NATO ASI Series

Advanced Science Institutes Series

A series presenting the results of activities sponsored by the NATO Science

Committee, which aims at the dissemination of advanced scientific and technological

knowledge, with a view to strengthening links between scientific communities.

The Series is published by an international board of publishers in conjunction with the

NATO Scientific Affairs Division

A Life Sciences

B Physics

Plenum Publishing Corporation

London and New York

C Mathematical and Physical Sciences

D Behavioural and Social Sciences

E Applied Sciences

Kluwer Academic Publishers

Dordrecht, Boston and London

F Computer and Systems Sciences

G Ecological Sciences

H Cell Biology

Global Environmental Change

Springer-Verlag

Berlin Heidelberg New York Barcelona

Budapest Hong Kong London Milan

Paris Santa Clara Singapore Tokyo

PARTNERSHIP SUB-SERIES

1.

2.

3.

4.

5.

Disarmament Technologies

Environment

High Technology

Science and Technology Policy

Computer Networking

Kluwer Academic

Springer-Verlag

Kluwer Academic

Kluwer Academic

Kluwer Academic

Publishers

Publishers

Publishers

Publishers

The Partnership Sub-Series incorporates activities undertaken in collaboration with

NATO's Cooperation Partners, the countries of the CIS and Central and Eastern

Europe, in Priority Areas of concern to those countries.

NATO-PCO DATABASE

The electronic index to the NATO ASI Series provides full bibliographical references

(with keywords and/or abstracts) to about 50000 contributions from international

scientists published in all sections of the NATO ASI Series. Access to the NATO-PCO

DATABASE compiled by the NATO Publication Coordination Office is possible in two

ways:

- via online FILE 128 (NATO-PCO DATABASE) hosted by ESRIN,

Via Galileo Galilei, 1-00044 Frascati, Italy.

- via CD-ROM "NATO Science & Technology Disk" with user-friendly retrieval software

in English, French and German (© wrv GmbH and DATAWARE Technologies Inc.

1992).

The CD-ROM can be ordered through any member of the Board of Publishers or

through NATO-PCO, Overijse, Belgium.

Series F: Computer and Systems Sciences, Vol. 143

Springer

Berlin

Heidelberg

New York

Barcelona

Budapest

Hong Kong

London

Milan

Paris

Santa Clara

Singapore

Tokyo

Batch Processing

Systems Engineering

Fundamentals and Applications

for Chemical Engineering

Edited by

Gintaras V. Reklaitis

School of Chemical Engineering, Purdue University

West Lafayette, IN 47907, USA

Aydin K. Sunol

Department of Chemical Engineering, College of Engineering

University of South Florida, 4202 East Fowler Avenue, ENG 118

Tampa, FL 33620-5350, USA

David W. T. Rippint

Laboratory for Technical Chemistry, Eidgenossische

Technische Hochschule (ETH) Zurich, Switzerland

Oner Hortagsu

Department of Chemical Engineering, Bogazi<;i University

TR-80815 Bebek-Istanbul, Turkey

Springer

Published in cooperation with NATO Scientific Affairs Division

Proceedings of the NATO Advanced Study Institute on Batch Processing

Systems Engineering: Current Status and Future Directions, held in Antalya,

Turkey, May 29 - June 7,1992

Library of Congress Cataloging-in-Publication data applied for

CR Subject Classification (1991): J.6, 1.6, J.2, G.1, J.7, 1.2

ISBN-13: 978-3-642-64635-5

DO I: 10.1007/978-3-642-60972-5

e-ISBN-13: 978-3-642-60972-5

Springer-Verlag Berlin Heidelberg New York

This work is subject to copyright. All rights are reserved, whether the whole or part of the material is

concerned, specifically the rights oftranslation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other way, and storage in data banks. Duplication of this

publication or parts thereof is permitted only under the provisions of the German Copyright Law of

September 9, 1965, in its current version, and permission for use must always be obtained from

Springer-Verlag. Violations are liable for prosecution under the German Copyright Law.

© Springer-Verlag Berlin Heidelberg 1996

Softcover reprint of the hardcover 1st edition 1996

Typesetting: Camera-ready by editors

Printed on acid-free paper

SPIN: 10486088

45/3142 - 5 4 3 210

Preface

Batch Chemical Processing, that ancient and resilient mode of chemical manufacture, has in the

past decade enjoyed a return to respectability as a valuable, effective, and, indeed, in many

instances, preferred mode of process operation. Batch processing has been employed in the past

in many sectors of chemical processing industries including food, beverage, pharmaceuticals,

agricultural chemicals, paints, flavors, polymers, and specialty chemicals. The batch mode is

increasingly being rediscovered by sectors that neglected it as the industry is focusing on more

specialized, application tailored, small volume but higher margin products. Moreover, as

information and control technologies have become both more technically accessible and

economically affordable, the operation of batch facilities has become more efficient, gradually

shifting from the conservative and simple operating strategies based on dedicated and cyclically

operating trains to more sophisticated and complex operating strategies involving flexibly

configured production lines using multi-functional equipment and employingjust-in-time inventory

management strategies.

The effects of these trends on the process systems engineering community has been a

renewed intensity of efforts in research and development on computational approaches to

modeling, design, scheduling, and control problems which arise in batch processing. The goal of

the NATO Advanced Study Institute (ASI), held from May 29 to June 7, 1992, in Antalya,

Turkey, was to review state-of-the-art developments in the field of batch chemical process systems

engineering and provide a forum for discussion of the future technical challenges which must be

met. Included in this discussion was a review of the current state of the enabling computing

technologies and a prognosis of how these developments would impact future progress in the

batch domain.

The Institute was organized into two interrelated sections. The first part dealt with the

presentations on the state of the batch processing in the Chemical Process Industries (CPI),

discussion of approaches to design and operation of more complex individual unit operations,

followed by the reviews of the enabling sciences. This four-day program served to set the stage

for a five-day program of discussions on the central problem areas of batch processing systems

VI

engineering. That discussion was preceded by a one-day interlude devoted to software

demonstrations, poster sessions, and small group meetings. A unique feature of this ASI was the

presence of a computer room at the hotel site equipped with an llM RISC workstation, terminals,

and personal computers which could be used for application software demonstrations and trials.

The Institute opened with industrial and academic perspectives on the role of batch

processing systems engineering in the CPI. Two presentations on the status of batch processing

systems engineering in Japan and Hungary provided perspectives on developments in the Far East

and the former eastern block countries. The Japanese innovations in batch plant organization using

moveable vessels offered insights into materials handling arrangements particularly suitable for

multiproduct, smaIl-batch production environments. These presentations were followed by a suite

of papers describing applications in CPI sectors such as polymer processing, food and beverages,

biochemical, specialty chemicals, textile, and leather industries.

The more complex batch unit operations which give rise to special modeling, design, and

control problems were given attention in separate lectures. These included batch distiIlation,

reactors with complex reacting systems, and sorptive separation systems. These presentations

were complemented by expositions on the estimation and unit control issues for these more

complex systems.

The three categories of enabling technologies which were reviewed were simulation,

mathematical programming, and knowledge based systems. The simulation component included

discussion of solution techniques for differential algebraic systems, the elements of

discrete/continuous simulation, and available simulation environments, as well as prospects

offered by advanced computer architectures. The mathematical programming review included a

critical assessment of progress in nonlinear optimization and mixed integer programming domains.

The knowledge based systems program consisted of a review of the field, continued with its

elements and closed with more advanced topics such as machine learning including neural

networks.

During the fifth day, attendees divided into small discussion groups on specific topics,

participated in the software demonstrations and workshops, and participated in the poster sessions.

The software demonstrations included the DICOPT MlNLP solver from Carnegie Mellon

University, the BATCHES simulation system from Batch Process Technologies, and the BATCHKIT system (a knowledge based support systems for batch operations scheduling) developed at

ETHZurich.

VII

The central problem areas in batch process systems engineering are those of plant and

process design and plant operations. One day was devoted to the former topic, focusing especially

on retrofit design as well as approaches to incorporating uncertainty in the design of processing

systems. The second day was devoted to scheduling and planning, including consideration of the

integration issues associated with linking the control, scheduling, and planning levels of

operational hierarchy. The Institute concluded with plenary lectures on future of batch processing

systems engineering and an open forum on questions which arose or were stimulated during the

course of the meeting.

The ASI clearly could not have convened without the financial resources provided by the

Scientific and Environmental Affairs Division of NATO. The support, advice, and understanding

provided by NATO, especially through the Division Director Dr. L. V. da Cunha, is gratefully

acknowledged. The additional financial support for specific attendees provided by the NATO

offices of Portugal and Turkey and by the US National Science Foundation is highly appreciated.

The enthusiastic and representative participation of the batch processing systems

engineering community was important for the realization of the goals of the ASI. Fortunately, such

participation was realized. Indeed, since the participation represented all the main research groups

in this domain, at one point the meeting concerns were voiced about the dire fate of the field if

some calamity were to visit the conference site. Fortunately, these concerns were abated the next

morning when the participants were greeted by maneuvers of NATO naval forces in Antalya bay.

Without question, the active participation of the distinguished lecturers, session chairs, reviewers,

and participants made this Advanced Study Institute a great success. Thanks are due to all!

Most of the manuscripts were updated considerably beyond the versions made available

to attendees during the Institute and we thank the authors for their diligent work. We sincerely

appreciate Springer-Verlag's understanding with unforeseeable delays with the manuscript as well

as their kind assistance throughout this endeavor. Special thanks are due to Dr. Hans Wossner and

1. Andrew Ross.

Finally, the organizers would like to recognize the help of the following individuals and

organizations without whom the Institute would have considerably diminished if not ineffective:

Sermin Gonen~ (now Sunol), Muzaffer Kapanoglu, Praveen Mogili, <;:agatay Ozdemir, Alicia

Balsera, Shauna Schullo, Nihat Giirmen, C. Chang, and Burak Ozyurt for assistance with

brochures, program, re-typing, indexing, and correspondence; Dean M. Kovac and Chairman R.

Gilbert of University of South Florida for supplementary financial support; Bogazi~i Turizm Inc.

VIII

and Tamer Tours for local arrangements in Turkey and social programs; IBM Turkey, especially

Mtinire Ankol, for the RISC Station and personal computers; Canan Tamerler and Vildan Din~bR§

(ASI's Angels) for tireless help accompanied by perpetual smiles throughout the AS I; and Falez

Hotel management and staff, especially Filiz Giiney, for making our stay a very pleasant one.

The idea of organizing a NATO ASI on systems engineering goes back to 1988 and was

partially motivated by AKS's desire to do something in this domain at home for Turkey. However,

its realization was accompanied by personal losses and impeded by unanticipated world events.

A week before the proposal was due AKS lost his best friend, mentor, and mother, Mefharet

Sunol. The Institute had to be postponed due to the uncertainties arising from the Gulf crisis. A

few months before finalization ofthis volume, our dear friend and esteemed colleague, Prof David

W. T. Rippin passed away. It is fitting that this proceedings volume be dedicated to the memories

of Mefharet Sunol and David Rippin.

Gintaras V. Reklaitis and Aydm K. Sunol

West Lafayette, Indiana and Tampa, Florida

September 1996

List of Contributors and Their Affiliation

Organizing Committee and Director

Dner Horta~su, Chemical Engineering Department, Bogazi~i Universitesi, Istanbul, Turkey

Gintaras. V. Reklaitis, School of Chemical Engineering, Purdue University, USA

David W.T. Rippin, Technical Chemistry Lab, ETH Zurich, Switzerland

Director: Aydm K. Sunol, Chemical Engineering Department, University of South Florida, USA

Main Lecturers and Their Current Affiliation

Michel Lucet, Rhone Poulenc, France

Sandro Macchietto, Imperial College, UK

Rodger Sargent, Imperial College, UK

A1irio Rodriguez, University of Porto, Portugal

John F. MacGregor, McMaster University, Canada

Christos Georgakis, Lehigh University, USA

Arthur W. Westerberg, Carnegie Mellon University, USA

Ignacio E. Grossmann, Carnegie Mellon University, USA

Giresh S. Joglekar, Batch Process Technologies, USA

Jack W. Ponton, University of Edinburgh, UK

Kristian M. Lien, Norwegian Institute of Technology, Norway

Luis Puigjaner, Catalunya University, Spain

Special Lecturers

Mukul Agarwal, ETH Zurich, Switzerland

RIdvan Berber, Ankara Universitesi, Turkey

Cristine Bernot, University of Massachusetts, USA

x

Ali Cmar, lIT, USA

Shinji Hasebe, Kyoto University, Japan

Laszlo Halasz, ETH, Switzerland

Gyula Kortvelyessy, SZEVIKI R&D Institute, Hungary

Joe Pekny, Purdue University, USA

Dag E. Ravemark, ETH, Switzerland

Nilay Shah, Imperial College, University of London, UK

Eva Sorensen, University ofTrondheim, Norway

Venkat Venkatasubramanian, Purdue University, USA

Zentner M. G., Purdue University, USA

Denis L.J. Mignon, Universite Catholique de Louvain, Belgium

Session Chairs (In Addition to Organizers and Lecturers)

Yaman Arkun, Georgia Tech, USA

Tiirker Giirkan, METU, Turkey

lisen Onsan, Bogazi~i Universitesi, Turkey

Canan Ozden, METU, Turkey

L. H. Garcia-Rubio, University of South Florida, USA

Additional Poster Contributors

Bela Csukas, Vezsprem University, Hungary

Bilgin Klsakiirek, METU, Turkey

Table of Contents

Plenary Papers

Current Status and Challenges of Batch Process Systems Engineering

David W T. Rippin

Future Directions for Research and Development in Batch Process

Systems Engineering ........................................................................................................

Gintaras V Reklaitis

20

Status of Batch Processing Systems Engineering in the World

Role of Batch Processing in the Chemical Process Industry ...........................................

Michel Lucet, Andre Charamel, Alain Chapuis, Gilbert Guido, and Jean Loreau

43

Present Status of Batch Process Systems Engineering in Japan

Shinji Hasebe and 10ri Hashimoto

49

Batch Processing Systems Engineering in Hungary

Gyula K6rlvelyessy

78

Design of Batch Processes

Design of Batch Processes

...............................................................................................

L. Puigjaner, A. Espuiia, G. Santos, and M Graells

86

Predesigning a Multiproduct Batch Plant by Mathematical Programming

Dag E. Ravemark and D. W T. Rippin

114

The Influence of Resource Constraints on the Retrofit Design of Multipurpose

Batch Chemical Plants .....................................................................................................

Savoula Papageorgaki, Athanasios G. Tsirukis, and Gintaras V Reklaitis

150

Design of Operation Policies for Batch Distillation

Sandro Macchietto and LM Mujtaba

174

Sorption Processes ...................... ... ............... ............. .... ... ......... ........ .......... ...... ... ... ..... ....

Alirio E. Rodrigues and Zuping Lu

216

Control of Batch Processes

Monitoring Batch Processes .............................................................................................

John F MacGregor and Paul Nomikos

242

XII

Tendency Models for Estimation, Optimization and Control of Batch Processes ...........

259

Control Strategies for a Combined Batch Reactor / Batch Distillation Process

..............

274

A Perspective on Estimation and Prediction for Batch Reactors .....................................

295

A Comparative Study of Neural Networks and Nonlinear Time Series

Techniques for Dynamic Modeling of Chemical Processes ............................................

A. Raich, X Wu, H F. Lin, and Ali (:mar

309

Christos Georgakis

Eva Sr/H"ensen and Sigord Skogestad

Mukul Agarwal

Enabling Sciences: Simulation Techniques

Systems of Differential-Algebraic Equations

331

R. W H Sargent

Features of Discrete Event Simulation ............................................................................ . 361

Steven M Clark and Girish S. Joglekar

Simulation Software for Batch Process Engineering .......................................................

376

The Role of Parallel and Distributed Computing Methods in

Process Systems Engineering ...........................................................................................

Joseph F. Pekny

393

Steven M Clark and Girish S. Joglekar

Enabling Sciences: Mathematical Programming

Optimization .. .................... .... ........ ........... ... ....... ..... ............. ..... ...... ..... ... ............ ....... ......

417

Mixed-Integer Optimization Techniques for the Design and Scheduling of

Batch Processes ................................................................................................................

451

Recent Developments in the Evaluation and Optimization of Flexible

Chemical Processes ..........................................................................................................

495

Arthur W Westerberg

Ignacio E. Grossmann, Ignacio Quesada, Ramesh Raman, and Vasilios T Voudouris

Ignacio E. Grossmann and David A. Straub

Enabling Sciences: Knowledge Based Systems

Artificial Intelligence Techniques in Batch Process Systems Engineering

.....................

517

Elements of Knowledge Based Systems - Representation and Inference

.......................

530

Selected Topics in Artificial Intelligence for Planning and Scheduling Problems,

Knowledge Acquisition, and Machine Learning ..............................................................

Aydm K. Sunol, MuzaJfer Kapanoglu, and Praveen Mogili

595

Jack W Ponton

Kristian M Lien

XIII

Integrating Unsupervised and Supervised Learning in Neural Networks for

Fault Diagnosis .................................................................................................................

Venkat Venkatasubramanian and Surya N Kavuri

631

Scheduling and Planning of Batch Processes

Overview of Scheduling and Planning of Batch Process Operations

Gintaras V Reklaitis

....... ...... ....... ...... ....

660

GanttKit - An Interactive Scheduling Tool .....................................................................

L. Halasz, M Hofmeister, and David W T Rippin

706

An Integrated System for Batch Processing .....................................................................

750

An Interval-Based Mathematical Model for the Scheduling of

Resource-Constrained Batch Chemical Processes .... ............... ... ........ ............ ....... ..........

M G. Zentner and Gintaras V Reklaitis

779

S. Macchietto, C. A. Crooks, and K. Kuriyan

Applications of Batch Processing in Various Chemical Processing Industries

Batch Processing in Textile and Leather Industry ............................................................

L. Puigjaner, A. Espufza, G. Santos, and M Graells

808

Baker's Yeast Plant Scheduling for Wastewater Equalization ........................................

Neyyire (Renda) Tilmsen, S. Giray Velioglu, and Oner Hortar;su

821

Simple Model Predictive Control Studies on a Batch Polymerization Reactor ...............

Ali Karaduman and Ridvan Berber

838

Retrofit Design and Energy Integration of Brewery Operations .. ............. ....... ................

Denis J Mignon

851

List of Participants

863

Index ................................................................................................................................

867

Current Status and Challenges of Batch Processing

Systems Engineering

David W.T. Rippin

Labor fur Technische Chernie, E. T.H. Zurich, Switzerland

Abstract: The field offine and speciality chemicals exhibits an enonnous variety in the nature of

the products and the character and size of their markets, in the number and type of process

operations needed for production, in the scale and nature of equipment items and in the

organizational and planning procedures used.

This introductory paper draws attention to the need for a careful analysis of a batch situation

to identify the dominant features. Some methods and tools are identified to aid design, planning

and operations and some challenges or growing points for future work are suggested. These

themes will be taken up in more detail in later papers.

Keywords: Recipe, batch size, cycle time, design, multi product plant, multi plant, multipurpose

plant, scheduling, equipment capacity

Factors Characterizing the Batch Production of Chemicals

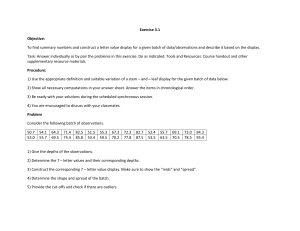

Any system for producing chemical products has three necessary components (Figure 1)

1.

A market

2.

A sequence of process tasks whereby raw materials are converted into products

3.

A set of equipment items in which the process tasks are carried out

For the production ofa single product in a continuous plant, the links between these components

are :finnIy established at the design stage. The process task sequence is designed to serve a specific

market capacity for the product and the equipment is selected or specially designed to perfonn

precisely those necessary tasks most effectively.

2

Process

Plant _ 0 - - - -__ Market

Figure 1: Components of a processing system

In a batch production system, the components themselves are much less rigidly defined and

the links between them are subject to change or fuzzy. For example, the market will not be for a

defined amount of a single product but may be for a range of products of which the relative

demands are likely to vary and to which new products are likely to be added. A variety of

processes may have to be considered which cannot be characterized with the precision demanded

for a continuous single product plant. Available equipment must be utilized or new equipment

selected from a standard range to serve multiple functions rather than specially designed. Similarly,

the allocation of process tasks to equipment items must be changed frequently to match the

changing requirements of the market.

A much wider range of choices may be available to the operators of batch plants than in a

continuous plant environment.

Furthermore, there is an enormous diversity of batch processing situations determined by

factors such as:

1.

Scale of production

2.

Variability of market demand

3. Frequency of "birth" of new products and "death" of old ones

4. Reproducibility of process operations

5. Equipment breakdowns

6. Value of materials in relation to cost of equipment

7.

Availability and skill of process workers

8.

Skill and experience of planning personnel

9.

"Company culture"

Thus, the dominating factors may be quite different in one batch environment compared with

3

another. No single sequential procedure can be called upon to solve all problems. A variety of

tools and practices will be needed which can be matched as necesslll)' to each situation.

The diversity of batch situations makes it important that, before starting on a particular plan

of action, an analysis of the situation should be made to assess problems and opportunities, to

identify the potential for improvement and to determine where effort and resources can most

effectively be invested.

In a busy production environment, the natural tendency, particularly if the overall situation is

not fully appreciated, is to treat the most pressing problems first, perhaps missing much more

profitable, but less obvious opportunities. Obviously, a right balance should be sought between

solving pressing problems, anticipating new problems, and grasping new opportunities. An overall

view is needed to do this effectively.

For example, a large chemical company I visited had set itself the task in a 5-year program for

its batch processes to reduce labor, cycle time and lost or waste material all by 35%. This certainly

provided a focus for activity, although it may not, of course, be the best focus in another

environment.

Analyzing Batch Processes

Some directions in which action might be taken to improve batch processing can be illustrated by

considering a series of questions:

1. What has to be done? - a breakdown of necesslll)' activities

2. How is achievement measured?

3. How to assess potential for improvement?

4. How to make improvement?

5. What facilities/tools are needed or advantageous?

6. Where to begin?

What Has to Be Done?

l. Batch recipe definition

2. Coordination of process tasks

4

3. Design of new equipment or realization in existing equipment

4.

Allocation of process tasks to equipment items

5.

Sequencing of production

6.

Timing of production

7. Realization in production with appropriate supervision and control measures

8. Matching the customer's requirements

How Is Achievement Measured?

Measures of performance can be associated with each of the activities that have been defined.

They may indicate the need for change in the corresponding activity, or in other activities earlier

in the list.

The batch recipe definition may be evaluated in terms of the raw materials and reaction

sequence, waste products, requirements for utilities and other resources, proportion of failed

batches and more quantitatively in the yield or productivity of reaction stages, the achieved

recovery of separations.

Coordination of process tasks at the development stage may be judged by how diverse are the

cycle time requirements of the different process tasks (although equipment and organizational

measures may be able to counter this diversity, if necessary). Overall optimization of a chain of

process tasks may give different results than attention only to isolated units.

Choice of new equipment items may be judged by investment cost. For existing equipment,

charges may be made for utilization or additional equipment may be called for. Choice of

equipment may also be judged by frequency of breakdown or availability.

Process definition and choice of new equipment will also be judged by whether the plant

performs to design specifications and achieves its design capacity.

Allocation of process tasks to equipment items may be judged by the size and frequency of

batches which can be produced of a single product or in some cases of a number of different

products.

The sequence in which products are produced may influence the total time and cost required

to produce a group of products, if the change over time and cost are sequence dependent.

The timing of production combined with the sequencing detennines if the delivery

5

requirements and due dates of the customers can be satisfied.

Due to the intrinsic variability of the manufacturing situation, a variety of supervision and

control procedures may be required to counter both recognized and unrecognized changes. They

will be applied and their effectiveness assessed at different levels:

1. Process control on individual process tasks/equipment items

2. Sequence control on individual items and between interconnecting items

3. Fault detection and methods of statistic process control to detect changes in the process

or its environment

4. Quality control to monitor the quality of products delivered to the customer or perhaps

also raw material deliveries or environmental discharges

The success of the plant as a whole will be assessed by the overall production costs and the

extent to which the market requirements can be met. Customer satisfaction will reflect delivery

times and the quantity and quality of products delivered. Production costs will be ascribed to

different components or activities of the system and may indicate dominant factors.

How to Assess Potential for Improvement?

First indications of where action can profitably be taken can often be obtained by making extreme

or limiting assumptions about the changes which might be effected.

For example:

•

At the process definition stage, what benefit would accrue if complete conversion/selectivity

could be achieved in the reactor or complete recovery in the separator? - or some less extreme

but conceivable assumption

•

What consequence would there be for equipment requirement or utilization if the

interdependencies between the processing tasks were neglected and each equipment item sized

or assigned assuming 100% occupation for those tasks it had to perform?

•

What benefits would there be in terms of operating costs, inventory costs, customer

satisfaction, iffailed batches or equipment breakdowns could be eliminated?

•

What benefits in terms oftirneliness of production, customer satisfaction, inventory reduction

or production capacity by improvement of scheduling?

•

What benefits if variability could be reduced or eliminated in terms of the costs of supervision

and inspection, product quality give away?

6

The discipline of assessing how achievement is measured and what potential for improvement

may be identified should draw attention to those features ofthe system where further effort may

best be invested. If properly applied, such an analysis should be equally valid for exploring

measures which might be taken to solve a current problem, to preempt a potential problem or to

exploit a new opportunity.

How to Make Improvement?

Attention should be directed, initially, to the most promising (or threatening!) aspects of the

situation. These may vary widely from case to case, so no general recipe can be given. An obvious

defect or lack of reliability in the way a particular operation is carried out may claim immediate

attention and resources. However, sight should not be lost of the fact that equal or greater benefits

may derive from some higher level coordination or planning activity of which the effects may not

be immediately obvious to the plant operator or manager.

To appreciate the potential benefits of many of the possible actions, a quantitative

characterization is required of the processing requirements of a product, how these can be

matched to available or potentially available equipment, and how the requirements of different

products can be accommodated.

At the level of individual process tasks, there may be potential for improvement, for example,

with respect to reactor conversion, selectivity, separator recovery, waste production, time

requirements, in the light of the current objectives. This may be realized by developing a

mathematical model to be used for determining the optimal levels for operating variables. In some

circumstances there may be further advantage in making optimal choice not only of the levels of

operating variables, but also of the time profile of these variables during the course of the batch.

Reviews are available of where such benefits may be expected.

Quantitative Characterization of Batch Processing Requirements

Quantitative characterization of the processing requirements at each step of the process allows the

7

determination of the perfonnance which can be achieved (amount of product per unit time) when

any step is allocated to an equipment item of appropriate type and a specified size. A process step

is any physical or chemical transfonnation which could be carried out in a separate equipment

item. For example heating, dissolving a solid, reacting, cooling, crystallization, are all regarded as

separate steps in the process specification, even though, at a later stage, several steps may be

carried out in sequence in the same equipment item.

The processing requirement of a step can be represented in different levels of detail by models

of widely differing complexity. The minimal specification of capacity is the size factor Sij that is

the volume (or other measure of capacity) required in a step j for each unit of product i to be

produced at the end of the batch and the batch time Tij required to complete the step.

Since the size factors of the processing steps are expressed relative to the amount of product

produced at the end of the batch, their calculation requires a complete balance of material and

corresponding capacity requirements encompassing all steps of the process.

If the size factor and cycle time are regarded as fixed, then the selection and allocation of

equipment and the determination of the overall production capacity of single and multi product

plants are relatively straightforward. Such a specification corresponds to a fixed chemical recipe

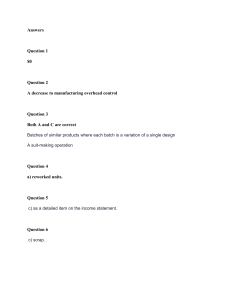

Table 1: Suggested Hierarchy of models

Item

Model Type

Function

Derivation

A

Comprehensive

model

Perfonnance as function of Mechanistic

time and all operating

understanding

variables

Effect of

individual unit on

whole plant

B

Perfonnance

model

Perfonnance as function of Reduced model

time

or empirical fit

Coordination of

cycle time of

sequence

C

Model of time

and capacity

requirement

Fixed perfonnance,

requirement may depend

on equipment or batch size

Reduced model

or external

specification

Equipment sizing

and task

assignment

D

Model of time

requirement

only

Reduced model

or independent

specification

Simple sequencing

and production

E

Stochastic

model

Superposition

on any of

above

Use

8

from which all change in operating conditions is excluded. It may be appropriate when a fixed

manufacturing specification is taken over from conditions established, for example, in a

development laboratory or in previous production experience.

The allowance for variation in operating conditions calls for more complex models to predict

the effects ofthese variations on the processing requirements and probably iterative recalculation

of equipment allocation and overall production capacity determination. A hierarchy of models can

be envisaged for different purposes with information being fed from one stage ofthe hierarchy to

another as required (Table 1). However, in many practical applications for the planning and

operation of batch facilities the assumption of constant size factor and batch time will be

acceptable.

The simple quantitative characterization of batch processing requirements is used to determine

production capability when a defined process is allocated to a set of equipment items of given size.

No account is taken here of uncertainty or variability in processing requirements.

Production Capability of a Set of Equipment Items

If a process for product i is allocated to a set of equipment items of specified capacity Vj the

production capability is determined by:

The Limiting Batch Size BJi

An upper limit for the amount of product I which can be manufactured in a batch is imposed by

the equipment at the stage j with the smallest value of the ratio

equipment capacity

size factor (capacity requirement per unit product)

B

Li

= Min "V;

.

]

S

ij

=~

Sij

9

The Limiting Cycle Time Tu

A lower limit to the interval between producing successive batches of product i is imposed by the

process stage with the largest batch time

The maximum production rate of product i per unit time is then

limiting batch size

limiting cycle time

BLi

TLi

~

~

Rl

R2

I

T

~

R3

I

TAl

TAJ

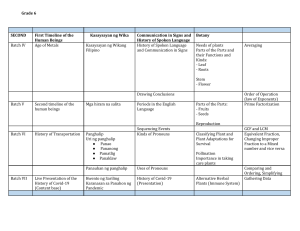

Figure 2: Limiting batch size and cycle time

10

The effect of the batch size and cycle time limitations are best illustrated graphically by a simple

example with three equipment items (Figure 2). The cycle time limitation occurs on the first item

and the batch size limitation on the second. Ifit is desired to increase the production rate of the

product, this can be done by addressing either of the two bottlenecks in capacity or cycle time.

The following measure:; can be taken to increase production rate, or to make underutilized

equipment available for other-purposes:

•

Add parallel equipment items

which operate in phase to increase batch size

which operate out of phase to reduce cycle time

•

Merge neighboring tasks to carry them out in the same equipment with potential saving of

equipment items or split a task, allowing it to be carried out in two consecutive items thus

reducing the cycle time

•

Insert storage provision between two consecutive tasks allowing different batch sizes and

cycle times up and downstream ofthe storage.

Design of Single Product Plant

If a batch plant is to be designed to meet a specified demand of a single product I with a known

process, the number of batches which can be manufactured is given by

available time

limiting cycle time

The required batch size is then

=

B

I

total product demand

number of batches

The necessary size of each equipment item is

~

= (batch

size) x (size factor)

=B

j

Sij

The design ofa single product plaut can be carried out immediately, if the configuration of the

plant is specified.

11

However, if the designer is free to choose different structural alternatives of the type discussed

in the previous section, consideration may be given to

•

The installation and function of parallel equipment items

•

Changing the allocation of process tasks to equipment items

•

The installation of intermediate storage

An acceptable design may be arrived at by examination of alternative cases or by optimization

over the range of discrete choices available, for example to minimize total equipment cost as is

discussed in later papers.

Multiproduct Operation

In multiproduct operation, several products are to be produced in sequence on the same plant with

a defined allocation of process tasks to equipment items for each product. For each product, the

limiting cycle time can be calculated and hence the production rate. It is then easy to check if

specified demands for a given set of products can be met within the available production time.

Bottlenecks to increased production for a particular product can be relaxed in ways already

discussed. However, in a multiproduct plant, the situation is likely to be complicated by the fact

that bottlenecks for different products will be differently located.

This is illustrated in Figure 3. The first product, as considered previously, is limited in batch

size by the equipment item on the second stage and its limiting cycle time is on the first stage. The

second product has its capacity limitation on the first stage and the cycle time limitation on the

second.

It is not immediately clear what is the most cost effective way of increasing the capacity of

such a plant. For example, increasing the size of the second equipment item would increase the

batch size of the first product enabling more to be manufactured in the same number of batches,

or the same amount to be manufactured in fewer batches leaving more time available for the

production of the second product. There are alternative ways, already discussed, for either product

by which its production rate can be increased.

The best design, for example, to satisfY specified demands for a set of products at minimum

equipment cost can be determined by solving an optimization problem. The optimization can be

12

J

t

~

RI

Rz

l

I

TAl

~

R3

I

~

TAl

---

TAl

'--

_ TA _

R,-----===,...._---1===r_

R3 ____________________

~~~

__________

==~

Figure 3: Multi-product production

formulated as choosing the best sizes (and possibly also the configuration) of the equipment items

to satisfy the product demands within the available production time, or alternatively it can be

viewed as choosing how the available time is divided between production of the different products.

With a fixed equipment configuration, when the time aIlocation to a product has been fixed the

equipment sizes to accommodate that product are also determined. For a particular time allocation

to the complete set of products the necessary size of any equipment item is determined by

scanning over the equipment size requirement at that stage for all products and choosing the

largest.

In a practical situation where exact cost optimization is not of major importance, a plausible

design can be arrived at by allocating the available time to products or groups of products

13

detennining the equipment cost and checking its sensitivity to time allocation or equipment

configuration.

Bottlenecks may be removed by changing configuration as for the single product.

Discrete Equipment Sizes

Much batch equipment is not available in continuously variable sizes. For example volumes of

available reaction vessels may increase by a factor of -1.6. A discrete optimization procedure,

such as a branch and bound search, may be used to make an optimal selection of equipment items

in these circumstances, if required.

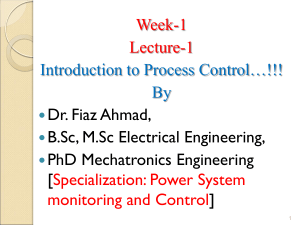

Partly Parallel Production (See Figure 4)

Products being produced on the same plant may differ substantially in the number of equipment

items needed. In a plant equipped to produce a complex product with many transformations it may

be possible at another time to produce several less demanding products in parallel. Capacity

evaluation or design can be carried out in ways similar to those already discussed.

Alternative Plant Configurations

1. Multiproduct

2. Partly parallel

3. Multiplant

4. Multiplant and

partly parallel

Figure 4: Partly parallel production

14

Multiplant Production

When a number of products have similar equipment requirements, it may appear attractive to

manufacture as many of them as possible in a single large multiproduct plant. The product will be

made in large batches and, by economy of scale, the equipment cost will be less than the total cost

of a number of smaller plants operating in parallel to produce subgroups of products or even

individual products.

However, other factors may militate against the very large multiproduct plant. Manufacturing

many products in the same plant will call for frequent product changeovers with associated loss

of time and material and other expenses. In addition, if a product is in continuous demand, but is

only manufactured for short periods, as will be the case if it shares the plant with many other

products, then the inventory level to maintain customer supplies will be much higher than for a

plant in which only a few products are manufactured. For high value products the cost of such

inventories may be far more significant than "economy of scale" savings on equipment costs. If

in addition, purity requirements are high leading to very stringent changeover procedures, the use

of parallel plants for single, or a few products, may easily be justified on economic grounds.

Discrete optimization procedures can be set up to assist the grouping of products into subsets for

production together.

Multipurpose Operation

Many batch products are made in multipurpose plants. A set of equipment items is available in

which a group of products is manufactured. The products may change from time to time calling

for the plant to be reconfigured. Several products may be manufactured in the plant at one time

and the same product may follow different routes through the plant at different times, perhaps

depending upon which other products are being produced at the same time.

One way of assessing the capacity of such a plant is to. plan its activity in campaigns. A

campaign is the assignment of all the equipment in the plant to the production of a subgroup of

products for a period. The total demand for a set of products over a planning period can be

15

satisfied by selecting and assigning times to an appropriate set of campaigns chosen from a larger

set of possible campaigns. This selection can be made by a linear programming procedure.

The candidate campaigns can be built up by assigning equipment to the manufacture of

batches of the same or different products in parallel (Figure 5). Candidates which do not make

good use ofthe equipment can be screened out, leaving a modest number of efficient campaigns,

from which the linear programming procedure can make an appropriate selection corresponding

to any distribution of demand.

The method described seeks to make the best use of the capacity of an existing multipurpose

plant. It could theoretically be extended to consider the selection of equipment items to include

in the plant, but at the cost of enormously more computing. It is also not at all clear how to specify

the potential product demand for such a plant at the design stage. In fact, many multipurpose

plants are built with limited knowledge of the products to be made in them, or even with the

intention that as yet unknown products will be produced there.

In those circumstances it is not surprising that the selection of items to include in a

multipurpose plant is commonly based on past experience rather than any mathematical

procedure. The choice of items may be based on the requirements of one, or a group of

representative products, possibly with special provision for other unusual products. Alternatively,

a typical mixture of equipment items may be chosen that has given good service in the past and

has sufficient flexibility to accommodate a range of types and amounts of products. Of course, the

selection of equipment items made in this way may be heavily dependent on the particular

application field being considered.

The Choice of Production Configuration and Short Term Scheduling

The choice of a production configuration depends on the character of the processes and the

market situation. A group of products with very similar equipment requirements can often be

produced conveniently in a multiproduct configuration. Very diverse products may be produced

in independent production lines or, depending on the availability of equipment and the level and

variability of demand in mixed multipurpose campaigns.

The structuring of campaigns described in the previous section is a device for identifying

favorable combinations of products. It may be useful for medium term and capacity planning, but

16

Plant Specifications

Production Process

Product A

Multi Purpose Batch Plant

Production Requirements

00 llal [.

<

~

t

c;J @ loo

(kaJ

450

300

.~

~

(kg)

500

~

planning period

A 5000

B4000

Clooo

lOO

Economic Data

>

t

t

B3000

C7000

D2000 [kg]

E6000

..

- Sales prices

- raw mat. costs

- storage costs

Subdivision of

Planning period

into production

campaigns

Camp

II

Camp

21

3

5

Module-Task

Allocations

Production line

(Product A)

G~~

Campaign I

Production line

(Product B)

~

S

I

Gantt Chart

Prod. line I

t

I

I

l----1-t----,r----_-1..t_.-_____

Figure 5: Multi-purpose planning

t

t

--t

17

it will not be rigidly adhered to in day to day production planning. There must be flexibility to

adapt, for example, to short-term changes in equipment availability, local working conditions or

utility capacity. There will probably be less freedom to assign process tasks to equipment items

than in the earlier construction of multipurpose campaigns. However, there must be the possibility

to make local adjustment to the timing and allocation of individual batches and to propagate the

consequences of these changes.

In practice, this is often done manually on a bar chart. A similar graphical facility can be made

available in a computer, or a more comprehensive computer program could not only propagate

the consequences of a change, but also examine alternative measures to adapt most profitably to

the change. Various aspects of scheduling will be reviewed later.

Accommodating the Variety of Batch Processing

If the manufacture of fine and speciality chemicals is to be undertaken, the following questions

should be considered:

1. Which products, in consideration of their process and market characteristics are suitable

for batch processing?

2. Which products might be produced together in shared equipment?

3. Which groups of products have sufficiently homogeneous processing requirements that

they might be produced consecutively in a single multi-production line?

4. Which products have diverse or fluctuating requirements suggesting that they might be

produced in a general mUlti-purpose facility?

5. On the basis of past experience and anticipated developments, what range of equipment

items should be installed in a multipurpose facility?

Whatever decisions are taken about product assignments to particular types of production and

choice and configuration of equipment, there will be continual need for monitoring performance,

for scheduling and rescheduling production, and for evaluation the effect of introducing new

products and deleting old ones.

Harnessing the inherent flexibility of batch processing to deal effectively with change and

uncertainty is a problem which is solved routinely in practice. However, the mathematical

representation of this problem and how it can be solved in a truly optimal way, are still the subject

of study, some of which is reported later.

18

What Facilities I Tools Are Needed or Advantageous?

•

The ability to assess relevant overall data and make rapid order of magnitude estimates of the

effect of constraining factors or potential benefits

Hence, to identify elements exercising the dominant constraints on improvements

•

The ability to predict the effect of measures to relieve the constraints and hence expected

improvements resulting from suggested changes

•

In some cases, optimization capability to extract the maximum benefit from certain defined

types of changes may be justified

•

Packages to perform some of these tasks may be available: overall or detailed simulation,

design, scheduling, optimization

•

Flexible capability to do a variety of simple calculations and easy access to the necessary

basic data may often be important

Some Challenges and Opportunities in Batch Processing

1. Because of the great diversity of batch processing, measures are needed to characterize

a batch processing situation to enable computer and other aids to be matched to requirements.

2. Quick estimation procedures to assess whether features of the system are sufficiently

significant to be considered in greater detail.

3. Integration of knowledge to make available as appropriate the totality of knowledge about

the system including hierarchical model representations.

4. Batch process synthesis including co-ordination of the performance of individual stages

with overall requirements of assignment and scheduling, perhaps also coupled with

multi-product considerations.

5. Non-linear and integer programming - efficient problem formulation, significance and

exploitation of problem structure.

6. Catalogue of potential benefits of profile optimization for different batch operations,

reaction kinetics and objective functions.

19

7. Guidelines for potential usefulness of adaptive control, on-line estimation, optimization

as a function of the batch operation, the conditions'to which it is exposed and the wider plant

environment in which it is situated.

8. Single/multi-product plant design - potential benefits of recipe adjustment. Is the more

detailed examination of scheduling at the design stage beneficial?

9. Effect of wide ranging uncertainty on multi-product or multi-purpose design. When is it

sensible to drop explicit consideration of product demands and what should be done then?

10. Are there significant advantages in coordinating the dynamic simulation of individual

batch units over the whole process and coupling with sequence control?

11. What can be achieved in scheduling, and where will further progress be made, for example

with reference to problem size, interaction with the user, relative merits of algorithmic

(integer programming) versus heuristic, knowledge-based methods?

12. What is really new - pipeless plants? anything else?

Conclusion

Industrial interest in fine and speciality chemicals has increased substantially in recent years, not

least because these often seem to be the most profitable parts ofthe chemical industry. Over the

same period academic work has produced a number of models which have been refined in various

ways to express details of how batch processing could be carried out.

There is certainly scope for further interaction between industry and university to match

modeling and optimization capabilities to industrial requirements. One benefit of the present

institute could be further moves in this direction.

Addendum

For further details and a comprehensive reference list, the reader is directed to D. W. T. Rippin,

Batch Process Systems Engineering: A Retrospective and Prospective Review, ESCAPE-2,

Supplement to Comput. & Chern. Engineering, 17, Supplement, S I-S 13 (1993)

Future Directions for Research and Development in

Batch Process Systems Engineering

Gintaras V. Reklaitis

School of Chemical Engineering, Purdue University, West Lafayette, IN 47907-1283, USA

Abstract: The global business and manufacturing environment, to which the specialized and

consumer products segments of the CPI are subjected, inexorably drive batch processing into the

high tech forefront. In this paper the features ofthe multipurpose batch plant of the year 2000 are

reviewed and the implications on its design and operation summarized. Research directions for

batch process systems engineering are proposed, spanning design applications, operations

applications and tool developments. Required advances in computer aided design encompass task

network definition, preliminary design of multipurpose plants, retrofit design, and plant layout.

Needs in computer support for operations include integration of the application levels of the

operational hierarchy as well as specific developments in scheduling, monitoring and diagnosis,

and control. Advances in tools involve improved capabilities in developing and testing algorithms

for solving structured 0-1 decision problems and interpreting their results, further enhancements

in capabilities for handling large scale differential algebraic simulation models with implicit

discontinuities, and creation of flexible data models for batch operations.

Keywords: Algorithm adversary, computer integrated manufacturing, continuous/discrete

simulation, control, data mode~ heat integration, manufacturing environment, materials handling,

mixed integer optimization, monitoring and diagnosis, multiplant coordination, multipurpose plant,

plant layout, preliminary design, reactive scheduling, resource constrained scheduling, retrofit

design, task networks, uncertainty

Introduction

The lectures and presentations of this Advanced Study Institute have amply demonstrated the

vigor and breadth of contemporary systems engineering developments to support batch chemical

processing. Much has been accomplished, particularly in the last ten years, to better understand

21

the design, operations, and control issues relevant to this sector of the chemical industry. New

computing technologies have been harnessed to solve very challenging and practical engineering

problems. Yet, given the explosive growth in hardware capabilities, software engineering and

tools, and numerical and symbolic computations, further exciting developments are within our

reach. In this presentation, we will attempt to sketch the directions for continuing developments

in this domain. Our proposals for future research are based on the conviction that the long term

goal for batch process systems engineering should be to fully realize computer integrated

manufacturing and computer aided engineering concepts in the batch processing industry in a form

which faithfully addresses the characteristics of this mode of manufacturing.

Trends in the Batch Processing Industry

Any projections of process systems engineering developments targeted for the batch processing

industry over the next five to ten years necessarily must be based on our anticipation of the

manufacturing challenges which that industry will need to face. Thus, the point of departure for

our discussion must lie in the assumptions that we make about the directions in which the batch

processing industry will evolve. Accordingly, we will first present those assumptions and then

launch into our discussion of necessary batch process systems developments.

Chemical Manufacturing Environments 2000

As noted by Loos [12] and Edgerly [6] the chemical industry in the year 2000 will evolve to four

basic types of manufacturing environments: the consumer products company, the specialized

company, the utility, and the megacompany.

The consumer products company, of which 3M, Procter & Gamble, and Unilever are present

day precursors, features captive chemical manufacturing which supports powerful consumer

franchises. The manufacture offine chemicals, polymers, and petrochemicals within this type of

company will be driven by consumer demands and as these peak and wane chemical processing

will have to change to accommodate. The market life of such products is often two years or less

[24]. Many food processing companies are tending in this direction.

The specialized companies, of which Nalco and Lubrizol are illustrative, will be midsized

organizations that possess unique technical capabilities and marketing/customer access. These

organizations will be involved in continuous technical innovation and intensive focus on customer

22

service and thus their manufacturing functions will subject to continuous product tum-overs,

pressures for quick start-up and rapid response to market needs. Pharmaceutical companies are

evolving in this direction.

The utility, of which SABIC is a precursor, will be the low cost converter of chemical

feedstocks into basic building block chemicals for the other sectors of the CPI. This type of

organization will flourish by virtue of its leading-edge technology, world-class scale of production,

and advantaged access to raw material or energy sources. Manufacturing in such an organization

will be highly automated and optimized for operation with minimum upsets and quality deviations.

The fourth category, the megacompany will be the leader in diverse segments of the chemical

market, encompassing some or all of the above manufacturing models. These organizations will

operate on a global basis with great technical depth, and financial and marketing strength. DuPont,

Hoechst, and ICI could be precursors of such companies. Manufacturing in the megacompany

will be subject to the same factors as the above three types of companies depending upon the

sector in which that particular arm of the organization competes.

It is clear that the specialized and consumer products companies and analogous arms of the

megacompanies will be the CPI components in which batch processing will continue to grow and

flourish. These sectors of the processing industry will increasingly share in the same business

environment as experienced in discrete manufacturing: a high level of continuous change in

products and demands, close ties to the customer, whether consumer or other organization, strong

emphasis on maintaining quality and consistency, accelerating demands for worker, product, and

community safety and prudent environmental stewardship, and relentless competitive pressures

to be cost effective.

Consequences of the Changing Environment

The consequences of these factors are that batch processing, the most ancient mode of chemical

manufacturing, will be increasingly driven into the high technology forefront. The batch plant of

the year 2000 will be a multipurpose operation which uses modularized equipment and novel

materials handling methods and is designed using highly sophisticated facilities layout tools. It will

feature a high degree of automation and well integrated decision support systems and,

consequently, will require significantly lower levels of operating staff than is present practice. The

batch processing based firm will employ a high degree of integration of R&D, manufacturing and

business functions, with instantaneous links to customers, suppliers, as well as other cooperating

23

plant sites on a global basis. It will employ computer aided process engineering tools to speed the

transition from the development of a product to its manufacture, without the protracted learning

curves often now encountered.

Design Implications: Short product life and intensely competitive markets will impose major

challenges on both the manufacturing and the product development processes. Responsiveness to

the customer needs for tailored formulations, generally, will lead to increasing specialization and

multiplication of products, resulting in increased focus on very flexible, small batch production.

The multipurpose chemical plant will become the workhorse of the industry. At the same time, in

order to reduce the operational complexity often associated with multipurpose plants,

standardization and modularization of the component units operations will be employed, even at

the cost of higher capital requirements and possibly lower capacity utilization levels. As in the

manufacture of discrete parts, streamlining of flexible, small batch production will require

increased focus on the materials handling aspects of batch operations. With small batch operation,

the traditional pipes, pumps, and compressors can, depending upon recipe details, loose their

effectiveness as material transfer agents. Other modes of transfer of fluids and powders such as

moveable bins, autonomous vehicles, and mobile tanks can become more efficient alternatives.

Factors such as efficient materials handling logistics, reduction of in-process inventories,

minimization of cross-contamination possibilities and increased operating staff safety will dictate

that consideration of physical plant layout details be fully integrated into the design process and

given much greater attention than it has in the past.

The industry will also need to give increased emphasis to reducing the product development

cycle. This means employing sophisticated computational chemistry tools to guide molecule design

and exploiting laboratory automation at the micro quantity level to accelerate the search for

optimum reaction paths, solvents and conditions. The use of large numbers of automated parallel

experimental lines equipped with robotic aids and knowledge based search tools will become quite

wide-spread. To insure that recipe decisions take into account available production facilities early

in product development, process chemists will need to be supported with process engineering tools

such as preliminary design and simulation software. Use of such tools early in the development

process will identifY the time, resource, and equipment capacity limiting steps in the recipe,

allowing process engineering effort to be- focused on steps of greatest manufacturing impact. The

models and simulations used in development will need to be transferred to production sites in a

24

consistent and usable fonn to insure that processing knowledge gained during development is fully

retained and exploited.

Operational Implications: Since maintenance of tight product quality standards will be even more

of a necessity, sophisticated measurement and sensing devices will be required. The need to

control key product quality indices throughout the manufacturing process will put high demands

on the capabilities of regulatory and trajectory tracking control systems. Early prediction and

correction of recipe deviations will become important in order to reduce creation of off-spec

materials and eliminate capacity reducing reprocessing steps. Thus, integrated process monitoring,

diagnosis and control systems will be widely employed. The needs to largely eliminate operator

exposure to chemical agents and to contain and quickly respond to possible releases of such

materials will further drive increased use of automation and robotic devices. Indeed, all routine

processing and cleaning steps will be remotely controlled and executed. To allow the reduced

number of operating staff to effectively manage processes, intelligent infonnation processing and

decision support systems will need to be provided. Effective lateral communications means

between corporate staff world-wide will be employed to facilitate sharing of manufacturing

problem solving experience, leading to continued manufacturing quality improvements. Rapid and

predictable response to customer orders will require development of simple, reliable operating

strategies and well integrated scheduling tools. Manufacturing needs for just-in-time arrival of raw

materials, key intennediates, and packaging supplies will drive the development of large scale

planning tools that can encompass multiple production site and suppliers. The realization of

computer integrated process operations will require extensive and realistic operator and

management training using high fidelity plant training simulations. These models will further be

used in parallel with real plant operation to predict and provide benchmarks for manufacturing

perfonnance.

The inescapable conclusion resulting from this view of trends in batch chemical processing is

that the needs for infonnation management, automation, and decision support tools will accelerate

dramatically over the next decade. The marching orders for the process systems community are

thus to deliver the concepts and tools that will

~ncrease

the cost-effectiveness, safety, and quality

of multipurpose batch operations. The greatest challenge will be to use these tools to discover

concepts and strategies that will lead to drastic simplifications in the design and operation of batch

facilities without loss in efficiency or quality. Simplifications and streamlining of potentially

25

complex manufacturing practices will be the key to maximum payoffs in safety, reliability, and

competitiveness.

Research Directions for Batch Process Systems Engineering

In this section, we will outline specific areas in which productive process systems developments

should be made. Our projection of research directions will be divided into three areas: design

applications, operations applications, and tool development. This division is admittedly artificial

since in the batch processing domain design and operation are closely linked and successful

developments in both domains depend critically on effective tools for optimization, simulation, and

information processing and solution comprehension. However, the division is convenient for

discussion purposes.

Advances in Design

While considerable methodological progress has been made since the review of computer aided

batch process design given at FOCAPD-89 [20], a number ofissues remain unexplored. These can

be divided into four categories: task network definition, preliminary design methodology, retrofit

design approaches, and plant layout.

Task Network Definition: The key process synthesis decisions made early in the development of

a product center on the definition of the precise product recipe and the aggregation of subsets of

the contiguous steps ofthe recipe into tasks which are to be executed in specific equipment types.

These decisions define the task network which is the basis for selecting the number and size of the

process equipment. Recipe definition is usually made by process chemists in the course of

exploring alternative synthesis paths for creating the product or molecule of interest. The

decisions involved include the selection of the most effective reaction path which has direct impact

on solvents to be employed, reaction conditions, by-product formation, and the types of unit

operations which will be required. Task selection involves a range of qualitative and experiential

information which incorporates choices of the broad types of equipment which will be selected to

execute the tasks. The overall task network definition problem would be greatly facilitated if a

knowledge based framework could be developed for task network synthesis which incorporate

both the recipe definition and task selection components. To date the proprietary PROVAL

package [1] remains the only development which addresses some aspects of this synthesis

problem.

26

Preliminary Design ofMultipurpose Plants: The recent work ofPapageorgaki [16] and Shah

and Pantelides [23] does address the deterministic, long campaign case, while Voudouris and

Grossmann [27] offer approaches to incorporating discrete equipment sizes. However, one of the

key issues in grass roots design of such facilities is the treatment of uncertainties. Shah and

Pantelides [22] do suggest an approach for treating multiple demand scenarios within a

deterministic formulation of the problem, an idea which had previously been advanced by Reinhart

and Rippin [19] in the multiproduct setting. Moreover, it would appear that the staged expansion

concept, initially explored by Wellons [28,29] for longer term demand changes, merits

consideration in the multipurpose case, especially in the context of modular plant expansion. Yet

missing is a framework for handling likely changes in the product slate, in other words

uncertainties in recipe structures, since one of the key reasons for the existence of multipurpose

plants is the adaptability of the plant in accommodating not only demand but also product changes.

The latter aspect of flexibility needs to be given a quantitative definition.

The increasing interest in alternative material handling modes raises questions of under what

recipe conditions these various alternatives are most cost effective. For instance, the vertical

stacker crane concept appears to be advantageous for the short campaign, reaction dominated

recipe, while the tracked vessel concept is said to be appropriate for mixinglblending type recipes.

Clearly, depending upon recipe structure and campaign length, different combinations of these

handling modes together with conventional pipe manifold systems might be most economical. The

incorporation of these material handling options within an overall process design framework

would appear to be highly desirable as a way of allowing quantitatively justified decisions to be

made at the preliminary design stage.

While mathematical programming based design formulations are adequate at the preliminary

design stage, detailed investigation of designs requires the use of simulation models. Simulation

models do allow consideration of the dynamics of key units, step level recipe details, complex

operating strategies, as well as stochastic parameter variations. Ideally such simulations should

also form the basis for detailed design optimizations. However, while batch process simulation

capability does exist (see [3]), the optimization of dynamic plant models with many state and time

event discontinuities continues to present a challenging computational problem. Although some

interesting developments in the optimization of differentiaVaigebraic systems involving applications

27

such as batch distillation columns [2] have been reported, further investigation of strategies for

the optimization ofDAE systems with implicit discontinuities are clearly appropriate.

Retrofit Design: A MINLP formulation and decomposition based solution approach for the

retrofit design of multipurpose plants operating under the long campaign operating strategy was

reported in [15]. This formulation included consideration of changes in product slate and demands