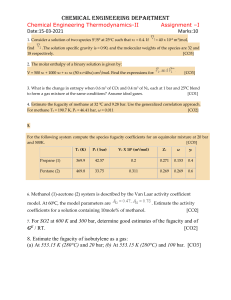

A Textbook ofChemical Engineering thermodynamics KV NARAYANAN

advertisement