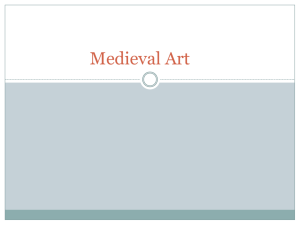

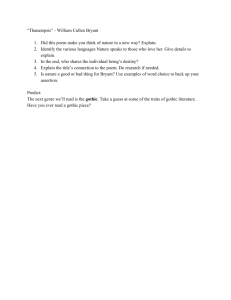

Journal of Global History (2011) 6, pp. 381–406 ª London School of Economics and Political Science 2011 doi:10.1017/S1740022811000386 Mega-structures of the Middle Ages: the construction of religious buildings in Europe and Asia, c.1000–1500* Maarten Prak Department of History and Art History, Utrecht University, Drift 10, 3512 BS Utrecht, the Netherlands E-mail: m.prak@uu.nl Abstract How did medieval builders manage to construct some of the tallest structures in the world without access to modern engineering theories? Construction drawings were limited to details and, with only a handful exceptions, manuals for builders only appeared in the late fifteenth century. By implication, the relevant knowledge had to be transferred on a personal basis. Its underlying principles must therefore have been reasonably simple. This article shows how a modular design, combined with on-site experimentation, guided much of the construction work on large projects such as European cathedrals, Middle Eastern mosques, Indian temples, and Chinese pagoda towers. Keywords apprenticeship, construction technology, craft skills, modularity, religious buildings Introduction When building began in 1136 on the new choir for the church of Saint-Denis, north of Paris, the Latin West started a building boom that was to last some three hundred years.1 The Helpful suggestions came from Lex Bosman (Amsterdam), Qinghua Guo (Melbourne), and Aart Mekking (Leiden, emeritus); from audiences at Universität Konstanz, Cambridge University, the London School of Economics, and Utrecht University; from five anonymous referees; and from the editors of this journal, especially William Gervase Clarence-Smith, who has been very supportive. Throughout the work on this article, the enthusiasm of Merlijn Hurx (Utrecht) and Jan Luiten van Zanden (Utrecht) has been very encouraging. Essential assistance was provided by Koen Ottenheym (Utrecht); Daniel Curtis (Utrecht) improved my English. The original idea for the article was inspired by materials found in S. R. (Larry) Epstein’s study after his death in 2007, and by an as yet unpublished paper due to appear in a volume edited by the present author and Jan Luiten van Zanden. Even though I am not sure that he would have approved of what I have done with them, I would still like to dedicate this article to Larry’s memory. All errors are mine alone. 1 Robert A. Scott, The Gothic enterprise: a guide to understanding the medieval cathedral, Berkeley, CA: University of California Press, 2003, ch. 1. The term ‘Latin West’ is used here because I also discuss the Byzantine empire, which was partly located in Europe. To avoid cumbersome description, I will henceforth use the word ‘Europe’ to stand in for the Latin West. 381 j 382 j M A A R T E N P R A K Gothic building style, of which the Saint-Denis choir was the first example, originated as the visual expression of a bid for power by the French kings, and early projects were undertaken in the region around their capital, Paris. The size and symbolism of these buildings were tributes in equal measure to the power of God and to that of the sovereign as his worldly representative.2 The style became popular throughout Europe: medieval cathedrals are still among the tallest structures in many European towns. They are triumphs of human ingenuity, culturally as well as technologically. The Latin West, however, was not the only area of Eurasia where major building projects were undertaken for religious purposes.3 In China during the Song (960–1279), many pagodas and pagoda towers were built, of heights not previously attained.4 In Cambodia from the eighth to the thirteenth centuries, ‘admirable structures of exceptional scope’ were built, most notably the Angkor Wat temple complex.5 In Asia Minor, spectacular works had been completed earlier, such as Hagia Sophia (Aya Sofya) in Istanbul, and during the Byzantine era routine church construction continued apace.6 In the Islamic world, a great many architectural monuments date from the first half of the second millennium, and many of these were built with a religious purpose. These include several mosques and madrassas in Cairo, the Great Mosque in Bursa, Turkey, and the 72.5-metre-high Qutb minaret in Delhi, as well as non-religious buildings such as the Alhambra in Granada, Spain.7 Much as we can admire the artistic achievements of these works, they also raise questions of a more practical nature. How did builders master the techniques necessary to erect these large structures and ensure their technical integrity? Because of the complex challenges associated with tall constructions, and their presence throughout Eurasia, the building industry provides us with an opportunity to compare the application of cutting-edge technology under more or less identical circumstances across many different regions and cultures. It allows us, in other words, to identify the characteristics of the technological platforms for economic development available to the societies that are central to the debate on the ‘Great Divergence’.8 By focusing on a single industry, this 2 Dieter Kimpel and Robert Suckale, Die gotische Architektur in Frankreich 1130–1270, Munich: Hirmer Verlag, 1985, pp. 67–76. Compare Elena Paskaleva, ‘The architecture of the Four-Iw an building tradition as a representation of paradise and dynastic power aspirations’, PhD thesis, Leiden University, 2010. 3 James W. P. Campbell, Brick: a world history, London: Thames & Hudson, 2003, ch. 3. 4 Ibid., p. 92. 5 Jacques Dumarçay and Pascal Royère, Cambodian architecture, eighth to thirteenth centuries, trans. and ed. by Michael Smithies, Handbook of Oriental Studies, section 3: South-East Asia, vol. 12, Leiden: Brill, 2001, p. 109. 6 Robert Mark and Ahmet Ş . Çakmak, eds., Hagia Sophia from the age of Justinian to the present, Cambridge: Cambridge University Press, 1992; Robert Ousterhout, Master builders of Byzantium, Princeton, NJ: Princeton University Press, 1999. 7 George Michell, ed., Architecture of the Islamic world: its history and social meaning, London: Thames & Hudson, 1984, pp. 209–80. Other surveys include K. A. C. Creswell, A short account of early Muslim architecture, revised and supplemented by James W. Allan, Aldershot: Scolar Press, 1989; Robert Hillenbrand, Islamic architecture: form, function and meaning, Edinburgh: Edinburgh University Press, 1994, pp. 66–128; M. Shokooy, Muslim architecture of South India, London: Routledge, 2002. 8 Referring to Kenneth Pomeranz, The great divergence: China, Europe, and the making of the modern world economy, Princeton, NJ: Princeton University Press, 2000, and the subsequent debate about the argument found in that book, in the pages of this journal, and elsewhere. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 383 article may offer a form of comparison that has so far been underemployed in global economic history, where scholars have instead followed in the footsteps of Pomeranz’ book, preferring to compare geographical regions, in spite of the problems created by such heterogeneous units of analysis.9 As in other historical disciplines, the history of technology is usually subdivided into two clearly distinguishable periods: before and after the eighteenth century. In earlier ages, technological improvements were not entirely absent, but they were haphazard, the result of trial and error.10 Once scientists were able to explain the underlying principles – that is, when the Scientific Revolution kicked in – inventors could develop new technologies much more systematically. As a result, the pace of technological improvements increased dramatically, leading in turn to long-term economic growth. There is no reason to quarrel with the general outline of this story. It does, however, offer some intriguing questions about technology and technological change in the pre-modern era. To address these it is useful to start with a distinction that Joel Mokyr made between propositional (or ‘what’) knowledge and prescriptive (or ‘how’) knowledge, which he also called V or epistemic and l or technical types of knowledge.11 For Mokyr, the two are intimately related: ‘for a technique to exist, it must have an epistemic base in V’.12 It is immediately clear that the weakness of V before the Scientific Revolution of the seventeenth century must have fatally held back the development of l, or technology, and thus, by implication, economic progress. However, the building industry seems to suggest a different relation between V and l types of knowledge. The industry achieved impressive accomplishments in practice, without much change in the theoretical foundations of the building craft. This raises three specific questions: first, how could the building industry progress along the scales of size and complexity; second, what was the nature of the knowledge utilized by builders; and third, how was this knowledge transmitted from one generation to the next? The building industry is an appropriate laboratory to investigate issues of knowledge and human capital formation for several reasons. First and foremost, the construction of large religious buildings far outstripped the scientific understanding of the mechanics working on such large structures. Second, the industry experienced a string of innovations necessary to realize the artistic ambitions of those who commissioned Gothic churches and similar structures. Third, the industry was a truly global one. Finally, thanks to the record-keeping of church institutions, and to the hard work of generations of art historians, the source material for this industry is relatively abundant, especially for Europe. The more complete European picture is used here to flesh out the fragmented evidence from the Middle East and South and East Asia. 9 Other examples include Karel Davids, ‘River control and the evolution of knowledge: a comparison between regions in China and Europe, c. 1400–1800’, Journal of Global History 1, 1, 2006, pp. 59–80, and Robert Finlay, The pilgrim art: cultures of porcelain in world history, Berkeley, CA: University of California Press, 2010. 10 Steven A. Epstein, An economic and social history of later medieval Europe, 1000–1500, Cambridge: Cambridge University Press, 2009, pp. 190–215. 11 Joel Mokyr, The gifts of Athena: historical origins of the knowledge economy, Princeton, NJ: Princeton University Press, 2002, ch. 1. 12 Ibid., p. 13. j 384 j M A A R T E N P R A K This comparison allows us to gauge whether Europe’s production and reproduction of lknowledge was unique, or instead fitted a wider pattern. Unfortunately, medieval builders have left precious few written documents about the theories underpinning their work. Where available, those documents articulating construction theories are used here, but we also have to rely on the material record – that is, the church buildings themselves, and what these can tell us about the ways in which they were constructed.13 In this article, data from the art-historical literature is applied to questions raised by global historians and historians of technology. Church-building Between roughly 1150 and 1250, the new Gothic style transformed both the outlook and the construction of European religious buildings in fundamental ways. The stylistic innovations were first and foremost a radical shift in the balance between walls and windows. Romanesque buildings had thick walls and relatively few windows, whereas Gothic churches consisted almost entirely of glass, held together by slim, stone pillars. Other innovations included the placing of towers (which proliferated in Gothic buildings), the development of sculpted porches placed in deep recesses, the creation of round or ‘rose’ windows, the ribbed vault, and the flying buttress.14 The Gothic design was first developed in the region around Paris, and many innovations also originated there, although not always in connection with the famous cathedrals.15 From the Île-de-France, the style spread to other parts of Europe, being adapted to local tastes and traditions. In England, for instance, flying buttresses were rarely found, and builders continued the tradition of constructing thicker walls.16 In northern Germany, where natural stone was in short supply, builders had to construct Gothic designs in brick, creating the distinctive Backsteingotik, or brick Gothic.17 Construction challenges for tall buildings include the problems created by the structure’s own weight, the resistance to pressures from the natural elements, especially wind, and the necessity of natural light to illuminate the interior of the building.18 Gothic design was a huge improvement over Romanesque in terms of lighting because it allowed far larger surfaces of glass. At the same time, the height of the buildings made them more susceptible to 13 This approach has been particularly inspired by the works of John James and Robert Mark cited in nn. 6, 15, 18, 21, 49, 65, and 94, as well as by Robert Mark, ed., Architectural technology up to the Scientific Revolution: the art and structure of large-scale buildings, Cambridge, MA: MIT Press, 1993. 14 Christopher Wilson, The Gothic cathedral: the architecture of the great church 1130–1530, London: Thames & Hudson, 2000, pp. 69–70; Bill Addis, Building: 3000 years of design engineering and construction, London: Phaidon, 2007, pp. 95–9. 15 John James, The template-makers of the Paris Basin, Leura, New South Wales: West Grinstead Nominees, 1989, ch. 9. 16 Wilson, Gothic cathedral, p. 74. 17 Rudolf Pfefferkorn, Norddeutsche Backsteingotik, Hamburg: Christians, 1984. 18 Robert Mark, Light, wind, and structure: the mystery of the master builders, Cambridge, MA: MIT Press, 1990, ch. 2. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 385 wind pressures. The less solid construction of the vertical elements only increased the problems that builders had to overcome.19 One important aid was the ‘invention’ of the flying buttress.20 Through a complex combination of horizontal extension and vertical loading, builders managed to prevent the vaults from pushing the walls of the church outwards, and the vaults themselves from collapsing as a result.21 Another was the development of the pointed arch, which, through the double arc of its construction, created downward rather than outward pressure; this the builders probably copied from Arabic examples.22 They had to understand these problems and find solutions for them intuitively, as they had no laboratories to test the various pressures to which their constructions were exposed.23 In the Byzantine empire, the heyday of church-building was long over by 1000 CE. Hagia Sophia dates from the sixth century, and no equivalent church buildings were constructed during the subsequent millennium. However, a great many new churches were created in the revival following the Iconoclast Controversy, which ended in 843. Moreover, this period saw the development of a new church layout, the so-called cross-in-square. In contrast to the Latin churches, where the cross shape determined the ground plan of the building, this Byzantine type was almost square, with a cross shape inserted into the interior layout.24 Brick was the dominant building material in south-eastern Europe and Asia Minor. Such was also the situation in much of the Islamic world, where building stone was in short supply. Many early mosques were relatively simple constructions, consisting of a flat roof supported by rows of pillars. Their designers, descendants of nomads, had no great building tradition to help them.25 Early mosques incorporated Byzantine examples, building knowledge, and building materials.26 Ottoman builders later also used Byzantine examples as a source of inspiration, but even they were intimidated by the constructional challenge of Hagia Sophia, as they found it difficult to create a dome of equal size. (This, incidentally, was used by Christian critics as proof that Christianity was superior to Islam.27) In the 19 Philip Ball, Universe of stone: a biography of Chartres cathedral, New York: Harper Collins, 2008, ch. 8; also Jacques Heyman, The stone skeleton: structural engineering of stone masonry, Cambridge: Cambridge University Press, 1995. 20 Jean Gimpel, The medieval machine: the industrial revolution of the Middle Ages, London: Victor Gollancz, 1977 (originally published as La révolution industrielle du Moyen Âge), p. 121. 21 Alan Borg and Robert Mark, ‘Chartres cathedral: a reinterpretation of its structure’, Art Bulletin, 55, 1973, pp. 367–72; M. Wolfe and R. Mark, ‘Gothic cathedral buttressing: the experiment at Bourges and its influence’, Journal of the Society of Architectural Historians, 33, 1974, pp. 17–26; William Clark and Robert Mark, ‘The first flying buttresses: a new reconstruction of the nave of Notre-Dame de Paris’, Art Bulletin, 66, 1984, pp. 47–65; Mark, Light, ch. 1 and pp. 108–22. 22 Donald Hill, A history of engineering in classical and medieval times, London: Croom Helm, 1984, p. 99. 23 See Nicola Coldstream, Masons and sculptors: medieval craftsmen, London: British Museum Press, 1991, p. 60. For modern laboratory experiments on Gothic constructions, see the works of Robert Mark, esp. Light. 24 Ousterhout, Byzantium, p. 12. 25 Ulya Vogt-Göknil, Die Moschee: Grundformen sakraler Baukunst, Zürich: Verlag für Architektur, 1978, pp. 22, 26; Creswell, Muslim architecture, p. 16. 26 Henri Stierlin, Islam von Bagdad bis Córdoba: frühe Bauwerke vom 7. bis 13. Jahrhundert, Hong Kong: Taschen, 2009, pp. 28, 32, 48, 52. 27 Metin Ahunbay and Zeynep Ahunbay, ‘Structural influence of Hagia Sophia on Ottoman mosque architecture’, in Mark and Çakmak, Hagia Sophia, p. 180. j 386 j M A A R T E N P R A K sixteenth century, however, Ottoman architecture blossomed again, under the inspiring leadership of Sinan ibn Abdülmennan, who was appointed Chief Court Architect in 1538. Sinan single-handedly designed almost 500 mosques, and was the main source of inspiration for the best-known building from the era, the Sultan Ahmed Mosque, or Blue Mosque, in Istanbul.28 Most of the building in Song China (960–1279) remained of the traditional wooden post-and-beam type. An important innovation during this period, however, was the construction of brick towers, of which a good number survive. They seem to have been introduced by the Liao dynasty (907–1125), who were the first non-Chinese rulers of the empire.29 Their Buddhist towers often achieved impressive heights: the ‘Iron Pagoda’ of Kaifeng, which in fact was made of iron-grey glazed bricks, reached 57 metres; the wooden pagoda of the Fogong temple in Shanxi came to 67 metres; and the Liuhe, or Six Harmonies Pagoda in Hangzhou, also built in brick, stood 60 metres tall. The tallest still in existence is the Liaodi Pagoda, built in 1055, at 84 metres.30 Unlike most European towers, the Buddhist pagodas in China were free-standing buildings, without any support from an appended church building.31 They therefore had wide-spreading eaves, which helped to stabilize the construction.32 Aside from the usual dangers of fire (the pagoda in Kaifeng was struck by lightning and burned down in 1044), they also had to cope with problems of high winds and earthquakes.33 For this reason, the wooden posts-and-beams method of building was often preferred, set on top of a concrete platform but not inserted into it. The curved shape of the roofs helped the wind to skid over the structure, while the extension of the roofs also protected the wooden frame from the rain. Chinese builders used roof tiles up to four times as heavy as those employed in Europe, again to stabilize the constructions. Compared to European cathedrals, pagodas were built quickly, in less than ten years.34 The workforce Major European building projects employed highly variable workforces. During the summer months of 1253, up to 435 people were working on Westminster Abbey, of whom 130 were stonemasons and 220 were assistants employed on various tasks. In September the number was halved, mainly because the assistants left the site, presumably to participate in the harvest. For the building of the cathedral in Regensburg, in 1459 master Conrad Roriczer 28 Aptullah Kuran, Sinan: the grand old master of Ottoman architecture, Istanbul: Ada Press, 1987; Robert Hillenbrand, Islamic art and architecture, London: Thames & Hudson, 1999, p. 264. 29 William Watson, The arts of China 900–1620, New Haven, CT: Yale University Press, 2000, pp. 67–72. 30 Watson, China, ch. 5; also Ernst Börschmann, Die Baukunst und religiöse Kultur der Chinesen, vol. 3: Pagoden, Berlin: Walter de Gruyter, 1931. 31 Qinghua Guo, Chinese architecture and planning: ideas, methods, techniques, Stuttgart: Edition Axel Menges, 2005, ch. 5. 32 Watson, Arts of China, p. 78. 33 Else Glahn, ‘Chinese building standards in the 12th century’, Scientific American, 244, 5, 1981, p. 132; Lothar Ledderose, Ten thousand things: module and mass production in Chinese art, Princeton, NJ: Princeton University Press, 2000, pp. 106, 110. 34 Guo, Chinese architecture, p. 64. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 387 employed between eight and twelve stonemasons and a lodge-assistant, an apprentice for three weeks, as well as two to four carpenters.35 The employment of a few dozen workers seems to have been the normal situation. ‘Routine’ activities could be interspersed with short campaigns, when much larger numbers were employed. The building of Canterbury Cathedral, which lasted from 1175 till 1517, consisted of 161 years of high activity and 182 years of low activity.36 The specialist workforce was recruited from a wide area and was therefore highly mobile.37 On the building site of Prague Cathedral in 1372–78, next to the local workers were found Germans from twenty different towns and regions, as well as workers originating from Hungary, Poland, and Brabant in the Low Countries. Of 131 stonemasons employed at Vale Royal Abbey between 1278 and 1280, at most 10% were recruited locally; the rest came from a variety of English counties. On the other hand, at least half the carpenters and blacksmiths were local people, and around 90% of the semi-skilled and unskilled assistants came from the area itself.38 Similar mobility among stonemasons was found in the town of Kampen in the Netherlands. During the fifteenth and sixteenth centuries, the town’s stonemasons, mainly charged with the building of the town’s major churches, came from a wide area in the Low Countries and western Germany. The town’s official carpenters, however, seem to have been recruited mostly (although not exclusively) from the ranks of local masters.39 Both the organization of the building process and the distribution of technical knowledge required a collaboration of local and itinerant craftsmen.40 Transportation costs were such that stone was preferably quarried on the site of the building project. Stone used in Marlborough in 1237 cost 3 shillings per unit at the quarry but another 22 shillings for carriage. In the early fourteenth century, land transport of stone across five or six miles cost the equivalent of the stone itself, and it was much cheaper to carry it across water. Stone from Normandy was shipped through Caen to England, and in 1287 the transport costs of a shipload ordered for the building of Norwich Cathedral were only twice as much as the stone itself.41 A first implication was that, whenever the two were situated far apart, stone was preferably prepared at the quarry rather than at the building site; otherwise expensive transport would be wasted on excess material. Moreover, this allowed the identification of low-quality pieces before shipping.42 In the Low Countries, stone was found in a crescent-shaped region running roughly from Ghent, across 35 Günther Binding, in collaboration with Gabriele Annas, Bettina Jost, and Anne Schunicht, Baubetrieb im Mittelalter, Darmstadt: Wissenschaftliche Buchgesellschaft, 1993, pp. 272–6. 36 Scott, Gothic enterprise, p. 40. 37 Spiro L. Kostof, ‘The architect in the Middle Ages, east and west’, in Spiro L. Kostof, ed., The architect: chapters in the history of the profession, Berkeley, CA: University of California Press, 2000, p. 83. 38 Binding, Baubetrieb im Mittelalter, pp. 284–5. 39 C. J. Kolman, Naer de eisch van ’t werck: de organisatie van het bouwen te Kampen 1450–1650, Utrecht: Matrijs, 1993, chs. 7 and 9. 40 S. R. Epstein, ‘Transferring technical knowledge and innovation in Europe, c.1200–c.1800’, unpublished paper for the Economic History Association Annual Conference, San Jose, September 2004. 41 L. F. Salzman, Building in England down to 1540: a documentary history, Oxford: Clarendon, 1967, pp. 119, 132–3. 42 H. Janse and D. J. de Vries, Werk en merk van de steenhouwer: het steenhouwersambacht in de Nederlanden voor 1800, Zwolle: Waanders, 1991, p. 10. j 388 j M A A R T E N P R A K Brussels, to Maastricht. This stone supplied the northern territories, which were deprived of their own stock of raw materials.43 The system eventually became so sophisticated that, in the course of the Middle Ages, complete pre-fabricated churches were prepared at the quarry to be shipped as parts to the building site, where they were assembled by local workmen.44 The other implication was that crucial knowledge tended to be connected to the building material. Again the Low Countries provide intriguing examples.45 Between the late fourteenth and the mid sixteenth century, successive generations from the Keldermans family, who originated from Brussels but later moved to Antwerp, were contracted to supply stone, as well as to design and execute numerous public buildings, both religious and civic, in the northern Netherlands. They prepared complete plans (‘patterns’, in the sources), as well as specific features, and provided the templates for the various stone parts necessary to erect the structure. The Keldermans’ firm also supplied their customers with sculptures, and they were charged with working the stone from quarry to finished building.46 Before a church was built in stone, it had to be constructed in wood. Because these wooden structures were taken down after the building was finished, one often overlooks the contribution of carpenters, who were vital to the whole construction process.47 First, carpenters set up the scaffolding that allowed builders to move around. For the building of Westminster Abbey, the accounts of 1324 refer to 400 pieces of alder of 38 feet, 25 pieces of 20 feet, and 61 pieces of ash of 42 feet; all this wood was used for scaffolding.48 Second, complex parts such as stone vaults were set in wooden frames until the mortar hardened, a process that could take six months or longer.49 Third, some important parts of the church were built of wood, notably the roofs. The vaults were usually made of stone but these were covered by roofs made entirely of timber and covered in slate, tile, or lead to keep the water out. These timber roof structures were often very elaborate. It is estimated that the roof of Our Lady’s Church (Liebfraukirche) in Ingolstadt, Germany, contained the wood of some 3,800 trees.50 Unfortunately, very little is known about the carpenters who undertook this work. We do know that they had to be able to use a variety of tools to exercise their trade: the largest 43 Ibid., pp. 10–19. 44 R. Meischke, De gothische bouwtraditie, Amersfoort: Bekking, 1988, pp. 79–84; Merlijn Hurx, ‘Middeleeuwse ‘‘pre-fab’’ in de Nederlanden? De Hollandse kerken van de Antwerpse loodsmeester Evert Spoorwater’, KNOB-Bulletin 106, 2007, pp. 112–34; and Merlijn Hurx, Architect en aannemer: de opkomst van de bouwmarkt in de Nederlanden, 1350-1530, Nijmegen: Vantilt, 2011. 45 Janse and de Vries, Werk en merk, ch. 5. 46 J. H. van Mosselveld, Keldermans: een architectonisch netwerk in de Nederlanden, The Hague: Staatsuitgeverij, 1987, ch. 1. 47 John Fitchen, The construction of Gothic cathedrals: a study of medieval vault erection, Oxford: Clarendon Press, 1961, ch. 2; James W. P. Campbell ‘The carpentry trade in seventeenth-century England’, Georgian Group Journal, 12, 2002, pp. 216–17. 48 Salzman, Building in England, pp. 318–19. 49 John James, Chartres: the masons who built a legend, London: Routledge & Kegan Paul, 1982, p. 41. 50 Barbara Schock-Werner, ‘Bauhütten und Baubetrieb der Spätgotik’, in Anton Legner, ed., Die Parler und der Schöne Stil 1350–1400: Europäische Kunst unter den Luxemburgern, vol. 3, Cologne: Kunsthalle, 1978, p. 58. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 389 number of different items listed in a study of medieval building tools concerned carpentry. These included various types of axes, saws, drills, hammers, and chisels, as well as a compass, square, plane, file, and rasp.51 Carpenters seem to have been mostly local craftsmen, but this is inferred from the absence of references to itinerant carpenters rather than from any positive evidence. One source to have survived on the building workers who constructed the Timurid sacred buildings, in what is today northern Iran, Afghanistan, Uzbekistan, and Turkmenistan, is a picture copied in 872 AH/1467 CE, which is now in the Johns Hopkins University library (see Figure 1). It shows a variety of artisans, including stonecutters, tile-makers, brickmasons, and mortar-makers. There is also scaffolding in evidence, suggesting a contribution by carpenters. Equally interesting is the variety of ethnic backgrounds of the workmen pictured here, which include people from the region, as well as people seemingly of Mongol and African descent, suggesting mobility among building workers.52 The variety of crafts is confirmed by a compilation of the names of craftsmen found on a range of Timurid buildings, which covered over twenty different crafts; carpenters were among the most numerous with 15 references, out of a total of 107 craftsmen.53 This seems typical of the situation in other parts of the Islamic world, where we find the same types of crafts on building sites.54 These must have been highly skilled men: one of their great feats was the building of large domes without centring – that is, without the help of a wooden support structure. A striking difference with European building practices was the speed of construction: in the Islamic areas large structures were usually erected within a decade.55 Although some master-builders were identified by name, the great majority of them worked anonymously, as they did in the Latin West.56 This underlines the dominant role of the community of builders, as opposed to the single creator. The Islamic building community was highly mobile, possibly owing to conscription or slavery, rather than to voluntary migration.57 In Egypt, occupational terms in the building industry closely followed those of raw materials.58 In India, architects and sculptors were indicated with the same word – r uv ar – suggesting a connection between knowledge of stone and construction expertise that was similar to 51 Frieda Van Tygem, Op en om de middeleeuwse bouwwerf: de gereedschappen en toestellen gebruikt bij het bouwen van de vroege middeleeuwen tot omstreeks 1600, Brussels: Paleis der Academiën, 1966, pp. 1–70. 52 Lisa Golombek, Donald Wilber, et al., The Timurid architecture of Iran and Turan, 2 vols, Princeton, NJ: Princeton University Press, 1988, vol. 1, pp. 91–2, and vol. 2, pl. 481. 53 Ibid., vol. 1, pp. 65–6; Oleg Grabar and Renata Holod, ‘A tenth-century source for architecture’, in Ihor Sevchenko and Frank E. Sysyn, eds., Eucharisterion: essays presented to Omeljan Pritsak on his sixtieth birthday by his colleagues and students, special issue of Harvard Ukranian Studies 3–4, 1979–80, p. 316. 54 Hans E. Wulff, The traditional crafts of Iran: their development, technology, and influence on Eastern and Western civilizations, Cambridge, MA: MIT Press, 1966, pp. 102–35. 55 L. A. Mayer, Islamic architects and their works, Geneva: Albert Kundig, 1956, p. 23. 56 Ibid., p. 21; Kostof, ‘Architect’, p. 65; but see also Donald L. Wilber, ‘Builders and craftsmen of Islamic Iran: the earlier periods’, Art and Archaeology Research Papers (AARP), 10, 1976, pp. 31–40. 57 Ronald Lewcock, ‘Architects, craftsmen and builders: materials and techniques’, in Michell, Architecture, pp. 131, 134; Mayer, Islamic architects, p. 28. 58 Maya Shatzmiller, Labour in the medieval Islamic world, Leiden: Brill, 1994, p. 211. j 390 j M A A R T E N P R A K Figure 1. Workers of different ethnic backgrounds collaborate on the building of the Masjid- i jami’ mosque (now called Bibi Khanum) in Samarqand, which was built c. 805 AH/1400 CE. Illustration from Sharaf al-Din ‘Ali Yazdi, Zafar Nameh, fo. 359v. From the Collection of The Johns Work Garrett Library, The Sheridan Libraries, The Johns Hopkins University, reprinted by permission. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 391 what we have observed in Europe.59 Indian builders were initially seen as being of inferior social status but this had improved markedly by the twelfth century.60 Building sites used both local and migrant artisans;61 this is very clear in Gujar at, where a new style developed in the late tenth and early twelfth centuries. The rapid distribution of this Maru-Gurjara style is difficult to explain without artisan migration. At the same time, local variations suggest the involvement of local workers.62 Cambodian records do not mention wages, and we must thus assume that their remarkable temple complexes were constructed with the help of forced labour.63 Chinese building workers, too, were required to provide corvée labour. A register of 129,977 provincial (lunban) artisans from 1393, divided over sixty-two different trades, showed half of them to be builders. Not surprisingly, given the prominence of wooden constructions in China, a great many were carpenters and sawyers, but the register also mentioned thousands of tilers, bricklayers, and masons. All these people were commanded to come and work for a specified time in the capital. By implication they travelled long distances and therefore had an opportunity to meet colleagues from other regions.64 Knowledge In 1516, Lorenz Lechler, a mason from the Neckar area in Germany, wrote down a number of ‘Instructions’ on the building trade for his son. Although he did not set these out in a particularly systematic way, one can identify four major problems facing the builder, once the decision to launch a major project had been taken.65 First, he had to make sure that he obtained the right quality of stone. We have already discussed in the previous section how a vertical integration of the industry could take care of this problem. Second, a decision was required about the scale of the building and the type of measurements to be used. Third, the builder had to apply his accumulated knowledge to overcome pressing problems that could arise during the building process. At several points Lechler emphasized that a builder could not rely on rules and principles alone but also had to apply his judgement in making 59 S. Settar, The Hoysala temples, vol. 1: text, Bangalore: Kal a Y atra Publications, 1992, p. 84; Sudh akara N ath Miśhra, Gupta art and architecture (with special reference to Madhya Pradesh), New Delhi: Agamkala Prakashan, 1992, pp. 231–6; Gerard Foekema, Architecture decorated with architecture: later medieval temples of Karn ataka, AD 1000–1300, New Delhi: Munshiram Manoharlal, 2003, p. 79. 60 Settar, Hoysala temples, p. 89. 61 Ahsan Jan Qaisar, Building construction in Mughal India: the evidence from painting, New Delhi: Oxford University Press, 1988, pp. 11–12. 62 Alka Patel, Building communities in Gujar at: architecture and society during the twelfth through fourteenth centuries, Leiden: Brill, 2004, p. 79. 63 Dumarçay and Royère, Cambodian architecture, p. 7. 64 Klaas Ruitenbeek, Carpentry and building in late imperial China: a study of the fifteenth-century manual Lu Ban Jing, 2nd edition, Leiden: Brill, 1996, pp. 16–17. 65 Lon Shelby and Robert Mark, ‘Late Gothic structural design in the ‘‘Instructions’’ of Lorenz Lechler’, Architectura, 9, 1979, p. 115. j 392 j M A A R T E N P R A K decisions. Finally and most importantly, the builder had to ensure the structural integrity of the building: ‘for an honourable work glorifies its master, if it stands up’.66 To achieve this, masons used a combination of experience and practical geometry. Geometry was taught in universities as a subject, but there is no reason to assume that masons took academic degrees.67 Therefore, what they required was a practical form of geometry that did not entail complicated calculations, which was exactly what Lechler was providing for his son. The underlying principle was that a small number of dimensions allowed the builder, through a few intermediate steps, to arrive at all the dimensions of the large structure that he was commissioned to erect. In other words, one ‘macro-module’68 determined most of the other crucial variables of the church; it was the cathedral’s ‘genetic code’.69 In Lechler’s instructions, this macro-module was the width of the choir. The choir had to be twice as long as it was wide, while the nave of the church was to be twice as long as the choir. The width of the nave, Lechler suggested, was to be the same as that of the choir, and the aisles of the nave half the width of the choir and nave. The height of the building was equally determined by the basic module.70 Other structural elements were derived from the same fundamental measurement. The walls of the choir, Lechler recommended, should be a tenth of the width of the choir. The precise ratio, however, also depended on the quality of the stone. With good stone, three inches could be subtracted, but, when the stone was poor, three inches had to be added.71 This principle was thus one of modularity, although the term ‘proportional’ knowledge has also been used.72 The same underlying principle had already applied to Romanesque building.73 It has been argued that ‘modularity’ was necessary to organize work across the long periods of time required to build a church,74 and the ‘modular system’ has also been interpreted as the grid for the symbolic programme of the great churches.75 Similar principles governed the design of the smaller elements of a building.76 A booklet by Mathes Roriczer, another German builder active in the second half of the fifteenth century, described the design of pinnacles in terms similar to those used for the ground plan of the church as a whole. By drawing squares within squares, according to fixed patterns, the 66 Ibid. 67 Lon Shelby, ‘The geometrical knowledge of mediaeval master masons’, Speculum 47, 1972, p. 397. 68 Shelby and Mark, ‘Late Gothic structural design’, p. 117; Paul Frankl, ‘The secret of the mediaeval masons’, Art Bulletin, 27, 1945, p. 49. 69 Scott, Gothic enterprise, p. 106. 70 Shelby and Mark, ‘Late Gothic structural design’, p. 118. 71 Ibid., pp. 118–20. 72 John Harvey, Mediaeval craftsmen, London: B.T. Batsford, 1975, ch. 5. 73 Charles M. Radding and William W. Clark, Medieval architecture, medieval learning: builders and masters in the age of Romanesque and Gothic, New Haven, CT: Yale University Press, 1992, pp. 37, 48. 74 Scott, Gothic enterprise, pp. 141–2. 75 Aart J.J. Mekking, De dom van bisschop Adalbold II te Utrecht: de architectuur en de rol van een elfdeeeuwse bouwheer, Utrecht: Clavis, 1997, p. 8. 76 François Bucher, ‘Design in Gothic architecture: a preliminary assessment’, Journal of the Society of Architectural Historians, 27, 1968, p. 51. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 393 mason could derive a pinnacle from a basic measurement without any understanding whatsoever of mathematical principles.77 For the design of vaults, even where their patterning seems very complicated at first sight, the same modular principles applied. The ground plan of the nave and choir were subdivided into a series of rectangles, of which the central point was then easy to establish. Having set out these measurements at life size, the builder could establish with a compass the curvature of the ‘principal arch’ (Prinzipalbogen) connecting the four corners of the rectangle and the central point. From this principal arch, the smaller arches making up the vault were then derived, again using proportional measurements.78 Perhaps predictably, there was more than one system in use at the time. This is brought into sharp focus by two debates, based around the commissioners of the cathedral in Milan, who were insecure about both the aesthetics and the construction of their expensive project. In May 1392, experts from Lombardy met Heinrich Parler, from Gmünd in Germany, to discuss the issues, but failed to agree on the best way forward. A similar debate in January 1400, between builders from Lombardy and Jean Mignot, a French architect brought in by the duke, likewise failed to reach a compromise. Their exchanges, faithfully recorded by the cathedral administrators, point to the clash of two different sets of design principles: both modular, but with different proportions. Mignot was convinced that the Italian system was aesthetically imperfect and structurally unsound, but his opponents were unwilling to accept his opinions, and in the end had their way.79 It is also worth emphasizing that these sources hardly ever discussed religious or cosmic principles behind procedures, although these were evidently important to their patrons.80 They did, however, keep on referring to building experience as the guiding light. As Lechler wrote to his son: ‘Give to this writing careful attention, just as I have written it for you. However, it is not written in such a way that you should follow it in all things. For [in] whatever seems to you that it can be better, then it is better, according to your own good thinking.’81 Few architectural drawings as we now understand them have survived from before the fourteenth century, and those that do tend to show details, such as towers or a chapel, rather than the building as a whole.82 When the chapel for King’s College, Cambridge, was commissioned by Henry VI in 1448, its principal dimensions were simply outlined on 77 Lon Shelby, ed., Gothic design techniques: the fifteenth-century design booklets of Mathes Roriczer and Hanns Schuttermayer, Carbondale, IL: Southern Illinois University Press, 1977, pp. 84–5. 78 Shelby and Mark, ‘Late Gothic structural design’, pp. 124–6. 79 James S. Ackerman, ‘‘‘Ars sine scientia nihil est’’: Gothic theory of architecture at the cathedral of Milan’, Art Bulletin, 31, 1949, pp. 84–111. 80 Kimpel and Suckale, Gothische Architektur, pp. 45–54; Nigel Hiscock, The symbol at your door: number and geometry in religious architecture of the Greek and Latin Middle Ages, Aldershot: Ashgate, 2007; Ball, Universe of stone, ch. 5. 81 Shelby and Mark, ‘Late Gothic structural design’, p. 115. 82 Arnold Pacey, Medieval architectural drawing: English craftsmen’s methods and their later persistence (c.1200–1700), Stroud: Tempus, 2007, pp. 59, 139; Anthony Gerbino and Stephen Johnston, Compass and rule: architecture as mathematical practice in England, New Haven, CT, and London: Yale University Press, 2009, ch. 1; James S. Ackerman, Origins, imitation, conventions: representation in the visual arts, Cambridge, MA: MIT Press, 2002, p. 31. Bucher, ‘Design’, disagrees, but his examples refer to late Gothic. j 394 j M A A R T E N P R A K the ground; there was no mention of any plan.83 Wooden models likewise seem to have appeared only in the sixteenth century.84 It is possible that the general plan of the building was sketched on a piece of paper or parchment (though precious few examples survive), but they were no more than a rough guide to the building that was eventually to emerge. The layout of Soissons Cathedral, for example, underwent at least six major revisions during a fifty-year period.85 The basic dimensions of the ground plan were instead set out on the building site, while the various elements of the elevation were drawn at life size on the floor of the building lodge.86 The main instruments used by the master mason for his design work were a ruler, square, and compass.87 Given the patchiness of the general design, much depended on the specific interventions of the builders during the building process itself. As we have seen, this was often a discontinuous process, in which low levels of activity were punctuated by short, intense campaigns. Churches, which at first sight suggest unity of design, in fact displayed all kinds of ‘junctions’, marking the end of one campaign and the start of another.88 The reason for these junctions seems to have been that each group of builders used their own template.89 Templates guided the stonecutters’ work, and there must have been many identical templates to allow groups of stonecutters to work simultaneously on similar elements of the building. Because of the huge weights involved, and given the characteristics of the lime mortar that kept the stones in place, the various elements, particularly of the vault structures, had to be executed with great precision. Small margins of error had fatal consequences for the stability of the vault’s construction.90 Rigorous quality controls of stonecutters’ work were imposed by insisting that they mark individual pieces with their own distinctive signature.91 Templates were therefore a repository of the most significant information about the vital elements of the building.92 It was particularly the building of large churches that was undertaken in short campaigns, separated by intervals that could be lengthy. These intervals were necessary to re-stock the treasuries of the commissioning institutions, and also to allow the mortar of the construction to set and create stability. During the setting, which might take more than a year, signs of pressure could appear as cracks in the newly finished work. Cracks 83 Salzman, Building in England, p. 520. Radding and Clark, Medieval architecture, ch. 7, argue that there was a single individual who designed the whole building, but fail to address the implications of the fact that the execution of that design usually took many generations, and was thus subject to numerous personnel changes among the builders in charge of the project. 84 Meischke, Gothische bouwtraditie, p. 163. 85 James, Template-makers, pp. 119, 198. 86 Pacey, Medieval architectural drawing, esp. ch. 2. 87 Lon Shelby, ‘Medieval mason’s tools: the level and the plumb rule’, Technology and Culture, 2, 1961, pp. 127–30. 88 James, Template-makers, chs. 2 and 7. 89 Ibid. 90 Ibid., 86. 91 Harvey, Mediaeval craftsmen, p. 126; Janse and de Vries, Werk en merk, p. 50. 92 James, Template-makers, p. 34. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 395 led to adaptations in the construction, to reduce pressure on vulnerable points.93 Although this method produced satisfactory results in most building projects, at times the experiment went horribly wrong. The best-known example in western Europe was the collapse of the vaults in Beauvais Cathedral in 1284, and the fall of its tower in 1573. The present building shows clear signs of reinforcement of precisely those areas that laboratory tests have shown to be most at risk.94 In Troyes, one of the towers collapsed in 1362, while the upper nave came crashing down in 1395.95 Both the organization of the workforce and the evidence related to the organization of knowledge point in the same direction: the building of churches was a ‘messy’ process.96 It was conducted as a full-scale experiment,97 the building site acting as a ‘laboratory’, where builders applied their ‘local and tacit knowledge’.98 This practice was also common in the building of Hindu temples. An eleventh-century treatise required the architect (sthapati) both to be knowledgeable in the ‘science of architecture’ and to be ‘skilled in the work’. Yet that was not enough: intuition, ‘readiness of judgement in contingencies’, and the ability to combine theoretical and practical skills were the hallmark of the all-round builder.99 The building industry in Byzantium also had characteristics reminiscent of those of the Latin West. The people in charge of design and construction were engineers rather than artists. No architectural plans have survived, and traces in extant buildings suggest that whatever drawing was needed was done full-scale and on location, with the help of practical geometry.100 Churches were designed and built as ‘modular units’, and designs were changed repeatedly in the course of the construction process.101 The churches were remarkably uniform in general design, suggesting an intensive exchange of information throughout the empire, but at the same time they displayed local variations in detailing, which suggests that labour markets for building workers were regional rather than national.102 Proportional geometry was key to the designing of a church. Whereas in the Latin West the choir was the most important element of the building, and hence determined the proportions of its 93 Clark and Mark, ‘Flying buttresses’; Mark, Light, p. 105. 94 M. Wolfe and R. Mark , ‘The collapse of the vaults of Beauvais cathedral in 1284’, Speculum 51, 1976, pp. 462–76 95 Stephen Murray, Building Troyes cathedral: the Late Gothic campaigns, Bloomington: Indiana University Press, 1987, p. 36. 96 James, Chartres, ch. 2. 97 Stephen Murray, Beauvais Cathedral: architecture of transcendence, Princeton, NJ: Princeton University Press, 1989, p. 58. 98 David Turnbull, ‘The ad-hoc collective work of building Gothic cathedrals with templates, string, and geometry’, Science, Technology, & Human Values, 18, 1993, pp. 316–17. 99 Stella Kramrisch, The Hindu temple, Delhi: Motilal Banarsidass, 1976, vol. 1, p. 8. 100 Charalambos Bouras, ‘Master craftsmen, craftsmen, and building activities in Byzantium’, in Angeliki E. Laiou, ed., The economic history of Byzantium: from the seventh through the fifteenth century, Washington, DC: Dumbarton Oaks Research Library and Collection, 2002, pp. 546–7. 101 Ousterhout, Byzantium, pp. 44, 58 (quote), and 86. 102 Ibid., pp. 26, 56–7, 116. j 396 j M A A R T E N P R A K other features, the central ‘module’ in Byzantine churches was the dome. Its height therefore acted as the ‘controlling element’ of the design.103 Islamic architects were known for the intricate detail of their designs, and there was immense variation. However, the proportions of their buildings were extremely regular, and utilized a severe logic of ‘modules’ that determined the size of all crucial elements.104 It has been suggested that both general and detailed drawings were made, as well as scale models,105 but none have survived. The first treatise on building in the Islamic world was written at the end of the thirteenth century by the prime minister of the Il-Khanid rulers in Iran, presumably an administrator and not a builder: unfortunately no copies survive.106 Timurid builders used sophisticated geometry, again based on ‘modular’ principles.107 A series of drawings by a sixteenth-century architect from Bukhara in Uzbekistan showed various complex buildings set out on modular grids. No single element was consistently used as the basic module, and the most prominent element was normally picked for this purpose. In the case of religious buildings this was most obviously the dome.108 It has been suggested that one reason why both drawings and manuals appeared relatively late in Central Asia and Europe was because the medieval architect’s practical geometry provided its own design dynamic, once the outline of the ground plan had been established.109 In Hindu architecture, the square determined both the overall plan and the details of architectural design. Temples had a square ground plan, usually subdivided into sixty-four smaller squares, each with their specific religious identity.110 In Kerala, in south-west India, a variety of basic forms were used for the ground plan, but by far the most common was the square.111 The Maru-Gurjara style of Gujar at consisted of a series of ‘repeatable modules’.112 Building treatises were rare, and described buildings rather than providing prescriptions as to how to build them. It is possible that builders had access to these texts, but they were always applied in combination with locally developed praxis. As the volume of temples 103 Ibid., pp. 72, 80–1. 104 Lewcock, ‘Architects’, pp. 130, 132. 105 Ahmad Y. al-Hassan and Donald R. Hill, Islamic technology: an illustrated history, Cambridge: Cambridge University Press, 1986, p. 265. 106 Lewcock, ‘Architects’, p. 133. 107 Golombek, et al., Timurid architecture, vol. 1, p. 139; G ulru Necipo glu, The Topkapi scroll: geometry and ornament in Islamic architecture, Santa Monica, CA: Getty Center for the History of Art and the Humanities, 1995, p. 44. 108 Golombek, et al., Timurid architecture, vol. 1, pp. 139–40; Yvonne Dold-Samplonius, ‘The volume of domes in Arabic mathematics’, in M. Folkerts and J. P. Hogendijk, eds., Vestigia mathematica: studies in medieval and early modern mathematics in honour of H. L. L. Busard, Amsterdam: Rodopi, 1993, pp. 93–106. 109 Necipo glu, Topkapi scroll, ch. 3. 110 Kramrisch, Hindu temple, vol. 1, parts ii and iii. 111 H. Sarkar, An architectural survey of temples of Kerala, New Delhi: Archaeological Survey of India, 1978, p. 63; also Michael W. Meister, ‘Analysis of temple plans: Indor’, Artibus Asiae, 43, 1981–82, pp. 302–20; idem, ‘Geometry and measure in Indian temple plans: rectangular temples’, Artibus Asiae, 44, 1983, pp. 266–96; idem, ‘De- and reconstructing the Indian temple’, Art Journal, 49, 1990, pp. 395–400. 112 Patel, Building communities, pp. 85, 87. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 397 increased in the course of the fourteenth century, builders increasingly had to rely on their ‘experientially gained knowledge’.113 Chinese architecture was likewise based on modular principles, which came out very clearly in a treatise completed by Li Jie around 1100, at the end of the reign of Emperor Zhe Zong. The Yingzao fashi, or State building standards, was an administrative document meant to regulate wooden post-and-beam building.114 At 1,078 pages long, and first printed in 1103, it provided guidelines for the construction of a variety of public buildings and private homes. Li Jie was not a builder but a bureaucrat, as well as a painter and the author of other books, on geography, history, and philology. The Yingzao fashi was compiled by the government to regulate a number of its own activities (the so-called Wang Anshi Reform), including the construction of public buildings.115 Li worked as Superintendent for State Buildings in the Ministry of Works, and as such had first-hand experience of the building trade. The second part of the Yingzao fashi discussed standards and regulations for design and construction, as well as guidelines for the production of bricks and tiles.116 As in Europe, the mathematics was mostly based on proportions. The Yingzao fashi identified eight building sizes and recommended a standard size of beam for each of them. That beam size, the cai, determined the proportions for all the elements used for complex construction of roofs and their support structures, as well as other aspects of the building. Standard measurements, incidentally, also allowed the readers of the Yingzao fashi, especially government officials, to calculate the number of workdays involved in the construction process, and hence the cost of projects.117 As in Europe, this combined prescriptive knowledge of the module’s measurement with a tacit understanding of how to apply it in practice.118 Chinese builders also used architectural drawings. The Yingzao fashi provided various types of working drawings, although no others have survived from the medieval period.119 Perhaps the standardized form of building made these superfluous. Interestingly, many architectural clay models have survived in China, although the majority date from the earlier Han Period (206 BCE–220 CE). Most of them are so unsophisticated that we must assume that they served decorative purposes.120 Some, however, clearly had a function 113 Ibid., p. 163. 114 Ledderose, Ten thousand things, ch. 5; see also Yuhuan Zhang, ed., History and development of ancient Chinese architecture, Beijing: Science Press, 1986, p. 471; Guo, Chinese architecture, p. 93; Watson, Arts of China, p. 85. 115 Guo, Chinese architecture, ch. 7. For other Chinese building manuals, see Ruitenbeek, Carpentry, pp. 24–31. 116 Guo, Chinese architecture, ch. 7. 117 Ibid., pp. 93–6; Zhang, Chinese architecture, pp. 471–2; Ledderose, Ten thousand things, p. 137. 118 Cf. S. R. Epstein and Maarten Prak, ‘Introduction: guilds, innovation and the European economy, 1400– 1800’, in idem, eds., Guilds, innovation and the European economy, 1400–1800, Cambridge: Cambridge University Press, 2008, p. 14. 119 Guo Chinese architecture, ch. 10. The drawings discussed in Zhang, Chinese architecture, pp. 473–4, seem either to relate to urban planning or to date from a later era. Those pictured in Ruitenbeek, Carpentry, p. 53, are highly stylized, suggesting variations of standard models. 120 Nicole De Bisscop, Onder dak in China: oude architectuurmodellen uit het Henan museum, exhibition catalogue, Koninklijke Musea voor Kunst en Geschiedenis, Brussels: Mercatorfonds, 2007, p. 53. j 398 j M A A R T E N P R A K similar to European models: that is, to provide a small-scale impression of the building for both patrons and builders.121 Apprenticeship and other sources of information Like many other pre-industrial products, these ambitious buildings made huge demands on the skills of their producers. Cognitive psychologists have discovered that the time of training required to master complicated skills is remarkably similar across a wide variety of tasks: it takes roughly ten years to become a top-level expert in any kind of skill-based task.122 One reason why it took, and still takes, so long for adolescents and young adults to become fully trained is that crafts typically combine propositional and tacit types of knowledge.123 Tacit knowledge cannot be articulated – ‘we can know more than we can tell’, as one scholar puts it – and it needs to be transferred from person to person.124 This happens most effectively in ‘communities of practice’.125 It is therefore important to pay attention not only to the contents of skills education but also to its social organization. Before we look at apprenticeship, however, we must briefly discuss two other potential sources of information on building: the clergy in their capacity as patrons of buildings, and written documentation. For a long time it has been thought that the original impulse for the Gothic style in Europe, its innovative design, came from the church itself. There are two good reasons for this assumption. The clergy were the learned class in medieval society, and surely the beauty of the Gothic style must have been inspired by faith and knowledge, two forms of human capital that were uniquely concentrated in the hands of clergymen. It is an assumption confirmed in one of the great architectural documents of the period, the writings of Suger, abbot of Saint-Denis at a time when the monastery obtained a new choir, often identified as the start of the Gothic style. However, it is not evident what Suger’s precise role was in the design process, or whether he dictated the general direction at all. There is no evidence that he had any specific ideas on how to execute plans, something generally true of the contribution of the clergy.126 Written documentation about building and related crafts is rare before the sixteenth century. The famous Villard de Honnecourt, author, or rather compiler, of a manuscript on French Gothic cathedrals dating from around 1230, was possibly not a builder himself. 121 Zhang, Chinese architecture, pp. 474–5; Guo, Chinese architecture, pp. 123–4. 122 K. A. Ericsson, ‘The acquisition of expert performance: an introduction to some of the issues’, in K.A. Ericsson, ed., The road to excellence: the acquisition of expert performance in the arts and sciences, sports and games, Mahwah, NJ: Lawrence Erlbaum Associates, 1996, pp. 10–11. 123 S. R. Epstein, ‘Property rights to technical knowledge in premodern Europe, 1300–1800’, American Economic Review, 94, 2004, p. 383. 124 M. Polanyi, The tacit dimension, Gloucester: Peter Smith, 1966, p. 4. 125 A.C. Cianciolo, C. Matthew, R. J. Sternberg, and R. K. Wagner, ‘Tacit knowledge, practical intelligence, and expertise’, in K. A. Ericsson, et al., eds., Cambridge handbook of expertise and expert performance, Cambridge: Cambridge University Press, 2006, pp. 623–4. 126 Radding and Clark, Medieval architecture, proposes a more elegant solution, pointing to parallel changes in philosophy and building style in the Paris basin in the first half of the twelfth century as an expression of similar intellectual developments, without claiming a direct impact from one upon the other. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 399 His drawings seem to have been made either from the building as it was constructed or from plans that he observed on site.127 It was only in the later decades of the fifteenth century that the first building ‘manuals’ started to appear. Several small books from Germany survive, with detailed instructions on the design and execution of major building works; we have already discussed their contents in the previous section.128 During the sixteenth century, similar guides for carpenters were published, containing the same practical types of calculations as those found in stonemasons’ manuals. This was mathematics without the theory, because carpenters could not be assumed to know how to multiply.129 If neither learned institutions such as the church nor written documentation were much of a help to builders, we must look for alternative sources of information that they could tap into. Apprenticeship was (and still is) found throughout the world as the main institutional context for the acquisition of craft skills.130 It was, however, embedded in other institutions, notably the family, the guild, and the state. In Europe, there were several dynasties of architects, the best known of whom were perhaps the Parler, who were active in central Europe in the fourteenth and fifteenth centuries. Their last name was derived from the word for a building lodge foreman: parlier. Their activities were first recorded in Cologne and Gmünd in central and southern Germany, where Heinrich Parler was working around the middle of the fourteenth century. The portrait of his son Peter Parler, the most famous of the family, was incorporated into the structure of Prague Cathedral, where he was in charge of construction work in the second half of the fourteenth century. Two of his brothers worked as stonemasons in Prague and Freiburg, and in Basel. Peter’s sons Wenzel and Johann succeeded him as master of the cathedral works in Prague, and Wenzel also worked in Vienna. Their cousin Michael was master in Strasbourg, while Johann’s son, another Johann, worked as a stonemason in Prague.131 Meanwhile, four members of the Roriczer family in three successive generations held the office of cathedral architect at the building lodge in Regensburg.132 The family was by no means the only environment in which building knowledge was transferred in Europe, and data from a later period point in exactly the opposite direction. Of eighty apprentice bricklayers in York between 1654 and 1752 whose fathers’ occupation was known, only twenty-one of those fathers were also bricklayers (and eleven of them apprenticed their son). In other words, three-quarters came from outside the trade. If we take into account the likelihood that there were very few bricklayers’ sons among the 200-plus apprentice bricklayers during that same period whose fathers’ occupations were unknown, it could be that less than one-tenth were actually continuing their fathers’ 127 Robert Branner, ‘Villard de Honnecourt, Reims and the origin of Gothic architectural drawing’, Gazette des Beaux-Arts, 61, 1963, pp. 137–8; Kimpel and Suckale, Gothische Architektur, p. 44; Wilson, Gothic cathedral, p. 141. 128 Shelby, Gothic design techniques; Shelby and Mark, ‘Late Gothic structural design’. 129 David T. Yeomans, ‘Early carpenters’ manuals 1592–1820’, Construction History, 2, 1986, p. 14. 130 Bert De Munck, Steven L. Kaplan, and Hugo Soly, eds., Learning on the shop floor: historical perspectives on apprenticeship, New York: Berghahn, 2007; Michael W. Coy, ed., Apprenticeship: from theory to method and back again, Albany, NY: State University of New York Press, 1989; Trevor H. J. Marchand, The masons of Djenné, Bloomington, IN: Indiana University Press, 2009, ch. 5. 131 Barbara Schock-Werner, ‘Die Parler’, in Legner, Die Parler, pp. 7–11. 132 Shelby, Gothic design techniques, pp. 7–28. j 400 j M A A R T E N P R A K Figure 2. The building of Gothic cathedrals was a lengthy process that required the collaboration of many different craftsmen, who transferred their skills on the job to apprentices. Illustration from the Roman de Girart de Roussillon, which was copied in a workshop in Mons, in the Burgundian Netherlands, in 1448, and illustrated shortly afterwards, probably by Dreux Jean in Bruges. Source: Österreichische Nationalbibliothek, Vienna, ONB/Wien BAG Cod. 2549 fo. 164r (DNRSign.: #5049880), reprinted by permission. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 401 trade.133 Possibly the great majority of builders learned the tricks of their trade outside the family environment. Three settings for learning have already been suggested in the course of the previous discussion: the stone quarry, the building lodge, and the local guild. The actual work in the quarries has been insufficienly investigated thus far, and we can therefore say next to nothing about its contribution to the training of the skilled workforce. However, the names of stonemasons in the northern Low Countries very often referred to places of origin in the areas where the stone was found, strongly suggesting a close connection between quarrying and the acquisition of skills necessary to work the stone.134 The building lodge was both a concrete location and an organizational form. Like families and guilds, it was a hierarchical and regulated institution, headed by one or more directores fabricae.135 It was financed by its patrons, but some had more or less independent sources of income, as in Strasbourg, where lodge property secured a steady and substantial income stream.136 Under the Master and his substitute, the parlier, were the journeymen, as well as the apprentices.137 The masons’ guilds had an ambiguous role in the history of European church-building, as the earliest craft guilds were established halfway through the twelfth century, well into the Gothic building boom.138 Moreover, guilds in the building industry were not among the early foundations. The masons’ guild established in Lincoln in 1313 was a religious confraternity, not a craft guild. In London, the first sign of an organization of masons dates from 1376, although regulations for the trade had already been introduced a little earlier, in 1356.139 Clearly guilds were not a prerequisite for the construction of Gothic churches. Still, they became more important as time went on, and building crafts in Italian towns obtained statutes in the course of the fourteenth century.140 Guild statutes regulated the training of aspiring workers in the trade, even though the training itself was left to individual masters. The minimum training period varied significantly, even in relatively small areas. In Verona the minimum was just one year, in Piacenza four, in Bologna five, in Genoa and Savona six, and in Venice six to seven. The statutes in 133 Donald Woodward, Men at work: labourers and building craftsmen in the towns of northern England, 1450–1750, Cambridge: Cambridge University Press, 1995, pp. 54–5. This was true in many other trades as well: see Epstein and Prak, ‘Introduction’, pp. 9–10. 134 Janse and de Vries, Werk en merk, p. 25. 135 Schock-Werner, ‘Bauhütten’. 136 On the financing of cathedral building see Henry Kraus, Gold was the mortar: the economics of cathedral building, London: Routledge & Kegan Paul, 1979; Wim Vroom, Financing cathedral building in the Middle Ages: the generosity of the faithful, Amsterdam: Amsterdam University Press, 2010. 137 Volker Segers, ‘Studien zur Geschichte der Deutschen Steinmetzbruderschaft: mit besondere Berücksichtigung der für das Strassburger Gebiet geltenden Ordnungen und Bestätigungsurkunden (15. bis 17. Jahrhundert)’, PhD thesis, Freie Universität Berlin, 1980. 138 Steven A. Epstein, Wage labor and guilds in medieval Europe, Chapel Hill, NC: University of North Carolina Press, 1991, ch. 2. 139 Douglas Knoop and G. P. Jones, The mediaeval mason: an economic history of English stone building in the later Middle Ages and early modern times, Manchester: Manchester University Press, 1967, pp. 135–6. 140 Richard A. Goldthwaite, The building of Renaissance Florence: an economic and social history, Baltimore, MD: The Johns Hopkins University Press, 1980, pp. 431–4. j 402 j M A A R T E N P R A K Padua distinguished between stonecutters, who were required to learn for six years, and the wallers, whose apprenticeship took up to eight years.141 In Germany it was the other way around: wallers had to be apprenticed for four years, stonemasons for six.142 Clearly these regulations were referring to very different levels of accomplishment, suggesting that five to six years were required to become fully competent. It was very likely that additional experience was necessary before admission as an independent master.143 The regulations for Parisian masons from the mid thirteenth century stipulated the following: ‘In Paris everyone can be a mason, provided he knows the trade (le mestier) and works according to the customs and practices of the trade, which are as follows: Only those who have been apprenticed can work in a workshop, and after his apprenticeship he can exercise the trade independently only after six years of experience.’144 Rules drafted by the meeting of master stonemasons from the Holy Roman Empire in Regensburg in 1459 included a special section on the dienner, or apprentices.145 The most important aim of these regulations seems to have been the continuous supply of qualified labour. Thus there existed in Europe a range of institutions offering opportunities for the acquisition of skills. The available evidence suggests that these institutions existed side by side, working out their relations in local settings according to contextual peculiarities.146 Neither the family, nor the quarry or the building lodge, nor even the guild, provided a fully fledged training programme. What these institutions did provide was an environment with educational potential. Among these, the guilds were most focused towards the training of the workforce. As the guilds seem to have become more significant in the regulation of the building trade over time, training became a more important concern for the industry as a whole. Because of the relative unimportance of stone in Byzantine building, quarries were insignificant as locations for the training of its workforce. The two other environments we identified in the Latin West were, however, equally important for the Byzantine building industry: the workshop and the guild.147 Unfortunately very little is known about the early history of Byzantine guilds, although we do know that they emerged earlier than in the Latin West and that they continued to function throughout the Middle and Late Byzantine periods. The guilds enforced quality controls by holding the master accountable (for brick buildings the warranty extended to a ten-year period) and prohibiting him from taking on a new project before he had finished the current one. They also insisted on proper skills: ‘Those who build walls and domes or vaults must possess great exactitude and experience lest the foundation prove unsound and the building crooked or uneven’, reads the Book of the Eparch, a source from the tenth century listing some craft regulations.148 Whereas 141 Ibid., p. 260. 142 Segers, ‘Studien’, pp. 179–80. 143 Epstein and Prak, ‘Introduction’, p. 8. 144 Quoted from Binding, et al., Baubetrieb, pp. 104–5. 145 Segers, ‘Studien’, pp. 179–80. 146 Schock-Werner, ‘Bauhütte und Zunft’, in Legner, Die Parler, pp. 64–5. 147 Ousterhout, Byzantium, pp. 49–57. 148 Ibid., p. 50. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 403 guilds were permanent institutions, workshops were temporary arrangements, attached to the building project itself. They were headed by a master builder or master mason, who was in charge of the work force. Apprentices must have been trained on the job, but the sources are silent on this aspect. In the Timurid empire, craft skills seem to have been acquired principally through the family system.149 In some parts of the Islamic world (notably Iran, Iraq, Egypt, and Turkey) craft guilds emerged, albeit somewhat later than in the Latin West. These guilds were closely tied to religious functions, as in Europe.150 Called futuwwa in places, they had a patron saint, organized examinations, and provided the title of ‘master’.151 But the comparison only takes us so far. A French traveller from the seventeenth century was struck by how different local craft organizations in Isfahan looked from what he knew about the corporations back home. They united men of the same profession, and there was a chief officer, but there were no rules of membership, apprenticeship schemes, or quality controls imposed on the members.152 There are hints, from the south Indian Hoysala kingdom (eleventh to fourteenth centuries) of builders’ ‘assemblies’, which suggest that they were organized either as professionals or in castes, two types of organization that overlapped. Like European guilds, these organizations also had a religious component, and one of them was described as ‘the servants of Goddess Saravastı’. However, these Indian crafts were not as regulated as guilds.153 Chinese builders were definitely organized in family guilds, which were registered, regulated, and supervised by the government.154 However, craft guilds somewhat similar to the European guild system only appeared in the seventeenth century.155 This was a time when compulsory labour for the government declined.156 Until then, the craft (and therefore its skills) had to be transferred to at least one member of the next generation in each craft family.157 The Yingzao fashi and similar manuals also testify to the importance of the Chinese state in the transfer of knowledge; under the Qing, this role was taken over by the guilds. Another Chinese peculiarity was that building knowledge was transferred orally in verse form, presumably because that made it easier to memorize.158 As in Europe, this knowledge was embedded in metaphysical beliefs and rituals.159 149 Golombek, et al., Timurid architecture, vol. 1, p. 67. 150 Lewcock, ‘Architects’, p. 133. 151 al-Hassan and Hill, Islamic technology, pp. 267–9. 152 Ronald W. Ferrier, trans. and ed., A journey to Persia: Jean Chardin’s portrait of a seventeenth-century empire, London: I.B. Taurus, 1996, p. 167; also Lewcock, ‘Architects’, p. 133. 153 Settar, Hoysale temples, pp. 86–8. 154 Guo, Chinese architecture, p. 90. 155 Peter J. Golas, ‘Early Ch’ing guilds’, in G. William Skinner, ed., The city in late imperial China, Stanford, CA: Stanford University Press, 1977, pp. 555–80. 156 Christine Moll-Murata, ‘Chinese guilds from the seventeenth to the twentieth centuries: an overview’, in Jan Lucassen, Tine de Moor, and Jan Luiten van Zanden, eds., The return of the guilds, International Review of Social History Supplement, Cambridge: Cambridge University Press, 2008, p. 219. 157 Guo Chinese architecture, p. 90. 158 Ibid. 159 Ruitenbeek, Carpentry, pp. 82–9. j 404 j M A A R T E N P R A K Conclusions In his 1998 Mellon Lectures in the Fine Arts, the German sinologist Lothar Ledderose argued that Chinese art, from calligraphy to images to architecture, was essentially modular. Aside from a general point about Chinese culture, he saw this as an explanation for the emergence of artistic mass production in China, which nonetheless managed to maintain distinctive characteristics in individual pieces, simply by recombining existing elements.160 Likewise, in this article it has been argued that the builders of some of the greatest works of medieval architecture throughout Eurasia used modules to design their projects.161 Where I differ from Ledderose is in the intention to explore how pre-modern builders were able to overcome the challenges of projects whose mechanics they were unable to fully understand. Three points stand out. First, builders’ knowledge was practical, and related to their working experience, rather than theoretical. This is probably an unsurprising conclusion but it is a point worth making nonetheless, because the other two conclusions follow on from it.162 It is also important because it underscores a point made by S. R. Epstein, namely that it was not technological constraints as such that hampered the pre-modern economy but the under-utilization of available technologies.163 The knowledge that I have described in this article was already available to the Romans. It was insufficient to build a steam engine, but the accomplishments of the constructors of medieval religious buildings across Eurasia demonstrate that, despite the limitations of their practical knowledge, they were capable of remarkable progress in the construction of other quite complex ‘machines’.164 The second point to emerge from our investigation of the medieval building industry is that modular knowledge could indeed substitute for theoretical knowledge. This conclusion is consistent with psychologists’ arguments that modularity is a characteristic feature of the human mind itself,165 and with the related argument that human creativity is a product of the ‘creative generation of action schemata’ by our ‘massively modular minds’.166 Even without reference to the architecture of the mind, however, it is not so difficult to see why, across all the major civilizations of Eurasia, builders used modules to create large structures. On the basis of practical experience, builders had worked out how the various modules of a complex structure, such as a church building or the tall towers attached to 160 Ledderose, Ten thousand things. 161 More specific parallels between the Latin West and Central Asia are highlighted in G ulru Necipo glu, ‘Geometric design in Timurid/Turkmen architectural practice: thoughts on a recently discovered scroll and its late Gothic parallels’, in Lisa Golombek and Maria Subtelny, eds., Timurid art and culture: Iran and Central Asia in the fifteenth century, Leiden: Brill, 1992, pp. 48–66. 162 See also Tim Ingold, The perception of the environment: essays on livelihood, dwelling and skill, London: Routledge, 2000, pt. iii; Pamela H. Smith, The body of the artisan: art and experience in the Scientific Revolution, Chicago, IL: University of Chicago Press, 2004, ch. 3; Richard Sennett, The craftsman, New Haven, CT: Yale University Press, 2008. 163 S. R. Epstein, Freedom and growth: the rise of states and markets in Europe, 1300–1750, London: Routledge, 2000, p. 7. 164 Gimpel, Medieval machine. 165 Jerry A. Fodor, The modularity of mind: an essay on faculty psychology, Cambridge, MA: MIT Press, 1983. 166 Peter Carruthers, The architecture of the mind: massive modularity and the flexibility of thought, Oxford: Clarendon Press, 2006, ch. 5. j R E L I G I O U S B U I L D I N G S I N E U R O P E A N D A S I A , C . 1 0 0 0 – 1 5 0 0 j 405 these buildings, could be reduced to a coherent set of proportional dimensions. These dimensions were often embedded in complex religious, cosmological, and scientific theories.167 However, I have argued that an important function, perhaps even the primary function, of modular design principles was their easy transmission between builders.168 Modular dimensions guided the general patterns of builders’ work. At the same time, the details of that work had to be adapted to local circumstances, such as the quality of the surface on which the building was to be constructed, the type of building material available for the construction, and the financial constraints of the project. Therefore the application of this knowledge was always embedded in the practice of the building process itself. The construction of a large church building was an ‘experiment’ and the building site was a ‘laboratory’.169 The propositional knowledge used in this laboratory was relatively simple, while the prescriptive knowledge was embodied in the builders’ tacit skills. Work in this laboratory – and this is my third conclusion – was almost by definition collective, and so was the process of acquiring the knowledge of how to build properly.170 Building a complex structure such as a church was therefore a social as much as a technological challenge. We have seen how the medieval building industry utilized a number of different social institutions to accomplish its remarkable feats: the family, the building lodge, and the guild. These three institutions were found throughout Eurasia as the appropriate environments for construction work. Religion (everywhere) and the state (in China) also provided important contexts for the consolidation of building technology. The specific mixtures of these institutions are, however, still something of a mystery, as is the possible implication of varying mixtures for the development of the industry. Each area of Eurasia reached its peak level of building achievements at a different point in time, but those peak levels seem to have been functions of general socioeconomic and cultural trends, rather than autonomous developments. Fundamentally new directions were only explored in European architecture after our period, with the application of mathematics to construction challenges in the eighteenth and nineteenth centuries.171 Although it is tempting to argue that this development was an expansion of earlier connections between geometry and building,172 it is worth remembering that such connections existed throughout Eurasia during the Middle Ages, and that everywhere academic geometry during the Middle Ages served aesthetic and religious, rather than constructional, purposes. St Paul’s Cathedral in London, designed in the late 167 Hiscock, Symbol; Richard Padovan, Proportion: science, philosophy, architecture, London: Routledge, 1999. 168 Rowland J. Maidstone, ‘Structural theory and design before 1742’, Architectural Review, 143, 1968, p. 304. 169 Turnbull, ‘Collective work’. 170 Howard S. Becker, Art worlds, Berkeley, CA: University of California Press, 1984; Pamela H. Smith, ‘In a sixteenth-century goldsmith’s workshop’, in Lissa Roberts, Simon Schaffer, and Peter Dear, eds., The mindful hand: inquiry and invention from the late Renaissance to early industrialisation, Amsterdam: KNAW, 2007, pp. 35, 39. 171 Gerbino and Johnston, Compass, p. 98; Addis, Building, chs. 5–6. 172 Pamela O. Long, ‘The contribution of architectural writers to a ‘‘scientific’’ outlook in the fifteenth and sixteenth centuries’, Journal of Medieval and Renaissance Studies, 15, 1985, pp. 265–9. j 406 j M A A R T E N P R A K 1660s by the mathematician Christopher Wren, professor of astronomy at Oxford, was still built as an experiment, complete with collapsing vaults and major design changes during the building process.173 Maarten Prak is Professor of Social and Economic History at Utrecht University. Among his recent publications is Guilds, innovation and the European economy, 1400–1800, edited together with S. R. Epstein and published by Cambridge University Press in 2008. 173 James W. Campbell, Building St Paul’s, London: Thames & Hudson, 2007, ch. 12; Gerbino and Johnston, Compass, pp. 100, 164. Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.