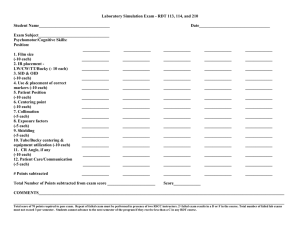

Technical

Publications

sm 2401594--100

Revision 4

Proteus XR/e

sm

Service Manual

do not duplicate

WARNING

THIS EQUIPMENT IS DANGEROUS TO BOTH PATIENT AND OPERATOR

UNLESS MEASURES OF PROTECTION ARE STRICTLY OBSERVED

Though this equipment is built to the highest standards of electrical and mechanical safety, the useful radiation

beam becomes a source of danger in the hands of the unauthorized or unqualified operator. Excessive

exposure to radiation causes damage to human tissue.

Therefore, adequate precautions must be taken to prevent unauthorized or unqualified persons from

operating this equipment or exposing themselves or others to its radiation.

Before operation, persons qualified and authorized to operate this equipment should be familiar with the

Recommendations of the International Commission on Radiological Protection, contained in Annals Number

60 of the ICRP, with applicable National Standards, and should have been trained in use of the equipment.

ENVIRONMENTAL STATEMENT

ON THE LIFE CYCLE OF THE EQUIPMENT OR SYSTEM

This equipment or system contains environmentally dangerous components and materials (such as PCB‘s,

electronic components, used dielectric oil, lead, batteries etc.) which, once the life-cycle of the equipment or

system comes to an end, becomes dangerous and need to be considered as harmful waste according to the

international, domestic and local regulations.

The manufacturer recommends to contact an authorized representative of the manufacturer or an authorized

waste management company once the life-cycle of the equipment or system comes to an end to remove this

equipment or system.

--- MEDICAL EQUIPMENT --WITH RESPECT TO ELECTRIC SHOCK,

FIRE AND MECHANICAL HAZARDS

ONLY IN ACCORDANCE WITH

UL 60601---1, CAN/CSA C22.2 NO.601.1

<14NN>

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

REVISION HISTORY

REV

DATE

REASON FOR CHANGE

1

NOV 23, 2004

First edition.

2

OCT 25, 2005

Updated Schematics.

3

FEB 02, 2007

Added Wall Bucky stand 40 x 120 (optional).

4

JUL 31, 2008

Adjustments and general review.

This Document is the English original version, edited and supplied by the manufacturer.

ADVISORY SYMBOLS

The following advisory symbols will be used throughout this manual.

Their application and meaning are described below.

DANGERS ADVISE OF CONDITIONS OR SITUATIONS THAT

IF NOT HEEDED OR AVOIDED WILL CAUSE SERIOUS

PERSONAL INJURY OR DEATH.

ADVISE OF CONDITIONS OR SITUATIONS THAT IF NOT

HEEDED OR AVOIDED COULD CAUSE SERIOUS PERSONAL

INJURY, OR CATASTROPHIC DAMAGE OF EQUIPMENT OR

DATA.

Advise of conditions or situations that if not heeded or

avoided could cause personal injury or damage to equipment

or data.

Note

.

Alert readers to pertinent facts and conditions. Notes represent

information that is important to know but which do not necessarily

relate to possible injury or damage to equipment.

3

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

SAFETY SYMBOLS

The following safety symbols will be used in the equipment.

Their meaning are described below.

Attention, consult accompanying documents.

Ionizing radiation.

Type B equipment.

Dangerous voltage.

Ground.

This symbol indicates that the waste of electrical and

electronic equipment must not be disposed as unsorted

municipal waste and must be collected separately. Please

contact an authorized representative of the manufacturer or

an authorized waste management company for information

concerning the decommissioning of your equipment.

4

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

TABLE OF CONTENTS

Section

1

Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1.1

Objective and Scope of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1.2

Pre-installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1.3

Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

2

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

3.1

Installation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

3.2

Floor Mounted Tube Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

3.3

Radiographic Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

3.4

Wall Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

3.5

Undertable Installation of the Generator (option) . . . . . . . . . . . . . . . . . . . . . . . .

22

3.6

Wall Bucky Stand 40 x 120 (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

3.7

Interconnection Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

3.7.1

Cables from Floor Mounted Tube Stand . . . . . . . . . . . . . . . . . . . . . . . . .

27

3.7.2

Cables from Radiographic Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

3.7.3

Cables from Table / Wall Bucky . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

Installation of the Adhesive Scales for SID Reference . . . . . . . . . . . . . . . . . . . .

29

FINAL INSTALLATION AND CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

4.1

Floor Mounted Tube Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

4.2

Cable Fastening and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

3.8

4

1

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Section

5

Page

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

5.1

Perpendicular Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

5.2

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

5.2.1

Table Brakes (Lateral and Bucky) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

5.2.2

Column Vertical Brakes (Left and Right) . . . . . . . . . . . . . . . . . . . . . . . . .

38

5.2.3

Column Foot Brakes (Left and Right) . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

5.3

Pedal Microswitch Replacing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .

39

5.4

Eccentric Bearing Adjustment for the Floor Mounted Tube Stand . . . . . . . . . .

41

5.4.1

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

5.4.2

Field Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

Alignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

5.5.1

X-ray Beam Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

5.5.1.1 Light and X-ray Field Alignment . . . . . . . . . . . . . . . . . . . . . . . . .

46

5.5.1.2 Adjusting Perpendicularity (X-ray Beam and Image Receptor)

49

5.5

5.5.1.3 X-ray Field and Image Receptor (Bucky Assembly) Centering51

5.5.2

X-ray Beam and Wall Bucky Stand Alignment . . . . . . . . . . . . . . . . . . . .

52

5.5.3

Field Size Indicator Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53

5.5.4

Collimator Lamp Brightness Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54

5.5.4.1 Collimator Light Field Intensity . . . . . . . . . . . . . . . . . . . . . . . . . .

54

5.5.4.2 Collimator Light Field Contrast Ratio . . . . . . . . . . . . . . . . . . . .

56

PERIODIC MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

59

6.1

Maintenance Activities Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

59

6.2

Checking of Floor Mounted Tube Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60

6.3

Checking of Radiographic Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60

6.4

Checking of Wall Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

6.5

Check Off Maintenance Revision Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

7

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

63

8

SYSTEM INTERCONNECTION MAPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71

6

2

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

SECTION 1

1.1

INTRODUCTION

OBJECTIVE AND SCOPE OF THIS MANUAL

This Service Manual is intended to describe the installation, adjustments,

configuration, calibration, troubleshooting and periodic maintenance of the

Proteus XR/e.

1.2

PRE-INSTALLATION CHECK

Prior to beginning installation, it is recommended to inspect the site and verify

that the X-ray room complies with Pre-installation requirements, such as:

incoming line, main switch(es), safety devices, conduits and space

requirements.

Note

1.3

.

Refer to Direction 2401591--100 “Pre-Installation Manual” of

Proteus XR/e for more Pre-Installation details.

TOOLS AND TEST EQUIPMENT

The following tools and test equipment are required for the installation:

•

Standard service engineers tool kit.

•

Standard and extended levels (1 meter for Column Base).

•

Electric drill motor and assorted bits.

The following special Tools are commonly used for adjustment of the Rad Room

(these tools are not included with the System. Use the suggested tools or

equivalent):

•

Collimator Test Tool (Model RMI 161B9).

•

Beam Alignment Test Tool (Model RMI 162A).

•

SID Test Stand Tool (Inside Case: RMI Model 175).

•

Light Meter (Standard).

7

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

This page intentionally left blank.

8

Proteus XR/e

GE Healthcare

REV 4

SECTION 2

sm 2401594--100

UNPACKING

The system is shipped in different crates to facilitate transport and installation.

Upon receipt of components and parts of the equipment, inspect all shipping

crates for signs of damage. If damage is found, immediately notify the agent or

carrier.

1.

Place crates close to the location in the room where the system is

intended to be placed and remove each wood--packed part. Do not

discard any packing material (envelopes, boxes, bags) until all parts are

identified as listed in the packing list.

AT LEAST 2 / 3 PEOPLE ARE REQUIRED TO REMOVE ALL

HEAVY COMPONENTS FROM THE SHIPPING PALLET.

2.

When the equipment is unpacked, check the part and serial number of

each component’s identification label. Inspect all pieces for visible

damages. If any damaged part is found, repair it or order a replacement

to prevent unnecessary delay in installation.

3.

Verify that all items on the customer order are present.

4.

Leave a free working area around the equipment until installation is

complete.

9

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

This page intentionally left blank.

10

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

SECTION 3

Note

3.1

INSTALLATION

.

Follow Installation sequence process as described. At least two or

three people are required for the following tasks.

INSTALLATION TIPS

The following advices are to be taken in a common installation, as every room

has it own characteristics and options, please plan the room distribution before

starting the installation.

•

For Column Base positioning, a good reference is 1140 mm distance

from the wall where the Wall Bucky Stand is installed to the first drilling

hole of the Column Base. Otherwise keep in mind the length of the Wall

Spacer or Support to increase the reference distance. (Refer to

Illustration 1).

The minimum distance from the Column Base to its parallel wall is

variable depending on the room size.

•

For Wall Stand positioning, a good reference is to install it at 1021 mm

from the transverse axis of the Wall Bucky to the Column Base Back Wall

for Non Telescopic Column Arm, (Refer to Illustration 1) and 1215 mm for

Telescopic Column Arm (Refer to Illustration 1).

•

For Table positioning, a good reference is to install it at 748 mm from

the longitudinal Axis of the Table Bucky to the Column Base Back Wall

for Non Telescopic Column Arm, (Refer to Illustration 1) and 942 mm for

Telescopic Column Arm (Refer to Illustration 1).

11

A

12

12

(0.5”)

DETAIL A

480

(18.9”)

20

(0.8”)

DETAIL B

10

(0.4”)

1215

(47.8”)

480

(18.9”)

200 Min.

(7.9”)

480

(18.9”)

480

(18.9”)

1693 Min.

(66.7”)

100

(3.9”)

1140 Max.

(44.9”)

(*) 155 Min (6.1”)

275 Max (10.8”)

(*)

Distances in italic- bold correspond to

Rooms with optional Telescopic Arm

885

691

(27.2”) (34.8”)

113

(4.5”)

434

(17.1”)

40

(1.6”)

B

1215

(47.8”)

1021

(40.2”)

1091

(43”)

897

(35.3”)

248

(9.8”)

942

(37.1”)

748

(29.5”)

457

(18”)

3650 Min.

(143.7”)

REV 4

20

(0.8”)

GE Healthcare

Proteus XR/e

sm 2401594--100

Illustration 1

Drilling Template

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Illustration 1 (cont.)

Drilling Template

(*) Depends on type of spacer used

(*)

155

(6.1”)

140

(5.5”)

41

Film

(1.6”)

(9.8”)

Floor Cable Entrance

(4”)

Wood Block 600 x 25 mm (23.5” x 1”)

2 Wall Drilling Holes for M10 Bolts

(1.2”)

(2.4”)

2165 mm (85.2”)

STANDARD WALL BUCKY STAND

(*) Depends on type of spacer used

338(13.3”)

(*)

155

(6.1”)

Film 1

69

40

(2.7”)

(1.5”)

Film 2

(4”)

(9.8”)

Floor Cable Entrance

(1.2”)

(*) Depends on type of spacer used

Minimum 155 mm (6.1”)

Maximum 275 mm (10.8”)

(2.4”)

Film 1 -- Film in the Extended Cassette

Film 2 -- Film in the Cassette of the Tray

2 Floor Drilling Holes for M10 Bolts

13

40x120 WALL BUCKY STAND (optional)

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Illustration 1 (cont.)

Drilling Template

OPTIONAL FLOOR AND WALL SUPPORTS

FOR LINE POWERED GENERATORS

(ONLY 1 TUBE -- LOW SPEED STARTER)

OPTIONAL FLOOR AND WALL SUPPORTS

FOR LINE POWERED GENERATORS

(1 or 2 TUBES -- LOW or HIGH SPEED STARTER)

592

445

57

83

57

57

68

67

57

57

57

57

57

57

57

57

40

280

250

206

Wall Support

336

150

150

33 40

33

40

251

580

105

110

435

Floor Support

234

224

Floor Support

19

40

19

40

Wall Support

200

150

200

8

8

80

28

28

68

40 44

57

44

67

462

315

14

Proteus XR/e

GE Healthcare

REV 4

3.2

sm 2401594--100

FLOOR MOUNTED TUBE STAND

1.

Position the Column Base on the floor according to the distribution plan

for the RAD Room. Keep in mind the dimensions and final position of

each component in the System (Column, Wall Bucky, Table, etc.).

The Column Base has to be placed with the Brake Track at the rear side

and perpendicular to the wall where the Vertical Bucky will be installed.

2.

Mark the position of the ten (10) anchoring holes on the floor. Move the

Base and drill the anchoring holes. Bolts and hardware are field provided.

3.

Check the leveling in different points on the Base and adjust it by using

leveling plates. Anchor slightly the Base to the floor.

4.

Remove the Rail Stop from one of the Base laterals. Rail Stops can be

installed in the front or in the rear rails.

Illustration 2

Column Base

BRAKE TRACK

ANCHORING HOLES

BUCKY - COLUMN BASE LINK

(OPTIONAL)

COLUMN SCREWS

COLUMN FOOT

BRAKES

COLUMN CARRIAGE

5.

With the Column laid on the floor, remove the Upper Cap and Upper Front

Cover (both are secured with two screws). (Refer to Illustration 3).

6.

Stand the Column up, in line with the Column Base.

7.

In order to ease the placement of the Column inside the Base, remove

or loosen the Column Foot Brakes located at the rear side of the Column

Foot. (Refer to Illustration 2).

8.

Carefully slide the Column into the Base.

15

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Do not remove the Counterweight Safety Bar nor the two

Shipping Safety Screws close to the Vertical Carriage until

specifically instructed to do so in this document.

Make sure that the iron cables are properly routed around the

pulleys before standing the Column up.

9.

Reinstall the Rail Stop at the lateral side of the Base and the Column Foot

Brakes.

10.

Vertically level the Column (both laterals and front side). Adjustments are

carried out by means of the leveling plates at the Column Base. Anchor

the Base tightly to the floor. (Refer to Illustration 3).

Illustration 3

Column Base

UPPER CAP

UPPER FRONT COVER

COUNTERWEIGHT SAFETY BAR

LEVELS

UPPER FRONT COVER

SHIPPING SAFETY SCREW

VERTICAL CARRIAGE

COLUMN FOOT

BASE

ANCHORING HOLES

16

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

11.

To facilitate the installation of the Tube-Collimator Assembly, remove the

two Shipping Safety screws close to the Vertical Carriage and re-install

them in the medium position of the Column (refer to Illustration 4).

Then remove the Counterweight Safety Bar while the Vertical Carriage

is held in position. Carefully move the Vertical Carriage up to the Shipping

Safety screws.

Illustration 4

Removing the Counterweight Safety Bar

COUNTERWEIGHT SAFETY BAR

SHIPPING SAFETY SCREW

VERTICAL CARRIAGE

SHIPPING SAFETY SCREW

VERTICAL CARRIAGE

COLUMN FOOT

COLUMN FOOT

BASE

BASE

17

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

12.

Install the Tube-Collimator Support to the Column Arm (Coupling Plate)

by using the four screws mounted at the rear side of the Support (upper

and lower holes). The two rods will be used to level the Support when all

the components are assembled.

Illustration 5

Coupling of Tube-Collimator Support -- Rear View

Coupling Plate of the Column Arm(Fixed SID)

Coupling for Telescopic Arms

Coupling Screws

Tube-Collimator Support

Coupling for Non Telescopic Arms

Tube-Collimator Support

Levelling Rods

13.

Tube-Collimator Support

On the backside of the Control Panel, remove the six (6) Allen Screws

that fix the Control Panel Cover to the Control Panel and then dismount

the Control Panel Cover.

Allen Screws

14.

Pass the GND wire and the Rot/Transv Lock Cable (A7220-XX) through

the left hole and the Vertical Lock Cable (A7219-XX) through the right

hole; connect these cables to TS2 inside the Control Console as shown

in block diagram 54301085.

Connection for A7219 & A7220 to TS2

GND

18

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Note

15.

Remount the Control Panel Cover and fix it with the six (6) Allen Screws.

16.

Install the Column Control Panel by using the two bolts in the rear side

of the Control Panel.

17.

Carefully remove the Collimator Adaptation Ring from the Collimator.

.

When removing the Adaptation Ring, the screws could fall into the

Collimator which may cause later damage to the Collimator.

18.

Install the X-ray Tube on its Support using the Collimator Adaptation Ring

and its four Security Screws (Allen).

Illustration 6

X-ray Tube, Collimator and Control Panel

X-RAY TUBE

CONTROL PANEL

COLLIMATOR

COLLIMATOR ADAPTATION RING

19.

Before installing the Collimator, unscrew the four Centering Adjustment

and Security Screws of the Collimator Adaptation Ring using the same

number of turns to allow an even Collimator fastening. Adjust the

Collimator Blades to their widest setting and carefully install the

Collimator centering it with the X-ray Tube window.

Tighten the four Centering Adjustment and Security Screws (Allen)

equally (same number of turns) until the Collimator is centered and held

firm on the Collimator Adaptation Ring. (See the Collimator Manual).

19

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

20.

Level the Tube-Collimator Assembly on the Tube and Collimator base.

Adjust the horizontal level by using the two rods on the backside of the

Coupling Plate (Arm).

21.

Remove the two Shipping Safety screws close to the Vertical Carriage.

The weight of the Counterweight is equal or slightly greater than the

weight of the Carriage + Arm + Tube + Collimator + Console. It is factory

adjusted including the HV Cables of the Tube that will be installed later.

22.

Install the Upper Front Cover and then the Upper Cap (both are secured

with two screws). Install the Foot Cover of the Column by snapping it in.

Illustration 7

Tube Support Arm Leveling

UPPER CAP

UPPER FRONT COVER

SHIPPING SAFETY SCREW

LEVEL

LEVELING RODS

VERTICAL CARRIAGE

LEVEL

20

Proteus XR/e

GE Healthcare

REV 4

3.3

sm 2401594--100

RADIOGRAPHIC TABLE

1.

Remove the transport screws that secure the Radiographic Table to the

pallet and move away the Table.

2.

Remove the front cover screws of the Table in order to access inside the

Table.

3.

Power ON the Collimator Lamp and align perfectly the Bucky axes with

the Collimator light beam. During alignment, place the Tube-Collimator

Assembly and the Bucky Carriage at different positions to check that it

is correctly aligned.

4.

Mark on the floor the four anchoring holes of the Table Base.

ANCHORING HOLES

Note

5.

Move away the Table Base and prepare its anchors.

6.

Position the Table Base at its final place and anchor the Table Base to the

floor. Check that it is properly leveled placing levels in different points of

the Upper Frame. Use leveling plates to level the Base, before securing

definitively the Table.

.

Use an extended level (1 meter) or several standard levels placed

in different points for leveling the Table Base.

7.

Connect the Power Supply cable for the Table Locks from the Table TS1

the TB7 of the Lock Board in the Generator, and connect the GND cable

from the Table Base to the GND Stud in the Generator (refer to

schematics 54302065).

21

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

8.

Connect the Table Bucky Cables as per Bucky schematics. The Bucky

ground cable (yellow/green) must be connected to the GND Stud in the

Generator.

9.

Bucky link option. If this option is provided, although the Bucky Link is

factory-levelled, it may require height adjustment. Four (4) Bucky Link

Screws fix the Link through a Fitted--slot Plate which may be used for this

adjustment.

The Base Screws may also be used for height adjustment; but if doing

so, the Microswitch must also be adjusted by using the Slot Screws

shown in the photo below.

Bucky Link Screws

Switch Slot Screws

Bucky Link

Base Screws

Cover Screws

22

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

10.

Route the cables through the rear cables outlet of the Table Base along

the room for their later connection.

11.

Re-install the Front Cover of the Table Base.

12.

Remove the two rubber stops of the same end of the Table-Top.

To avoid damage to the Lock Pin of the longitudinal lock of

the Table-Top, place the Lock Pin in its lower position and

secure it by using a wire ty-wrap before sliding the Table-Top

over the frame.

LOCK PIN

WIRE TY-WRAP

23

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

13.

Install the Table-Top from one of the Table sides (right or left) inserting the

Bearings inside of their Rails. At least two people are required for this

operation.

Be sure that the Table-Top slides over the bearings and

Longitudinal Lock Pin do not block its way.

14.

Remove the wire ty-wrap of the Longitudinal Lock Pin.

15.

Re-install the rubber stops of the Table-Top end.

24

Proteus XR/e

GE Healthcare

REV 4

3.4

sm 2401594--100

WALL STAND

The Shipping Safety Screws used to block carriage

movement and the Counterweight Safety Bar are used to

prevent not only damage during shipment but also unwanted

weight imbalance in the column during installation.

The counterweights come pre-adjusted for the weight of the

Bucky with the Tray inserted. Make sure that the mechanical

brake is secure before releasing the safety screws.

There are three options for this assembly: A) Spacers anchored to the wall;

B) Wall Support; C) Column anchored directly to the wall (No support between

the Wall Bucky Stand and the wall).

1.

Place the Wall Stand in Vertical position.

Illustration 8

Wall Bucky Stand

ANCHORING HOLES

COUNTERWEIGHT SAFETY BAR

UPPER CAP

UPPER FRONT COVER

LEVELS

SHIPPING SAFETY SCREW

VERTICAL CARRIAGE

BASE

ANCHORING HOLES

25

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

2.

Remove the Upper Cap and Upper Front Cover. The two lower screws

shown in the photo below are used to secure the Upper Front Cover to

the Column. The tool below is an Allen Type Screwdriver.

3.

Remove the Counterweight Safety Bar (behind the Front Cover).

4.

Remove the Shipping Safety Screws from the Carriage Rails. For this

operation, it is advisable to have a person pushing the Bucky Assembly

downwards to ease the removal (Mechanical Brake should be released).

Shipping Safety Screw

Counterweight Safety Bar

5.

Lock the Carriage with the Mechanical Brake.

6.

Decide wether installing the wall anchors with the supplied Small

Spacers, Wall Support or nothing to separate the Wall Bucky Stand from

the wall.

7.

Place the Column at its desired final position in the room so that the

longitudinal axis of the X-ray Tube meets the vertical axis of the Bucky.

8.

Power ON the Collimator Lamp and correctly align the Wall Bucky axes

with the Collimator light beam (the counterweights are made for the

Bucky with the Cassette Tray). During alignment, place the

Tube-Collimator Assembly and the Bucky Vertical Carriage at different

heights to check that it is correctly aligned.

26

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

9.

If Column is to be anchored directly to the wall: Mark two of the upper

anchoring holes of the Column on the wall as well as the two anchoring

holes on the floor.

If using a Spacer or Wall Support: Separate the Column from the wall

and assemble the Spacer or Wall Support at the upper part of the Column

before marking the anchoring holes in the wall.

10.

Move the Column aside and prepare their anchors.

Illustration 9

Wall Stand -- Anchoring Holes and Dimensions

Wood Block 600 x 25 mm (23.5” x 1”)

2 Wall Drilling Holes for M10 Bolts

(*) Depends on type of spacer used

(*)

155

(6.1”)

140

(5.5”)

Film

(4”)

(9.8”)

2165 mm (85.2”)

Floor Cable Entrance

(1.2”)

(2.4”)

STANDARD WALL BUCKY STAND

(*) Depends on type of spacer used

Minimum 155 mm (6.1”)

Maximum 275 mm (10.8”)

2 Floor Drilling Holes for M10 Bolts

27

41

(1.6”)

Proteus XR/e

GE Healthcare

REV 4

3.5

sm 2401594--100

11.

Position the Column and secure it to the floor and wall. Check that it is

properly leveled in both laterals and front side. Use the leveling plates

provided to raise and level the Column previous to secure it definitively.

(Refer to Illustration 8).

12.

Install the Upper Front Cover and then the Upper Cap (both are secured

with two screws). Install the Foot Cover of the Column pushing it.

13.

Route the cables along the room to the Generator for their later

connection.

UNDERTABLE INSTALLATION OF THE GENERATOR (OPTION)

Follow the steps below to install the Generator underneath the Table.

1.

Remove the Front Cover after unscrewing the four (4) screws.

FRONT COVER SCREWS

2.

Disconnect the ground cable and dismount the front cover.

3.

Disconnect the three faston terminals of microswitch SW1 located inside

the Table Base.

4.

Remove the four (4) allen screws of the pedal assembly at both sides of

the Table Base (a pair on each side) and pull out the pedal assembly.

MICROSWITCH SW1

PEDAL ASSEMBLY SCREWS

28

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

5.

Place the Generator Cabinet (without covers) on its carriage in front of

the Table. This component is freestanding below the Table. Seismic

areas and other conditions require the Generator Cabinet to be secured

to the floor through the mounting holes on the bottom.

GENERATOR CARRIAGE

Note

.

Do not slide the Generator under the Table until Configuration and

Calibration procedures are completed. Refer to the Generator

Service Manual for further information.

6.

Once configured and calibrated, push the Generator inside the Table.

7.

Reassemble all of the components, parts and connections; then replace

the Front Cover of the Table.

29

Proteus XR/e

GE Healthcare

REV 4

3.6

sm 2401594--100

WALL BUCKY STAND 40 X 120 (OPTIONAL)

The Shipping Safety Screws used to block carriage

movement and the Counterweight Safety Bar are used to

prevent not only damage during shipment but also unwanted

weight imbalance in the column during installation.

The counterweights come pre-adjusted for the weight of the

Bucky with the Tray inserted. Make sure that the mechanical

brake is secure before releasing the safety screws.

There are three options for this assembly: A) Spacers anchored to the wall;

B) Wall Support; C) Column anchored directly to the wall (No support between

the Wall Bucky Stand and the wall).

1.

Place the Wall Stand in Vertical position.

Illustration 10

Wall Bucky Stand

UPPER CAP

ANCHORING HOLES

COUNTERWEIGHT SAFETY BAR

UPPER FRONT COVER

LEVELS

SHIPPING SAFETY SCREW

VERTICAL CARRIAGE

BASE

ANCHORING HOLES

30

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

2.

Remove the Upper Cap and Upper Front Cover. The two lower screws

shown in the photo below are used to secure the Upper Front Cover to

the Column. The tool below is an Allen Type Screwdriver.

3.

Remove the Counterweight Safety Bar (behind the Front Cover).

4.

Remove the Shipping Safety Screws from the Carriage Rails. For this

operation, it is advisable to have a person pushing the Bucky Assembly

downwards to ease the removal (Mechanical Brake should be released).

Shipping Safety Screw

Counterweight Safety Bar

5.

Lock the Carriage with the Mechanical Brake.

6.

Decide wether installing the wall anchors with the supplied Small

Spacers, Wall Support or nothing to separate the Wall Bucky Stand from

the wall.

7.

Place the Column at its desired final position in the room so that the

longitudinal axis of the X-ray Tube meets the vertical axis of the Bucky.

8.

Power ON the Collimator Lamp and correctly align the Wall Bucky axes

with the Collimator light beam (the counterweights are made for the

Bucky with the Cassette Tray). During alignment, place the

Tube-Collimator Assembly and the Bucky Vertical Carriage at different

heights to check that it is correctly aligned.

31

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

9.

If Column is to be anchored directly to the wall: Mark two of the upper

anchoring holes of the Column on the wall as well as the two anchoring

holes on the floor.

If using a Spacer or Wall Support: Separate the Column from the wall

and assemble the Spacer or Wall Support at the upper part of the Column

before marking the anchoring holes in the wall.

10.

Move the Column aside and prepare their anchors.

Illustration 11

Wall Bucky Stand -- Anchoring Holes and Dimensions

Wood Block 600 x 25 mm (23.5” x 1”)

2 Wall Drilling Holes for M10 Bolts

(*) Depends on type of spacer used

338(13.3”)

(*)

155

(6.1”)

Film 1

69

40

(2.7”)

(1.5”)

Film 2

(4”)

(9.8”)

2165 mm (85.2”)

Floor Cable Entrance

(1.2”)

(2.4”)

Film 1 -- Film in the Extended Cassette

Film 2 -- Film in the Cassette of the Tray

40x120 WALL BUCKY STAND (optional)

(*) Depends on type of spacer used

Minimum 155 mm (6.1”)

Maximum 275 mm (10.8”)

2 Floor Drilling Holes for M10 Bolts

32

Proteus XR/e

GE Healthcare

REV 4

3.7

3.7.1

sm 2401594--100

11.

Position the Column and secure it to the floor and wall. Check that it is

properly leveled in both laterals and front side. Use the leveling plates

provided to raise and level the Column previous to secure it definitively.

(Refer to Illustration 8).

12.

Install the Upper Front Cover and then the Upper Cap (both are secured

with two screws). Install the Foot Cover of the Column pushing it.

13.

Route the cables along the room to the Generator for their later

connection.

14.

Route and connect the following cables to the Generator: 3TS1 and

Ground as per schematics 5432039 and IF-048.

INTERCONNECTION CABLES

CABLES FROM FLOOR MOUNTED TUBE STAND

1.

Connect aerial cable connections J1-J1 (Lock cables from the Vertical

Carriage) and J2-J2 (from the Column Control Panel) located at the

Tube-Collimator Support (refer to Interconnection Map IM 341).

2.

Connect the Collimator Lamp (if not already connected).

3.

Route all cables from the Collimator and X-ray Tube along the Arm,

securing them with the Cable Clamp over the Arm.

CABLES CLAMP

4.

Ground cables should be connected to the main Generator GND stud.

33

Proteus XR/e

GE Healthcare

REV 4

3.7.2

3.7.3

sm 2401594--100

CABLES FROM RADIOGRAPHIC TABLE

1.

Route and connect the Locks cables (24V Power Supply) from the Table

to Terminal Block TB7 of the Locks Board (Refer to Fixed Table Block

Diagram 54302065).

2.

The Table Bucky Cable runs directly to Terminal Block 3TS1 of the

Generator Cabinet (refer to Interconnection Map IM 341).

3.

Ground cable should be connected to the main GND stud in the

Generator.

CABLES FROM TABLE / WALL BUCKY

Cables from the Bucky are connected directly to the Terminal Block 3TS1 of the

Generator Cabinet as indicated in Section 8 “System Interconnections Maps”

(refer to Map -- IM 341) and in “Installation” chapter of the “Generator Service

Manual sm2401593--100” (refer to Bucky Connections and Maps IF-001 and

IF-002). Check the Bucky operation before connecting the Ion Chambers (if

applicable).

34

Proteus XR/e

GE Healthcare

REV 4

3.8

sm 2401594--100

INSTALLATION OF THE ADHESIVE SCALES FOR SID REFERENCE

The System includes 2 autoadhesive scales for operator easy reference. The

scale for the Wall Bucky Stand SID reference is stuck on the Column Base and

the Scale for the Table Bucky SID reference is stuck on the Tube-Support

Column.

The following illustrations show the recommended placing of the scales

although it is the operator convenience what the installer should meet.

1.--

Place the Tube-Collimator Assembly at

91.5 cm (40”) from the table-top.

For that, measure with the Collimator tape.

(91.5 + 8.5 tabletop-Film distance).

2.--

Mark the Position of the LOWER PART of the

Carriage in the Column.

3.--

Raise the Tube-Collimator Assembly.

4.--

Stick the Scale, for that make sure that the

100 (40”) in the scale coincides with the mark.

91.5 cm (36”)

Scale Mark 100 cm (40”)

The reference mark is the lower part of the carriage

100 cm (40”)

Illustration 12

Installation of Vertical SID Scale in the Column

8.5 cm (3.3”)

Tabletop -- Film distance

35

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

2.--

Mark the Position of the RIGHT SIDE of the Carriage on

the Base of the Column.

3.--

Move away the Tube-Collimator Assembly.

4.--

Stick the Scale, for that make sure that the 100 (40”)

in the scale coincides with the mark.

Scale Mark

(100 cm (40”)

The reference mark

is the Side part of the carriage

4.1 cm (1.6”)

95.9 cm (37.7”)

Place the Tube-Collimator Assembly at 95.9 cm (37.7”)

from the table-top of the Wall Bucky Stand. For that

measure with the Collimator Tape.

(95.9 + 4.1 tabletop-film distance = 100 cm)

100 cm (40”)

1.--

COLUMN BASE

Illustration 13

Installation of Horizontal SID scale on the Column Base with the Wall Bucky Stand at the Right

side of the room

Tabletop -- Film distance

GENERATOR

WALL BUCKY STAND

36

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

1.--

Place the Tube-Collimator Assembly at 95.9 cm (37.7”)

from the table-top of the Wall Bucky Stand. For that

measure with the Collimator Tape.

(95.9 + 4.1 tabletop-film distance = 100 cm)

2.--

Mark the Position of the LEFT SIDE of the Carriage on

the Base of the Column.

3.--

Move away the Tube-Collimator Assembly.

4.--

Stick the Scale, for that make sure that the 100 (40”)

coincides with the mark.

Scale Mark

(100 cm (40”)

4.1 cm (1.6”)

The reference mark

is the Left Edge of the carriage

95.9 cm (37.7”)

100 cm (40”)

COLUMN BASE

Illustration 14

Installation of Horizontal SID scale on the Column Base with the Wall Bucky Stand at the Left side

of the room

Tabletop -- Film distance

GENERATOR

WALL BUCKY STAND

37

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

This page intentionally left blank.

38

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

SECTION 4

4.1

FINAL INSTALLATION AND CHECKS

FLOOR MOUNTED TUBE STAND

Install the Cable Support on the upper right/left side of the Column. Route and

Fasten all the cables to it by using cable ties (tie wraps) as strain reliefs.

TOP OF COLUMN

CABLE SUPPORT

CABLE SUPPORT

Position the Floor Mounted Tube Stand with the Tube-Collimator Assembly

facing the Wall Bucky. With the Collimator Metric Tape, measure the SID from

the Collimator to the Wall Bucky to determine the position where the Column

should stop when the required SID is reached (1 m, 1.8 m, 2 m, etc.). Drill the

Base and install the Centering Plates where the Column has to stop. Adjust the

Longitudinal Detent. on the Column Foot.

Illustration 15

Centering Plate in Base

COLUMN FOOT

CAP OF DETENT

COLUMN BASE

CENTERING PLATE

LONGITUDINAL DETENT

39

Proteus XR/e

GE Healthcare

REV 4

4.2

sm 2401594--100

CABLE FASTENING AND COVERS

Note

.

Before re-installing the cabinet covers, perform the rest of the

Calibration procedures if required.

Ensure that all cables are correctly routed and that electrical connections are

firm and secure. Remove the ferrite blocks that are factory clamped to the

cables when required to carry out a correct routing; re-installing them at the

same place around cables once routing is completed. (Refer to Section 3.7)

In order to avoid signal interferences, it is strongly

recommended to fold and fasten the portion of cables not

routed close to Generator Cabinet (see picture below). Never

wrap in circles.

YES

NO

Reinstall Cabinet Covers and connect internal ground wires. Power line, High

Voltage and Interconnections cables must go through the cable outlet.

40

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

SECTION 5

5.1

ADJUSTMENTS

PERPENDICULAR BALANCE

Due to differences in some Tube and Collimator weights, the balance for the

Tube-Collimator Assembly may need adjustment. Position the Tube-Collimator

Assembly around 70o and release the brakes (switch off the system), if the

assembly does not remain in position and rotates either upwards or downwards,

perform the following steps to adjust the balance of the Tube-Collimator

Assembly.

1.

Place the Tube-Collimator Assembly at 0o.

2.

Installing both Shipping Safety Screws in the Column rails (medium

height of the Column) and move/lock the Central Carriage in this position.

3.

Once the Central Carriage is locked in position, adjust the balance of the

Tube-Collimator Assembly by moving the Tube-Collimator Support one

level upward or downward respect to the Coupling Plate of the Column

Arm.

G

If during the test, the Collimator tends to be facing up, move the

Support one level downward. (Refer to Illustration 15-1 for more

information).

G

If during the test, the Collimator tends to be facing down, move the

Support one level upward. (Refer to Illustration 15-2 for more

information).

At least two (2) people are needed to carry out this

adjustment, one for holding the Tube-Collimator Assembly

while the other secures the Support to the Coupling Plate.

4.

Check the balance of the Tube-Collimator Assembly again and repeat

the above steps if needed.

41

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Illustration 16

Coupling of Tube-Collimator Support -- Rear View

Coupling Plate of the Column Arm(Fixed SID)

Coupling Screws

Tube-Collimator Support

Levelling Rods

Coupling for Telescopic Arms

Tube-Collimator Support

Coupling for Non Telescopic Arms

Tube-Collimator Support

42

Proteus XR/e

GE Healthcare

REV 4

5.2

sm 2401594--100

BRAKE ADJUSTMENT

Note

.

As brakes come factory-adjusted, field adjustment should only be

necessary when replacing Brakes.

All brakes must have a space between the brake surface and the actioned

surface of less than or equal to one (1) millimeter (≤1mm). If the space is too

close, the equipment may drag, or movements may be difficult. If the space is

too large, the brakes may not be strong enough to block movement.

5.2.1

TABLE BRAKES (LATERAL AND BUCKY)

To raise, lower or level the Brake Assembly, loosen the screws indicated in the

following illustration and move the Brake Assembly to the desired position.

Illustration 17

Lateral and Bucky Brakes

Screws

Lateral Brakes

Screws

Bucky Brake

43

Proteus XR/e

GE Healthcare

REV 4

5.2.2

sm 2401594--100

COLUMN VERTICAL BRAKES (LEFT AND RIGHT)

The Vertical Brakes are levelled, raised or lowered by loosening the two (2)

screws as in Illustration 18 and then adjusting the Brake Assembly position.

Illustration 18

Column Vertical Brakes (Left shown)

Screws

Space

5.2.3

COLUMN FOOT BRAKES (LEFT AND RIGHT)

Column Foot Brakes are levelled, raised or lowered by dismounting the Brakes

and then loosening or tightening the two (2) Set Screws as in Illustration 19.

Illustration 19

Column Foot Brakes

Screws

Set Screws

44

Proteus XR/e

GE Healthcare

REV 4

5.3

sm 2401594--100

PEDAL MICROSWITCH REPLACING AND ADJUSTMENT

1.

Remove the Table Front Cover.

2.

Disconnect Microswitch cables (check previously the cable identification

to connect the cables to the new switch in the same position).

3.

Remover nut 2, for that hold nut 1 with a 14 mm. open wrench and loose

nut 2 with another 14 mm. Remove nut 2.

4.

Remove defective Microswitch.

5.

Install the new Microswitch.

6.

Adjust the Microswitch at 1 or 2 mm. from the cam to the wheel neck with

the Table Pedal fully pressed.

Illustration 20

Microswitch Replacement

Nut 1

Nut 2

Microswitch Wheel

Wheel neck

Adjust at 1 or 2 mm

CAM

45

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

7.

Check that the rolling wheel is perfectly aligned with the cam movement

to ensure proper activation of the wheel.

8.

Avoid wrong assembling of Microswitch as shown in illustrations below:

Illustration 21

Wrong Installation of Microswitch

Rolling wheel not aligned

Rolling wheel not aligned

Rolling wheel too close to cam, microswitch breaks

9.

Re-install the Table Font Cover.

46

Proteus XR/e

GE Healthcare

REV 4

5.4

sm 2401594--100

ECCENTRIC BEARING ADJUSTMENT FOR THE FLOOR MOUNTED TUBE

STAND

Adjustment of the two Eccentric Bearings (factory set) at the Column Foot to

remove a possible gap between the Bearings of the Column Foot and the

Column Base. The photo below shows a perfect fit (no gap) for one of the

Eccentric Bearings.

Illustration 22

Eccentric Bearing Adjustment

Bearing Track at Column Base

Column Foot

Possible Gap

Eccentric Bearing

5.4.1

TOOLS

Note

.

•

Standard service engineers tool kit.

•

Specially--designed Wrench (supplied with the unit).

This on-site adjustment is only necessary if the Column Base is

replaced and/or a gap is present between the Column Foot and the

Column Base. Movements not smooth and/or wobbling.

47

Proteus XR/e

GE Healthcare

REV 4

5.4.2

sm 2401594--100

FIELD ACTION

1.

Remove the Rail Stop from each one of the Base Lateral and place the

Column Foot into the Column Base as shows the image in order to

evaluate the space between the Eccentric Bearing and the Column Base.

The two Eccentric Bearing are located at the rear side of the Column

Foot.

2.

If the Eccentric Bearing does not fit perfectly into the Bearing Track of the

Column Base, adjust the bearing by first loosening the nut below the plate

with the Standard Wrench (see photo below).

3.

Adjust the bearing to the required position (above the plate) with the

Special Wrench (supplied) and then tighten the nut to secure the position

with the Standard Wrench (see photo below).

Plate

Special Wrench (supplied)

Standard

Wrench

Note

.

The bearing should fit perfectly, as shown on the first page.

4.

Slide the Column to the other end and repeat the same sequence of

procedures for the other bearing.

5.

Verify that the movement of the Floor Mounted Tube Stand is smooth and

without wobbling.

48

Proteus XR/e

GE Healthcare

REV 4

5.5

sm 2401594--100

ALIGNMENTS

The following Tools are used to adjust the X-ray System (these tools are not

included with the System):

5.5.1

•

Collimator Test Tool (Model RMI 161B9).

•

Beam Alignment Test Tool (Model RMI 162A).

•

SID Test Stand Tool (Inside Case: RMI Model 175).

•

Light Meter (Standard).

X-RAY BEAM ALIGNMENT

1.

Place the Tube-Collimator Assembly facing the Horizontal Bucky at a SID

of 1 meter. Check for a level and correct horizontal position of both the

Tube-Collimator Assembly and Table-Top.

2.

Turn on the Collimator Lamp and center the light with the Bucky.

Horizontal and transverse position of light axes projected by the

Collimator Lamp must be in line with the axes of the horizontal Bucky.

If needed, modify the position of the Collimator by carefully unscrewing

or screwing the four Centering Adjustment and Safety Screws (Allen).

Illustration 23

Collimator -- Centering Screws

CENTERING ADJUSTMENT AND SAFETY SCREWS

49

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

3.

Position the Collimator Test Tool (RMI model 161B) on the Table-Top.

4.

Turn on the Collimator Lamp and, by means of the Collimator Control

Knobs, center the Collimator Test Tool with the light axes projected by the

Collimator Lamp.

5.

Adjust the Light Field of the Collimator Lamp to the rectangle within the

Collimator Test Tool.

6.

Place the Beam Alignment Test Tool (RMI model 162A) on the center of

the Collimator Test Tool.

Illustration 24

Alignment Test Tools

BEAM ALIGNMENT TEST TOOL -- RMA MODEL 162A

COLLIMATOR TEST TOOL -- RMA MODEL 161B

7.

Load the Cassette Film Tray with a cassette film of 24x30 and insert it into

the Bucky.

8.

Make an exposure at 60 kVp / 5 mAs.

9.

Process film and:

a.

Check that the X-ray Field falls just within the image of the inner

rectangle of the Collimator Test Tool.

An edge of the X-ray Field outside of the inner rectangle means a

misalignment of the Light Field with the X-ray Field. The maximum

acceptable misalignment is 2 % of the SID (for SID 1m = 2 cm

tolerance).

Refer to Section 5.5.1.1 for alignment of the Light Field with the X-ray Field.

50

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

b.

Check that the X-ray Beam is perpendicular to the plane of the

Image Receptor. If the Image receptor is parallel to the Table-Top,

the perpendicularity of the X-ray Beam can be checked using the

Beam Alignment Test Tool along with the Collimator Test Tool.

Based on next illustration, the criteria for the SID at 1 meter is:

-- If the image of the two balls coincide as in the first drawing (A),

the X-ray Beam is perpendicular; within 0.5o.

-- If the image of the top ball (larger shadow) is within the threshold

of the first circle (B), the X-ray Beam is about 1.5o away from the

perpendicular.

-- If the image of the top ball (larger shadow) is within the threshold

of the second circle (C), the X-ray Beam is about 3o away from the

perpendicular.

In cases (A) and (B), perpendicularity is within tolerance for a SID

at 1 meter (top ball is within the threshold of the first circle). The

third case (C) needs readjustment.

Refer to Section 5.5.1.2 for perpendicularity adjustment.

A

c.

B

C

Check that the X-ray Beam is centered within the Image Receptor.

To determine the center of the Image Receptor, draw diagonal

lines from corner to corner of the X-ray Film. (Alternatively, the film

can be folded in half and creased at the center).

The two lines will cross in the center of the Image Receptor (film).

Draw diagonal lines from the corners of the imaged X-ray Field.

When the X-ray Field and Image Receptor centers coincide, the

diagonals of both sets of lines cross at the same point. The

maximum misalignment allowed is 2 % of the SID (for a SID of

1m = 2 cm tolerance).

Refer to Section 5.5.1.3 to center the X-ray Field with the Image

Receptor.

51

Proteus XR/e

GE Healthcare

REV 4

5.5.1.1

sm 2401594--100

LIGHT AND X-RAY FIELD ALIGNMENT

1.

Turn on the Collimator Lamp and place the Tube-Collimator Assembly

perfectly centered with the Horizontal Bucky (use the mark on the Bucky

Tray Handle as a reference for centering). With a level, check for correct

horizontal positioning of the Tube-Collimator Assembly and Table-Top.

2.

Set the SID at 1 meter.

3.

Center the Collimator Test Tool (RMI model 161B) on the Table-Top with

the light axes projected by the Collimator Lamp.

4.

Adjust the Light Field of the Collimator Lamp to the rectangle drawn

inside the Collimator Test Tool.

COLLIMATOR TEST TOOL

52

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

5.

On the processed film, the adjustment required to meet the Light Field

with the X-ray Field will be shown by the deviation on the axes displayed

on the film.

PROCESSED FILM

COLLIMATED LIGHT FIELD

COLLIMATED X-RAY FIELD

LIGHT FIELD MISALIGNMENT

PROCESSED FILM

COLLIMATED LIGHT FIELD = COLLIMATED X-RAY FIELD

LIGHT FIELD ALIGNMENT

53

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

6.

Adjust the Light Field by moving the Collimator Unit and/or Lamp; but do

not remove the Collimator Test Tool from its original position.

a.

Collimator Lamp must be ON during the Light Field adjustment.

b.

Modify the position of the Collimator by carefully unscrewing

and/or screwing the four Centering Adjustment and Safety Screws

(Allen) until the Light Field coincides with the reference axes of the

images (numbers and dots) on the processed film.

Illustration 25

Collimator Screws

CENTERING ADJUSTMENT AND SAFETY SCREWS

c.

7.

If adjustment is still necessary, modify the position of the

Collimator Lamp (refer to the Collimator Manual).

Repeat exposures and follow the same steps in this section until a

satisfactory result is acheived. The maximum misalignment allowed is

2 % of the SID (for a SID of 1m = 2 cm of tolerance).

54

Proteus XR/e

GE Healthcare

REV 4

5.5.1.2

sm 2401594--100

ADJUSTING PERPENDICULARITY (X-RAY BEAM AND IMAGE RECEPTOR)

In case the perpendicularity is out of tolerance (top ball is out of first circle),

adjust as follows:

1.

Place the Tube-Collimator Assembly perfectly centered with the

Horizontal Bucky (use the mark at the Bucky Tray Handle as a reference

for centering). Check with a level for the correct horizontal position of the

Tube-Collimator Assembly and Table-Top.

2.

Place the SID at 1 meter.

3.

Position the Collimator Test Tool (RMI model 161B) on the Table-Top.

4.

Turn on the Collimator Lamp and, by means of the Collimator Control

Knobs, center the Collimator Test Tool with the light axes projected by the

Collimator Lamp.

5.

Place the Beam Alignment Test Tool (RMI model 162A) centered on the

Collimator Test Tool (fix the Test Tool with adhesive or another product).

Turn on the Collimator Lamp and ensure that the shadow of the Beam

Alignment Test Tool is projected in equal proportion around it.

6.

Check for any required adjustment to center the top ball mark on the

processed film. The shadow around the Beam Alignment Test Tool can

also help to make a first correction.

7.

Loosen slightly the four Safety Screws (M6) at the rear side of the

Coupling Plate (Tube-Collimator Assembly). Then loosen or tighten the

two rods (Allen M5) to adjust horizontally the Tube-Collimator Assembly

with reference to the Horizontal Bucky. (Refer to Illustration 26).

If horizontal deviation is considerable, loosen the two Safety Screws of

the Arm (refer to Illustration 26), perform the horizontal adjustment and

tighten the two Safety Screws again. This adjustment is only possible for

Non Telescopic Arms.

8.

Repeat exposures and the procedure until the result is satisfactory (top

ball must be inside of the first circle).

55

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

Illustration 26

Safety Screws and Rods for Perpendicularity Adjustment

SAFETY SCREWS (M6)

COUPLING PLATE

LEVELING RODS (M5)

ARM SAFETY SCREWS (ALLEN)

COUPLING PLATE OF COLUMN ARM

SAFETY SCREWS

TUBE-COLLIMATOR SUPPORT

LEVELING RODS

56

Proteus XR/e

GE Healthcare

REV 4

5.5.1.3

sm 2401594--100

X-RAY FIELD AND IMAGE RECEPTOR (BUCKY ASSEMBLY) CENTERING

The error between the center of the X-ray Field and the Image Receptor should

not be greater than 2% of the SID. (for SID 1m = 2 cm tolerance).

CENTER OF THE IMAGE

CENTER OF THE X--RAY FILM

DEVIATION

If the deviation is greater than 2% of the SID, perform the following procedure:

1.

On the processed film, check for the correction required to center the

X-ray Field with the Image Receptor. Adjustments will be performed as

the same way described for Perpendicularity correction, so only re-adjust

if absolutely necessary.

Centering adjustments

corrections.

2.

may

affect

perpendicularity

Repeat exposures and check centering until the result is satisfactory

(center positions are within tolerance).

57

Proteus XR/e

GE Healthcare

REV 4

5.5.2

sm 2401594--100

X-RAY BEAM AND WALL BUCKY STAND ALIGNMENT

1.

Wall Bucky Stand has to be properly positioned and aligned with the

Tube-Collimator Assembly in its central position.

2.

Place the Tube-Collimator Assembly at a SID of 1 meter centered in front

of the Vertical Bucky. With a level, check for a correct vertical position of

the Tube-Collimator Assembly and Bucky Table-Top.

3.

Turn on the Collimator Lamp and center the Collimator with the Bucky

Table-Top.

The horizontal and transverse position of the light axes projected by the

Collimator Lamp must be in line with the axes or film sizes marked on the

Table-Top.

The horizontal and vertical position of the light axes projected by the

Collimator Lamp must be in line with the horizontal and vertical axes of

the Table-Top. (Alignment can also be performed by placing a mirror in

the center of the Table-Top and checking the Collimator light reflection).

If needed, readjust the position of the Wall Bucky Stand.

4.

Load the Cassette film Tray with a 24x30 cassette film and insert it into

the Bucky.

5.

Make an exposure at 60 kVp / 5 mAs.

6.

Process the film and check that the X-ray Beam is properly centered with

the Image Receptor.

a.

To determine the center of the Image Receptor, draw diagonal

lines from corner to corner of the X-ray film. (Alternatively, the film

can be folded in half and creased at the center). The two lines will

cross in the center of the Image Receptor (film).

b.

Draw diagonal lines from the corners of the imaged X-ray Field. If

the center of the X-ray Field and Image Receptor are the same, the

diagonals of both sets of lines should cross at the same point. The

maximum misalignment allowed is 2 % of the SID (for a SID of

1 m = 2 cm tolerance).

7.

If the deviation is greater than 2 % of the SID, correct the position of the

Wall Bucky Stand by adjusting its anchors at the wall and floor.

8.

Repeat exposures and check centering until the result is satisfactory

(center positions are within tolerance).

58

Proteus XR/e

GE Healthcare

REV 4

5.5.3

sm 2401594--100

FIELD SIZE INDICATOR TEST

Note

.

Before starting with the Field Size Indicator Test, the Alignment of

X-Ray Beam Test and the Alignment of Light Field with X-Ray Field

Test should be performed.

1.

Place the Tube-Collimator Assembly perfectly centered with the

Horizontal Bucky (use the mark at the Bucky Tray Handle as a reference

for centering). With a level, check for a correct horizontal position of the

Tube-Collimator Assembly and Table-Top.

2.

Position the SID at 1 meter.

3.

Open the Collimator blades, setting a Field Size of 24 x 30 cm for a SID

at 1 m.

4.

Turn on the Collimator Lamp and center the Collimator with the

Horizontal Bucky. The Horizontal and Transverse position of the light

axes projected by the Collimator Lamp must be in line with the axes of

the Horizontal Bucky.

5.

Load the Cassette Film Tray a Cassette Film of 35 x 43 cm centered and

insert it into the Bucky.

6.

Make an exposure at 60 kVp, 1 mAs.

7.

Process film and check the following measurements (refer to

Illustration 27):

a.

Measure the length of the X-ray Field on the Processed Film

(identified as L)

b.

Measure the width of the X-ray Field on the Processed Film

(Identified as W)

Illustration 27

X-ray Field Size

X-RAY FIELD SIZE ON THE FILM

PROCESSED FILM

LENGTH DIMENSION (L)

59

WIDTH DIMENSION (W)

FILM 35x43 cm

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

8.

With the measurements obtained and according to the field size

indication selected, the results should be:

G

Length dimension (L) = 300 mm

G

Width dimension (W) = 240 mm

9.

The difference between the indicated Field Size and the obtained Field

Size can not exceed 1.5 % (rejection limit) of the SID in either direction.

Therefore, the deviation in any direction should not be higher than 15 mm

(rejection limit) for a SID at 1 meter.

10.

If the deviation of the Field Size Indication is beyond acceptable limits,

it will be necessary to readjust the index of the Control Knobs of the

Collimator Blades: Loosen each Collimator Control Knob and position it

according to the deviation. Repeat the complete test until the X-Ray Field

Size selected (24 x 30 cm) is obtained.

5.5.4

COLLIMATOR LAMP BRIGHTNESS TEST

5.5.4.1

COLLIMATOR LIGHT FIELD INTENSITY

1.

Place the Tube-Collimator Assembly perfectly centered with the

Horizontal Bucky (use the mark at the Bucky Tray Handle as a reference

for centering). With a level, check for the correct horizontal position of the

Tube-Collimator Assembly and Table-Top.

2.

Position the SID at 1 meter.

3.

Open the Collimator Blades with the Collimator Control Knobs and set a

Field Size of 25 x 25 cm for a SID of 1m.

4.

Turn on the Collimator Lamp and center the Collimator with the

Horizontal Bucky. The horizontal and transverse positions of the light

axes projected by the Collimator Lamp must be in line with the axes of

the Horizontal Bucky.

5.

Place the Light Meter on the Table-Top with the sensor directed towards

the Light Source.

60

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

6.

Place the Light Meter in the center of a quadrant within the light field (refer

to Illustration 28).

Illustration 28

Light Meter on Table-Top

LIGHT SENSOR ON THE 2nd QUADRANT

1st QUADRANT

4th QUADRANT

3rd QUADRANT

LIGHT FIELD

LIGHT METER

7.

With Collimator Lamp OFF, measure and note the ambient light level.

8.

Without moving the Light Meter and with the Collimator Lamp ON,

measure and note the light level of the chosen quadrant.

9.

Determine the light intensity of this quadrant by subtracting the ambient

light level from the corresponding light level.

10.

Repeat these measurements at the approximate center of the other three

quadrants within the light field.

11.

With the measurements obtained in the step-10., the results of the Light

Field Intensity in all quadrants should be higher than 170 lux

(16 foot-candles) Among all the quadrants, the light field intensity should

not differ by more than 10%.

12.

The average illumination at a distance of 1 meter from the focal spot

should not be less than 160 lux (15 foot-candles). The rejection limit is

170 lux (16 foot-candles).

13.

If the deviation of the Light Field Intensity is beyond acceptable limits, the

following should be taken into account:

a.

If the difference of Light Field Intensity among all quadrants is

higher than 10%, the Collimator Lamp socket must be readjusted.

(Refer to the Collimator Manual).

61

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

b.

c.

5.5.4.2

If the light level in all quadrants is less than 170 lux, it is necessary

to check the following:

G

The lamp voltage level when it is ON should not be lower

than 24VAC. (Measure on the Bulb socket contact).

G

Check that the Collimator Lamp, the Mirror and the Mylar

window are not dirty or discolored.

G

The Mirror should be correctly positioned (Refer to the

Collimator Manual).

If the light level is still low:

G

Replace the Collimator Bulb.

G

Replace the Collimator Bulb socket.

COLLIMATOR LIGHT FIELD CONTRAST RATIO

1.

Center the Tube-Collimator Assembly perfectly with the Horizontal

Bucky (use the mark at the Bucky Tray Handle as a reference for

centering). With a level, check for a correct horizontal position of the

Tube-Collimator Assembly and Table-Top.

2.

Position the SID at 1 meter.

3.

Open the Collimator Blades to set a Field Size of 25 x 25 cm for a SID

of 1 m.

4.

Turn ON the Collimator Lamp and center the Collimator with the

Horizontal Bucky. The horizontal and transverse positions of the light

axes projected by the Collimator Lamp must be in line with the axes of

the Horizontal Bucky.

5.

Place the Light Meter on the Table-Top with the sensor directed toward

the Light Source.

6.

Place the Light Meter in the center of a quadrant within the light field.

(Refer to Illustration 28).

7.

Minimize the room lighting. With the Collimator Lamp OFF, measure and

record the ambient light level.

62

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

8.

Turn ON the Collimator Lamp. Measure the maximum illumination; this

should occur near the field center. Slide the light sensor along the

Table-Top and locate the point where the illumination drops to 75% of the

maximum. This point is defined by BRH as “lying on the edge of the Light

Field” (refer to Illustration 29). All subsequent measurements will be

referred to hereinafter using this definition of “edge”.

Illustration 29

Light Contrast Calculation

EDGE OF A QUADRANT

LIGHT SENSOR ON THE RIGHT EDGE

LIGHT SENSOR ON THE LEFT EDGE

BRH POINT

(LIGHT DROPS 25%)

9.

Measure the illumination at a point 3 mm from the edge of the field toward

the center of the field (Light sensor on the left of edge). (Refer to

Illustration 29). Record this value as I1.

10.

Measure the illumination at a point 3 mm from the edge of the field away

from the center of the field (Light sensor on the right of edge). (Refer to

Illustration 29). Record this value as I2.

11.

Correct the values of I1 and I2 by subtracting from each value the ambient

light level measured in step-7. Now divide the corrected value of I1 by

I2. This ratio should be 4 or more.

12.

Repeat the process from step-8. for all quadrants within the Light Field.

13.

If the deviation of Contrast Ration in the Light Field is beyond the

acceptable limits, it will be necessary check the following:

G

Check that the Collimator Lamp, the Mirror and the Mylar window

are not dirty or discolored.

G

The Light Field Intensity level should be higher than 170 lux.

G

The ambient light level should be low as possible due to the fact

that it affects the accuracy of these measurements.

63

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

This page intentionally left blank.

64

Proteus XR/e

GE Healthcare

REV 4

sm 2401594--100

SECTION 6

PERIODIC MAINTENANCE

The first maintenance service is to be performed before the end of twelve

months after the installation. The rest of maintenance services will be

performed according to the following table.

Table 1

Periodic Maintenance

Floor Mounted

Tube Stand

Radiographic Table

Wall Stand

Electrical cables and connections

Yearly

Yearly

Yearly

Mechanical cables

Yearly

N/A

Yearly

Brakes, locks and detents

Yearly

Yearly

Yearly

Functional Check

Yearly

Yearly

Yearly

Adjustment and calibration

Yearly

Yearly

N/A

Lubrication

Yearly

Yearly

Yearly

Cleaning

Yearly

Yearly

Yearly

Maintenance

6.1

MAINTENANCE ACTIVITIES DESCRIPTION

Electrical cables and connections: Visually check for electrical cables proper

isolation and proper connection inside and outside the unit.

Mechanical cables: Visually check for possible frayed cable and replace if

necessary.

Brakes, locks and detents: Perform a functional check of all the locks, brakes

and detents of the Room equipment. Adjust or replace as needed.

Functional Check: Perform a functional check of all Room equipment, motion

of Vertical Bucky, Table-top, Column travel, brakes, keys of consoles, lamps and

indicators, Collimator etc.

Adjustments and calibrations: Perform adjustments and Calibration of Table,

Column and Vertical Bucky as explained in the Adjustments Section of this

manual.

Lubrication: Lubricate mobile components such as chains, guides, bearings

etc as specifies in the Adjustments Section.

Cleaning: Clean from dust or moist inner components as Electronic Racks,

grids, filters, bearings and rails.

65

Proteus XR/e

GE Healthcare

REV 4

6.2

6.3

sm 2401594--100

CHECKING OF FLOOR MOUNTED TUBE STAND

1.

Turn OFF the system and mains. Check that there is not voltage at

Tube-Stand.

2.

Disassemble Front covers and check steel cable and brakes.

3.

Check anchoring screws, they should be strongly tighten.

4.

Turn ON the system and check that the Column and Tube-Collimator

Assembly is blocked in all motions.

5.

Check motion of Column: horizontal and rotation.

6.

Check motion of Tube-Collimator Assembly: vertical, Telescopic Arm

motion and rotation. Detents configured should be checked too.

7.

Place the Tube at 0o on the Table-Top and check that X-ray indicator lamp

and the chassis centering indicator are aligned and they turn off after

30 seconds.

8.

Check in the Collimator that light beam is centered with the X-ray beam

and the tolerance is not above 1% from focus-film distance.

CHECKING OF RADIOGRAPHIC TABLE

1.

Turn OFF the system and mains. Check that there is not voltage at Table.

2.

Disassemble Front Table cover.

3.

Check anchoring screws of the Table, they should be strongly tighten.

4.

Turn On the system and press the mushroom shaped switch. Verify that

Table is disconnected and the Table travels are blocked.

5.

Release the mushroom shaped switch.

6.

Connect Table power and check Table-Top brakes and correct motion by

pressing the Table pedal.

7.

Assemble the Front Table cover.

8.

Release the horizontal Bucky brakes and check correct traveling.

9.

Take out the Cassette film tray and check correct functioning.

66

Proteus XR/e

GE Healthcare

REV 4

6.4

6.5

sm 2401594--100

CHECKING OF WALL STAND

1.

Disassemble Front covers of Wall Stand and clean steel cable and

brakes.

2.

Check anchoring screws, they should be strongly tighten.

3.

Check the vertical lock.

4.

Loose the carriage lock and verify that vertical motion is released and

counterweighted at any point.

5.

Take out the Cassette film tray and check correct functioning.

CHECK OFF MAINTENANCE REVISION TABLE

Hospital name:

Date:

System Name:

System Number ID:

Customer:

Field Engineer Name:

Floor Mounted Tube Stand

Maintenance activity

Comments

Electrical cables and connections

-