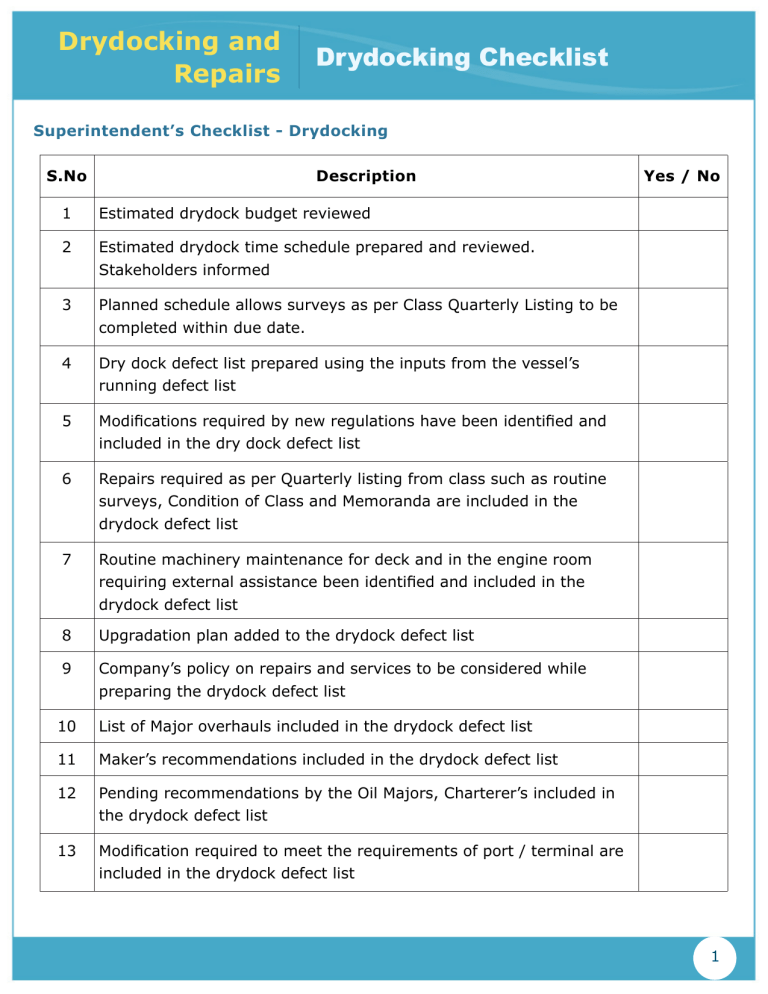

Drydocking and Repairs Drydocking Checklist Superintendent’s Checklist - Drydocking S.No Description 1 Estimated drydock budget reviewed 2 Estimated drydock time schedule prepared and reviewed. Stakeholders informed 3 Planned schedule allows surveys as per Class Quarterly Listing to be completed within due date. 4 Dry dock defect list prepared using the inputs from the vessel’s running defect list 5 Modifications required by new regulations have been identified and included in the dry dock defect list 6 Repairs required as per Quarterly listing from class such as routine surveys, Condition of Class and Memoranda are included in the drydock defect list 7 Routine machinery maintenance for deck and in the engine room requiring external assistance been identified and included in the drydock defect list 8 Upgradation plan added to the drydock defect list 9 Company’s policy on repairs and services to be considered while preparing the drydock defect list 10 List of Major overhauls included in the drydock defect list 11 Maker’s recommendations included in the drydock defect list 12 Pending recommendations by the Oil Majors, Charterer’s included in the drydock defect list 13 Modification required to meet the requirements of port / terminal are included in the drydock defect list Yes / No 1 Drydocking and Repairs Drydocking Checklist 14 Recommendations from Port State Control Inspections included in the drydock defect list 15 Previous drydocking report referred and items verified 16 Guarantee repairs, if any, are included in the drydock defect list 17 Underwater inspection of the vessel prior to the drydocking to ascertain the condition of the hull, and determine the scope of repairs to be carried out 18 Superintendent’s pre drydock inspection carried out and all drydock items identified and verified 19 Dry dock specification prepared for all the items in the defect list 20 Requirements like Gas free certificate, lighting & ventilation, cleaning after, cleaning before, staging, crane service, transport, access work, pressure testing, paint work, function testing, specialist supervision and Class approval are specified for each item . 21 Initial budget prepared based on the drydock specifications and discussed with Fleet Manager 22 Request for Quotation (RFQ) sent to shipyards including general service items like electricity, water, sewage etc 23 Ordered spares and stores for drydocking 24 Quotations compared on total cost, time, payment terms & penalty clause 25 Quotations compared for yard’s experience on specialized jobs, yard congestions, port costs and possible labor strikes 26 Length of ballast passage to the shipyard compared for different shipyards 27 Length of ballast passage to reach designated load port after drydock compared for different shipyards 2 Drydocking and Repairs Drydocking Checklist 28 Weather patterns in the shipyard region (monsoon, humidity, low temperatures, etc.) considered 29 Checked availability of external expertise relevant to the planned jobs 30 Checked availability of Class surveyors, approved Flag State at the shipyard 31 Specifications in shipyard’s quotation are verified with vessel’s drydock specifications 32 Quotations checked for vague or inappropriate quotes and clarified with shipyards 33 Managing Director and Fleet Manager advised of the different factors and shipyard selected 34 Approved budget prepared for the selected shipyard and agreed on with the Managing Director and Fleet Manager 35 Discussions held and provision made for expenses above the approved budget 36 Dry dock schedule confirmed and all stakeholders informed 37 Contract signed with the shipyard and other service providers. Follow Company guidelines on terms and conditions for ship repair contracts 38 Relevant plans forwarded to the shipyard 39 Paint company appointed and painting scheme confirmed 40 Master and Chief Engineer informed to carry out the preparatory work for drydocking 41 Agent appointed at the drydock port and vessel informed of the contact details 42 Arrival formalities and any other special requirements of the drydock port communicated to the vessel 3 Drydocking and Repairs Drydocking Checklist 43 Fleet personnel department appraised about crew matters and riding gang requirements 44 Job cards prepared for all the jobs 45 Additional jobs communicated to the shipyard before arrival and quotations obtained and verified. 46 Deposit payment for shipyard and service providers arranged 47 Port clearance arranged through agent 48 Assurance from service providers on insurance cover for their staff 49 Sludge discharge arranged and payment terms agreed 50 Delivery of critical spares verified 51 H&M, P&I insurance informed of any damage claims 52 Attendance of specialist / service engineers confirmed 53 Scope of jobs verified by shipyard representative prior docking 54 Vessel informed to switch off the impressed current system prior to docking 55 On arrival at the shipyard jobs are re-inspected and job cards updated 56 Re-evaluate additional jobs to be done at the shipyard with reference to cost 57 Any job deletion informed to the shipyard manager 58 Ship’s staff delegated to monitor shipyard work 59 Ship’s crew instructed to maintain log of labor and work progress 60 Ship’s staff briefed on shipyard’s safety and security procedures 61 Daily meetings organized with shipyard manager, specialist and ship staff. 4 Drydocking and Repairs Drydocking Checklist 62 Photographs taken to show conditions before, during, and after each job 63 2 Coordinate with the Class surveyor 64 Completed jobs inspected by the Master/ Chief Engineer and work done reports signed. Remarks endorsed with relevant facts of any discrepancy if noted 65 Budget variance monitored regularly 66 Unplanned activities monitored regularly 67 Records of delays, incorrect work, interruptions etc maintained and discusse 68 Fleet Manager and Managing Director updated regularly on the progress of jobs, additional work and budget overruns 69 Survey and inspection reports compiled 70 Before flooding and after flooding inspections carried out by the ship’s crew. 71 Machinery and equipment tested after flooding dock 72 Sea Trial conducted after major repairs 73 Invoices and reports from the shipyard and service providers compiled 74 Costs / statements / invoices verified and negotiated with the Shipyard 75 Fleet Manager and Managing Director updated on the final costs and bills settled. 76 Final agreement reached, discount and payment terms agreed with shipyard 77 Drydocking report prepared and submitted to Management 5