intercept represents Ln k◦. The relationship between Lnk1 vs 1/T using Arrhenius equation. Lnk1 = Lnko - 𝐸 𝑅𝑇 Substitute values of k1 in equation (10) to calculate values of k2 Ciso = CAO [1- exp(- k1t) - [exp (- k1t) - exp (- k2t) ] Figure (5.36) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1 Figure (5.37) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1. Figure (5.38) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1 Figure (5.39) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1 Figure (5.40) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1 Figure (5.41) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1. Figure (5.42) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1. Figure (5.43) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1. Figure (5.44) Arrhenius plot ♦WHSV=1.5hr-1, ■WHSV=3hr-1, ▲WHSV=4.5hr-1.