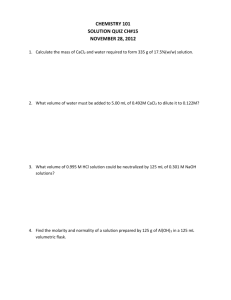

Designation: E 34 – 94 (Reapproved 2002) Standard Test Methods for Chemical Analysis of Aluminum and Aluminum-Base Alloys1 This standard is issued under the fixed designation E 34; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval. This standard has been approved for use by agencies of the Department of Defense. 1. Scope 1.1 These test methods cover the chemical analysis of aluminum and aluminum-base alloys having compositions within the following limits: Beryllium, ppm Bismuth, % Boron, % Cadmium, % Chromium, % Copper, % Gallium, % Iron, % Lead, % Lithium, % Magnesium, % Manganese, % Nickel, % Silicon, % Tin, % Titanium, % Vanadium, % Zinc, % Zirconium, % 0.3 0.02 0.005 0.001 0.01 0.01 0.001 0.01 0.01 0.001 0.002 0.005 0.01 0.05 0.03 0.002 0.002 0.003 0.01 to to to to to to to to to to to to to to to to to to to Sections Copper and Lead by the Electrolytic (Gravimetric) Test Method Copper and Zinc by the Atomic Absorption Test Method Copper by the Electrolytic (Gravimetric) Test Method Copper by the Neocuproine (Photometric) Test Method 100 1.0 0.060 0.50 1.0 20.0 0.05 3.0 1.0 4.0 12.0 2.0 4.0 20.0 1.0 0.30 0.16 12.0 0.30 Gallium by the Ion Exchange-Atomic Absorption Test Method Iron by the 1,10-Phenanthroline (Photometric) Method Iron and Manganese by the Atomic Absorption Method Lithium by the Atomic Absorption Test Method Magnesium: Pyrophosphate (Gravimetric) Method Ethylenediamine Tetraacetate (Titrimetric) Test Method Magnesium by the Atomic Absorption Test Method Manganese by the Periodate (Photometric) Test Method Nickel: Dimethylglyoxime (Photometric) Test Method Dimethylglyoxime (Gravimetric) Test Method Nickel by the Atomic Absorption Test Method Silicon: Molybdisilicic Acid (Photometric) Test Method Sodium Hydroxide-Perchloric Acid (Gravimetric) Method Tin by the Iodate (Titrimetric) Test Method Titanium by the Chromotropic Acid (Photometric) Test Method Titanium by the Diantipyrylmethane Photometric Test Method Vanadium by an Extraction-Photometric Test Method using N-Benzoyl-N-Phenylhydroxylamine Zinc: Ammonium Mercuric Thiocyanate or the Zinc Oxide (Gravimetric) Test Method Ethylenediamine Tetraacetate (Titrimetric) Test Method Ion Exchange-EDTA Titrimetric Test Method Zirconium by the Arsenazo III (Photometric) Method 1.2 The analytical procedures appear in the following order: Sections Beryllium by Argon Plasma Optical Emission Spectroscopy Beryllium by the Morin (Fluorometric) Test Method Bismuth by the Thiourea (Photometric) Method Bismuth and Lead by the Atomic Absorption Test Method Boron by the Carmine (Photometric) Test Method Cadmium by the Atomic Absorption Test Method Chromium: Diphenylcarbazide (Photometric) Test Method Persulfate Oxidation (Titrimetric) Test Method Chromium by the Atomic Absorption Test Method 283 to 292 8-19 1a 188 to 198 30 to 38 167 to 177 39 to 47 1b 199 to 209 1c 210 to 220 303 to 311 1a 312 to 323 73 to 81 221 to 231 324 to 334 1b 88 to 93 232 to 242 293 to 302 1a 1b 243 to 253 118 to 127 128 to 133 134 to 140 141 to 150 254 to 263 264 to 273 1b 1d 274 to 282 178 to 187 1.3 The values stated in SI units are to be regarded as the standard. 1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given throughout these test methods. 1 These test methods are under the jurisdiction of ASTM Committee E-1 on Analytical Chemistry for Metals, Ores, and Related Materials and are the direct responsibility of Subcommittee E01.04 on Aluminum and Magnesium. Current edition approved Jan. 15, 1994. Published March 1994. Originally published as E 34 – 60 T. Last previous edition E 34 – 88. 1a Discontinued as of Feb. 25, 1983. 1b Discontinued as of May 29, 1981. 1c Discontinued as of Oct. 25, 1985. 1d Discontinued as of March 25, 1983. Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States. 1 E 34 – 94 (2002) 2. Referenced Documents 2.1 ASTM Standards: E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications2 E 50 Practices for Apparatus, Reagents, and Safety Precautions for Chemical Analysis of Metals3 E 55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition3 E 60 Practice for Photometric and Spectrophotometric Methods for Chemical Analysis of Metals3 E 88 Practice for Sampling Nonferrous Metals and Alloys in Cast Form for Determination of Chemical Composition3 E 173 Practice for Conducting Interlaboratory Studies of Methods for Chemical Analysis of Metals3 E 716 Practices for Sampling Aluminum and Aluminum Alloys for Spectrochemical Analysis4 E 1024 Guide for Chemical Analysis of Metals and Metal Bearing Ores by Flame Atomic Absorption Spectrophotometry4 3. Significance and Use 3.1 These test methods for the chemical analysis of metals and alloys are primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these test methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory. 4. Apparatus, Reagents, and Photometric Practice 4.1 Apparatus and reagents required for each determination are listed in separate sections preceding the procedure. The apparatus, standard solutions, and certain other reagents used in more than one procedure are referred to by number and shall conform to the requirements prescribed in Practices E 50, except that photometers shall conform to the requirements prescribed in Practice E 60. 4.2 Photometric practice prescribed in these test methods shall conform to Practice E 60. NOTE 1—Shaded areas are suitable for sampling. FIG. 1 Type A and Type B Disks (Note 1). Use a minimum of two positions approximately opposite each other and combine the drillings or millings.5 NOTE 1—The use of a machined disk may result in the exclusion of an element-rich portion of the sample. This practice should be avoided wherever possible, especially for analyses affecting product acceptance. 6.2.2 The outer edges of the holes shall be approximately 0.48 cm (3⁄16 in.) from the edge of the disk. Drills shall be not less than 0.95 cm (3⁄8 in.) in diameter and not larger than 1.27 cm (1⁄2 in.) in diameter.4 6.2.3 Mill disks at similar points to a distance of 40 % of the sample diameter. Use a 0.95-cm (3⁄8 in.) milling cutter.4 6.2.4 Sample book mold disks (Type A, Practices E 716) at approximately the 9 o’clock and the 3 o’clock positions when the sprue is at the 12 o’clock position. Center pour (Type B, Practices E 716) and vacuum cast disks may be sampled around the entire circumference. Fig. 1 illustrates the areas suitable for sampling Type A and Type B disks. Vacuum cast disks are sampled in the same manner as Type B disks.4 6.2.5 Drilling or milling techniques ideally should produce uniformly small chips. Break large continuous pieces into 5. Precautions 5.1 For precautions to be observed in the use of certain reagents in these test methods, reference shall be made to Practices E 50. 6. Sampling 6.1 Wrought products shall be sampled in accordance with Practice E 55. Cast products shall be sampled in accordance with Practice E 88. 6.2 Chill cast disks produced for analysis by spectrochemical methods (see Practices E 716) shall be considered cast products. The principles of Practice E 88 shall apply. 6.2.1 Prepare such disks for chemical analysis by drilling or milling through the entire thickness of an unmachined disk 2 Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 03.05. 4 Annual Book of ASTM Standards, Vol 03.06. 3 5 Olson, H. A., and Macy, D. W., “Metallurgical Approach to Evaluating Chemical Sample Disks,” Light Metals, Vol 2, 1978, pp. 301–311. 2 E 34 – 94 (2002) excess. Allow to stand for 2 to 3 h or overnight. Filter using a low-ash, medium paper and wash well with NH4NO 3 wash solution. Transfer the precipitate and paper to a weighed, covered platinum crucible and char. Finally ignite to constant weight at 1000°C and weigh as beryllium oxide (BeO). 14.5 Beryllium, Standard Solution B (1 mL = 0.10 µg Be)— Transfer a 10-mL aliquot of Beryllium Solution A to a 100-mL volumetric flask. Add 1 mL of HClO4, dilute to volume, and mix. Transfer a 10-mL aliquot of this solution to a 1-L volumetric flask. Add 10 mL of HClO4, dilute to volume, and mix. 14.6 Chloroform (CHCl 3). 14.7 Diethylenetriaminepentaacetic Acid (DTPA), Recrystallized (Note 2)—Add 100 g of DTPA to 800 mL of boiling water and heat to boiling. Add 8 to 10 g of high-quality decolorizing carbon and mix thoroughly. Filter with suction through a hardened retentive paper. Transfer the clear filtrate to a 1-L beaker and stir vigorously to induce crystallization throughout the solution. Cool thoroughly in a water bath. Filter with suction using a hardened paper and remove as much water as possible. Dry the salts at 110°C. smaller pieces 0.64 cm (1⁄4 in.) to 0.95 cm (3⁄8 in.) long. Drilling or milling techniques should minimize production of fine, dust-like material.4 7. Rounding Calculated Values 7.1 Calculated values shall be rounded to the desired number of places in accordance with the rounding method given in 3.4 and 3.5 of Practice E 29. BERYLLIUM BY THE MORIN (FLUOROMETRIC) TEST METHOD 8. Scope 8.1 This test method covers the determination of beryllium in concentrations from 1 to 100 ppm. 9. Summary of Test Method 9.1 In an alkaline solution, beryllium and morin form a compound which produces a yellow-green fluorescence at approximately 520 nm when excited by light at approximately 430 nm. 10. Concentration Range 10.1 The recommended concentration range is from 0.05 to 0.5 µg of beryllium in 25 mL of solution. NOTE 2—It is essential that the DTPA salts be recrystallized since commercial DTPA contains impurities that absorb ultraviolet and visible light. These impurities produce bright blue fluorescence under ultraviolet light, and react under certain conditions to produce a bright yellow fluorescence. 11. Stability of Fluorescence 11.1 The fluorescence is stable for at least 1 h if the test solutions are kept at constant temperature. 14.8 Disodium Ethylenediaminetetraacetate (EDTA) Solution (100 g/L)—Dissolve 100 g of EDTA in water and dilute to 1 L. 14.9 EDTA Wash Solution—Add 5 mL of H2SO4 and 10 mL of the EDTA solution to 300 mL of water. Add 2 drops of phenol red indicator solution and NH4OH until the solution turns red. Cool and dilute to 500 mL. 14.10 Morin Solution (0.075 g/L)—Dissolve 0.0075 g of anhydrous morin (3,5,7,28,48-penta-hydroxyflavone), reagent grade, in 40 mL of ethanol. Transfer to a 100-mL volumetric flask with water, dilute to volume, and mix. 14.11 Phenol Red Indicator Solution (1 g/L)—Dissolve 0.1 g of phenol red in 50 mL of methanol and dilute to 100 mL with water. 14.12 Piperidine Buffer Solution—Dissolve 15 g of the recrystallized DTPA in 200 mL of water. Add 75 mL of redistilled piperidine and cool. Add 20 g of anhydrous sodium sulfite (Na2SO 3) and dilute to 500 mL. Store in a plastic bottle. This solution slowly decomposes and should be discarded after 6 months. 14.13 Potassium Iodide-Starch Paper. 14.14 Quinine Sulfate Solution (0.1 g/L)—Dissolve 0.1 g of quinine sulfate in 300 mL of water. Add 10 mL of HClO4 and dilute to 1 L. 14.15 Sodium Hydroxide-Sodium Perchlorate-DTPATriethanolamine (TEA) Solution—Dissolve 60 g of sodium hydroxide (NaOH) and 320 g of anhydrous sodium perchlorate (NaClO4) in 250 mL of water. Filter through a double 7-cm glass-fiber filter. Add 10 mL of TEA solution (20 volume %) to 13.0 g of the recrystallized DTPA and dissolve in 50 mL of water and about 20 mL of the NaOH-NaClO 4 solution. When 12. Interferences 12.1 Silicon must be removed by dehydration or volatilization. Beryllium is separated from interfering ions by an acetylacetone extraction. Fluoride and pyrophosphate interfere in the extraction. 13. Apparatus 13.1 Bottles, plastic, 500-mL capacity. 13.2 Constant-Temperature Bath, 20 or 25°C. 13.3 Fluorescence-Measuring Instrument— A suitable filter fluorometer or spectrofluorometer with primary excitation at approximately 430 nm and a means of isolating and measuring the secondary fluorescent emission at approximately 520 nm. 14. Reagents 14.1 Acetylacetone (2,4-pentanedione), practical. 14.2 Aluminum Sulfate Solution (49 g/L)—Dissolve 4.9 g of aluminum sulfate (Al2(SO 4)3·18H2O) in 70 mL of water, add 1 mL of HClO4, transfer to a 100-mL volumetric flask, dilute to volume, and mix. 14.3 Ammonium Nitrate Wash Solution (10 g/L)—Dissolve 5 g of ammonium nitrate (NH4NO 3) in water and dilute to 500 mL. 14.4 Beryllium, Standard Solution A (1 mL = 100 µg Be)— Dissolve 1.964 g of beryllium sulfate (BeSO4·4H2O) in water, add 10 mL of HClO4, transfer to a 1-L volumetric flask, dilute to volume, and mix. Standardize as follows: transfer a 100-mL aliquot of this solution to a 250-mL beaker, add NH4OH (1+1) until a permanent turbidity forms, and then add 10 mL in 3 E 34 – 94 (2002) to avoid bumping and continue fuming for 10 min. Cool to room temperature. Add 100 mL of water and heat to dissolve the salts. Filter through a medium paper into a 500-mL volumetric flask. Wash the paper and precipitate with 10 mL of H2SO4(1+4) followed by several washings with hot water. Cool to room temperature, dilute to volume, and mix. 17.1.3 Transfer an aliquot containing an amount of beryllium that is in the linear portion of the calibration curve, but not containing more than 70 mg of aluminum, to a 150-mL beaker. Add 10 mL of EDTA solution and adjust the volume to approximately 40 mL. Add 2 drops of phenol red indicator solution and NH4OH until the solution turns red. Add 5 drops of HClO4, cover the beaker with a watch glass, and boil for 5 min (Note 3). Cool to room temperature. dissolution is complete, add the remainder of the NaOHNaClO 4 solution and dilute to 500 mL. Store in a plastic bottle. Acidify a small portion of the solution and test for oxidizing agents with the potassium iodide-starch paper. If the presence of an oxidizing agent is indicated, add sodium sulfite (Na2SO3) in small portions until the oxidizing agent is destroyed. 14.16 Sodium Hydroxide Solution (40 g/L)—Dissolve 20 g of NaOH in water and dilute to 500 mL. Store in a plastic bottle. 15. Hazards 15.1 Beryllium and its compounds are extremely toxic and care must be exercised in the handling of these compounds. Hot perchloric acid and organic compounds present the possibility of an explosion if not handled carefully. NOTE 3—The aluminum-EDTA complex is slow in forming and, therefore, requires the 5-min boiling period. If the complex is not formed, an emulsion will result in the extraction procedure causing erroneous results. Ten millilitres of EDTA solution will chelate approximately 70 mg of . 16. Preparation of Calibration Curve 16.1 Calibration Solutions—Transfer 0.5, 1.0, 3.0, 5.0, 7.0, and 9.0 mL of Beryllium Solution B (1 mL = 0.10 µg Be) to six 25-mL volumetric flasks. Proceed as directed in 16.3. 16.2 Reference Solution—Transfer 5 mL of water to a 25-mL volumetric flask and proceed as directed in 16.3. 16.3 Fluorescence Development: 16.3.1 Add 1 mL of Al2(SO4) 3 solution, 3 mL of NaOHNaClO4-DTPA-TEA solution, and 3 drops of quinine sulfate solution. 16.3.2 Add HClO4 dropwise until the solution fluoresces under an ultraviolet light, then add 1 drop in excess. Swirl the contents of the flask so that any beryllium that may have been deposited as the hydroxide on the wall of the flask is redissolved. 16.3.3 Add NaOH solution dropwise until the fluorescence is destroyed and then add 2 drops in excess. Rinse down the neck of the flask with water. 16.3.4 Add 5 mL of piperidine buffer solution and mix. 16.3.5 Add 1.00 mL of morin solution, dilute to volume, and mix. Place the flask in the constant-temperature bath for 20 min. 16.4 Fluorometry: 16.4.1 Following the manufacturer’s operating instructions, adjust the fluorometer so that the calibration solution is excited by light at approximately 430 nm, and its fluorescence is detected at approximately 520 nm. 16.4.2 Transfer a suitable portion of the reference solution to the cuvette and adjust the fluorometer to the initial setting. While maintaining this adjustment, take the fluorometric readings of the calibration solutions. 16.5 Calibration Curve—Plot the fluorometric readings of the calibration solutions against micrograms of beryllium per 25 mL of solution. 17.1.4 Transfer the solution to a 125-mL separatory funnel. A standard containing an amount of beryllium that is in the linear portion of the calibration curve must be carried through the extraction for calibration purposes. Add 10 drops of acetylacetone, stopper the funnel, and mix by shaking. Add NH4OH dropwise until the solution turns red and add 5 drops in excess. Add 10 mL of CHCl3 and shake vigorously for 2 min; allow the phases to separate. Transfer the CHCl3 (lower) layer to a clean 125-mL separatory funnel and reserve. Repeat the extraction from the aqueous layer with 4 drops of acetylacetone and 10 mL of CHCl3 and add the CHCl3 layer to the reserved one. Add 20 mL of EDTA wash solution to the reserved CHCl3 extracts, shake for 30 s, and allow the phases to separate. Drain the CHCl3 layer into a 100-mL beaker. Add 2 drops of acetylacetone and 10 mL of CHCl3 to the EDTA wash solution layer, shake for 30 s, and add the CHCl3 extracts to those in the 100-mL beaker. 17.1.5 Add 3 mL of HNO3 and 5 mL of HClO 4. Cover the beaker with a watchglass and volatilize the CHCl3 at a temperature just sufficient to boil the CHCl3. When volatilization of the CHCl3 is complete, increase the heat and allow the solution to boil until HClO4 fumes appear. This refluxing action will dissolve materials adhering to the walls of the beaker. Cool, remove the watchglass after rinsing with water, and evaporate the solution to a volume of 0.5 mL. Do not bake or allow the beaker to go dry during the evaporation. Cool, add a few drops of water, warm to dissolve salts, and cool again. Transfer the solution to a 25-mL volumetric flask, keeping the volume in the flask to approximately 10 mL. 17.2 Reference Solution—Carry a reagent blank through the entire procedure, using the same amounts of all reagents, for use as a reference solution. 17.3 Fluorescence Development—Proceed as directed in 16.3. 17. Procedure 17.1 Test Solution: 17.1.1 Transfer 1.00 g of the sample, weighed to the nearest 1 mg, to a 250-mL beaker. Add 25 mL of water and 10 mL of HCl. Warm the solution, if necessary, to hasten dissolution. When dissolution is complete, boil for a few minutes. 17.1.2 Add 5 mL of HNO3 and 20 mL of HClO 4 and evaporate to the appearance of HClO4 fumes. Reduce the heat NOTE 4—If the solution fluoresces after the addition of the reagents in 16.3.1, neutralize the excess acid with NaOH solution (50 %) dropwise until the fluorescence disappears. This neutralization step will keep the solution within the 25-mL volume. 4 E 34 – 94 (2002) 35.1 Boron, Standard Solution (1 mL = 0.05 mg B)— Dissolve 0.2857 g of boric acid (H3BO3) crystals in warm (not over 40°C) water. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. 35.2 Bromine Water (Saturated). 35.3 Carmine Solution (0.92 g/L)—Transfer 0.46 g of carmine to a dry 1-L stoppered plastic bottle. Add 500 mL of H2SO4, and a plastic-coated magnetic stirring bar. Stopper the bottle and stir on a magnetic stirrer until the carmine is completely dissolved. Store in a dark place. 35.4 Sodium Carbonate (Na2CO 3), anhydrous. 17.4 Fluorometry—Take the fluorometric readings of the standard beryllium and test solutions as directed in 16.4. NOTE 5—If the beryllium standard differs significantly from the calibration curve, the test solution and the beryllium standard must be rerun. 18. Calculation 18.1 Convert the fluorometric reading of the test solution to micrograms of beryllium by means of the calibration curve. Calculate the parts per million of beryllium as follows: Beryllium, ppm 5 A/B (1) where: A = beryllium found in 25 mL of the final solution, µg, and B = sample represented in 25 mL of the final solution, g. 36. Preparation of Calibration Curve 36.1 Calibration Solutions—Transfer 1.0, 2.0, 4.0, 6.0, 8.0, 10.0, and 12.0 mL of boron solution (1 mL = 0.05 mg B) to seven 50-mL volumetric flasks (Note 7). Add 10 mL of H2SO4 (1+1), dilute to 40 mL, mix, and cool to room temperature. Dilute to volume, and mix again. Proceed as directed in 36.3. 19. Precision 19.1 Due to the limited number of laboratories participating in the cooperative testing of this test method, a precision statement conforming to the requirements of Practice E 173 cannot be furnished. However, in a cooperative program conducted by three laboratories, the between-laboratory range was from 8.4 to 8.5 ppm beryllium on a sample averaging 8.5 ppm, and from 13.5 to 14.2 ppm on a sample averaging 13.8 ppm. NOTE 7—All glassware must be rinsed with warm H2SO4, then with water, and air-dried. It must not be contaminated with grease or soap. 36.2 Reference Solution—Transfer 10 mL of H2SO4 (1+1) to a 50-mL volumetric flask, dilute to 40 mL, mix, and cool to room temperature. Dilute to volume and mix again. Proceed as directed in 36.3. 36.3 Color Development—Transfer 2-mL aliquots of the reference solution and of each of the calibration solutions to dry 50-mL glass-stoppered Erlenmeyer flasks. Add 10.0 mL of H2SO 4, mix, and cool to room temperature. Add 10.0 mL of carmine solution, stopper, mix, and allow to stand away from strong light for at least 45 min. 36.4 Photometry—Transfer a suitable portion of the reference solution to a dry absorption cell with a 1-cm light path and adjust the photometer to the initial setting, using a light band centered at approximately 585 nm. While maintaining this adjustment, take the photometric readings of the calibration solutions. 36.5 Calibration Curve—Plot the photometric readings of the calibration solutions against milligrams of boron per 22 mL of solution. 37. Procedure 37.1 Test Solution: 37.1.1 Transfer 1.0 g of the sample, weighed to the nearest 1 mg, to a 250-mL Erlenmeyer flask. Add 15 mL of bromine water followed by 10 mL of HCl. If effervescence becomes so rapid as to obscure the surface of the solution, cool until the reaction moderates. If reaction becomes very slow, heat the solution moderately. When dissolution is complete, heat just below boiling to remove any excess bromine. 37.1.2 Filter the solution using a 7-cm, low-ash, coarse paper into a 50-mL volumetric flask. Wash the Erlenmeyer flask and paper 3 or 4 times with hot water, being careful to keep the volume of the filtrate below 40 mL, and reserve the filtrate. 37.1.3 Cover any residue on the filter paper with 0.25 g of anhydrous Na2CO3 and transfer the paper to a small platinum crucible. Dry and char at a low heat over a Meker burner, gradually raising the temperature until the paper is completely oxidized and the melt fuses. Continue to heat the melt until it is clear (about 10 min). Cool to room temperature. Dissolve the BISMUTH BY THE THIOUREA (PHOTOMETRIC) TEST METHOD (This test method, which consisted of Sections 20 through 29 of this standard, was discontinued in 1983.) BORON BY THE CARMINE (PHOTOMETRIC) TEST METHOD 30. Scope 30.1 This test method covers the determination of boron in concentrations from 0.005 to 0.060 %. 31. Summary of Test Method 31.1 Boron, in the form of boric acid, reacts with carmine in concentrated sulfuric acid to produce a violet color. Photometric measurement is made at approximately 585 nm, at which wavelength the blue boron complex absorbs strongly while the absorption due to the reagent is very slight. 32. Concentration Range 32.1 The recommended concentration range is from 0.002 to 0.025 mg of boron per 22 mL of solution, using a cell depth of 1 cm. NOTE 6—Use of a cell having other dimensions may alter the recommended concentration range. 33. Stability of Color 33.1 Color development is slow. It is practically complete after 45 min, however, and thereafter the rate of increase of absorbance is negligible. The effect of the slight photosensitivity of the complex is minimized by protecting the solutions against strong light during the color development. 34. Interferences 34.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere. Vanadium, if present in amounts greater than 0.3 %, will interfere. 35. Reagents 5 E 34 – 94 (2002) 44.4 Sodium Chloride Solution (2 g/L)—Dissolve 2 g of sodium chloride (NaCl) in water and dilute to 1 L. melt with about 5 mL of hot water and add H2SO4 (1+1) dropwise until the effervescence ceases. Add the solution to the reserved filtrate in the 50-mL volumetric flask, cool, dilute to volume, and mix. 37.2 Reference Solution—Carry a reagent blank through the entire procedure using the same amounts of all reagents, for use as a reference solution. 37.3 Color Development—Transfer a 2-mL aliquot of the solution to a dry 50-mL glass-stoppered Erlenmeyer flask and proceed as directed in 36.3. 37.4 Photometry—Take the photometric reading of the test solution as directed in 36.4. 38. Calculation 38.1 Convert the photometric reading of the test solution to milligrams of boron by means of the calibration curve. Calculate the percentage of boron as follows: Boron, % 5 A/~B 3 10! 45. Preparation of Calibration Curve 45.1 Calibrations Solutions: 45.1.1 Transfer 1.0, 2.0, 5.0, 10.0, 15.0, and 20.0 mL of chromium solution (1 mL = 0.08 mg Cr) to six 300-mL Erlenmeyer flasks and dilute to 20 mL with water. Add 0.500 g of low-chromium aluminum, 7 mL of HClO 4, and 10 mL of H2SO4. 45.1.2 Allow to react without applying heat. When the reaction is complete, wash down the sides of the flask with a minimum of water, and add 5 mL of HNO3 and 2 mL of HF. Heat to complete the dissolution of any metal sponge and silicon, and continue heating to copious white fumes (Note 8). Cool somewhat, add 30 mL of water, and heat to dissolve the soluble salts. Add 5 mL of NaCl solution (Note 9) and boil for 5 min to remove any chlorine formed by the presence of oxidized manganese. Cool, transfer to a 100-mL volumetric flask, dilute to volume, and mix. Proceed as directed in 45.3. (2) where: A = boron found in 22 mL of the final solution, mg, and B = sample represented in 22 mL of the final solution, g. NOTE 8—In order to oxidize the chromium completely to chromate, it is necessary to heat the solution through the stage where copious white fumes of HClO 4 are evolving and refluxing. This operation may be carried out over a free flame; avoid heating to dryness. NOTE 9—In some cases, manganese is precipitated as manganese dioxide (MnO 2) after fuming. The NaCl solution is added to dissolve any MnO 2 that might be present. CHROMIUM BY THE DIPHENYLCARBAZIDE (PHOTOMETRIC) TEST METHOD 39. Scope 39.1 This test method covers the determination of chromium in concentrations from 0.01 to 0.30 %. 40. Summary of Test Method 40.1 After dissolution of the sample in acids, chromium is oxidized to the hexavalent state in fuming perchloric acid. Hexavalent chromium forms a soluble red-violet complex with diphenyl-carbazide. Photometric measurement is made at approximately 540 nm. 41. Concentration Range 41.1 The recommended concentration range is from 0.004 to 0.08 mg of chromium per 100 mL of solution, using a cell depth of 2 cm (see Note 6). 42. Stability of Color 42.1 The color of the chromium diphenylcarbazide complex develops almost immediately but starts to fade within a short period of time. Photometric measurement must be made within 5 min after adding the diphenylcarbazide. 43. Interferences 43.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere if their concentrations are under the maximum limits shown in 1.1. Oxidizing agents cause rapid fading of the chromium diphenylcarbazide complex. 44. Reagents 44.1 Aluminum or Aluminum-Base Alloy, Low-Chromium— Aluminum or aluminum-base alloy containing less than 0.005 % chromium. 44.2 Chromium, Standard Solution (1 mL = 0.08 mg Cr)— Prepare as directed for Reagent No. 10, using 0.2263 g instead of the specified weight. 44.3 Diphenylcarbazide Solution (10 g/L)—Dissolve 0.20 g of diphenylcarbazide in 20 mL of methanol. This solution decomposes within a few hours and must be prepared fresh as needed. 45.2 Reference Solution—Transfer 0.500 g of low-chromium aluminum to a 300-mL Erlenmeyer flask. Add 20 mL of water, 7 mL of HClO4, and 10 mL of H2SO4. Proceed as directed in 45.1.2 and 45.3. 45.3 Color Development—Transfer a 5-mL aliquot to a 100-mL volumetric flask. Dilute to about 90 mL, add 1 mL of diphenylcarbazide solution, dilute to volume, and mix. 45.4 Photometry—Transfer a suitable portion of the reference solution to an absorption cell with a 2-cm light path and adjust the photometer to the initial setting, using a light band centered at approximately 540 nm. While maintaining this adjustment, take the photometric readings of the calibration solutions. 45.5 Calibration Curve—Plot the photometric readings of the calibration solutions against milligrams of chromium per 100 mL of solution. 46. Procedure 46.1 Test Solution—Transfer 0.500 g of the sample, weighed to the nearest 1 mg, to a 300-mL Erlenmeyer flask. Add in the following order (Precaution: see Note 10), 20 mL of water, 7 mL of HClO4, and 10 mL of H2SO 4. Proceed as directed in 45.1.2. NOTE 10—Precaution: The order of adding the reagents used in decomposing the sample must be strictly adhered to. Under no circumstances should HClO4 be added directly to the metallic aluminum. See the Safety Precautions Section of Practices E 50 for a discussion of the hazards involved in the use of HClO4. 46.2 Reference Solution—Carry a reagent blank through the entire procedure, using the same amount of all reagents, for use as a reference solution. 46.3 Color Development—Proceed as directed in 45.3 6 E 34 – 94 (2002) of water, 25 mL of HCl, and 1 mL of HNO3. Heat gently to dissolve the iron and expel brown fumes. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. 78.3 Iron, Standard Solution B (1 mL = 0.02 mg Fe)— Transfer a 100-mL aliquot of Iron Solution A to a 500-mL volumetric flask, add 10 mL of HCl, dilute to volume, and mix. 78.4 1,10-Phenanthroline Solution (2 g/L)—Dissolve 0.4 g of 1,10-phenanthroline monohydrate in methanol and dilute to 200 mL with methanol. 78.5 Sodium Acetate-Acetic Acid Buffer Solution—Dissolve 272 g of sodium acetate trihydrate in 500 mL of water. Add 240 mL of glacial acetic acid, cool, and dilute to 1 L. 78.6 Sodium Hydroxide Solution (200 g/L)—Dissolve 200 g of sodium hydroxide (NaOH) in water and dilute to 1 L. Store in a plastic bottle. 78.7 Test Lead—Finely granulated lead containing less than 0.001 % iron. 46.4 Photometry—Take the photometric reading of the test solution as directed in 45.4. 47. Calculation 47.1 Convert the photometric reading of the test solution to milligrams of chromium by means of the calibration curve. Calculate the percentage of chromium as follows: Chromium, % 5 A/~B 3 10! where: A = chromium found in 100 mL of the final solution, mg, and B = sample represented in 100 mL of the final solution, g. CHROMIUM BY THE PERSULFATE OXIDATION (TITRIMETRIC) TEST METHOD (This test method, which consisted of Sections 48 through 53 of this standard, was discontinued in 1981.) 79. Preparation of Calibration Curve 79.1 Calibration Solutions—Transfer 1.0, 2.0, 4.0, 7.0, and 10.0 mL of Iron Solution B (1 mL = 0.02 mg Fe) to five 100-mL volumetric flasks. Dilute to 60 mL and proceed as directed in 79.3. 79.2 Reference Solution—Transfer 60 mL of water to a 100-mL volumetric flask and proceed as directed in 79.3. 79.3 Color Development—Add successively, mixing after each addition: 4 mL of NH2OH·HCl solution, 10 mL of sodium acetate-acid buffer solution, and 10 mL of 1,10-phenanthroline solution. Dilute to volume and mix. Allow to stand for 5 min. 79.4 Photometry—Transfer a suitable portion of the reference solution to an absorption cell with a 2-cm light path and adjust the photometer to the initial setting, using a light band centered at approximately 510 nm. While maintaining this adjustment, take the photometric readings of the calibration solutions. 79.5 Calibration Curve—Plot the photometric readings of the calibration solutions against milligrams of iron per 100 mL of solution. 80. Procedure 80.1 Test Solution: 80.1.1 Remove adventitious iron as follows: immerse the entire sample in HCl (1+9) for 5 to 10 s, decant the acid, wash with water, then with acetone, and dry. Transfer 0.50 g of the sample, weighed to the nearest 1 mg, to a 250-mL nickel beaker. Cover with a watchglass and dissolve by adding, in small increments, 15 mL of NaOH solution. When the reaction subsides, wash down the cover and sides of the beaker, and boil gently until the silicon is completely dissolved. Cool, transfer to a 250-mL glass beaker containing 25 mL of HCl (1+1), and wash and police the nickel beaker. 80.1.2 Place the beaker containing the solution on a hot plate and boil until the salts are dissolved. Remove from the hot plate, and add a few drops of H2O2. Allow to react without further heating until any metallic sponge is dissolved. Boil gently until the H2O 2 is decomposed and chlorine removed. Cool, transfer to a 250-mL volumetric flask, dilute to volume, and mix. COPPER BY THE NEOCUPROINE (PHOTOMETRIC) TEST METHOD (This test method, which consisted of Sections 54 through 63 of this standard, was discontinued in 1983.) COPPER AND LEAD BY THE ELECTROLYTIC (GRAVIMETRIC) TEST METHOD (This test method, which consisted of Sections 64 through 72 of this standard, was discontinued in 1985.) IRON BY THE 1,10-PHENANTHROLINE (PHOTOMETRIC) TEST METHOD 73. Scope 73.1 This test method covers the determination of iron in concentrations from 0.01 to 3.0 %. 74. Summary of Test Method 74.1 Ferrous iron, in a solution having a pH of about 5, forms an orange-red complex with 1,10-phenanthroline. Photometric measurement is made at approximately 510 nm. 75. Concentration Range 75.1 The recommended concentration range is from 0.02 to 0.20 mg of iron per 100 mL of solution, using a cell depth of 2 cm (see Note 6). 76. Stability of Color 76.1 The color develops within 5 min and is stable for at least 2 h. 77. Interferences 77.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere. Zinc and nickel form complexes and consume 1,10-phenanthroline; however, enough reagent is added to complex the maximum amounts of nickel and zinc to be encountered, in addition to the iron. 78. Reagents 78.1 Hydroxylamine Hydrochloride Solution (100 g/L)— Dissolve 10 g of hydroxylamine hydrochloride (NH2OH·HCl) in water and dilute to 100 mL. 78.2 Iron, Standard Solution A (1 mL = 0.10 mg Fe— Dissolve 0.1000 g of iron metal (purity 99.8 % min) in 50 mL 7 E 34 – 94 (2002) water, add 70 mL of NH4OH, and proceed as directed in 92.1.3 and 92.2. Calculate the magnesium equivalent of the disodium ethylenediamine tetraacetate solution as follows: 80.1.3 Transfer an aliquot containing between 0.02 and 0.20 mg of iron to a 150-mL beaker, dilute to approximately 30 mL, and add 1 to 2 g of test lead. Boil gently until the iron is reduced to the ferrous state and the copper is displaced completely, approximately 5 to 8 min being required. Cool, transfer the solution to a 100-mL volumetric flask, and wash the residue by decantation. 80.2 Reference Solution—Carry a reagent blank through the entire procedure, using the same amounts of all reagents, for use as a reference solution. 80.3 Color Development—Proceed as directed in 79.3. 80.4 Photometry—Take the photometric reading of the test solution as directed in 79.4. 81. Calculation 81.1 Convert the photometric reading of the test solution to milligrams of iron by means of the calibration curve. Calculate the percentage of iron as follows: Iron, % 5 A/~B 3 10! Magnesium equivalent, g/mL 5 0.020/~A 2 B! (4) where: A = EDTA solution required for titration of the magnesium solution, mL, and B = EDTA solution required for titration of the blank, mL. 91.3 Eriochrome Black-T Indicator Solution (8 g/L)— Dissolve 0.4 g of the sodium salt of Eriochrome Black-T in a mixture of 20 mL of ethanol and 30 mL of triethanolamine. This solution is stable for at least 3 months when kept in a tightly closed plastic dropping bottle. 91.4 Magnesium, Standard Solution (1 mL = 1.00 mg Mg)— Dissolve 1.000 g of magnesium turnings (purity, 99.9 % min) in 25 mL of HCl (1+1). Transfer to a 1-L volumetric flask, dilute to volume, and mix. 91.5 Potassium Cyanide Solution (250 g/L)—Dissolve 250 g of potassium cyanide (KCN) in water and dilute to 1 L. Store in a plastic bottle. (3) where: A = iron found in 100 mL of the final solution, mg, and B = sample represented in 100 mL of the final solution, g. NOTE 11—Precaution: The preparation, storage, and use of KCN solutions require care and attention. Avoid inhalation of fumes and exposure of the skin to the chemical or its solutions. Work in a well-ventilated hood. MAGNESIUM BY THE PYROPHOSPHATE (GRAVIMETRIC) TEST METHOD (This test method, which consisted of Sections 82 through 87 of this standard, was discontinued in 1981.) 91.6 Sodium Hydroxide Solution, Low-Carbonate (200 g/L)—Dissolve 200 g of sodium hydroxide (NaOH) (lowcarbonate) in water in a nickel or stainless steel beaker. Cool, dilute to 1 L, and transfer to a plastic bottle. 92. Procedure 92.1 Test Solution: 92.1.1 Transfer 1.0 g of the sample, weighed to the nearest 1 mg, to a 250-mL beaker. Carefully add 30 mL of NaOH solution. When the reaction subsides, wash down the sides of the beaker with a small amount of water and boil until the reaction ceases. Add a few drops of H2O2, followed by 5 mL of KCN solution, and boil. Dilute to about 150 mL with hot water and filter using a hardened rapid paper. Wash well with hot water. 92.1.2 Dissolve the precipitate on the paper with 40 mL of hot HCl (1+1). Collect the solution in the original 250-mL beaker and wash the paper well with hot water. Add 10 mL of saturated bromine water, neutralize with NH 4OH until the bromine color disappears, and add 6 to 8 drops in excess. A large excess of NH4OH must be avoided to prevent dissolution of any aluminum, which would interfere with the end point in the subsequent titration. Bring the solution to a boil to coagulate the precipitated MnO 2, and boil for at least 5 min to expel excess NH3. Let settle for 1 min and filter through a medium paper with pulp, collecting the filtrate in a 400-mL beaker. Wash well with hot water. (If the manganese or iron content is high, as indicated by a large amount of a darkcolored precipitate, redissolve and reprecipitate as before.) Cool the filtrate to room temperature, dilute to 250 mL, and add 70 mL of NH4OH. 92.1.3 Add 10 drops of KCN solution, 7 to 10 drops of Eriochrome Black-T indicator solution and titrate with 0.05 M EDTA solution. MAGNESIUM BY THE ETHYLENEDIAMINE TETRAACETATE (TITRIMETRIC) TEST METHOD 88. Scope 88.1 This test method covers the determination of magnesium in concentrations from 0.1 to 5.0 %. The range may be extended by suitably varying the sample weight. 89. Summary of Test Method 89.1 Magnesium is separated from the bulk of the alloy constituents by treatment of the sample with sodium hydroxide in the presence of hydrogen peroxide and potassium cyanide. The magnesium hydroxide is dissolved in hydrochloric acid and any remaining aluminum is separated by precipitation with ammonium hydroxide. Manganese is oxidized with bromine and separated as manganese dioxide. Magnesium is then determined by titration with disodium ethylenediamine tetraacetate. 90. Interferences 90.1 The elements ordinarily present in aluminum and aluminum-base alloys, except calcium, do not interfere if their concentrations are under the maximum limits shown in 1.1. Calcium is rarely present in significantly high concentrations. 91. Reagents 91.1 Bromine Water (Saturated). 91.2 Disodium Ethylenediamine Tetraacetate (EDTA), Standard Solution (0.05 M)—Dissolve 18.61 g of disodium ethylenediamine tetraacetate dihydrate (EDTA) in water, transfer to a 1-L volumetric flask, dilute to volume, and mix. Standardize as follows: transfer a 20-mL aliquot of magnesium solution (1 mL = 1.00 mg Mg) to a 400-mL beaker. Add 40 mL of HCl (1+1) and neutralize with NH 4OH. Dilute to 250 mL with 8 E 34 – 94 (2002) 123.1 Plastic Ware (polyethylene, polypropylene, or tetrafluoroethylene): 123.1.1 Beakers and Covers. 123.1.2 Bottles, 1-L capacity. 123.1.3 Graduated Cylinders, 10-mL and 1-L capacity. 123.2 Nickel Crucibles and Covers, 50-mL capacity. 123.3 Nickel or Stainless Steel Beakers and Covers, 250-mL and 1-L capacity. 123.4 pH Meter—Any commercial instrument capable of determining pH in the range from 0 to 7 6 0.1 is suitable. 124. Reagents 124.1 Aluminum Nitrate Solution (Al(NO 3)3)—Transfer 1.0 g of aluminum, low-silicon,6 to a 250-mL nickel beaker. Add 100 mL of NaOH solution and cover. Allow to react without applying heat until the reaction subsides, and then warm gently to complete the dissolution. Cool, and transfer to a 400-mL beaker containing 125 mL of HNO3 (1+1). Cover and warm gently until the salts dissolve and the solution becomes clear. Cool, transfer to a 250-mL volumetric flask, dilute to volume, and mix. 124.2 Ammonium Molybdate Solution (100 g/L)—Dissolve 100 g of ammonium molybdate tetrahydrate ((NH4)6Mo7O24·4H 2O) in water and dilute to 1 L. Store in a plastic bottle. Filter before using. If a precipitate forms on standing, the solution should be discarded. 124.3 Silicon, Standard Solution (1 mL = 0.05 mg Si)—Fuse 0.1070 g of anhydrous silicon dioxide (SiO2) with 1.0 g of sodium carbonate (Na 2CO3) in a covered platinum crucible. Cool, dissolve the melt completely in water in a plastic beaker, cover, and heat on a steam bath for 1⁄2 to 1 h. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. Store the solution in a plastic bottle. If anhydrous SiO2 is not available, the weight should be adjusted according to the actual silicon content of the SiO 2 used, as determined by gravimetric analysis. 124.4 Sodium Hydroxide Solution (300 g/L)—Dissolve 300 g of sodium hydroxide (NaOH) in about 600 mL of water, using a nickel or stainless steel beaker. Cool and dilute to 1 L. Store in a plastic bottle. 92.2 Blank Determination—Neutralize 40 mL of HCl (1+1) with NH4OH. Dilute to 250 mL with water and add 70 mL of NH4OH. Proceed as directed in 92.1.3. 93. Calculation 93.1 Calculate the percentage of magnesium as follows: Magnesium, % 5 [~A 2 B!C/D] 3 100 (5) where: A = EDTA solution required for titration of the test solution, mL, B = EDTA solution required for titration of the blank, mL, C = magnesium equivalent of the EDTA solution, g/mL, and D = sample used, g. MANGANESE BY THE PERIODATE (PHOTOMETRIC) TEST METHOD (This test method, which consisted of Sections 94 through 102 of this standard, was replaced in 1984 by Sections 293 through 302.) NICKEL BY THE DIMETHYLGLYOXIME (PHOTOMETRIC) TEST METHOD (This test method, which consisted of Sections 103 through 111 of this standard, was discontinued in 1983.) NICKEL BY THE DIMETHYLGLYOXIME (GRAVIMETRIC) TEST METHOD (This test method, which consisted of Sections 112 through 117 of this standard, was discontinued in 1981.) SILICON BY THE MOLYBDISILICIC ACID (PHOTOMETRIC) TEST METHOD 118. Scope 118.1 This test method covers the determination of silicon in concentrations from 0.05 to 1.0 %. 119. Summary of Test Method 119.1 Silicic acid in a true (not colloidal) solution reacts with molybdate to form a soluble yellow-colored molybdisilicic acid. Maximum color development occurs over a pH range from 1.1 to 1.3. Photometric measurement is made at approximately 400 nm. 120. Concentration Range 120.1 The recommended concentration range is from 0.05 to 1.0 mg of silicon per 100 mL of solution, using a cell depth of 2 cm (see Note 6). 121. Stability of Color 121.1 The color develops in less than 5 min and does not fade appreciably for at least 20 min. 122. Interferences 122.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere. 125. Preparation of Calibration Curve 125.1 Calibration Solutions—Transfer 12.5 mL of (NO3)3 solution and 1.0 mL of HNO3 (1+1) to seven 100-mL beakers. Transfer 1.0, 2.0, 4.0, 8.0, 12.0, 16.0, and 20.0 mL of silicon solution (1 mL = 0.05 mg Si) to each of the 100-mL beakers. Dilute to about 80 mL and mix. Proceed as directed in 125.3. 125.2 Reference Solution—Transfer 12.5 mL of Al(NO3)3 solution and 1 mL of HNO3 (1+1) to a 100-mL beaker, dilute to about 80 mL, and mix. Proceed as directed in 125.3. 125.3 Color Development—Using a pH meter, check the pH of the solution. If the pH is not within 1.1 to 1.3, adjust it to this range using HNO3 (1+1) or NaOH solution as required. Add 10 mL of ammonium molybdate solution, transfer the solution to NOTE 12—If detergents are used for cleaning, all traces of the detergents must be removed by boiling with HCl followed by thorough rinsing. Many detergents contain phosphorus compounds, which also form a yellow color with ammonium molybdate, and would cause interference if not completely removed. 6 National Bureau of Standards Sample No. 44c (melting point aluminum) has been found satisfactory for this purpose. 123. Apparatus 9 E 34 – 94 (2002) a 100-mL volumetric flask, dilute to volume, and mix. Let stand at least 5 min but no longer than 20 min before taking the photometric reading. 125.4 Photometry—Transfer a suitable portion of the reference solution to an absorption cell with a 2-cm light path and adjust the photometer to the initial setting, using a light band centered at approximately 400+. While maintaining this adjustment, take the photometric readings of the calibration solutions. 125.5 Calibration Curve—Plot the photometric readings of the calibration solutions against milligrams of silicon per 100 mL of solution. 126. Procedure 126.1 Test Solution: 126.1.1 Transfer 0.10 g of the sample, weighed to the nearest 0.1 mg, to a 50-mL nickel crucible, add 10.00 mL of NaOH solution, and cover. Allow to react without applying heat until the reaction subsides, wash down the cover and sides of the crucible with a minimum amount of water, and boil gently until the reaction is complete and the silicon completely oxidized (Note 13). Cool, dilute to approximately 30 mL with water, and transfer quantitatively to a 150-mL beaker containing 12.5 mL of HNO3 (1+1). Cover and warm gently until the solution becomes clear (Notes 14 and 15). Cool, transfer to a 100-mL volumetric flask, dilute to volume, and mix. NOTE 16—For routine work, the reference solution correction may be omitted unless the test solution is colored yellow. 127. Calculation 127.1 Convert the photometric readings of the test and reference solutions to milligrams of silicon by means of the calibration curve. Calculate the percentage of silicon as follows: Silicon, % 5 ~A 2 B!/~C 3 10! (6) where: A = silicon found in 100 mL of the final solution, mg, B = reference solution correction, expressed as milligrams of silicon, and C = sample represented in 100 mL of the final solution, g. SILICON BY THE SODIUM HYDROXIDEPERCHLORIC ACID (GRAVIMETRIC) TEST METHOD 128. Scope 128.1 This test method covers the determination of silicon in concentrations from 0.5 to 20.0 %. 129. Summary of Test Method 129.1 The sample is dissolved with sodium hydroxide and hydrogen peroxide, and the solution acidified with perchloric acid. The silica is dehydrated, ignited, weighed, and then volatilized with hydrofluoric acid. The residue is ignited and weighed. The loss in weight represents silicon dioxide. 130. Interferences 130.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere if their concentrations are under the maximum limits shown in 1.1. 131. Reagents 131.1 Ammonium Acetate Wash Solution (250 g/L)— Dissolve 25 g of ammonium acetate in 1 mL of glacial acetic acid and 99 mL of water. 131.2 Sodium Hydroxide Solution (500 g/L)—Dissolve 500 g of sodium hydroxide (NaOH) in water in a nickel or stainless steel beaker, and dilute to 1 L. Store in a plastic bottle. 131.3 Sulfurous Acid (H2SO 3)—Saturate water with sulfur dioxide (SO2). Prepare fresh as needed. NOTE 13—With certain alloys it may be necessary to evaporate the caustic solution to pastiness in order to completely dissolve the silicon. Care should be taken to avoid mechanical loss by spattering. NOTE 14—Cloudiness (gray) of the solution at this point usually indicates incomplete dissolution of the silicon and another portion of the sample must be taken. Prolonging the heating after the NaOH attack will probably correct the difficulty. However, excessively prolonged heating will tend to cause precipitation of the manganese. NOTE 15—If the sample contains high manganese, the solution may be colored brownish-yellow due to suspended manganese dioxide (MnO2). To bleach the color, add a saturated sodium sulfite (Na2SO3) solution dropwise to the hot solution. Avoid any appreciable excess. Add potassium permanganate (KMnO4) solution (3.2 g/L) until the solution is tinted pink. Finally add just enough oxalic acid (10 g/L) to destroy the pink color. Transfer the solution to a 100-mL volumetric flask, dilute to volume, and mix. 126.1.2 Transfer a 50-mL aliquot to a 100-mL beaker, add 1.0 mL of HNO 3 (1+1), dilute to approximately 80 mL, and mix. 126.2 Reagent Blank: 126.2.1 Transfer 10.0 mL of NaOH solution to a 100-mL volumetric flask containing 11.5 mL of HNO3 (1+1). Dilute to approximately 50 mL, cool, dilute to volume, and mix. Transfer a 50-mL aliquot to a 100-mL beaker, add 1 mL of HNO3 (1+1), dilute to 80 mL, and mix. 126.2.2 To the remaining portion of the reagent blank add 1 mL of HNO 3 (1+1), dilute to volume, and mix. This portion is used as the reagent blank for the reference solution in 126.4. 126.3 Color Development—Proceed as directed in 125.3. 126.4 Reference Solution—To the remaining portion of the test solution add 1 mL of HNO3 (1+1), dilute to volume, and mix. Take the photometric reading of the reference solution as directed in 125.4 using the reagent blank obtained in 126.2.2 for the initial setting of the photometer. 132. Procedure 132.1 Test Solution: 132.1.1 Weigh, to the nearest 1 mg, a portion of the sample calculated to contain from 0.010 to 0.075 g of silicon, but weighing not less than 0.35 g and transfer to a covered 250-mL nickel beaker. Add 12 mL of NaOH solution for each gram of sample (Note 17). When the reaction is complete, wash down the cover and sides of the beaker with a small jet of hot water, keeping the volume as small as possible. Place the covered beaker on the hot plate and cautiously evaporate to a syrupy consistency. Cool, add H2O2 dropwise, and repeat the evaporation. Continue the addition of H2O2 and the evaporation until the silicon is completely oxidized as shown by the absence of any black or gray particles. NOTE 17—The following procedure for decomposition may be used: add 6 g of NaOH pellets for each gram of sample and add 10 mL of water, in small increments. 10 E 34 – 94 (2002) 134.1 This test method covers the determination of tin in concentrations from 0.03 to 1.0 %. 135. Summary of Test Method 135.1 The sample is dissolved in hydrochloric acid and any insoluble material is removed. Tin is reduced with aluminum in the presence of antimony in an inert atmosphere. The stannous tin is titrated with iodate solution using starch as the indicator. 136. Interferences 136.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere if their concentrations are under the maximum limits shown in 1.1. 137. Apparatus 137.1 Apparatus for Reduction of Tin—Apparatus No. 7A. 138. Reagents 138.1 Aluminum, sheet or rolled foil. 138.2 Antimony, powdered. 138.3 Potassium Iodate, Standard Solution ( approximately 0.017 N)—Prepare as directed for Reagent No. 12, using 0.5945 g instead of the specified weight. Standardize against aliquots of tin solution (1 mL = 0.001 g Sn) containing approximately the same amount of tin as the samples to be tested. Carry the standard through the procedure as directed in 139.1.2 and 139.1.3 and 139.2. Calculate the tin equivalent of the potassium iodate (KIO3) solution as follows: 132.1.2 Remove the beaker from the hot plate, cool, wash the cover and sides of the beaker with 10 mL of water, and pour the solution into a 400-mL glass beaker containing 40 mL of HClO4 (3+2) (Notes 18 and 19). Rinse the nickel beaker, first with hot water and then with a few millilitres of HClO4 (3+2) to which an equal volume of water has been added. Police the beaker thoroughly, and finally rinse with hot water. Add all the rinsings to the main solution. Add 5mL of HNO3 and 5 mL of H2SO3. NOTE 18—Perchloric acid can be used safely as specified in the procedure. It should not, however, be brought in contact with finely divided aluminum, silicon, or organic matter. NOTE 19—The HClO4 (3+2) may be replaced with the following H 2SO4-HClO4 mixture: 315 mL of water, 625 mL of H2SO4, and 85 mL of HClO4. In this case, after fuming, dissolve the salts with 90 mL of water and 10 mL of H2SO4 solution (1+3). 132.1.3 Evaporate to dense white fumes, cover, and fume for 15 min (Note 20). Cool, add 100 mL of hot water, stir well, and heat until the salts are dissolved (Note 21). If manganese dioxide (MnO 2) is present, dissolve it by adding H2O2 or H 2SO3 dropwise. Add ashless paper pulp, and filter using a medium, low-ash paper. Thoroughly police the beaker to remove all the SiO 2. Wash the precipitate with hot water until the washings no longer give an acid reaction to litmus. Finally wash once with H2SO 4 (1+9). Reserve the paper and precipitate. Tin equivalent, g/mL 5 A/B where: A = tin represented in the standard, g, and B = KIO3 solution required for titration of the tin, mL. 138.4 Sodium Bicarbonate Solution (100 g/L)—Dissolve 100 g of sodium bicarbonate (NaHCO 3) in water and dilute to 1 L. 138.5 Sodium Bicarbonate Tablets (10 grains). 138.6 Starch-Potassium Iodide Solution—Prepare as directed for Reagent No. 110, using 40 g of KI instead of the specified weight. 138.7 Tin, Standard Solution (1 mL = 0.001 g Sn)—Reagent No. 19. NOTE 20—If lead is present, it may be removed after filtering and washing the precipitate with water and H2SO4. Wash the precipitate on the paper with hot ammonium acetate wash solution. The ammonium acetate wash solution must be excluded from the silicon filtrate. NOTE 21—If appreciable amounts of tin and antimony are present, make the dehydration with H2SO4 and dissolve the salts with HCl. 132.1.4 Evaporate the filtrate and washings and proceed as directed in 132.1.3. 132.1.5 Place the filter papers and precipitates in a platinum crucible, dry and char the paper at a low temperature, and then ignite at 1000°C or above to constant weight. Cool in a desiccator and weigh. 132.1.6 To the residue, add a few drops of H2SO4 (1+1) and about 5 mL of HF. Evaporate carefully to dryness on a hot plate, ignite at 1000°C or above, cool in a desiccator, and weigh. Repeat the treatment with HF and ignite to constant weight. The loss in weight represents silicon dioxide (SiO2). 132.2 Reagent Blank—Make a blank determination, following the same procedure and using the same amounts of all reagents. 133. Calculation 133.1 Calculate the percentage of silicon as follows: Silicon, % 5 [~~A 2 B! 3 0.4674!/C] 3 100 (8) 139. Procedure 139.1 Test Solution: 139.1.1 Transfer 1.0 to 3.0 g of the sample, weighed to the nearest 1 mg, to a 500-mL flask. Add 0.25 g of antimony and 150 mL of HCl (1+2). When the reaction subsides, heat the solution and then boil it for about 10 min to ensure complete dissolution of the tin. Filter through a medium paper (Note 22) and wash with HCl (1+2). NOTE 22—If the sample has no appreciable insoluble residue on dissolution with HCl, the filtration step may be omitted. (7) 139.1.2 Return the filtrate to the original flask and add 0.25 g of antimony and 0.5 g of aluminum. Stopper the flask with the special stopper and syphon, as directed in Apparatus 7A. 139.1.3 Boil gently for 10 to 15 min (until all the metallic tin and aluminum are in solution). Place the flask in a cooling bath with the outlet of the syphon tube immersed in the NaHCO3 solution. When the solution is cold, remove the stopper, immediately add 4 NaHCO3 tablets and 5 mL of fresh starch-KI solution, and titrate rapidly with KIO3 solution to a persistent blue end point. where: A = silicon dioxide found, g, B = correction for blank, g, and C = sample used, g. TIN BY THE IODATE (TITRIMETRIC) TEST METHOD 134. Scope 11 E 34 – 94 (2002) 146.4 Reagent Mixture—Transfer 300 mL of water to a 1-L volumetric flask, add in order 250 mL of NaOH Solution A, 250 mL of H2SO4 (1+4), and 18 mL of HNO3 and mix. Cool, dilute to volume, and mix. (The pH should be about 0.50.) 146.5 Sodium Hydroxide Solution A (200 g/L)—Dissolve 200 g of sodium hydroxide (NaOH) in about 500 mL of water, dilute to about 900 mL, and cool. Transfer to a 1-L volumetric flask, dilute to volume, and mix. Immediately transfer to a plastic bottle. 146.6 Sodium Hydroxide Solution B (80 g/L)—Dissolve 80 g of sodium hydroxide (NaOH) in about 200 mL of water, dilute to about 900 mL, and cool. Transfer to a 1-L volumetric flask, dilute to volume, and mix. Immediately transfer to a plastic bottle. 146.7 Sodium Metadisulfite (Na2S 2O5). 146.8 Sodium Monochloroacetic Acid Buffer Solution— Dissolve 189 g of monochloroacetic acid in 150 mL of water. Dissolve 40 g of sodium hydroxide (NaOH) in about 100 mL of water, and cool. Add the NaOH solution to the monochloroacetic acid solution, mix thoroughly, and cool. If turbid, filter through a fine paper and wash the filter with water. Transfer to a 500-mL volumetric flask, dilute to volume, and mix. (The pH should be about 2.9.) 146.9 Sodium Sulfite Solution (20 g/L)—Dissolve 2 g of sodium sulfite (Na2SO 3) in water and dilute to 100 mL. Do not use a solution that has stood more than 8 h. 146.10 Sulfurous Acid Solution (saturated). 146.11 Titanium, Standard Solution A (1 mL = 0.4 mg Ti)—Dissolve 0.400 g of titanium (purity: 99.5 % minimum) in 125 mL of H2SO4(1+4). When dissolution is complete, oxidize with 10 drops of HNO3, and boil gently to expel fumes of nitrous oxide. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. 146.12 Titanium, Standard Solution B (1 mL = 0.02 mg Ti)—Using a pipet, transfer 50 mL of Titanium Solution A to a 1-L volumetric flask, dilute to volume, and mix. 146.13 Titanium, Standard Solution C (1 mL = 0.002 mg Ti)—Using a pipet, transfer 100 mL of Titanium Solution B to a 1-L volumetric flask. Add 2.5 mL of H 2SO4 (1+4), cool, dilute to volume, and mix. Do not use a solution that has stood more than 1 day. 139.2 Reagent Blank—Make a blank determination, following the same procedure and using the same amounts of all reagents. 140. Calculation 140.1 Calculate the percentage of tin as follows: Tin, % 5 [~~A 2 B! 3 C!/D] 3 100 (9) where: A = KIO3 solution required for titration of the test solution, mL, B = KIO3 solution required for titration of the blank, mL, C = tin equivalent of the KIO3 solution, g/mL, and D = sample used, g. TITANIUM BY THE CHROMOTROPIC ACID (PHOTOMETRIC) TEST METHOD 141. Scope 141.1 This test method covers the determination of titanium in concentrations from 0.002 to 0.3 %. 142. Summary of Test Method 142.1 The sample is dissolved in a sodium hydroxide solution and acidified with nitric and sulfuric acids. Iron is reduced with ascorbic acid. The yellow complex of titanium with chromotropic acid is formed at a pH between 3.1 and 3.2. Photometric measurement is made at approximately 470 nm. 143. Concentration Range 143.1 The recommended concentration range is from 0.002 to 0.10 mg of titanium per 50 mL of solution, using a 2-cm cell. NOTE 23—This test method has been written for cells having a 2-cm light path. Cells having other dimensions may be used, provided suitable adjustments can be made in the amounts of sample and reagents used. 144. Stability of Color 144.1 The color develops within 5 min and is stable for 40 min. 145. Interferences 145.1 Chromium, if present, interferes because of the background color of the solution. Provision is made to correct for this interference. 146. Reagents 146.1 Ascorbic Acid Solution (40 g/L)—Dissolve 1 g of ascorbic acid in 25 mL of water. Do not use a solution that has stood more than 1 h. 146.2 Chromotrophic Acid Solution (Disodium Salt)(20 g/L)—Dissolve 2 g of chromotropic acid (4,5-dihydroxy-2,7naphthalenedisulfonic acid, disodium salt) in 70 mL of water containing 0.75 mL of acetic acid. Add 0.2 g of sodium metadisulfite (Na2S2O5) and stir until completely dissolved. Filter through a fine paper into a 100-mL volumetric flask. Wash with water, dilute to volume, and mix. Select a lot of reagent that meets the following criteria: The solution must be light, clear yellow and have an absorbance reading of 0.3 or less when measured at 470 nm in a 2-cm cell, using distilled water as the reference. Do not use a solution that has stood more than 3 weeks. 146.3 Potassium Permanganate Solution (1 g/L)—Dissolve 0.1 g of potassium permanganate (KMnO 4) in water and dilute to 100 mL. 147. Preparation of Calibration Curve 147.1 Calibration Solutions: 147.1.1 Using pipets, transfer 1, 2, 5, 10, and 15 mL of Titanium Solution C to 100-mL beakers containing 10 mL of the reagent mixture. 147.1.2 Using pipets, transfer 1, 2, 3, 4, and 5 mL of Titanium Solution B to 100-mL beakers containing 10 mL of the reagent mixture. 147.1.3 Add KMnO4 solution dropwise until a permanent red color is developed. Add Na2SO3 solution dropwise, while mixing the solution thoroughly, until the permanganate is decomposed, and then add 1 drop in excess. Add 10 mL of monochloroacetic acid buffer solution and mix. Add 1.0 mL of ascorbic acid solution and mix. Adjust the volume to about 35 12 E 34 – 94 (2002) 148.5 Background Color Reference Solution—Use a portion of the reagent blank to which no chromotropic acid has been added. 148.6 Photometry—Take the photometric reading of the test solution and background color solution, if necessary, as directed in 147.4. 149. Calculation 149.1 Convert the net photometric readings of the test solution and the background color solution to milligrams of titanium by means of the calibration curve. Calculate the percentage of titanium as follows: mL. Using a pH meter, adjust the pH from 2.1 to 2.2 with H2SO4 (1+4) or NaOH Solution B, as required. Proceed as directed in 147.3. 147.2 Reference Solution—Transfer 10 mL of reagent mixture to a 100-mL beaker and proceed as directed in 147.1.3. 147.3 Color Development—Using a pipet, add 5 mL of chromotropic acid solution, transfer to a 50-mL volumetric flask, dilute to volume, and mix. 147.4 Photometry: 147.4.1 Multiple–Cell Photometer—Measure the cell correction using absorption cells with a 2-cm light path and a light band centered at approximately 470 nm. Using the test cell, take the photometric readings of the calibration solutions. 147.4.2 Single–Cell Photometer—Transfer a suitable portion of the reference solution to an absorption cell with a 2-cm light path and adjust the photometer to the initial setting, using a light band centered at approximately 470 nm. While maintaining this adjustment, take the photometric readings of the calibration solutions. 147.5 Calibration Curve—Plot the net photometric readings of the calibration solutions against milligrams of titanium per 50 mL of solution. 148. Procedure 148.1 Test Solution: 148.1.1 Select and weigh a sample in accordance with the following table and transfer it to a 250-mL beaker. Titanium, % 0.001 to 0.03 0.02 to 0.30 Sample Weight, g 1.000 0.500 Titanium, % 5 ~A 2 B!/~C 3 10! (10) where: A = titanium found in 50 mL of the final test solution, mg, B = background color correction, mg of titanium, and C = sample represented in 50 mL of the final test solution, g. 150. Precision 150.1 Six laboratories cooperated in testing this test method and obtained eight sets of data summarized in Table 1. TABLE 1 Statistical Information Test Specimen 1. 1075 alloy 2. 356 alloy Tolerance in Sample Weight, mg 0.5 0.2 Titanium Found, % 0.003 0.112 Repeatability (R1, E 173) 0.001 0.006 Reproducibility (R2, E 173) 0.001 0.006 ZINC BY THE AMMONIUM MERCURIC THIOCYANATE OR THE ZINC OXIDE (GRAVIMETRIC) TEST METHOD (This test method, which consisted of Sections 151 through 159 of this standard, was discontinued in 1981.) 148.1.2 Add 25 mL of NaOH Solution A, cover, and, if necessary, heat gently to start reaction. When reaction slows, wash the cover and sides of the beaker with hot water. Boil gently for a few minutes to complete the dissolution, and cool. NOTE 24—For alloys containing more than 3 % silicon, proceed as follows: Transfer the sample to a platinum dish and cover with a platinum cover. Add 25 mL of NaOH solution A. When the major reaction ceases, wash down the sides of the dish and the cover with hot water, and evaporate the solution to a syrupy paste. Proceed as directed in 148.1.3. ZINC BY THE ETHYLENEDIAMINE TETRAACETATE (TITRIMETRIC) TEST METHOD (This test method, which consisted of Sections 160 through 166 of this standard, was discontinued in 1983.) 148.1.3 Dilute to about 50 mL. Add 2 mL of HNO3 and 40 mL of H2SO4(1+4). Mix and boil gently until the salts dissolve. If manganese dioxide has separated, add a few drops of H2SO 3 solution and boil for 3 to 5 min. Cool, transfer to a 100-mL volumetric flask, dilute to volume, and mix. 148.1.4 Filter through a fine, dry paper, discard the first 10 to 20 mL, and collect about 50 mL. Using a pipet, transfer 10 mL if the expected titanium concentration is less than 0.15 %, or 5 mL if the expected titanium concentration is greater than 0.15 %, to a 100-mL beaker. Proceed as directed in 147.1.3. 148.2 Reference Solution—Carry a reagent blank through the entire procedure, using the same amounts of all reagents with the sample omitted. 148.3 Color Development—Proceed as directed in 147.3. 148.4 Background Color Solution—If the test solution contains chromium or other elements which form colored ions, transfer a second aliquot of the filtered solution obtained in 148.1.4 and proceed as directed in 147.1.3. After the pH adjustment, transfer to a 50-mL volumetric flask, dilute to volume, and mix. CADMIUM BY THE ATOMIC ABSORPTION TEST METHOD 167. Scope 167.1 This test method covers the determination of cadmium in concentrations from 0.001 to 0.5 %. 168. Summary of Test Method 168.1 An acid solution of the sample is aspirated into the air-acetylene flame of an atomic absorption spectrophotometer. The absorption by the sample of the cadmium resonance line at 2288 Å is measured and compared with that of calibration solutions containing known amounts of cadmium and aluminum. 169. Concentration Range 169.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.02 µg/mL at 0.0044 absorbance is frequently obtained. 170. Interferences 13 E 34 – 94 (2002) 174.1.1 Transfer a 1.00-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 22 mL of HCl (1+1) in small increments. After the reaction has subsided, heat to hasten dissolution. Cool for 5 min, add 2 mL of HNO 3, and boil gently for 3 to 5 min. 170.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 171. Apparatus 171.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 2 %. 171.1.1 Operation Parameters: Wavelength Bandpass Gas mixture Flame type NOTE 26—If insoluble silicon is present, dilute to 50 mL with hot water, filter using a medium paper into a 250-mL beaker, and wash the residue with hot water. Reserve the filtrate. Transfer the paper and residue to a platinum crucible, dry, and ignite at 600°C. Cool, add 5 drops of HNO3 and 5 mL of HF, and evaporate carefully to dryness. Cool, add 1 mL of HCl (1+1) and 5 mL of hot water. Heat to dissolve the salts and add the solution to the reserved filtrate. 2288Å about 6 Å air-acetylene lean 174.1.2 For 0.001 to 0.05 % cadmium, transfer the solution to a 100-mL volumetric flask, dilute to volume, and mix. Use a 500-mL volumetric flask for 0.05 and 0.5 % cadmium. 175. Measurements 175.1 Optimize the response of the instrument and take preliminary readings; complete the analysis and calculate the cadmium concentration as in the graphical, ratio, or singlepoint procedures, as described in Guide E 1024. 172. Reagents 172.1 Aluminum Solution (1 mL = 50 mg Al)—Transfer 10 g of aluminum (purity: 99.999 % min) to a 400-mL beaker. Add 50 mL of water and a small drop of mercury. Add 110 mL of HCl in small increments, heating moderately to accelerate the dissolution. When dissolution is complete, add 2 mL of HNO3 and boil gently for 5 min. Cool, transfer to a 200-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. NOTE 27—A three-slot burner is recommended for the lower range, and a 5-cm single slot burner for the higher range. 176. Calculation 176.1 Calculate the percentage of cadmium as follows: NOTE 25—The high purity aluminum is necessary when determining cadmium in concentrations less than 0.01 %. A Cadmium, % 5 B 3 100 172.2 Cadmium, Standard Solution A (1 mL = 1.00 mg Cd)—Transfer 1.00 g of cadmium (purity: 99.9 % min) to a 400-mL beaker. Add 5 mL of water, 10 mL of HCl, and 2 mL of HNO3. Cover, heat gently until dissolution is complete, cool, and add 50 mL of water. Transfer to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 172.3 Cadmium, Standard Solution B (1 mL = 0.08 mg Cd)—Using a pipet, transfer 20 mL of Cadmium Solution A to a 250-mL volumetric flask. Add 10 mL HCl, dilute to volume, and mix. Store in a polyethylene bottle. 172.4 Cadmium, Standard Solution C (1 mL = 0.02 mg Cd)—Using a pipet, transfer 20 mL of Cadmium Solution A to a 250-mL volumetric flask. Add 10 mL HCl, dilute to volume, and mix. Store in a polyethylene bottle. (11) where: A = cadmium in the final test solution, mg, and B = sample represented in the test solution, mg. 177. Precision7 177.1 Eight laboratories cooperated in testing this test method. The data are summarized in Table 2. TABLE 2 Statistical Information Test Specimen Pure aluminum (Aluminum Association 1080 alloy, 99.80 % Al) Pure aluminum (Aluminum Association 1075 alloy, 99.75 % Al) Aluminum-copper alloy (Aluminum Association X2020 Alloy, 4 Cu-1 Li-0.6 Mn-0.2 Cd) 173. Calibration 173.1 Calibration Solutions: 173.1.1 0.001 to 0.05 % Cadmium—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Cadmium Solution C to 100-mL volumetric flasks. Add 20 mL of aluminum solution (171.1) to each flask, dilute to volume, and mix. 173.1.2 0.05 to 0.50 % Cadmium—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Cadmium Solution B to 200-mL volumetric flasks. Add 8 mL of aluminum solution (171.1) to each flask, dilute to volume, and mix. 173.2 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. 174. Procedure 174.1 Test Solution: Cadmium Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.0018 0.00008 0.0005 0.011 A 0.002 0.191 0.007 0.025 A R1 is indeterminate because no deviations were observed in the pairs of determinations, which were carried to only three decimal places. ZIRCONIUM BY THE ARSENAZO III PHOTOMETRIC TEST METHOD 178. Scope 7 Supporting data are available from ASTM Headquarters. Request RR: E031007. 14 E 34 – 94 (2002) ceased, heat gently to complete the attack. Add 20 mL of HCl and evaporate to moist salts but do not bake. Add 75 mL of HCl (1+3) and heat gently until dissolution of the salts is complete. Cool, transfer to a 1-L volumetric flask, dilute to volume with HCl (1+3), and mix. 183.5.2 Transfer 0.354 g of zirconyl chloride octahydrate (ZrOCl 2·8H2O) to a 250-mL beaker and add 100 mL of HCl (1+3). Boil for 5 min. Cool, transfer to a 1-L volumetric flask, dilute to volume with HCl (1+3), and mix. Standardize as follows: Using a pipet, transfer 200 mL to a 400-mL beaker. Add 2 mL of H2O2 and 25 mL of the (NH4)2HPO4 solution. An excess of H 2O2 must be present at all times. Filter using a 9-cm medium paper containing ashless paper pulp and wash thoroughly with cold NH 4NO3 solution. Transfer the paper to a platinum crucible, dry, and ignite carefully so that the paper chars but does not flame. When the paper is charred, gradually increase the temperature until all the carbon is gone, and then heat at 1050°C for 15 min. Cool in a desiccator and weigh as zirconium pyrophosphate (ZrP2O7). 183.6 Zirconium, Standard Solution B (1 mL = 0.005 mg Zr)—Using a pipet, transfer 5 mL of Zirconium Solution A to a 100-mL volumetric flask. Add 2.5 mL of HCl, cool, dilute to volume with HCl (1+1), and mix. Do not use a solution which has stood for more than 8 h. 178.1 This test method covers the determination of zirconium in concentrations from 0.01 to 0.3 %. 179. Summary of Test Method 179.1 Zirconium in hydrochloric acid reacts with Arsenazo III to form a complex suitable for photometric measurement at approximately 665 nm. 180. Concentration Range 180.1 The recommended concentration range is from 0.002 to 0.030 mg of zirconium per 50 mL of solution, using a 1-cm cell. NOTE 28—This test method has been written for cells having a 1-cm light path. Cells having other dimensions may be used, provided suitable adjustments can be made in the amounts of sample and reagents used. 181. Stability of Color 181.1 The color develops within 5 min and is stable for 3 h; however, because of the possible loss of hydrochloric acid, it is advisable to take photometric readings promptly and to use covered absorption cells. 182. Interferences 182.1 Strong oxidants, reductants, sulfates, and fluorides interfere. Concentrations of fluoride and sulfate in the final solution must be less than 2 µg/mL and 1 mg/mL, respectively. The elements ordinarily present in aluminum and aluminumbase alloys do not interfere if their concentrations are under the maximum limits shown in 1.1. 183. Reagents 183.1 Aluminum Solution (1 mL = 25 mg Al)—Dissolve 45 g of aluminum chloride hexahydrate (AlCl3·6H2O) in about 150 mL of HCl (1+1). Transfer to a 200-mL volumetric flask, dilute to volume with HCl (1+1), and mix. 183.2 Ammonium Nitrate Wash Solution (50 g/L)—Dissolve 25 g of ammonium nitrate (NH4NO 3) in about 400 mL of water and dilute to 500 mL. 183.3 Arsenazo III Solution (2.5 g/L)—Dissolve 0.250 g of Arsenazo III [2,28-(1,8-dihydroxy-3,6-disulfonaphthylene2,7diazodibenzenearsonic acid)] in 90 mL of water containing 300 mg of sodium carbonate (Na2CO 3), and heat gently. Using a pH meter, adjust the pH to 4.0 6 0.1 with HCl (1+1), and cool. Transfer to a 100-mL volumetric flask, dilute to volume, and mix. This solution is stable at least 6 months. 184. Preparation of Calibration Curve 184.1 Calibration Solutions—Using pipets, transfer 1, 2, 3, 4, 5, and 6 mL of Zirconium Solution B to six 50-mL volumetric flasks containing 10 mL of HCl (1+1). Add 2 mL of aluminum solution (1 mL = 25 mg Al). Proceed as directed in 184.3. 184.2 Reference Solution—Transfer 2 mL of aluminum solution (1 mL = 25 mg Al) to a 50-mL volumetric flask containing 10 mL of HCl (1+1). Proceed as directed in 184.3. 184.3 Color Development—Using a pipet, add 1 mL of Arsenazo III solution, dilute to volume with HCl (1+1), and mix. 184.4 Photometry: 184.4.1 Determine the wavelength of maximum absorbance (Note 29) by taking photometric readings of the calibration solution containing 0.020 mg of zirconium over the range from 600 to 700 nm. Between 630 and 670 nm, take 5-nm increments. Using the reference solution, adjust the photometer to the initial setting before each reading. NOTE 29—Some lots of reagent have been found to be completely unsatisfactory. Therefore, the reagent should be checked with a standard zirconium solution before use in this test method. A satisfactory reagent should give an absorbance of about 0.8 for the high standard (0.6 µg/mL Zr) at 665 nm using 1-cm cells.8 NOTE 30—The maximum absorbance of the zirconium-Arsenazo III complex normally occurs at 665 nm. It is advisable to verify this absorption maximum for each new lot of Arsenazo III. 183.4 Diammonium Phosphate Solution (120 g/L)—Dissolve 60 g of diammonium phosphate ((NH 4)2HPO4) in about 400 mL of water and dilute to 500 mL. 183.5 Zirconium, Standard Solution A (1 mL = 0.100 mg Zr)—Prepare as described in 183.5.1 or 183.5.2. Store in a polyethylene bottle. 183.5.1 Transfer 0.100 g of zirconium (purity: 99.5 % min) to a 250-mL beaker. Add 30 mL of methanol (CH3OH) and, while cooling, 5 mL of bromine (Br2). When the reaction has 184.4.2 Multiple Cell Photometer—Measure the cell correction using stoppered absorption cells with a 1-cm light path and a light band centered at the wavelength determined in 184.4.1. Using the test cell, take the photometric readings of the calibration solutions. 184.4.3 Single Cell Photometer—Transfer a suitable portion of the reference solution to a stoppered absorption cell having a 1-cm light path and adjust the photometer to the initial setting using a light band centered at the wavelength determined in 184.4.1. While maintaining this adjustment, take the photometric readings of the calibration solutions. 8 Aldrich Chemical Co. Reagent No. A9277-5 and G. Frederick Smith Chemical Co. Reagent No. 594 have been found to be suitable for this purpose. 15 E 34 – 94 (2002) 188.1 This test method covers the determination of bismuth in concentrations from 0.02 to 1.0 %, and lead in concentrations from 0.01 to 1.0 %. 189. Summary of Test Method 189.1 An acid solution of the sample is aspirated into the air-acetylene flame of an atomic absorption spectrophotometer. The absorption by the sample solution of the bismuth resonance line at 2230Å and the lead resonance line at 2833 Å is measured and compared with the absorption of calibration solutions containing known amounts of bismuth and lead. The 2170-Å lead resonance line may be used successfully on some instruments, especially if an electrodeless discharge lamp is employed. 190. Concentration Range 190.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.4 to 0.8 µg/mL for 0.0044 absorbance for bismuth, and 0.4 to 0.8 µg/mL for 0.0044 absorbance for lead using the 2833-Å line is widely obtained. At 2170Å, the sensitivity for lead is 0.2 µg/mL for 0.0044 absorbance. 191. Interferences 191.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 192. Apparatus 192.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 193. Reagents 193.1 Aluminum Solution (1 mL = 50 mg Al)—Transfer 25 g of aluminum (purity: 99.99 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 315 mL of HCl in small increments, heating moderately to accelerate the dissolution. When dissolution is complete, add 2 mL of H2O2 (30 %) and boil gently for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 193.2 Bismuth, Standard Solution A (1 mL = 0.40 mg Bi)—Transfer 0.400 g of bismuth (purity: 99.9 % min) to a 400-mL beaker and dissolve in 50 mL of HNO3 (1+1), heating gently if necessary. When dissolution is complete, boil for 5 min, cool, and transfer to a 1-L volumetric flask. Add 100 mL of HNO3 (1+1), dilute to volume, and mix. Store in a polyethylene bottle. 193.3 Bismuth, Standard Solution B (1 mL = 0.04 mg Bi)—Using a pipet, transfer 25 mL of Bismuth Standard Solution A to a 250-mL volumetric flask. Dilute to volume and mix. Do not use a solution that has stood for more than 24 h. 193.4 Lead, Standard Solution A (1 mL = 0.40 mg Pb)— Transfer 0.400 g of lead (purity: 99.9 % min) to a 400-mL beaker and proceed in accordance with 193.2. 193.5 Lead, Standard Solution B (1 mL = 0.04 mg Pb)— Dilute Lead Standard Solution A as directed in 193.3. 184.5 Calibration Curve—Plot the net photometric readings of the calibration solutions against milligrams of zirconium per 50 mL of solution. 185. Procedure 185.1 Test Solution: 185.1.1 Transfer a 0.200-g sample, weighed to the nearest 0.5 mg, to a 250-mL beaker. 185.1.2 Add 20 mL of HCl (1+1), heat until dissolution is complete, and evaporate carefully to moist salts. Cool, add about 180 mL of HCl (1+1), and heat gently to dissolve salts. 185.1.3 Cool and transfer to a 200-mL volumetric flask, ignoring any remaining residue. Dilute to volume with HCl (1+1), and mix. Allow any residue to settle. 185.1.4 Using a pipet, transfer to a 50-mL volumetric flask, 20 mL if the expected zirconium concentration is less than 0.10 %, 10 mL if the expected zirconium concentration is between 0.10 and 0.20 %, or 5 mL if the expected zirconium concentration is between 0.20 and 0.30 %. Add 2 mL of aluminum solution (1 mL = 25 mg Al). 185.2 Reference Solution—Proceed as directed in 184.2. 185.3 Color Development—Proceed as directed in 184.3. 185.4 Photometry—Take the photometric reading of the test solution as directed in 184.4.2 or 184.4.3. 186. Calculation 186.1 Convert the net photometric reading of the test solution to milligrams of zirconium by means of the calibration curve. Calculate the percentage of zirconium as follows: A Zirconium, % 5 B 3 10 (12) where: A = zirconium found in 50 mL of the final test solution, mg, and B = sample represented in 50 mL of the final test solution, g. 187. Precision9 185.1 Seven laboratories cooperated in testing this test method and obtained eight sets of data summarized in Table 3. TABLE 3 Statistical Information Test Specimen Zirconium Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 1. 6151 alloy 2. 2219 alloy 3. 7046 alloy 0.023 0.152 0.282 0.0027 0.0097 0.0278 0.0033 0.019 0.060 BISMUTH AND LEAD BY THE ATOMIC ABSORPTION TEST METHOD 188. Scope 194. Calibration 194.1 Calibration Solutions: 194.1.1 0.01 to 0.10 % Bi or Pb—Using pipets, transfer 5, 10, 15, 20, and 25-mL portions of the appropriate Standard 9 Supporting data are available from ASTM Headquarters. Request RR: E031011. 16 E 34 – 94 (2002) Solution B to 100-mL volumetric flasks. Add 20 mL of aluminum solution and 10 mL of HNO3 (1+1). Cool, dilute to volume, and mix. 194.1.2 0.10 to 1.0 % Bi or Pb—Using pipets, transfer 5, 10, 15, 20, and 25-mL portions of the appropriate Standard Solution A to 250-mL volumetric flasks. Add 20 mL of aluminum solution and 10 mL of HNO3 (1+1). Cool, dilute to volume, and mix. 194.2 Reference Solution—Prepare a reference solution by adding the appropriate amount of aluminum solution and 10 mL of HNO3 (1+1) to the appropriate size volumetric flask. Dilute to volume and mix. 194.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. 195. Procedure 195.1 Test Solution: 195.1.1 Transfer a 1.000-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and 25 mL of HCl (1+1) in small increments, and cover with a borosilicate cover glass. When the reaction subsides, add 10 mL of HNO3 (1+1) and boil for 5 min. 195.1.2 Filter using a medium paper into a 100-mL volumetric flask when the bismuth or lead content is expected to be 0.10 % or less, or into a 250-mL volumetric flask when the bismuth or lead content is expected to be greater than 0.10 %. Wash the residue with hot water and reserve the filtrate. 195.1.3 When the silicon content is 0.5 % or greater, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 550°C. Cool, add 5 mL of HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, and dissolve the residue in 5 drops of HCl (1+1) and a minimum amount of water. Add this solution to the reserved filtrate obtained in 195.1.2. 195.1.4 Cool the solution obtained in 195.1.2 or the combined filtrates obtained in 195.1.3. Dilute to volume and mix. 196. Measurements 196.1 Optimize the response of the instrument and take preliminary readings; then complete the analysis and determine the concentration of bismuth or lead using the graphical, ratio, or single-point procedure, as described in Guide E 1024. 197. Calculations 197.1 Calculate the percentage of bismuth or lead as follows: A Bismuth or lead, % 5 B 3 100 198.1 Precision—Eight laboratories cooperated in testing this test method. The precision of this test method can be estimated by examining the data in Tables 4 and 5 TABLE 4 Statistical Information Test Specimen 1000 KS-0010-12 6262 alloy Bismuth Found, % 0.033 0.60 Repeatability (R1, E 173) 0.0046 0.0089 Reproducibility (R2, E 173) 0.008 0.024 TABLE 5 Statistical Information Test Specimen NBS 85b 2024 alloy (0.021 % Pb) BCS No. 181/2 2218 alloy (0.04 % Pb) KS-0010-12 6262 alloy Lead Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.021 0.0014 0.003 0.041 0.0029 0.005 0.55 0.015 0.044 198.2 Bias—No information on the accuracy of this test method is available. The accuracy may be judged, however, by comparing accepted reference values with the corresponding arithmetic averages obtained by interlaboratory testing. CHROMIUM BY THE ATOMIC ABSORPTION TEST METHOD 199. Scope 199.1 This test method covers the determination of chromium in concentrations from 0.01 to 1.0 %. 200. Summary of Test Method 200.1 An acid solution of the sample is aspirated into the nitrous oxide-acetylene flame of an atomic absorption spectrophotometer. The absorption of the chromium resonance line at 3579 Å is measured and compared with the absorption of calibration solutions containing known amounts of chromium. 201. Concentration Range 201.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.1 to 0.2 µg/mL for 0.0044 absorbance is widely obtained. 202. Interferences 202.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 203. Apparatus 203.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 204. Reagents 204.1 Aluminum Solution (1 mL = 50 mg Al)—Transfer 25 g of aluminum (purity: 99.99 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 275 mL of HCl in small increments, heating moderately to accelerate the dissolution. When dissolution is complete, add 2 mL of H2O2 (30 %) and boil gently for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. (13) where: A = bismuth or lead in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. 198. Precision and Bias10 10 Supporting data are available from ASTM Headquarters. Request RR: E031014. 17 E 34 – 94 (2002) 207.1 Optimize the response of the instrument and take preliminary readings; then complete the analysis and determine the chromium concentration using the graphical, ratio, or single-point procedure, as described in Guide E 1024. 208. Calculation 208.1 Calculate the percentage of chromium as follows: 204.2 Chromium Standard Solution A (1 mL = 0.40 mg Cr)—Transfer 0.400 g of chromium (purity: 99.9 % min) to a 400-mL beaker containing 50 mL of water. Dissolve the metal with 15 mL of HCl. Transfer the solution to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 204.3 Chromium Standard Solution B (1 mL = 0.04 mg Cr)— Using a pipet, transfer 25 mL of Chromium Solution A to a 250-mL volumetric flask. Dilute to volume and mix. 205. Calibration 205.1 Calibration Solutions: 205.1.1 0.01 to 0.10 % Cr—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of the Chromium Standard Solution B to 100-mL volumetric flasks. Add 20 mL of aluminum solution, dilute to volume, and mix. 205.1.2 0.1 to 1.0 % Cr—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Chromium Standard Solution B to 100-mL volumetric flasks. Add 2 mL of aluminum solution and 5 mL of HCl (1+1). Cool, dilute to volume, and mix. 205.2 Reference Solution—The 0 calibration solution is used as the reference solution. 205.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. A Chromium, % 5 B 3 100 (14) where: A = chromium in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. TABLE 6 Statistical Information Test Specimen Chromium Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) MD 184 NBS 85b 2024 alloy (0.211 % Cr) KNB 793-96 0.010 0.21 0.80 0.0009 0.008 0.015 0.002 0.014 0.032 209. Precision and Bias11 209.1 Precision—Nine laboratories cooperated in testing this test method. The precision of the test method can be estimated by examining the data in Table 6. 209.2 Bias—No information on the accuracy of this test method is available. The accuracy may be judged, however, by comparing the accepted reference values with the corresponding arithmetic averages obtained by interlaboratory testing. 206. Procedure 206.1 Test Solution: 206.1.1 Transfer a 1.000-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and 22 mL of HCl (1+1) in small increments. Cover with a ribbed cover glass and when the reaction subsides, add 2 mL of H2O2 (30 %) and boil for 5 min. 206.1.2 Filter through a medium paper into a 100-mL volumetric flask. Wash with hot water and reserve the filtrate. 206.1.3 When the silicon content is 0.5 % or greater, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 500°C. Cool, add 5 mL of HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, and dissolve the residue in 5 drops of HCl (1+1) and a minimum amount of water. Add this solution to the reserved filtrate obtained in 206.1.2. 206.1.4 Cool the solution obtained in 206.1.2 or the combined filtrates obtained in 206.1.3. Dilute to volume and mix. This is Sample Solution A. 206.1.5 Pipet 10 mL of Sample Solution A into a 100-mL volumetric flask containing 5 mL of HCl (1+1). Dilute to volume and mix. This is Sample Solution B. 206.1.6 When the chromium concentration is less than 0.10 %, aspirate Sample Solution A into the flame using the standards from 205.1.1 206.1.7 When the chromium content is between 0.10 and 1.0 %, aspirate Sample Solution B into the flame using standards from 205.1.2. 207. Measurements COPPER AND ZINC BY THE ATOMIC ABSORPTION TEST METHOD 210. Scope 210.1 This test method covers the determination of copper in concentrations from 0.01 to 10 %, and zinc in concentrations from 0.003 to 10 %. 211. Summary of Test Method 211.1 An acid solution of the sample is aspirated into the air-acetylene flame of an atomic absorption spectrophotometer. The absorption by the sample of the copper resonance line at 3247 Å and the zinc resonance line at 2139 Å is measured and compared with the absorption of calibration solutions containing known amounts of copper or zinc. 212. Concentration Range 212.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.05 to 0.10 µg/mL for 0.0044 absorbance is widely obtained for copper and 0.02 to 0.06 µg/mL for zinc. 213. Interferences 213.1 Elements normally present do not interfere when their concentrations are less than the maximum limits shown in 1.1. 214. Apparatus 11 Supporting data are available from ASTM Headquarters. Request RR: E031015. 18 E 34 – 94 (2002) 217. Procedure 217.1 Test Solution: 217.1.1 Transfer a 1.000-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and 22 mL of HCl (1+1). Warm, if necessary, to complete dissolution. When the reaction subsides, add 2 mL of H2O 2(30 %) and boil for 5 min. 217.1.2 Filter on a medium paper into a 100-mL volumetric flask. Wash the residue with hot water. Reserve the filtrate. 217.1.3 When the silicon content is 0.5 % or greater, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 500°C. Cool, add 5 mL of HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate carefully to dryness, cool, and dissolve the residue in 5 drops of HCl (1+1) and minimum amount of water. Heat to dissolve the salts and add this solution to the filtrate reserved in 217.1.2. 217.1.4 Cool the solution from 217.1.2 or the combined filtrates obtained in 217.1.3. Dilute to volume and mix. This is Sample Solution A. 217.1.5 Pipet 10 mL of Sample Solution A into a 100-mL volumetric flask containing 8 mL of HCl (1+1), dilute to volume, and mix. This is Sample Solution B. 217.1.6 For copper or zinc concentrations less than 0.1 %, pipet 50 mL of Sample Solution A into a 100-mL volumetric flask containing 6.5 mL of HCl (1+1), dilute to volume, and mix. Use standards prepared in accordance with 216.1.1. 217.1.7 If the copper or zinc content is between 0.1 and 0.5 %, use Sample Solution B. Use standards prepared in 216.1.2. 217.1.8 If the copper or zinc content is between 0.5 and 2.5 %, pipet 20 mL of Sample Solution B into a 100-mL volumetric flask containing 6.5 mL of HCl (1+1), dilute to volume, and mix. Use standards prepared in accordance with 216.1.3. 217.1.9 If the copper or zinc content is between 2 and 10 %, pipet 10 mL of Sample Solution B into a 200-mL volumetric flask containing 16 mL of HCl (1+1), dilute to volume, and mix. Use standards prepared in accordance with 216.1.4. 218. Measurements 218.1 Optimize the instrument response and take preliminary readings; then complete the analysis and determine the copper or zinc concentration using the graphical, ratio, or single-point procedure, as described in Guide E 1024. 219. Calculation 219.1 Calculate the percentage of copper or zinc as follows: 214.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 215. Reagents 215.1 Aluminum Solution A (1 mL = 50 mg Al)—Transfer 25 g of aluminum chips (purity: 99.99 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 275 mL of HCl in small increments, heating moderately to accelerate dissolution. When dissolution is complete, add 2 mL of H2O2 (30 %) and boil gently for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 215.2 Aluminum Solution B (1 mL = 2.50 mg Al)—Pipet 25 mL of Aluminum Solution A into a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 215.3 Copper Solution A (1 mL = 1.00 mg Cu)—Transfer 1.000 g of copper (purity: 99.9 % min) to a 250-mL beaker. Add 5 mL of water, cover, and dissolve in 3 mL of HNO3. After dissolution is complete, boil to remove oxides of nitrogen, cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 215.4 Zinc Solution A (1 mL = 1.00 mg Zn)—Transfer 1.000 g of zinc (purity: 99.9 % min) to a 400-mL beaker containing 50 mL of water. Dissolve in 3 mL of HCl. Transfer the solution to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 215.5 Copper and Zinc Standard Solution B (1 mL = 0.04 mg Cu and 0.04 mg Zn)—Pipet 10 mL of Copper Solution A and 10 mL of Zinc Solution A into a 250-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 216. Calibration 216.1 Calibration Solutions: 216.1.1 0.02 to 0.1 % Cu and Zn—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Copper-Zinc Standard Solution B to 200-mL volumetric flasks. Add 20 mL of Aluminum Solution A and 13 mL of HCl (1+1). Dilute to volume and mix. 216.1.2 0.1 to 0.5 % Cu and Zn—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Copper-Zinc Standard Solution B to 200-mL volumetric flasks. Add 4 mL of Aluminum Solution A and 16 mL of HCl (1+1). Cool, dilute to volume, and mix. 216.1.3 0.5 to 2.5 % Cu and Zn—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Copper-Zinc Standard Solution B to 200-mL volumetric flasks. Add 16 mL of Aluminum Solution B and 16 mL of HCl (1+1). Cool, dilute to volume, and mix. 216.1.4 2.0 to 10 % Cu and Zn—Using pipets, transfer 0, 5, 10, 15, 20, and 25-mL of Copper-Zinc Standard Solution B to 200-mL volumetric flasks. Add 4 mL of Aluminum Solution B and 17 mL of HCl (1+1). Cool, dilute to volume, and mix. 216.2 Reference Solution—The 0 calibration solution is used for the reference solution for each range of calibration. 216.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. A Copper or zinc, % 5 B 3 100 (15) where: A = copper or zinc in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. 220. Precision and Bias12 12 Supporting data are available from ASTM Headquarters. Request RR: E031016. 19 E 34 – 94 (2002) HCl in small increments, heating moderately to accelerate dissolution. When dissolution is complete, add 2 mL of H2O2 (30 %) and boil gently for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 226.2 Manganese Standard Solution A (1 mL = 0.40 mg Mn)—Transfer 0.400 g of manganese metal (purity: 99.9 % min) to a 400-mL beaker containing 50 mL water. Dissolve the metal with 15 mL of HCl. Transfer the solution to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 226.3 Manganese Standard Solution B (1 mL = 0.04 mg Mn)—Using a pipet, transfer 25 mL of Manganese Standard Solution A to a 250-mL volumetric flask. Dilute to volume and mix. 226.4 Iron Standard Solution A (1 mL = 0.40 mg Fe)— Transfer 0.400 g of iron wire (purity: 99.9 % min) to a 400-mL beaker and proceed in accordance with 226.2. 226.5 Iron Standard Solution B (1 mL = 0.04 mg Fe)— Dilute Iron Standard Solution A in accordance with 226.3. 220.1 Precision—Eight laboratories cooperated in testing this test method. The precision of this test method can be estimated by examining the data in Tables 7 and 8. TABLE 7 Statistical Information Test Specimen 1. 5082 alloy 2. 7049 alloy 3. BCS No. 216/2 2014 alloy (4.56 % Cu) 4. 2219 alloy Copper Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.050 1.16 4.52 0.0019 0.058 0.054 0.0035 0.075 0.24 6.18 0.093 0.26 TABLE 8 Statistical Information Test Specimen 1. 5082 alloy 2. 2219 alloy 3. BCS No. 216/2 2014 alloy (0.20 % Zn) 4. 7049 alloy Zinc Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.0028 0.036 0.20 0.0013 0.0031A 0.0021 0.0016 0.0028 0.0094 7.60 0.25 0.25 A R1 appears higher than R2 because one of the eight laboratories that participated showed much poorer repeatability than the others for this sample. 227. Calibration 227.1 Calibration Solutions: 227.1.1 0.01 to 0.10 % Mn or Fe—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of the appropriate Standard Solution B to 100-mL volumetric flasks. Add 20 mL of aluminum solution. Cool, dilute to volume, and mix. 227.1.2 0.1 to 1.0 % Mn or Fe—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of the appropriate Standard Solution B to 100-mL volumetric flasks. Add 2 mL of aluminum solution and 5 mL HCl (1+1). Cool, dilute to volume, and mix. 227.1.3 1.0 to 2.0 % Mn or Fe—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of the appropriate Standard Solution B to 100-mL volumetric flasks. Add 1 mL of aluminum solution and 5 mL HCl (1+1). Cool, dilute to volume, and mix. 227.2 Reference Solution—The 0 calibration solution is used as the reference solution. 227.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. 228. Procedure 228.1 Test Solution: 228.1.1 Transfer a 1.000-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and 22 mL of HCl (1+1) in small increments, and cover with a ribbed cover glass. When the reaction subsides, add 2 mL of H2O2 (30 %) and boil for 5 min. 228.1.2 Filter through a medium paper into a 100-mL volumetric flask. Wash the residue with hot water and reserve the filtrate. 228.1.3 When the silicon content is 0.5 % or greater, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 500°C. Cool, add 5 mL of HF, and then add HNO3, dropwise, until a clear solution is obtained. Evaporate to dryness, cool, and dissolve the residue in 5 drops of HCl (1+1) 220.2 Bias—No information on the accuracy of this test method is available. The accuracy may be judged, however, by comparing accepted reference values with the corresponding arithmetic averages obtained by interlaboratory testing. IRON AND MANGANESE BY THE ATOMIC ABSORPTION TEST METHOD 221. Scope 221.1 This test method covers the determination of iron in concentrations from 0.02 to 2.0 %, and manganese in concentrations from 0.01 to 2.0 %. 222. Summary of Test Method 222.1 An acid solution of the sample is aspirated into the air-acetylene flame of an atomic absorption spectrophotometer. The absorption of the iron resonance line at 2483 Å and the manganese resonance line at 2795 Å is measured and compared with the absorption of calibration solutions containing known amounts of manganese or iron. 223. Concentration Range 223.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.1 to 0.2 µg/mL for 0.0044 absorbance for manganese and iron is widely obtained. 224. Interferences 224.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 225. Apparatus 225.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 226. Reagents 226.1 Aluminum Solution (1 mL = 50 mg Al)—Transfer 25 g of aluminum chips (purity: 99.99 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 275 mL of 20 E 34 – 94 (2002) TABLE 10 Statistical Information and a minimum amount of water. Add this solution to the reserved filtrate obtained in 228.1.2. 228.1.4 Cool the solution obtained in 228.1.2 or the combined filtrates obtained in 228.1.3. Dilute to volume and mix. This is Sample Solution A. 228.1.5 Pipet 10 mL of Sample Solution A into a 100-mL volumetric flask containing 5 mL of HCl (1+1), dilute to volume, and mix. This is Sample Solution B. 228.1.6 Pipet 5 mL of Sample Solution A into a 100-mL volumetric flask containing 5 mL of HCl (1+1), dilute to volume, and mix. This is Sample Solution C 228.1.7 When the manganese or iron concentration is less than 0.10 %, aspirate Sample Solution A and use calibration solutions prepared in accordance with 227.1.1. 228.1.8 When the manganese or iron concentration is between 0.10 and 1.0 %, aspirate Sample Solution B and use calibration solutions prepared in accordance with 227.1.2. 228.1.9 When the manganese or iron concentration is between 1.0 and 2.0 %, aspirate Sample Solution C and use calibration solutions prepared in accordance with 227.1.3. 229. Measurements 229.1 Optimize the instrument response and take preliminary readings, then complete the analysis and determine the manganese or iron concentration using the graphical, ratio, or single-point procedure described in Guide E 1024. 230. Calculation 230.1 Calculate the percentage of manganese or iron as follows: A Manganese or iron, % 5 B 3 100 Test Specimen MD 184 NBS 85b 2024 alloy (0.61 % Mn) 3004 alloy (16) 231. Precision and Bias13 231.1 Precision—Ten laboratories cooperated in testing this test method. The precision of this test method can be estimated by examining the data in Tables 9 and 10. TABLE 9 Statistical Information 7075 alloy BCS No. 181/2 2218 alloy (0.42 % Fe) MD 184 Iron Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.046 0.41 0.0036 0.024 0.009 0.024 1.60 0.039 0.051 Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.015 0.60 1.16 0.0009 0.015 0.047 0.003 0.023 0.070 MAGNESIUM BY THE ATOMIC ABSORPTION TEST METHOD 232. Scope 232.1 This test method covers the determination of magnesium in concentrations from 0.002 to 5.0 %. 233. Summary of Test Method 233.1 An acid solution of the sample is aspirated into the nitrous oxide-acetylene flame of an atomic absorption spectrophotometer. The absorption of the magnesium resonance line at 2852 Å is measured and compared with the absorption of calibration solutions containing known amounts of magnesium. 234. Concentration Range 234.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.01 to 0.03 µg/mL for 0.0044 absorbance is widely obtained for magnesium. 235. Interferences 235.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 236. Apparatus 236.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 237. Reagents 237.1 Aluminum Solution A (1 mL = 50 mg Al)—Transfer 25 g of aluminum chips (purity: 99.999 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 275 mL of HCl in small increments, heating moderately to accelerate dissolution. When dissolution is complete, add 2 mL of H2O2 (30 %) and boil gently for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 237.2 Aluminum Solution B (1 mL = 2.50 mg Al)—Pipet 25 mL of Aluminum Solution A into a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 237.3 Aluminum Solution C (1 mL = 1.00 mg Al)—Pipet 10 mL of Aluminum Solution A into a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 237.4 Magnesium Standard Solution A (1 mL = 1.00 mg Mg)—Transfer 1.000 g of magnesium (purity: 99.9 % min) to a 400-mL beaker. Dissolve by adding carefully, in small portions, 30 mL of HCl (1+1). Transfer the solution to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 237.5 Magnesium Standard Solution B (1 mL = 0.010 mg Mg)—Pipet 10 mL of Magnesium Solution A into a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. where: A = manganese or iron in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. Test Specimen Manganese Found, % 231.2 Bias—No information on the accuracy is available. The accuracy may be judged, however, by comparing accepted reference values with the corresponding arithmetic averages obtained by interlaboratory testing. 13 Supporting data are available from ASTM Headquarters. Request RR: E031017. 21 E 34 – 94 (2002) 239.1.7 When the magnesium content is between 0.05 and 0.25 %, pipet 10 mL of Sample Solution A into a 250-mL volumetric flask containing 21 mL of HCl (1+1), dilute to volume, and mix. Use the calibration solutions prepared in accordance with 238.1.2. 239.1.8 When the magnesium content is between 0.2 and 1.0 %, pipet 25 mL of Sample Solution B into a 250-mL volumetric flask containing 19 mL of HCl (1+1), dilute to volume, and mix. Use the calibration solutions prepared in accordance with 238.1.3. 239.1.9 When the magnesium content is between 1 and 5 %, pipet 5 mL of Sample Solution B into a 250-mL volumetric flask containing 20 mL of HCl (1+1), dilute to volume, and mix. Use the calibration solutions prepared in accordance with 238.1.4. 240. Measurements 240.1 Optimize the instrument response and take preliminary readings; then complete the analysis and determine the magnesium concentration using the graphical, ratio, or singlepoint procedure, as described in Guide E 1024. 241. Calculation 241.1 Calculate the percentage of magnesium as follows: 238. Calibration 238.1 Calibration Solutions: 238.1.1 0.01 to 0.05 % Mg—Using pipets, transfer 0, 5, 10, 15, 20, and 25-mL portions of Magnesium Standard Solution B to 250-mL volumetric flasks. Add 10 mL of Aluminum Solution A and 20 mL of HCl (1+1). Cool, dilute to volume, and mix. 238.1.2 0.05 to 0.25 % Mg—Using pipets, transfer 0, 5, 10, 15, 20, and 25-mL portions of Magnesium Standard Solution B to 250-mL volumetric flasks. Add 40 mL of Aluminum Solution B and 21 mL of HCl (1+1). Cool, dilute to volume, and mix. 238.1.3 0.2 to 1 % Mg—Using pipets, transfer 0, 5, 10, 15, 20, and 25-mL portions of Magnesium Standard Solution B to 250-mL volumetric flasks. Add 10 mL of Aluminum Solution B and 21 mL of HCl (1+1). Cool, dilute to volume, and mix. 238.1.4 1 to 5 % Magnesium—Using pipets, transfer 0, 5, 10, 15, 20, and 25-mL portions of Magnesium Standard Solution B to 250-mL volumetric flasks. Add 5 mL of Aluminum Solution C and 21 mL of HCl (1+1). Cool, dilute to volume, and mix. 238.2 Reference Solution—The 0 calibration solution is used as the reference solution. 238.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. 239. Procedure 239.1 Test Solution: 239.1.1 Transfer a 1.000-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and 22 mL of HCl (1+1). Warm, if necessary, to complete dissolution. When the reaction subsides, add 2 mL of H2O 2 (30 %) and boil for 5 min. 239.1.2 Filter through a medium paper into a 100-mL volumetric flask. Wash the residue with hot water and reserve the filtrate. 239.1.3 When the silicon content is 0.5 % or greater, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 500°C. Cool, add 5 mL of HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate carefully to dryness, cool, and dissolve the residue in 5 drops of HCl (1+1) and a minimum amount of water. Heat to dissolve the salts and add this solution to the reserved filtrate obtained in 237.1.2. 239.1.4 Cool the solution obtained in 239.1.2 or the combined filtrates obtained in 239.1.3. Dilute to volume and mix. This is Sample Solution A. 239.1.5 Pipet 10 mL of Sample Solution A into a 100-mL volumetric flask containing 8 mL of HCl (1+1), dilute to volume, and mix. This is Sample Solution B. 239.1.6 For magnesium concentrations less than 0.05 %, pipet 20 mL of Sample Solution A into a 100-mL volumetric flask containing 8 mL of HCl (1+1), dilute to volume, and mix. Use the calibration solutions prepared in accordance with 238.1.1. A Magnesium, % 5 B 3 100 (17) where: A = magnesium in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. 242. Precision and Bias14 242.1 Precision—Eight laboratories cooperated in testing this test method. The precision of this test method can be estimated by examining the data in Table 11. TABLE 11 Statistical Information Test Specimen 1. 2219 alloy 2. BCS No. 216/2 2014 alloy (0.74 % Mg) 3. 7049 alloy 4. 5082 alloy Magnesium Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.0066 0.75 0.0008 0.013 0.001 0.030 2.78 4.25 0.042 0.14 0.15 0.18 242.2 Bias—No information is available on the accuracy of this test method. The accuracy may be judged, however, by comparing accepted reference values with the corresponding arithmetic averages obtained by interlaboratory testing. NICKEL BY THE ATOMIC ABSORPTION TEST METHOD 243. Scope 243.1 This test method covers the determination of nickel in concentrations from 0.01 to 4 %. 14 Supporting data are available from ASTM Headquarters. Request RR: E031018. 22 E 34 – 94 (2002) 250.1.1 Transfer a 1.0-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and 22 mL of HCl (1+1) in small increments. When the reaction subsides, add 2 mL of H2O2(30 %), heat until dissolution is complete, and boil gently for 5 min. Filter through a medium paper into a 100-mL volumetric flask, wash the residue with hot water, and reserve the filtrate. 250.1.2 When the silicon content is 0.5 % or greater, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 550°C. Cool, add 5 mL HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, and dissolve the salts in 5 drops of HCl (1+1) and a minimum amount of water. Add this solution to the reserved filtrate obtained in 250.1.1. 250.1.3 Cool the solution obtained in 250.1.1 or the combined filtrates obtained in 250.1.2. Dilute to volume and mix. This is Sample Solution A. 250.1.4 Pipet 10 mL of Sample Solution A into a 100-mL volumetric flask containing 8 mL of HCl (1+1), dilute to volume, and mix. This is Sample Solution B. 250.2 Prepare the test solution for aspiration according to the following: 250.2.1 When the nickel concentration is less than 0.2 %, pipet 50 mL of Sample Solution A into a 100-mL volumetric flask containing 7 mL of HCl (1+1), dilute to volume, and mix. Use the 0.01 to 0.20 % nickel set of calibration solutions. 250.2.2 When the nickel concentration is between 0.20 and 2.00 %, pipet 10 mL of Sample Solution A into a 200-mL volumetric flask containing 16 mL of HCl (1+1), dilute to volume, and mix. Use the 0.20 to 2.00 % nickel set of calibration solutions. 250.2.3 When the nickel concentration is between 2.00 and 4.00 %, pipet 25 mL of Sample Solution B into a 100-mL volumetric flask containing 6 mL of HCl (1+1), dilute to volume, and mix. Use the 2.00 to 4.00 % nickel set of calibration solutions. 251. Measurements 251.1 Optimize the response of the instrument and take preliminary readings; complete the analysis and determine the concentration of nickel in the test solution by the graphical procedure, as described in Guide E 1024. 244. Summary of Test Method 244.1 An acid solution of the sample is aspirated into the air-acetylene flame of an atomic absorption spectrophotometer. The absorption of the nickel resonance line at 2320 Å is measured and compared with the absorption of calibration solutions containing known amounts of nickel. 245. Concentration Range 245.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.2 µg/mL for 0.0044 absorbance is widely obtained. 246. Interferences 246.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 247. Apparatus 247.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 248. Reagents 248.1 Aluminum Solution A (1 mL = 50 mg Al)—Transfer 25.00 g of aluminum (purity: 99.99 % min) to a 1-L beaker. Add 100 mL of water, a small drop of mercury, and 275 mL of HCl in increments, heating moderately to accelerate the dissolution. When dissolution is complete, add 2 mL of H2O2 (30 %) and boil for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 248.2 Aluminum Solution B (1 mL = 2.5 mg Al)—Using a pipet, transfer 25 mL of Aluminum Solution A to a 500-mL volumetric flask, dilute to volume, and mix. 248.3 Nickel, Standard Solution A (1 mL = 1.00 mg Ni)— Transfer 1.000 g of nickel (purity: 99.9 % min) to a 400-mL beaker. Dissolve in 50 mL of HNO3 (1+1), boil for 5 min, cool, and transfer to a 1-L volumetric flask. Dilute to volume and mix. Store in a polyethylene bottle. 248.4 Nickel, Standard Solution B (1 mL = 0.04 mg Ni)— Using a pipet, transfer 10 mL of Nickel Standard Solution A to a 250-mL volumetric flask, dilute to volume, and mix. 249. Calibration 249.1 Calibration Solutions—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Nickel Standard Solution B to 100-mL volumetric flasks. Add Aluminum Solution A or B and HCl (1+1) as indicated as follows, dilute to volume, and mix. Nickel Concentration, % 0.01 to 0.20 0.20 to 2.00 2.00 to 4.00 Aluminum Solution, mL 10 Solution A 20 Solution B 10 Solution B NOTE 31—The graphical procedure is preferred because of the nonlinearity of nickel response at 2320 Å. 252. Calculation 252.1 Calculate the percentage of nickel as follows: HCl (1+1), mL 7 8 8 A Nickel, % 5 B 3 100 (18) where: A = nickel per 100 mL of final test solution, mg, and B = sample represented in 100 mL of the final test solution taken for analysis, mg. 249.2 Reference Solution—The 0 calibration solution is used as the reference solution. 249.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus as directed in Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions always must contain the same quantity of aluminum per millilitre. 250. Procedure 250.1 Test Solution: 253. Precision and Bias15 15 Supporting data are available from ASTM Headquarters. Request RR: E031019. 23 E 34 – 94 (2002) 259.4 Diantipyrylmethane Solution (50 g/L)—Dissolve 10.0 g of diantipyrylmethane (CH 2[C:(CH3)N(CH3)N(C6H5)CO] 2), in 34 mL of HCl (1+1), and 150 mL of water. Dilute to 200 mL. 259.5 Titanium, Standard Solution A (1 mL = 0.5 mg Ti)— Dissolve 0.500 g of titanium (purity 99.5 % min) in 125 mL of H2SO4. When dissolution is complete, cool, add 10 drops of HNO3, and boil gently for 5 min. Cool and dilute to about 800 mL. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. 259.6 Titanium, Standard Solution B (1 mL = 0.015 mg Ti)—Using a pipet, transfer 15 mL of Titanium Solution A to a 500-mL volumetric flask, dilute to volume, and mix. 253.1 Precision—Nine laboratories cooperated in testing this test method. The precision of this test method can be estimated by examining the data in Table 12. TABLE 12 Statistical Information Test Specimen MD 184 NBS 85b 2024 alloy (0.084 % Ni) BCS No. 181/2 2218 alloy (1.91 % Ni) Nickel Found, % Repeatability (R1, E 173) Reproducibility (R2, E 173) 0.011 0.087 1.88 0.0012 0.0053 0.042 0.004 0.009 0.101 260. Preparation of Calibration Curve 260.1 Calibration Solutions—Using pipets, transfer 1, 2, 4, 6, 8, and 10 mL of Titanium Solution B to 100-mL volumetric flasks. Add 20 mL of aluminum solution. Proceed as directed in 260.3. 260.2 Reference Solution—Transfer 20 mL of aluminum solution to a 100-mL volumetric flask. Proceed as directed in 260.3. 260.3 Color Development—Using a pipet, add 25 mL of H2SO4 (1+1), dilute to 75 mL, and cool. Add 2 drops of copper sulfate solution and 2 mL of ascorbic acid solution, and mix. Using a pipet, add 10 mL of diantipyrylmethane solution, dilute to volume, and mix. Allow the color to develop for 1 h. 260.4 Photometry: 260.4.1 Multiple–Cell Photometer—Measure the cell correction using absorption cells with a 1-cm light path and a light band centered at approximately 400 nm. Using the test cell, take the photometric readings of the calibration solutions. 260.4.2 Single–Cell Photometer—Transfer a suitable portion of the reference solution to an absorption cell with a 1-cm light path and adjust the photometer to the initial setting, using a light path centered at approximately 400 nm. While maintaining this adjustment, take the photometric readings of the calibration solutions. 260.5 Calibration Curve—Plot the net photometric readings of the calibration solutions against milligrams of titanium per 100 mL of solution. 261. Procedure 261.1 Test Solution: 261.1.1 Transfer a 1.00-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Cover with a ribbed cover glass. 261.1.2 Add 30 mL of water, and 30 mL of HCl (1+1) in small increments. Warm if necessary to complete dissolution. When the reaction subsides, add 2 mL of H2O2 (30 %), and boil for 5 min. 261.1.3 Filter, using a medium paper, into a 100-mL volumetric flask. Wash with hot water and reserve the filtrate. 261.1.4 When a visible silicon residue is present, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 600°C until the carbon is removed, Cool, add 5 mL of HF, and add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, add 5 drops of HCl (1+1), and a minimum amount of water. Heat to dissolve the salts, and add the solution to the filtrate reserved in 261.1.3. 253.2 Bias—No information on the accuracy of this test method is available. The accuracy may be judged, however, by comparing the accepted reference values with the corresponding arithmetic averages obtained by interlaboratory testing. TITANIUM BY THE DIANTIPYRYLMETHANE PHOTOMETRIC TEST METHOD 254. Scope 254.1 This test method covers the determination of titanium in concentrations from 0.003 to 0.3 %. 255. Summary of Test Method 255.1 The sample is dissolved in hydrochloric acid. Iron and vanadium are reduced with ascorbic acid in the presence of copper sulfate. The yellow titanium complex is formed with diantipyrylmethane. Photometric measurement is made at approximately 400 nm. 256. Concentration Range 256.1 The recommended concentration is from 0.015 to 0.15 mg of titanium per 100 mL, using a 1-cm cell. NOTE 32—This test method has been written for cells having a 1-cm light path. Cells having other dimensions may be used, provided suitable adjustments can be made in the amounts of sample and reagents used. 257. Stability of Color 257.1 The color is developed within 1 h and is then stable for 8 h. 258. Interferences 258.1 The elements ordinarily present in aluminum and aluminum-base alloys do not interfere if their concentrations are under the maximum limits shown in 1.1. 259. Reagents 259.1 Aluminum Solution (1 mL = 25 mg Al)—Transfer 25 g of aluminum (purity 99.99 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 275 mL of HCl in small increments, heating moderately to accelerate dissolution. When dissolution is complete, add 2 mL of H2O2(1+1), and boil gently for 5 min. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene container. 259.2 Ascorbic Acid Solution (20 g/L)—Dissolve 2 g of ascorbic acid (C6H 8O6) in 100 mL of water. Do not use a solution that has stood for more than 1 h. 259.3 Copper Sulfate Solution (48 g/L)—Dissolve 7.5 g of copper sulfate (CuSO4·5H 2O) in water and dilute to 100 mL. 24 E 34 – 94 (2002) TABLE 13 Statistical Information 261.1.5 Cool the solution from 261.1.3 or 261.1.4, dilute to volume, and mix. 261.1.6 According to the expected titanium content, proceed with the volumes of test solution and aluminum solution listed in the following: Expected Titanium, % 0.003 to 0.030 0.020 to 0.070 0.060 to 0.30 Volume of Test Solution, mL 50.0 20.0 5.0 Test Specimen ISO-30 (5182 alloy) ISO-22 (7005 alloy) ISO-9 (10 Cu-1 Ni alloy) Volume of Aluminum Solution, mL ... 12 18 Repeatability (R1, E 173; M = 1) Reproducibility (R2, E 173; M = 1) 0.0076 0.0168 0.155 0.00085 0.0013 0.0067 0.00089 0.0016 0.013 VANADIUM BY AN EXTRACTION-PHOTOMETRIC TEST METHOD USING N-BENZOYL-NPHENYLHYDROXYLAMINE 261.1.7 Using a clean, dry pipet, transfer the appropriate volume of test solution to a 100-mL volumetric flask. Add the appropriate volume of aluminum solution. Reserve the remaining test solution for use in 261.4. 261.2 Reference Solution—Proceed as directed in 260.2. 261.3 Color Development—Proceed as directed in 260.3. 261.4 Background Color Solution (Correction for elements in the test solution present as colored ions)—Pipet an additional aliquot of the test solution to a 100-mL volumetric flask and add aluminum solution equal to that selected in 261.1.7. For a 50-mL aliquot, use the remaining test solution without pipetting. Proceed as in 260.3, but omit the diantipyrylmethane solution. 261.5 Background Color Reference Solution—Proceed as in 260.3 and 260.3, but omit the diantipyrylmethane solution. 261.6 Photometry—Take the photometric readings of the test solution and background color solution as directed in 260.4, each with its appropriate reference solution. 262. Calculation 262.1 Convert the net photometric readings of the test solution and the background color solution to milligrams of titanium by means of the calibration curve. Calculate the percentage of titanium as follows: Titanium, % 5 [~A 2 B!/C] 3 10 Titanium Found, % 264. Scope 264.1 This test method covers the determination of vanadium in concentrations from 0.002 to 0.16 %. 265. Summary of Test Method 265.1 After dissolution of the sample in acids, the vanadium is oxidized with potassium permanganate. The vanadium (V) is complexed with N-benzoyl-N-phenylhydroxylamine, the complex is extracted with chloroform and photometric measurement is made at approximately 530 nm. 266. Concentration Range 266.1 The recommended concentration range is from 0.02 to 0.40 mg of vanadium per 50 mL of chloroform solution, using a 1-cm cell. NOTE 33—This test method has been written for cells having a 1-cm light path. Cells having other dimensions may be used, provided suitable adjustments can be made in the amounts of sample and reagents used. 267. Stability of Color 267.1 The color is stable for at least 48 h. 268. Interferences 268.1 Other than titanium, the elements ordinarily present in aluminum alloys do not interfere when concentrations are less than the maximum limits shown in 1.1. Titanium, at concentrations above 2 mg in the sample solution will produce a positive interference. This becomes significant only when operating near the lower limit of the scope of this test method with samples having a high Ti-to-V ratio. It is evidenced by an off color in the test solution. 269. Reagents 269.1 Chloroform (CHCl3), Spectrophotometric grade. 269.2 N-benzoyl-N-phenylhydroxylamine(BPHA) Solution (1g/L)—Dissolve 0.250 g of BPHA (C 6H5CON(OH)C6H5) in 100 mL of CHCl 3. Transfer to a dry 250-mL volumetric flask, dilute to volume with CHCl3, and mix. When stored in a brown glass bottle in the dark, this reagent is stable for at least 2 months. 269.3 Vanadium, Standard Solution A (1 mL = 0.100 mg V)—Dissolve 0.1785 g of reagent grade V2O5, which has been ignited at 300°C for 1 to 2 h, in 20 mL of NaOH (5 g/100 mL) solution. Add 25 mL of H 2SO4 (1+1) and cool to room temperature. Transfer to a 1-L volumetric flask, dilute to volume with water, and mix. Store in a polyethylene bottle. 269.4 Vanadium, Standard Solution B (1 mL + 0.010 mg V)—Using a pipet, transfer 25 mL of Vanadium Solution A to a 250-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. (19) where: A = titanium found in 100 mL of final test solution, mg, B = background color correction, equivalent milligrams of titanium, and C = sample represented in 100 mL of the final test solution, g. 263. Precision and Bias 263.1 Precision16—Ten laboratories cooperated in testing this test method on ISO-9 and ISO-22, and nine laboratories tested ISO-30. Seven of the laboratories analyzed each of the samples on five separate days while the other three laboratories analyzed their samples on either four or five separate days. Repeatability ( R1) and reproducibility (R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 13. 263.2 Bias—No information on the accuracy of the test method is available. 16 Supporting data are available from ASTM Headquarters. Request RR: E031031. 25 E 34 – 94 (2002) amount of water. Heat to dissolve the salts and add the solution to the filtrate reserved in 271.1.3. 269.5 Potassium Permanganate Solution (2 g/L)—Dissolve 0.20 g of KMnO4 in water and dilute to 100 mL. NOTE 34—Experimental data on alloys containing up to 6 % silicon have shown that this test method yields the same results for vanadium even when this recovery step is omitted. 270. Preparation of Calibration Curve 270.1 Calibration Solutions—Using pipets, transfer 5, 10, 20, 30, and 40 mL of Vanadium Solution B to a series of 250-mL separatory funnels. Add to each 27 mL of H2SO4 (1+1), dilute to about 100 mL with water, and proceed as directed in 270.3. 270.2 Reference Solution—Transfer 27 mL of H2SO4 (1 + 1), to a 250-mL separatory funnel, dilute to about 100 mL with water, and proceed as directed in 270.3. 270.3 Color Development: 270.3.1 To the solutions in the separatory funnels, add KMnO4 solution dropwise with mixing until a slight pink color persists for at least 10 min. 270.3.2 Add 30 mL BPHA solution and 34 mL of HCl. Immediately after addition of the HCl, shake for 1 min and allow the layers to separate. Collect the CHCl3 layer in a dry 50-mL volumetric flask. 270.3.3 Re-extract with 10 mL of BPHA solution and combine with the extract obtained in 270.3.2. Dilute to volume with CHCl3 and mix. Allow the extracts to stand for at least 1 h before taking photometric readings. 270.4 Photometry: 270.4.1 Multiple Cell Photmeter—Measure the cell correction using stoppered absorption cells with a 1-cm light path and a light band centered at approximately 530 nm. Using the test cell, take the photometric readings of the calibration solutions. 270.4.2 Single–Cell Photometer—Transfer a suitable portion of the reference solution to a stoppered absorption cell having a 1-cm light path and adjust the photometer to the initial setting, using a light band centered at approximately 530 nm. While maintaining this adjustment, take the photometric readings of the calibration solutions. 270.4.3 Calibration Curve—Plot the net photometric readings of the calibration solutions against milligrams of vanadium per 50 mL of solution. 271. Procedure 271.1 Test Solution: 271.1.1 Select a sample weight in accordance with the following table: Vanadium, % 0.002–0.025 0.025–0.070 0.07–0.16 271.1.5 To filtrate from 271.1.3 or 271.1.4, add 20 mL of H2SO 4 (1+1), cover with a ribbed cover glass, and carefully evaporate to fumes of H2SO4. Reduce the heat to avoid bumping and continue fuming for 15 min to remove chloride. After cooling, wash down with about 30 mL of water and heat to dissolve any salts. Dilute to 75 mL and boil the solution for 5 min. Cool and transfer to a 250-mL separatory funnel. Dilute to about 100 mL and proceed as directed in 270.3. 271.2 Reference Solution—Prepare a reference solution as described in 270.2. 271.3 Color Development—Proceed as directed in 270.3. 271.4 Photometry—Take the photometric reading of the test solution as described in 270.4.1 or 270.4.2. 272. Calculation 272.1 Convert the net photometric reading of the test solution to milligrams of vanadium by means of the calibration curve. Calculate the percentage of vanadium as follows: Vanadium, % 5 ~A/B 3 10! (20) where: A = vanadium found in 50 mL of the final test solution, mg, and B = sample represented in 50 mL of the final test solution, g. 273. Precision and Bias 220.1 Precision—Nine laboratories cooperated in testing this test method. The precision of this test method can be estimated by examining the data in Table 14. 220.2 Bias—No information on the accuracy of this test method is available. ZINC BY THE ION EXCHANGE-EDTA TITRIMETRIC TEST METHOD 274. Scope 274.1 This test method covers the determination of zinc in concentrations from 0.1 to 12 %. 275. Summary of Test Method 275.1 The sample is dissolved in acid, and excess acid is removed by evaporation. The residue is dissolved in dilute hydrochloric acid and passed through a strongly basic anion exchange resin. The adsorbed zinc is eluted from the column and titrated with disodium (ethylenedinitrilo) tetraacetate (EDTA), using dithizone as the indicator. 276. Interferences Sample Weight, g 1.0 0.5 0.25 271.1.2 Transfer the portion, weighed to the nearest 0.5 mg, to a 250-mL beaker. Add 25 mL of water, 7 mL of H2SO4 (1+1), and 2 mL HCl. Cover with a watch glass and, if necessary, heat gently to start reaction. When reaction slows, boil gently until reaction is completed and cool. 271.1.3 Filter, using a medium paper, into a 250-mL beaker. Wash with hot water and reserve the filtrate. 271.1.4 If a visible residue is present, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 500°C (Note 34). Cool, add 5 mL of HF, and add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, and dissolve the residue in 5 drops of H2SO4 (1+1) and a minimum TABLE 14 Statistical Information 26 Test Specimen Vanadium Found, % Repeatibility (R1, E 173) Reproducibility (R2, E 173) 1070 Alloy 7029 Alloy 2219 Alloy 0.0032 0.056 0.140 0.00018 0.0017 0.0045 0.00095 0.0072 0.0085 E 34 – 94 (2002) 278.7 Hydrochloric Acid (1 M)—Add 85 mL of HCl to water and dilute to 1 L. 278.8 Hydrochloric Acid (0.005 M)—Dilute 5 mL of HCl (1 M) with water and make up to a volume of 1 L. 278.9 Zinc, Standard Solution (1 mL = 2.00 mg Zn)— Dissolve 2.000 g of zinc (purity 99.95 % min) in 50 mL of HCl (1 + 1) diluted with 50 mL of water. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. 276.1 Cadmium remains with zinc, and will be titrated. Cadmium is rarely encountered in other than negligible amounts in alloys containing zinc. Other elements ordinarily present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 277. Apparatus 277.1 Anion Exchange Column—A glass column 20 mm in diameter and approximately 400-mm long, provided with a fritted disk and a stopcock. A modification of Apparatus No. 8 may be adapted to this test method. A reservoir for reagents may be added at the top of the column. However, reagents must be added according to the procedure described in 280.1. 278. Reagents 278.1 Acetic Acid (1 M)—Add 58 mL of glacial acetic acid (CH3COOH) to water and make up to a volume of 1 L. 278.2 Ammonium Acetate Solution (500 g/L)—Dissolve 50 g of ammonium acetate (CH3COONH4) in water, and dilute to 100 mL. 278.3 Anion Exchange Resin. 278.3.1 Use a strongly basic anion exchange resin of the polystyrene-quaternary-ammonium type, chloride form, having a crosslinkage of 2 to 3 % and a 50 to 100 nominal mesh size.17 Wash the resin with successive portions of HCl (0.005 M), decanting until a clear solution is obtained. Allow to stand for 12 h in HCl (0.005 M). 278.3.2 Preparation of the Ion Exchange Column—Stir the resin, and add a sufficient amount of the suspension to obtain a column approximately 150-mm high after the resin has settled. Precautions should be taken to avoid air bubbles or channels (Note 35). Wash the column with 100 mL of HCl (0.005 M) at a flow rate of 5 to 7 mL/min. 279. Hazards 279.1 Dilute acid concentrations are expressed as molarities in the sections pertaining to the ion exchange steps to emphasize the need for careful dilution of concentrated acids. Standardization is not required. 280. Procedure 280.1 Test Procedure: 280.1.1 Transfer a 2.0-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Cover with a ribbed cover glass. 280.1.2 Carry a reagent blank through the entire procedure, using the same amounts of all reagents, but with the sample omitted. 280.1.3 Carefully add 50 mL of HCl (1+1) in small increments. When the reaction subsides, wash down the sides of the beaker and the cover glass, and add 2 mL of H2O2 (30 %) to dissolve copper. Warm gently to complete the dissolution, and carefully evaporate just to crystallization. Cool, and dissolve the salts with 100 mL HCl (2 M). Heat to complete the dissolution. 280.1.4 Filter, using a medium-porosity paper previously washed with hot HCl (6 M) and hot water, into a 250-mL beaker. Wash with 30 to 50 mL of hot HCl (2 M), and reserve the filtrate. 280.1.5 When a visible silicon residue is present, wash the paper and residue with hot water and discard the washings. Transfer the filter paper and residue to a platinum crucible, dry, and ignite at 600°C until the carbon is removed. Cool, add 5 mL of HF, and add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, and add 5 mL of HCl (2 M). Heat to dissolve the salts, add the solution to the filtrate reserved in 280.1.4, and cool. 280.1.6 For samples containing more than 1.5 % zinc, transfer the solution to a 200-mL volumetric flask, using HCl (2 M) as the transfer solution. Dilute to volume with HCl (2 M) and mix. Using the following table as a guide, select the appropriate portion of the test solution for ion exchange. NOTE 35—When not in use, the resin bed in the column should always be covered with HCl (0.005 M). 278.4 Disodium Ethylenedinitrilo Tetraacetate (EDTA), Standard Solution. 278.4.1 Dissolve 7.5 g of disodium (ethylenedinitrilo) tetraacetate dihydrate (EDTA) in water. Transfer to a 1-L volumetric flask, dilute to volume, and mix. Store in a plastic bottle. 278.4.2 Standardize as follows: Using a pipet, transfer 25 mL of zinc standard solution to a 400-mL beaker and dilute to 100 mL. Proceed as directed in 280.1.11 and 280.1.12. Calculate the zinc equivalent of the EDTA solution as follows: Zinc equivalent, g/mL 5 A/~B 2 C! (21) where: A = zinc represented in 25 mL of zinc solution, g, B = EDTA solution required for titration of the zinc solution, mL, and C = EDTA solution required for titration of the blank, mL. 278.5 Dithizone Solution (0.25 g/L)—Dissolve 0.025 g of diphenyl thiocarbazone (C6H 5NHNHCSN:NC6H5) in ethanol (CH3·CH 2OH) and dilute to 100 mL with ethanol. 278.6 Hydrochloric Acid (2 M)—Add 170 mL of HCl to water and dilute to 1 L. Zn, % 0.1 to 1.5 1.5 to 3 3 to 6 6 to 12 Aliquot Volume, mL Solution from 280.1.5 100 50 25 280.1.7 Transfer the aliquot selected into a beaker, dilute to approximately 150 mL with HCl (2 M), and add 0.5 mL of HNO 3. 280.1.8 Condition the ion exchange column by passing 200 mL of HCl (2 M), containing 0.5 mL of HNO3, through the column at a rate of 5 to 7 mL/min 280.1.9 Pass the test solution through the column at a rate of 5 to 7 mL/min. Wash the beaker and the column with five 17 Dowex 1 3 2, manufactured by the Dow Chemical Co., Midland, MI, has been found satisfactory for this purpose. 27 E 34 – 94 (2002) BERYLLIUM BY ARGON PLASMA OPTICAL EMISSION SPECTROSCOPY successive 25-mL portions of HCl (2 M), and then wash the column with 125 mL of HCl (1 M), maintaining the flow rate. NOTE 36—If more than 6 mg of lead (Pb) are present, wash with 200 mL of HCl (1 M). 283. Scope 283.1 This test method covers the analysis of aluminum and aluminum alloys having beryllium composition within the limits of 0.3 to 100 ppm. 284. Summary of Test Method 284.1 An acid solution of the sample is aspirated into the jet of an argon plasma optical emission spectrometer. The beryllium concentration is measured at 234.86 nm by comparing it with matched matrix calibration solutions. 285. Interferences 285.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 286. Apparatus 286.1 Argon Plasma Optical Emission Spectrometer— Follow manufacturer’s instruction manual for installation and operation. 287. Reagents 287.1 Argon—Purity: 99.998 %, min. 287.2 Aluminum Solution (1 mL = 20 mg Al)—Transfer 20 g of aluminum (purity: 99.999 % min) into a 1-L beaker. Add 400 mL of HCl (1+1) in which 20 mg of HgCl 2 have been dissolved and heat moderately to accelerate dissolution (Note 38). When dissolution is complete, add 2 mL of H2O2 (30 %) and boil gently for 5 min. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 280.1.10 Elute the zinc from the column with 300 mL of HCl (0.005 M), at a flow rate of 5 to 7 mL/min, collecting the eluate in a 400-mL beaker. Cover with a ribbed cover glass, and evaporate carefully to approximately 100 mL. NOTE 37—When bismuth (Bi) is present in the alloy, it will be retained on the column and will be seen as a light-colored band at the top of the column. Remove by washing the column with 200 mL of HNO3 (7.5 M), followed by 200 mL of water. Condition the column for further samples as directed in 280.1.8. 280.1.11 Neutralize the evaporated eluate with ammonium hydroxide using a pH meter. Add 10 mL of acetic acid (1 M), and 10 mL of ammonium acetate solution. Adjust the pH to 5.3 6 0.2 with ammonium hydroxide or acetic acid (1 M). Add 50 mL of acetone, and cool to approximately 5°C. 280.1.12 Add 2 mL of dithizone solution, and titrate immediately with the EDTA solution, until the color changes from red to yellow. The color should not vary after the addition of two additional drops of EDTA. 281. Calculation 281.1 Calculate the percentage of zinc as follows: Zinc, % 5 [~A 2 B!C/D] 3 100 (22) where: A = EDTA solution required for titration of the test solution, mL, B = EDTA solution required for titration of the blank, mL, C = zinc equivalent of the EDTA solution, g/mL, and D = sample represented in the final test solution, g. NOTE 38—High purity aluminum is difficult to dissolve. An alternative procedure is to allow the aluminum and acid mixture to stand overnight in the covered beaker. After 16 h, only a minimum amount of heating is usually required to complete the dissolution. 282. Precision and Bias18 282.1 Precision—Sixteen laboratories cooperated in testing this test method on sample ISO-10 and fourteen laboratories tested sample ISO-15. All but one of the laboratories analyzed the samples on a minimum of five separate days. One laboratory analyzed ISO-15 on four separate days. Repeatability (R1) and reproducibility (R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 15. 287.3 Beryllium, Standard Solution A (1 mL = 0.1 mg Be)—Transfer 100 mg beryllium metal (purity: 99.95 %) into a 100-mL beaker. Add 20 mL of HCl (1+1) and warm gently to just dissolve the metal. Transfer into a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 287.4 Beryllium, Standard Solution B (1 mL = 0.01 mg Be)—Pipet 50 mL of Beryllium Standard Solution A into a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 287.5 Beryllium, Standard Solution C (1 mL = 0.001 mg Be)—Pipet 10 mL of Beryllium Standard Solution B into a 100-mL volumetric flask. Add 2 mL of HCl (1+1), dilute to volume with distilled water, and mix. Prepare fresh daily as needed. 287.6 Beryllium, Standard Solution D (1 mL = 0.0001 mg Be)—Pipet 10 mL of Beryllium Standard Solution C into a 100-mL volumetric flask. Add 2 mL of HCl (1+1), dilute to volume with distilled water, and mix. Prepare fresh daily as needed. 288. Hazards 288.1 Beryllium and its compounds are extremely toxic and care must be exercised in their handling. For precautions to be observed, refer to Practices E 50. To prevent eye damage, the ultraviolet radiation from the argon plasma must be shielded at all times. TABLE 15 Statistical Information Test Specimen Zinc Found, % ISO–10 ISO–15 5.97 0.432 Repeatability (R1, E 173, M = 1) 0.255 0.0155 Reproducibility (R2, E 173, M = 1) 0.305 0.0193 282.2 Bias—No information on the accuracy of this test method is available. 18 Supporting data are available from ASTM Headquarters. Request RR: E031035. 28 E 34 – 94 (2002) prepared in 289.3. Direct reading instruments will provide the results in the calibrated concentration units. 292. Precision and Bias19 292.1 Precision—Ten laboratories cooperated in testing this test method and obtained twelve sets of data. Five laboratories used ICP spectrometers and seven laboratories used DCP. All samples were analyzed on three separate days. Repeatability (R1) and reproducibility (R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 16. 289. Calibration 289.1 Calibration Solutions—Using pipets, transfer into 100-mL volumetric flasks the volumes of the appropriate beryllium standard indicated as follows: mL 0 2.0 5.0 10.0 5.0 10.0 25.0 5.0 10.0 Beryllium Standard ... D D D C C C B B Be in Al, ppm 0 0.2 0.5 1.0 5.0 10.0 25.0 50.0 100.0 TABLE 16 Statistical Information Add 50 mL of aluminum solution to each flask, dilute to volume, and mix. 289.2 Instrument Optimization—While aspirating the highest beryllium calibration solution, adjust all instrument parameters, argon flow rate, wavelength, photomultiplier tube voltage, viewing height, and sample uptake to optimize response according to the instrument manufacturer’s recommended operating practice. 289.3 Standardization—Aspirate each of the calibration solutions in 289.1 and record the emission intensity as related to concentration. Aspirate 0.01 M HCl between each run. Prepare an analytical curve by plotting the emission intensity of each calibration solution versus its concentration or calculate a standard curve. If the instrument is equipped for direct reading of concentrations, this method of calibration may be used provided that the proper blank correction is applied. 290. Procedure 290.1 Test Solution: 290.1.1 Transfer a 1.0-g sample, weighed to the nearest 1 mg, into a 250-mL beaker. Add 20 mL of water and 20 mL of HCl (1+1) in small increments, and cover with a ribbed cover glass. When the reaction subsides, add 2 mL of H2O2 (30 %) and boil for 5 min. 290.1.2 Filter, using a 0.45-µ membrane filter, into a 100-mL volumetric flask. Wash with hot water and reserve the filtrate. 290.1.3 When a visible silicon residue is present, transfer the membrane filter and residue into a platinum crucible, dry, and ignite at 500°C until the carbon is removed. Cool, add 5 mL HF, and add HNO3 dropwise until a clear solution is obtained. Add 4 drops of H2SO4 (1+1), evaporate to fumes, and gently fume for 2 min. Cool, add 5 drops of HCl (1+1) and a minimum amount of water. Heat to dissolve the salts and combine the solution with the filtrate reserved in 290.1.2. 290.1.4 Cool the solution from 290.1.2 or 290.1.3, dilute to volume, and mix. 290.1.5 Aspirate the test solution and record its emission intensity or concentration. Verify the calibration by analyzing a calibration standard with beryllium content similar to the test solution. If the value obtained is not within 5 % of the expected value, repeat the instrument calibration procedure. Wash with 0.01 M HCl between each run. 291. Calculation 291.1 Calculate the concentration of beryllium in the test solution in parts per million (µg/g) using the analytical curve Test Specimen Beryllium Found, µg/g (ppm) Repeatability (R1, E 173, M = 1) Reproducibility (R2, E 173, M = 1) 1145 Alloy 1145 Alloy 7075 Alloy (NBS 859) (26 ppm Be) 4032 Alloy 0.18 6.50 26.2 31.0 0.10 0.58 2.2 3.5 0.16 0.92 3.3 3.8 292.2 Bias—No information on the accuracy of this test method is available. The accuracy may be judged, however, by comparing the accepted reference value with the corresponding arithmetic average obtained by interlaboratory testing. MANGANESE BY THE PERIODATE (PHOTOMETRIC) TEST METHOD 293. Scope 293.1 This test method covers the determination of manganese in aluminum and aluminum alloys in concentrations from 0.005 to 2.0 %. 294. Summary of Test Method 294.1 Manganese, in acid solution, is oxidized to permanganate ion by potassium periodate. Photometric measurement is made at approximately 525 nm. 295. Concentration Range 295.1 The recommended concentration range is from 0.1 to 2.0 mg Mn/100 mL of solution using a cell depth of 1 cm (see Note 33). 296. Stability of Color 296.1 The color develops within 30 min if the concentration is less than 0.2 mg Mn/100 mL of solution and within 15 min if the concentration is greater than this amount. The color is stable for several weeks if excess periodate is present. 297. Interferences 297.1 The elements ordinarily present in aluminum and aluminum base alloys do not interfere if their concentrations are under the maximum limits shown in 1.1. 298. Reagents 298.1 Fluoroboric Acid Solution—Add 200 mL of HF to 800 mL of boric acid solution (Reagent No. 136) in a plastic bottle, and mix. 19 Supporting data are available from ASTM Headquarters. Request RR: E031037. 29 E 34 – 94 (2002) 298.2 Manganese, Standard Solution A (1 mL = 1.0 mg Mn)—Clean electrolytic manganese metal (purity 99.9 % min) in H2SO4 (1+9). Rinse thoroughly by decantation and dry. Transfer 1.000 g (weighed to within 1 mg) to a 400-mL beaker. Dissolve in 100 mL of H2SO4(1+9). When dissolution is complete, boil the solution for 5 min and cool. Transfer to a 1-L volumetric flask, dilute to volume, and mix. 298.3 Manganese, Standard Solution B (1 mL = 0.1 mg Mn)—Using a pipet, transfer 100 mL of Manganese Standard Solution A to a 1-L volumetric flask. Dilute to volume and mix. 298.4 Potassium Periodate Solution (50 g/L)—Dissolve 50 g of potassium periodate (KIO 4) in water, add 200 mL HNO3, and dilute to 1 L. 298.5 Sodium Hydroxide Solution (200 g/L)—In a nickel dish, dissolve 200 g of sodium hydroxide (NaOH) in water. Cool and dilute to 1 L. Store in a plastic container. 298.6 Sodium Nitrite Solution (20 g/L)—Dissolve 2 g of sodium nitrite (NaNO2) in water and dilute to 100 mL. Prepare fresh daily. 298.7 Sulfurous Acid Solution—Pass a stream of sulfur dioxide gas (SO2) through water until saturated. 298.8 Water, Free of Reducing Agents—To 1 L of water, and 10 mL of H2SO4 and heat to boiling. Add a few crystals of KIO4 and continue to boil for 10 min. where: A = net absorbance, B = gross absorbance of the calibration or test solution, C = absorbance of the solution after NaNO2 solution addition, D = gross absorbance of the reagent blank, and E = absorbance of the reagent blank after NaNO2 solution addition. 299.6 Calibration Curve—Plot the net absorbance readings of the calibration solutions against milligrams of manganese per 100 mL of solution. 300. Procedure 300.1 Test Solution: 300.1.1 Manganese Content, 0.1 to 2.0 %—Transfer 1.0 g of the sample, weighed to the nearest 1 mg to a 100-mL platinum or tetrafluoroethylene (TFE) vessel and add, in small amounts, 40 mL of NaOH solution. Cover with a platinum or TFE lid and heat gently to facilitate the attack. Move the lid slightly and evaporate with care until a syrupy consistency is reached. Cool, wash the lid and walls of the vessel with about 25 mL of warm water, and warm gently. Transfer to a 250-mL beaker containing 30 mL of H2SO4 (1+1) and 10 mL of HNO3. If manganese hydroxide adheres to the vessel, return some of the test solution and add several drops of sulfurous acid solution. Mix and transfer back to the beaker. Transfer the test solution to the volumetric flask indicated below. Dilute to volume, mix, and using a pipet, transfer the indicated aliquot into a 250-mL beaker. Add 5 mL of HNO3, 5 mL of H3PO4, and the required volume of H2SO4 (1+1). Dilute to about 70 mL. 299. Preparation of Calibration Curve 299.1 Calibration Solutions—Using pipets or a buret, transfer 1.0, 2.0, 5.0, 10.0, 15.0, and 20.0 mL of Manganese Standard Solution B (1 mL = 0.10 mg Mn) to 250-mL beakers. To each add 15 mL of H2SO4 (1+1), 10 mL of HNO3, and 5 mL of H3PO4. Dilute to about 70 mL. 299.2 Reagent Blank—Transfer 15 mL of H2SO4, 10 mL of HNO3, and 5 mL of H 3PO4 to a 250-mL beaker and dilute to about 70 mL. 299.3 Color Development—Heat to boiling and add 10 mL of KIO4 solution. Continue to boil until the characteristic color develops and for an additional 5 min (an additional 15 to 30 min if the manganese content is less than 0.2 mg). Cool and transfer to a 100-mL volumetric flask, previously rinsed with water treated to remove reducing agents (see 298.7). Dilute to volume with the treated water. 299.4 Photometry: 299.4.1 Multiple Cell Photometer—Measure the cell correction using absorption cells with a 1-cm light path and a light band centered at approximately 525 nm. Using the test cell, take photometric readings of the reagent blank and calibration solutions. After each reading, add 2 drops of NaNO2 solution to the cell, mix, and repeat the measurement. 299.4.2 Single Cell Photometer—Transfer a suitable portion of water to an absorption cell with a 1-cm light path and adjust the photometer to the initial setting using a light band centered at approximately 525 nm. While maintaining this adjustment, take photometric readings of the reagent blank and calibration solutions. After each reading, add 2 drops of NaNO2 solution to the cell, mix, and repeat the measurement. 299.5 For each solution, calculate the net absorbance as follows: A 5 ~B 2 C! 2 ~D 2 E! Mn, % (estimated) 0.1 to 0.4 0.4 to 1.0 1.0 to 2.0 Volumetric Flask, mL 100 250 250 Aliquot, mL 50 50 25 H2SO4(1+1) Addition, mL 5 10 10 300.1.2 Manganese Content, 0.005 to 0.1 %, Silicon Content Less Than 10 %—Weigh and dissolve 1.0 g of sample as directed in 300.1.1 but do not transfer to a volumetric flask. Concentrate the solution in the beaker to a volume of about 65 mL and add 5 mL of H3PO4. 300.1.3 Manganese Content, 0.005 to 0.1 %, Silicon Content More Than 10 %—Transfer 1.0 g of sample, weighed to the nearest 1 mg, to a 250-mL beaker. Add 20 mL of H2SO 4 (1+1), 10 mL of HNO3, and 2 mL of fluoroboric acid solution and warm gently to dissolve. Heat to boiling to remove nitrous fumes. Dilute to about 50 mL, add a little filter pulp, and heat for several minutes. Filter through closetextured paper, collecting the filtrate and washings in a 250-mL beaker. Transfer the filter paper and pulp to a platinum crucible and ignite in a muffle furnace at 500 to 600°C to complete destruction of the paper. Cool, add several drops of H2SO4, 2 to 5 mL of HF, and HNO3 dropwise until the solution clears. Evaporate to dryness over a Meker burner, continue heating for several more minutes, and cool. Take up the residue in a little H2SO4 (1+1) and warm water with heating. Filter if necessary and combine the solutions. Concentrate to about 65 mL and add 5 mL of H3PO4. NOTE 39—This alternative procedure may be used for siliconaluminum alloys, containing more than 0.1 % Mn, by diluting the test solution to volume before the addition of the 5 mL of H3PO4, and taking (23) 30 E 34 – 94 (2002) 304.1 The sample is dissolved in acid, silicon is removed by filtration, and copper is recovered from the nonvolatile residue remaining after treatment with HF. The sample solution is electrolyzed and the cathodic deposit is weighed. 305. Interferences 305.1 Of the elements ordinarily present in aluminum and aluminum alloys, only bismuth, tin, and antimony interfere. This test method should not be applied when these elements are known to be present. This test method should not be applied to alloys containing greater than 2.0 % silicon. 306. Apparatus 306.1 Electrodes for Electroanalysis—Apparatus No. 9. 307. Hazards 307.1 Perchloric acid can be safely used as specified in the procedure. It should not be brought into contact with finely divided aluminum, silicon, or organic matter if nitric acid is not present. Exhaust hoods should be in accordance with Practices E 50. 308. Reagents 308.1 Sulfamic Acid—NH2SO 3H. 309. Procedure 309.1 Select a sample weight in accordance with the following: a suitable aliquot as described in 300.1.1. 300.2 Reagent Blank—Carry a reagent blank through the entire procedure using the same amounts of all reagents. 300.3 Color Development—Proceed as directed in 299.3. 300.4 Photometry—Proceed as directed in 299.4. 301. Calculation 301.1 Calculate net absorbance as directed in 299.5. Convert the net absorbance of the test solution to milligrams of manganese by means of the calibration curve. Calculate the percentage of manganese as follows: Manganese, % 5 F/~G 3 10! (24) where: F = manganese in 100 mL of the final test solution, mL, and G = sample represented in 100 mL of the final test solution, g. 302. Precision and Bias20 302.1 Precision—Eleven laboratories cooperated in testing this test method using alkaline dissolution on sample ISO–17, ten laboratories on ISO–6, and eight on ISO–13. Each laboratory analyzed the samples on a minimum of six separate days. Six laboratories cooperated in testing the acid dissolution procedure on ISO–7 (12.9 % Si). Each laboratory analyzed the sample on a minimum of four separate days. Repeatability (R1) and reproducibility ( R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 17. Copper, % 0.5 to 2.0 2.0 to 5.0 5.0 to 20.0 NaOH Dissolution: ISO–17 ISO–6 ISO–13 Acid Dissolution: ISO–7 (12.9 % Si) Manganese Found, % Repeatability (R1, E 173, M = 1) Reproducibility (R2, E 173, M = 1) 0.848 0.244 0.0209 0.0200 0.00886 0.00163 0.0442 0.0157 0.00362 0.0096 0.00072 0.00124 HClO4 (1+1), mL 180 75 40 HNO3, mL 5 5 5 309.2 Transfer the sample, weighed to the nearest 1 mg, to a 400-mL beaker. Cover with a ribbed cover glass. Just before use, mix the quantities of HClO4 (1+1) and HNO3 as specified in 309.1, and add the mixture, in small increments. Moderate heat may be required to start the reaction. When dissolution is complete, evaporate to dense white fumes and fume for 15 min. Allow to cool, add 300 mL of hot water, stir, and boil for 5 min. 309.3 Allow the residue to settle, and filter while hot, using a medium-porosity paper and a little paper pulp. Wash well with hot water and collect the filtrate and washings in a 600-mL beaker. 309.4 Transfer the filter paper and residue to a platinum crucible, dry, and ignite at 550°C. Cool, add 1 mL of H2SO4 (1+3), 5 mL of HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness and dissolve the residue in 1 mL of HClO 4 (1+1) and a minimum amount of water. Filter if necessary and add to the solution obtained in 309.3. Adjust the volume to approximately 200 mL or to a volume sufficient to cover the electrodes. 309.5 Add 10 mL of HNO3 (1+1), and 1 g of sulfamic acid. Use weighed electrodes and a current density from 0.5 to 1 A/dm2 of cathode surface, and electrolyze while stirring until the solution is colorless. Raise the level of the electrolyte 1 cm by adding water, add 1 g of sulfamic acid, and continue the electrolysis for an additional 30 min. If deposition occurs, add more water, and continue electrolysis until there is no further deposition. 309.6 Without interrupting the current, remove the beaker containing the electrolyte and quickly replace it with a beaker containing sufficient water to cover the electrodes completely. Remove the beaker, disconnect the cathode, and rinse in two TABLE 17 Statistical Information Test Specimen Sample Weight, g 5 2 1 302.2 Bias—No data relating to the magnitude of the bias of results obtained using this test method are available. COPPER BY THE ELECTROLYTIC (GRAVIMETRIC) TEST METHOD 303. Scope 303.1 This test method covers the determination of copper in aluminum and aluminum alloys in concentrations from 0.5 to 20 %. 304. Summary of Test Method 20 Supporting data are available from ASTM Headquarters. Request RR:E031039. 31 E 34 – 94 (2002) 314.1 If the optimum concentration range is not known, determine it as directed in Guide E 1024. A sensitivity of 0.5 to 0.8 µg/mL for 0.0044 absorbance is widely obtained. 315. Interferences 315.1 Elements normally present do not interfere if their concentrations are less than the maximum limits shown in 1.1. 316. Apparatus 316.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use as prescribed in Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 316.2 Anion Exchange Column—A glass column 20 mm in diameter and approximately 400 mm long, provided with a fritted disk and a stopcock. A reservoir for reagents may be added at the top of the column. However, reagents must be added in accordance with the procedure described in 320.1. 317. Reagents 317.1 Anion Exchange Resin: 317.1.1 Use a strongly basic anion exchange resin of the polystyrene-quaternary ammonium type, chloride form, having a cross linkage of 8 % and a 50 to 100 nominal mesh size.22 Wash the resin with successive portions of water, decanting to remove “fines” until a clear supernatant solution is obtained. 317.1.2 Preparation of the Ion Exchange Column—Stir the resin slurry and transfer a sufficient amount of the suspension to the glass column to obtain a resin bed approximately 150 mm high after settling. Using a 19-mm outside diameter column, this is about 30 mL of wet resin. Precautions should be taken to avoid air bubbles or channels (Note 40). Wash the column with 150 mL of HCl (0.5 M), followed by 200 mL of water using a flow rate of 3 to 5 mL/min. successive beakers of ethanol. Dry in an oven at 110°C for 10 min, cool in a desiccator, and weigh as metallic copper. The electrolyte should not contain more than 0.2µ g/mL copper when tested with a sensitive method such as the neocuproine photometric or atomic absorption. 310. Calculation 310.1 Calculate the percentage of copper as follows: Copper, % 5 ~A/B! 3 100 (25) where: A = copper found, g, and B = sample used, g. 311. Precision and Bias21 311.1 Precision—Eleven laboratories cooperated in testing sample ISO–9; nine laboratories tested ISO–12; and ten laboratories tested ISO–8. Each laboratory analyzed the samples on a minimum of six separate days. Repeatability (R 1) and reproducibility (R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 18. TABLE 18 Statistical Information Test Specimen Copper Found, % Repeatability (R1, E 173, M = 1) Reproducibility (R2, E 173, M = 1) ISO–9 ISO–12 ISO–8 10.03 5.44 1.03 0.107 0.100 0.048 0.262 0.183 0.082 311.2 Bias—The accuracy of this test method could not be evaluated because adequate certified standard reference materials were unavailable at the time of testing. The user is cautioned to verify by the use of certified reference materials, if available, that the accuracy of this test method is adequate for the contemplated use. NOTE 40—Precaution: When not in use, the resin bed in the column should always be covered with water. 317.2 Gallium Solution A (1 mL = 1.00 mg Ga)—Transfer 0.500 g of gallium (purity: 99.9 % min) to a 250-mL beaker. Cover and add 10 mL of HCl (1+1). Cautiously add, in small amounts at a time, 2 mL of 30 % H2O2. When dissolution is complete, boil the solution for about 5 min. After cooling, add 33 mL of HCl (6 M) and transfer to a 500-mL volumetric flask. Dilute to volume and mix. Store in a polyethylene bottle. 317.3 Gallium Solution B (1 mL = 0.1 mg Ga)—Pipet 50 mL of Gallium Solution A into a 500-mL volumetric flask, add 33 mL of HCl (6 M), dilute to volume, and mix. Store in a polyethylene bottle. 317.4 Hydrochloric Acid (6 M)—Add 510 mL of HCl to water and dilute to 1 L. 317.5 Hydrochloric Acid (4 M)—Add 340 mL of HCl to water and dilute to 1 L. 317.6 Hydrochloric Acid—(0.5 M)—Dilute 125 mL of HCl (4 M) with water and make up to 1 L. GALLIUM BY THE ION-EXCHANGE-ATOMIC ABSORPTION TEST METHOD 312. Scope 312.1 This test method covers the determination of gallium in concentrations from 0.001 to 0.05 %. 313. Summary of Test Method 313.1 Gallium is adsorbed on a column of strongly basic anion exchange resin from a 6 M hydrochloric acid solution of the sample. The adsorbed gallium is eluted from the column with 0.5 M hydrochloric acid and the concentrated eluate is aspirated into the nitrous oxide-acetylene flame of an atomic absorption spectrophotometer. The absorption of the gallium resonance line at 2874 Å is measured and compared with the absorption of calibration solutions containing known amounts of gallium. 314. Concentration Range 318. Hazards 22 Dowex 1-X8 manufactured by Dow Chemical Co., Midland, MI, and AG 1-X8 produced by Bio-Rad, Richmond, CA, have been found satisfactory for this purpose. 21 Supporting data are available from ASTM Headquarters. Request RR: E031044. 32 E 34 – 94 (2002) 318.1 Dilute acid concentrations are expressed as molarities in the sections pertaining to the ion exchange steps to emphasize the need for careful dilution of concentrated acids. Standardization is not required. 320.1.8 Dissolve the residue in 2 to 3 mL of HCl (0.5 M) with gentle heating. Cool and transfer to a 10-mL volumetric flask using HCl (0.5 M). Dilute to volume with HCl (0.5 M) and mix. Complete the analysis as described in 321.1. 320.1.9 To prepare for the next determination, wash the column with 200 mL of hot water (boiling) using a flow rate of 5 to 7 mL/min to elute any zinc. Under these conditions, the resin bed will maintain a temperature of about 50°C. If high-zinc alloys, such as the 7000 series, have been analyzed, wash with a second 200-mL portion of hot water. (Note 42). 319. Calibration 319.1 Calibration Solutions—Using pipets, transfer 10, 20, 30, 40, and 50 mL of Gallium Solution B to 100-mL volumetric flasks. Dilute to volume with HCl (0.5 M) and mix. Store in polyethylene bottles. 319.2 Reference Solution—Use HCl (0.5 M) as the reference solution. 319.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus in accordance with Guide E 1024. 320. Procedure 320.1 Test Solution: 320.1.1 Transfer a 1.0-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 10 mL of water and cover with a ribbed cover glass. Carefully add 30 mL of HC1 (1+1) in small increments. When the reaction subsides, add 2 mL of H2O2 (30 %) and boil for 5 min. If no precipitate is observed, proceed as directed in 320.1.3. 320.1.2 When a visible silicon residue is present, filter through a 3.0-µm membrane filter into a 250-mL beaker. Wash any residue with hot water and reserve the filtrate. Transfer the membrane filter and residue to a platinum crucible. Moisten the filter with 1 mL HNO3(1+1) and heat on a hot plate until the membrane chars. Ignite in a muffle furnace at 500 to 600°C until the carbon is removed. Cool, add 5 mL of HF, and add HNO3 dropwise until a clear solution is obtained. Evaporate to dryness, cool, and dissolve the residue in 1 mL of HCl (1+1) and a minimum amount of water. Heat to dissolve the salts and add the solution to the reserved filtrate. 320.1.3 Evaporate the solution from 320.1.1 or 320.1.2, using a ribbed cover glass, to a volume of about 10 mL or until heavy crystallization occurs. Add 40 mL of HCl (6 M) and warm to dissolve the salts. 320.1.4 Condition the anion exchange resin by passing 50 mL of HCl (6 M) through the column at a flow rate of 3 to 5 mL/min. 320.1.5 Transfer the cooled solution from 320.1.3 to the reservoir of the column and rinse the beaker with small portions of HCl (6 M). Pass the test solution through the column at a flow rate of 3 to 5 mL/min. Wash the column reservoir three times with 10-mL portions of HCl (6 M). Allow each wash to drain before adding the next. 320.1.6 Wash the column with 200 mL of HCl (4 M) maintaining the same flow rate. This step separates all the aluminum and those metals not adsorbed by anion exchange, plus most of the copper, if present. Discard the eluate and washes. 320.1.7 Elute the gallium with 150 mL HCl (0.5 M) at a flow rate of 3 to 5 mL/min, collecting the eluate in a 250-mL beaker. Cover with a ribbed cover glass and evaporate just to dryness. NOTE 42—For alloys containing bismuth, recondition the column in a manner similar to that described in Note 37. The final conditioning should be done in accordance with 320.1.4. 321. Measurements 321.1 Optimize the response of the instrument and take preliminary readings using the standards prepared in 319.1. Complete the analysis and calculate the gallium concentration using one of the procedures described in Guide E 1024. 322. Calculation 322.1 Calculate the percentage of gallium as follows: A Gallium, % 5 B 3 100 (26) where: A = gallium in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. 323. Precision and Bias23 323.1 Precision—Eight laboratories cooperated in testing this test method by analyzing each of the samples on three separate days. Repeatability (R1) and reproducibility (R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 19. TABLE 19 Statistical Information Test Specimen Alcoa Standard GA-2-A, 1075 Alloy (0.005 % Ga) NBS 85b 2024 Alloy (0.019 % Ga) 0.0053 Repeatability (R1, E 173, M = 1) 0.00049 Reproducibility (R2, E 173, M = 1) 0.00050 0.0204 0.00108 0.00258 Gallium Found, % 323.2 Bias—No information of the accuracy of this test method is available. The accuracy may be judged, however, by comparing the accepted reference values with the corresponding arithmetic average obtained by interlaboratory testing. LITHIUM BY THE ATOMIC ABSORPTION TEST METHOD 324. Scope 324.1 This test method covers the determination of lithium in concentrations from 0.001 to 4 %. 325. Summary of Test Method NOTE 41—The only elements present in this eluate are gallium, iron, and, for copper-containing alloys, a small amount of residual copper. 23 Supporting data are available from ASTM Headquarters. Request RR: E03–1050. 33 E 34 – 94 (2002) 325.1 An acid solution of the sample is aspirated into the air-acetylene flame of an atomic absorption spectrophotometer. The absorption of the lithium resonance line at 670.8 nm is measured and compared with the absorption of matched matrix calibration solutions containing known amounts of lithium. 326. Concentration Range 326.1 If the optimum concentration range is not known, determine it in accordance with Guide E 1024. A sensitivity of 0.035 µg/mL for 0.0044 absorbance is widely obtained. 327. Interferences 327.1 Elements normally present do not interfere when their concentrations are less than the maximum limits shown in 1.1. 328. Apparatus 328.1 Atomic Absorption Spectrophotometer—Determine that the instrument is suitable for use in accordance with Guide E 1024. The percent variability for the highest calibration solution (Vc) should not exceed 1 %. 329. Reagents 329.1 Aluminum Solution A (1 mL = 50 mg Al)—Transfer 25 g of aluminum (purity: 99.99 % min) to a 1-L beaker. Add 100 mL of water and a small drop of mercury. Add 275 mL of HCl in small increments, heating moderately to accelerate dissolution. When dissolution is complete, add 2 mL of H2O2(30 %) and boil gently for 5 min. Cool, transfer to a 500-mL volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 329.2 Aluminum Solution B (1 mL = 5.0 mg Al)—Pipet 10 mL of Aluminum Solution A into a 100-mL volumetric flask. Dilute to volume, and mix. Store in a polyethylene bottle. 329.3 Lithium Standard Solution A (1 mL = 1.00 mg Li)— Dry a quantity of lithium carbonate (Li2CO3) (purity: 99.5 % min), for 12 h at 140°C. Weigh 5.324 g into a beaker and cover with 20 mL of water. Dissolve by adding HCl (1+1), dropwise. Add an additional 10 mL of HCl (1+1) and heat gently to remove CO2. Cool, transfer to a 1-L volumetric flask, dilute to volume, and mix. Store in a polyethylene bottle. 329.4 Lithium Standard Solution B (1 mL = 0.040 mg Li)—Pipet 10 mL of Lithium Standard Solution A into a 250-mL volumetric flask, dilute to volume, and mix. Prepare fresh as needed. 329.5 Lithium Standard Solution C (1 mL = 0.020 mg Li)—Pipet 10 mL of Lithium Standard Solution A into a 500-mL volumetric flask, dilute to volume, and mix. Prepare fresh as needed. 329.6 Lithium Standard Solution D (1 mL = 0.008 mg Li)—Pipet 20 mL of Lithium Standard Solution B into a 100-mL volumetric flask, dilute to volume, and mix. Prepare fresh as needed. volumetric flasks containing 8.5 mL of HCl (1+1). Add 2 mL of Aluminum Solution A to each flask, dilute to volume, and mix. 330.1.3 0.5 to 4 % Li—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Lithium Standard Solution B to 200-mL volumetric flasks containing 17 mL of HCl (1+1). Add 5 mL of Aluminum Solution B to each flask, dilute to volume, and mix. 330.2 Reference Solution—The zero lithium addition calibration solution is used for the reference solution for each range of calibration. 330.3 Since sensitivity may vary among instruments, determine the suitability of the selected concentration range and apparatus in accordance with Guide E 1024. Scale expansion may be required to meet the minimum response criteria for some ranges. Sample and calibration solutions must always contain approximately the same quantity of aluminum per millilitre. 331. Procedure 331.1 Test Solution: 331.1.1 Transfer a 1.000-g sample, weighed to the nearest 1 mg, to a 400-mL beaker. Add 20 mL of water and cover with a ribbed cover glass. Add 27 mL of HCl (1+1) in small increments. Warm, if necessary, to complete dissolution. When the reaction subsides, add 2 mL of H2O2 (30 %) and boil for 5 min. 331.1.2 Filter through a medium-porosity paper into a 100-mL volumetric flask. Wash the filter with hot water, but be careful not to exceed about 85 mL total filtrate. Reserve the filtrate. 331.1.3 When a visible residue is present, transfer the filter paper and residue to a platinum crucible, dry, and ignite at 600°C. Cool, add 5 mL of HF, and then add HNO3 dropwise until a clear solution is obtained. Evaporate carefully to dryness, cool, and dissolve the residue in 5 drops of HCl (1+1) and a minimum amount of water. Heat to dissolve the salts, and add this solution to the filtrate reserved in 331.1.2. 331.1.4 Cool the solution from 331.1.2 or the combined solutions from 331.1.3. Dilute to volume and mix. 331.1.5 For lithium concentrations less than 0.02 %, aspirate the solution from 331.1.4. Use calibration solutions prepared in accordance with 330.1.1. 331.1.6 For lithium concentrations between 0.02 and 0.5 %, pipet 10 mL of the solution obtained in 331.1.4 into a 100-mL volumetric flask containing 8 mL of HCl (1+1), cool, dilute to volume, and mix. Use calibration solutions prepared in accordance with 330.1.2. 331.1.7 For lithium concentrations between 0.5 and 4.0 %, prepare a solution as described in 331.1.6. Pipet 25 mL into a 200-mL volumetric flask containing 15 mL of HCl (1+1), cool, dilute to volume, and mix. Use calibration solutions prepared in accordance with 330.1.3. 332. Measurements 332.1 Optimize the instrument response and take preliminary readings; then complete the analysis and determine the lithium concentration using the graphical or ratio procedure in accordance with Guide E 1024. The graphical procedure is preferred above 0.02 % lithium. 333. Calculation 330. Calibration 330.1 Calibration Solutions: 330.1.1 0.002 to 0.02 % Li—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Lithium Standard Solution D to 100-mL volumetric flasks containing 5 mL of HCl (1+1). Add 20 mL of Aluminum Solution A to each flask, cool, dilute to volume, and mix. 330.1.2 0.02 to 0.5 % Li—Using pipets, transfer 0, 5, 10, 15, 20, and 25 mL of Lithium Standard Solution C to 100-mL 34 E 34 – 94 (2002) TABLE 20 Statistical Information 333.1 Calculate the percentage of lithium as follows: A Lithium, % 5 B 3 100 (27) where: A = lithium in the final test solution, mg, and B = sample represented in the test solution taken for analysis, mg. 334. Precision and Bias 334.1 Precision—Eight laboratories cooperated in testing this test method by analyzing each of the samples on three separate days. Repeatability (R1) and reproducibility (R2) were calculated by analysis of variance (Practice E 173) using M = 1. The data obtained are summarized in Table 20. 334.2 Bias—No certified reference materials suitable for testing this test method were available when the interlaboratory Test Specimen Lithium Found, % Repeatability (R1, E 173, M = 1) Reproducibility (R2, E 173, M = 1) 1075 Alloy 2020 Alloy 1.5 Cu, 1.1 Mg, 3.5 Li Alloy 0.00627 0.9567 3.457 0.000563 0.02615 0.0431 0.000673 0.05251 0.1340 testing program was conducted. The user of this test method is encouraged to employ accepted reference materials, if available, to determine the accuracy of this test method as applied in a specific laboratory. 335. Keywords 335.1 aluminum and aluminum alloys; analysis; chemical analysis ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility. This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards, at the address shown below. This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org). 35