See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/368661065

Acetone Production Process

Technical Report · May 2022

CITATIONS

READS

0

165

1 author:

Cavidan Zeynalov

Baku Higher Oil School

25 PUBLICATIONS 0 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Generation of wave energy from capturing ocean wave movements View project

All content following this page was uploaded by Cavidan Zeynalov on 20 February 2023.

The user has requested enhancement of the downloaded file.

Chemical Engineering Department

“Acetone production process”

Team number: 6

Team members: Shahin Huseynli

Yunis Garayev

Aytan Valiyeva

Naila Shakarova

Dzhavidan Zeinalov

Banovsha Mammadova

Supervisor:

Sevda Zargarova

Date of submission: 4th of May 2022

Table of contents

Contents

........................................................................................................................................ 1

Chemical Engineering Department.................................................................................. 1

Table of contents ............................................................................................................. 2

Introduction...................................................................................................................... 4

Description of the process ............................................................................................... 5

Mass Balance for the whole process ............................................................................... 6

Energy Balance for the whole process .......................................................................... 10

Health and Safety Precautions ...................................................................................... 12

References .................................................................................................................... 15

Introduction to the individual section ............................................................................. 47

Flow description ............................................................................................................ 47

Mass & Energy Balance ................................................................................................ 48

Pie and pump specification............................................................................................ 49

Heat exchanger design ................................................................................................. 55

HSE ............................................................................................................................... 67

References .................................................................................................................... 69

Material & Energy balance ............................................................................................ 71

Heat exchanger HE-103 design .................................................................................... 73

Heat exchanger safety ............................................................................................. 85

Pump P-105 design ....................................................................................................... 87

Step 1: Collecting physical parameter ................................................................... 87

Step 2: Pipe parameters .......................................................................................... 88

Step 3: Determination of flow parameters ............................................................. 89

Step 4: Suction side calculations ........................................................................... 90

Step 5: Discharge side calculations ....................................................................... 91

Step 6: Pump power, NPSH available calculation ................................................. 92

Pump safety .............................................................................................................. 93

Process description ....................................................................................................... 97

Material and Energy Balance ........................................................................................ 98

P-104 ............................................................................................................................. 99

HE-104 ........................................................................................................................ 107

References .................................................................................................................. 116

Heat Exchanger Design .............................................................................................. 126

Process description ..................................................................................................... 138

Material balance .......................................................................................................... 138

Energy balance ........................................................................................................... 140

Pump design ............................................................................................................... 141

Heat exchanger design ............................................................................................... 147

References .................................................................................................................. 160

Introduction

It comes off as no surprise that a favorable plant design dictates the project’s future

success rate. The efficacy of problem solving is increased via the high contest level for

the market, which supports the idea of initiative-taking, and assimilates the change in

processes. Thus, the possession of requisite knowledge, a sense of creativity, and a clear

purpose is a must to obtain a service product. The following report displays a plant’s

design, and its development for Acetone production via means of catalytic

dehydrogenation of Isopropyl Alcohol. The aim is to get slightly over 280000 tons of

Acetone product per year all the while keeping production costs and pollution levels low.

Acetone, otherwise called as propanone , is a solvent utilized in plastic manufacture and

a plethora of other industries. Acetone has no color, and can be utilized in personal care

products as well as cosmetics, mainly as an essential component of a nail polish remover.

Acetone breaks down nail polish, making the removal with a cloth, or something similar,

simple. Weirdly enough, as metabolism’s by-product, Acetone can also be found in

human body. That Acetone evaporates extremely fast in the air, and is able to mix with

water quite easily contribute to its wide usage. Furthermore, Acetone is broadly utilized

for degreasing degumming silk and wool in the textile industry. Acetone is also regularly

utilized in blends, solvent systems, and in lacquer formulation. Reducing lacquer

solutions’ viscosity is also viable via utilizing Acetone.

Currently, three methods are mainly utilized in Acetone production, and they are as

follows: The Isopropyl Alcohol’s dehydrogenation process, Polypropylene’s oxidation

process, and Cumene process. The last process is the most prevalent method. That said,

benzene, a by-product in Cumene Process, lowers Acetone’s purity level, and gives a

rise to production costs due to separation processes. When it comes to the second

process, the polypropylene’s oxidation’s conversion value is low for Acetone, whereas

the reactants’ purity value should be approximately 99%. In the last method, namely

Isopropyl Alcohol’s dehydrogenation, Acetone with a high level of purity is acquired.

Furthermore, it is probable to utilize the Isopropyl Alcohol’s aqueous solution, and

Acetone’s conversion rate is quite high while including no considerably harmful

substances. Aside from Acetone, the main product of the aforementioned method, a

secondary product is also obtained: Hydrogen. Hydrogen is utilized in an array of

industries, which makes utilizing this process for Acetone production all the more

favorable. These reasons altogether are precisely why the Isopropyl Alcohol’s

dehydrogenation process was opted for our project design.

Description of the process

First of all, it has to be mention that there are various methods for acetone production

such as co product of glycerine-H2O2 process, oxidation of propylene, butanol , or

isopropyl benzene, and catalytic dehydrogenation of isopropanol. The crucial reason why

the last one has been chosen is that this process is believed to be capable of obtaining

high-purity acetone which is of the importance in the biomedical sections, namely

approximately 99% pure product.

The main reaction has been conducted in the reactor the presence of zinc oxide

(ZNO):

(𝐶𝐻3 )2 𝐶𝐻𝑂𝐻 → (𝐶𝐻3 )3 𝐶𝑂 + 𝐻2

(1)

Giving comprehensive information about each step of the PFD, primarily, fresh

feed which is aqueous solution of isopropyl alcohol at the ambient temperature and

pressure has been heated to 320 K, before mixing with recycle stream which constituents

of mainly isopropanol and minor amount of water and acetone mixture (S4). As the

reaction mentioned above is endothermic, which means that reactor should be heated by

means of a solid catalyst; therefore, additional heater (H102) and vaporizer (V101) have

been utilized for reducing heat load on reactor by increasing the temperature of the fluid

from 320K to 389 and 415 K, respectively. After reactor, 3 heat exchanger have been

placed so as to cooling the products and unreacted reagents, namely H103 and H104

having cooled the gas mixture from 623 and to 550K, and to 470K, correspondingly.

However, H104.1 change their phase by decreasing their temperatures to 289K before

sending them to the flash tank (D101) where gas mixture which consists of mainly

hydrogen gas is planning to be separated from liquid mixture. The absorption column

(C201) provided with water which has been heated from ambient conditions to 320 K

before entering C201 separated mainly hydrogen from mixture. Since hydrogen is not

able to dissolved in the water, it is removed from the top of absorption column as a form

of gas with a few moles of other substances to the T103 hydrogen tanks; however,

another portion of the mixture which have been adsorbed by water have been connected

with the S14 which was the bottom product of the flash tank. After the combined mixture

has been pumped and heated from 325 to 352.25K, it is sent to the distillation column (or

acetone column) where the main product have been planned to be gathered. Adding more

information, from the top of the column most of the acetone, a few amount of the water

and remaining hydrogen gases at 360 K have been cooled to 295 K by means of HE107.

Consequently, certain part of it has been conveyed to the column itself for controlling

temperature inside by pretending overheating process which might damage the walls of

C202, whereas another proportion of it has been pumped to the shortage tank. The next

step is to remove isopropanol from mixture moved from the bottom of the C202 by means

of another distillation column where the temperature is higher than the C202 in order to

reach the boiling point of the isopropyl alcohol; therefore, before sending them to the

C203, mixture’s temperature should be raised to the 365-370K. By following these, gas

mixture which mainly constitutes of isopropanol have been cooled from 370K to 330K

before dividing into 2 parts, namely same procedures assuming this distillation column as

well. However, here the vital aim is to recycle that cooled mixture to the feed stream,

namely before reactor. Ultimately, water which has been separated in C203 has been

cooled and pumped to the shortage tanks.

Mass Balance for the whole process

It is an undeniable fact that material balance is considered as one of the most essential

and fundamental stages of chemical or physical processes as all subsequent steps are

done based on that. Generally, mass conservation is taken as the fundament on which

the mass balance is calculated. That mass is not created as well as not destroyed for

close systems is stated by the said law. For any component in the process, mass balance

equation’s general form is like below:

Input + Generation = Output + Consumption + Accumulation

However, the process of production of acetone occurs under steady state conditions

which means accumulation of species is zero. In addition to this, the consumption and

production values will be equal to zero if no chemical reaction is to occur. In our process,

the chemical reaction occurs only between Streams number 6 and 7. So, the last form of

material balance equation except for this stage is like that:

Input = Output

The table below demonstrates material balance for the process between S-1 – S-9 which

covers the entrance of the reactants to the reactor and their exit.

Table 1.Material balance

S1/S2

Mole (kmols

per hour)

isopro

panol

609.231

water

300.069

hydrog

en

aceton

e

TOTA

L

Co

mp.

0.6

7

0.3

3

S4

Mass

(kilograms per

hour)

Mole (kmols

per hour)

36553.86

66.885

5401.24

35.943

Co

mp.

Mass

(kilograms per

hour)

0.6

5

0.3

493

4013.1

646.97

0

0

0

0

0

0

0

0

0

0.072

0.0

007

4.18

909.3

1

41955.1

102.9

1

4664.25

Table 2.Material balance

S3/S5/S6

Mole

(kmol/h)

isopropan

ol

676.116

water

336.012

Comp.

0.66796

7

0.33196

2

hydrogen

0

0

Mass

(kg/h)

S7/S8/S9

Mole

(kmol/h)

40566.96

67.58681

6048.21

335.98914

0

608.60551

Comp

.

0.041

7

0.207

3

0.375

5

Mass

(kg/h)

4055.2090

7

6047.8046

1

1217.2110

4

0.00007

0.375 35299.120

acetone

0.072

1

4.18

608.60551

5

1

TOTAL

1012.2

1

46619.35

1620.787

1

46619.3

As it was mentioned before, the reaction that takes place in the reactor is like that:

It is clearly seen from the reaction that the coefficients for both reactants and products

are equal to 1. This fact also verifies itself in material balance as the moles of isopropanol

that participates in reaction is equal to moles of acetone and hydrogen gas that leaves

the reactor.

After leaving reactor the materials enter C-202 column for separating pure acetone. The

mass balance for following streams are like below:

Table 3.Material balance

S10

Mole

(kmol/h)

isopro

panol

79.9

Co

mp.

0.0

033

0.0

088

0.8

732

0.1

147

696.64

1

2.2989

water

hydrog

en

aceton

e

TOTA

L

6.154

608.30

Mass

(kg/h)

S11

Mole

(kmol/h)

Mass

(kg/h)

S12/S-12.1

Mole

Co

(kmol/h) mp.

Mass

(kg/h)

8.3496

0

0

0

779.02

1216.5

3

2558.5

96

350

1

6300

0

0

0

44.11

Co

mp.

0.0

002

0.0

622

0.8

742

0.0

634

137.93

0.143

110.77

43.279

1216.6

4634.4

67

6099.7

7

608.268

0

0

0

695.8

1

4562.5

350

1

6300

Table 4.Material balance

S14

Mole

(kmols

per

hour)

isop

rop 65.2879

anol

wat

er

329.916

7

Co

m

p.

0.

07

06

0.

35

71

6

Mass

(kilogram

s per

hour)

Mole

(kmols

per

hour)

3917.274

2.1754

5938.5

S13

C

Mass

o (kilogram

m

s per

p.

hour)

0.

00

130.52

62

0.

312.875 89

17

5631.754

S15/S16

Mole

C

Mass

(kmols

o (kilogram

per

m

s per

hour)

p.

hour)

0.

67.440 05 4046.453

29

0.

642.792 50

42

11570.26

hydr

oge

n

0.2199

acet 528.700

one

9

TO

924.125

TAL

0.

00

02

4

0.

57

2

1

0.4398

0.

0.03509 00

01

30664.65

35.789

0.

10

2

40520.87

350.875

1

0.070175

2075.77

7838.126

0.

0.25498 00

02

0.

564.387 44

27

1274.87

1

5

0.51

32734.46

48351.67

In the following stages, mixture which consists of mainly isopropanol and water is sent to

C-203 where isopropanol is recycled and transferred to the feed and water is pumped to

T-104 tank. The compositions and flowrates of these streams are provided below:

Table 5.Material balance

Mole

(kmols

per

hour)

isop

rop

anol

0

S19

C

Mass

o (kilogram

m

s per

p.

hour)

0

Mole

(kmols

per

hour)

0

S22

C

Mass

o (kilogram

m

s per

p.

hour)

S23/S24

Mole

(kmols

per

hour)

Co

mp

.

Mass

(kilogram

s per

hour)

0

0

0

0

0

0

10.16

0.564

0

0.228

0.

0.00048

00

9

06

0.008817

0.565

0.

00

1

hydr

0.

0.22842

oge

27

2

n

98

0.456843

0

0

0.

acet 0.58746

71

one

4

96

34.07288

0

0.

563.810 99

9

32701.02

564.398

TO 0.81637

TAL

5

34.53854

0

564.375

32711.18

565.190

wat

er

1

1

0.0

00

99

9

0.0

00

40

4

0.9

98

59

7

1

10.168

0.457

32735.08

9

32745.71

4

Table 6.Material balance

S27/S28/S29

isopropano

l

Mole

(kmol/h)

Comp.

Mass

(kg/h)

67.50198

0.095

1

4050.1188

S36/S37/S38

Mole

Comp

(kmol/h)

.

0.606725

0.001

Mass

(kg/h)

36.4035

water

642.22704

hydrogen

0

acetone

0.07098

TOTAL

709.8

0.904

8

0

0.000

1

1

11560.086

7

0

606.118275

0.999

10910.129

0

0

0

4.11684

0

0

0

15614.322

4

606.725

1

10946.532

5

What can be clearly seen from the tables is the flowrate of acetone product is 565.19

kmol/hour while 608.52919 kmol/hour isopropanol participates in reaction. It means

conversion of process is 93%. In addition, the purity of the product is 99.8%.

Energy Balance for the whole process

Energy changes are also balanced based on the conservation law as mass balance. It is

stated in this law that no energy can be generated or destroyed, it is only able to be

transferred from one form to another. Regarding to this law, the overall input and outputs

should be always the same, and in the subsequent equation energy conserving law for

open systems where both energy and mass transfer occurs is provided as 1st law of

thermodynamics:

heat transfer rate + shaft work- enthalpy change-kinetic energy changepotential energy change=0

As it should be known, most parts of the chemical also physical processes have

association with the changes of enthalpies. Since the main aim of this project is focusing

on heat exchangers and pumps’ designs, and if thermodynamics’ first law is taken into

account for them, it will be observed that for heat exchangers there is not any shaft work

done by or on the system, and for pumps there is no exchange of heat, and for both

kinetic and potential energies are in negligible amounts, these equations are derived:

For HEs:

heat transfer rate + shaft work- enthalpy change-kinetic energy change - potential

energy change=0

heat transfer rate = enthalpy change

For pumps:

heat transfer rate + shaft work- enthalpy change-kinetic energy change - potential

energy change=0

shaft work= enthalpy change

So, at it is evidently seen now, the examination of enthalpies in streams is very crucial for

being able to be well- informed about energy consumptions in the plant. However, it is

not possible to estimate the enthalpy of chemical components at only given operation

temperature and that is why it is required to use reference temperature whose value will

be 298K in this project’s calculations.

𝑇

∆𝐻_ = 𝑛_̇ ∗ ∫

𝑇𝑟𝑒𝑓

𝐶𝑝𝑚 _ 𝑑𝑇

If all parts are divided by the molar flow rate, molar enthalpy will be obtained which is

actually be shown in final energy balance table.

𝑇

∆ℎ_ = ∫

𝑇𝑟𝑒𝑓

𝐶𝑝𝑚 _ 𝑑𝑇

Where ∆ℎ_ I s molar enthalpy change and 𝐶𝑝𝑚 _ is molar heat capacity. However, for

doing the required calculations, it is needed to find out molar heat capacity values. After

using Antonius equation and compare saturation and operations pressures, the phases

of components in each stream were determined. Following 2 tables show the molar heat

capacity constants for liquid and gas phase component, and as it is expected they have

different calculation equations.

Table 7. Molar heat capacity constants for liquid phase

Liquid heat capacity

isopropanol

water

hydrogen

acetone

A

72.525

92.053

50.607

46.878

𝑪𝒑 [

B

0.79553

-0.03995

-6.1136

0.62652

C

-0.002633

0.00021103

0.3093

-0.0020761

D

3.6498E-06

5.3469E-07

-0.004148

2.9583E-06

E

0

0

0

0

𝑱

] = 𝑨 + 𝑩𝑻 + 𝑪𝑻𝟐 + 𝑫𝑻𝟑 + 𝐸𝑻𝟒

𝒎𝒐𝒍 ∗ 𝑲

Table 8. Molar heat capacity constants for liquid phase

Gas heat capacity

isopropanol

water

hydrogen

acetone

A

25.535

33.933

25.399

35.918

𝑪𝒑 [

B

0.21203

-0.00842

0.020178

0.093896

C

0.000053492

0.000029906

-0.000038549

0.0001873

D

-1.4727E-07

-1.7825E-08

3.188E-08

-2.1643E-07

𝑱

] = 𝑨 + 𝑩𝑻 + 𝑪𝑻𝟐 + 𝑫𝑻𝟑

𝒎𝒐𝒍 ∗ 𝑲

As final step, it is needed to multiply the corresponding molar heat capacity constants for

each component and to sum up them in order to obtain the constants of mixtures:

𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡𝑚𝑖𝑥𝑡𝑢𝑟𝑒 = ∑ 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡 𝑜𝑓 𝑒𝑎𝑐ℎ ∗ 𝑚𝑜𝑙𝑎𝑟 𝑓𝑟𝑎𝑐𝑡𝑖𝑜𝑛

Now, final results are tabulated within the following graph and some of the equipment’s

enthalpy changes will be also provided:

Table 9. Energy balance for all streams

Properties

Streams

S-1

S-2

S-3

S-4

S-4.1

S-5.1

S-5

S-6

S-7

S-8

S-9

S-10

S-11

S-12

S-12.1

S-13

S-14

S-14.1

S-15

S-16

S-19

S-22

S-23

S-24

S-27

S-28

S-29

S-36

S-37

S-38

Cp(J/mol*K)

Molar

enthalpy(J/mol)

152.78

157.12

157.59

159.01

159.01

157.59

83.89

109.76

71.39

91.94

88.69

88.69

40.92

113.04

118.40

114.67

0

3401.055

3411.499

4964.983

4964.983

3411.499

7064.131

27388.60

19784.23

1811.807

-444.954

-444.954

811.994

0

1142.877

-359.8234631

128.57

111.16

111.16

99.48

126.96

126.92

126.92

124.49

3387.951

5690.739

5690.739

-299.0220771

-381.670284

-381.5521058

-381.5521058

2916.34121

41.06

41.06

34.15

113.10

113.10

3281.883541

3281.883541

2441.450843

0

0

Health and Safety Precautions

It is necessary to take into consideration personal health and safety in acetone

production. All of the chemicals used in the production of the acetone can cause explosive

reactions, which should be avoided. Industries and organizations should undertake risk

assessments and precautions to prevent potential hazards arising from unintentional

cases. [1] Additional controls, including protective packaging and handling procedures

are designed in order to reduce any kind of risks.

Figure

1.

B2- During the early stages of design and development of the plant,

Flammable

liquid,

chemical process route must be taken into account. At normal

D2B- Eye irritant

environmental considerations, acetone has been demonstrated to

have a low toxicity and does not cause a neurotoxic, carcinogenic and reproductive

hazard. Long-term skin contact can cause skin to dry, resulting in cracking, mild irritation

and burning sensation. In order to lessen its effects, skin should be washed immediately.

Besides that, dizziness, and nausea can happen during exposure to excessive level of

vapor concentrations. High level of vapor can also irritates eyes, resulting in tearing and

sore, red eyes. During eye contact eyes should be flushed with water. If acetone is

ingested, as a first aid measure vomiting must not be induced

since vomiting may be dangerous and medical help should be

implemented to avoid lung damage as soon as possible. While

working with acetone, it is needed to wear safety goggles and

protective clothes as a personal protective equipment for

respiratory and skin protection. It is important to mention that

acetone is highly flammable liquid, which can also ignite at room

temperature and in other certain circumstances due to static

discharge. Even acetone and water mixture may be also

flammable. Therefore, identifying the risk assessment for

acetone is very critical. Ignition of gas acetone can generate very toxic chemicals, namely

carbon dioxide, formaldehyde, carbon monoxide and acetic acid. In order to avoid any

potential risks and extinguish aforementioned chemicals quickly and effectively, suitable

media for extinguishing should be implemented. Coming to the environmental issues,

acetone is relatively non-toxic to aquatic organisms. [2], [3] Moreover, it is easily

biodegradable, and has a limited bioaccumulation potential. According to the criteria of

regulation, acetone production via isopropyl is not classified as hazardous to the

environment and ozone layer, and does not cause greenhouse effect.

Table 10. Hazards identification of acetone

PHYSICAL AND CHEMICAL HAZARDS

Highly flammable vapor and liquid

HUMAN HEALTH

Serious eye, skin irritation, dizziness,

nausea, lightheadedness

ENVIRONMENT

Not classified

FLAMMABILITY LIMITS

Lower:2.2%

Upper:13%

PRECAUTIONARY STATEMENTS

1

Acetone storage should be kept away from open flames, hot surfaces, sparks

2

Protective gloves and goggles should be worn

3

Precautionary measures should be taken against static discharge

4

Containers should be tightly closed

5

Breathing vapors should be avoided

6

Direct sunlight, extremely high or low temperatures should be avoided

FIRST AID MEASURES

SKIN CONTACT

Contaminated clothing should be immediately removed.

EYE CONTACT

For a time period of at least 15 minutes, eyes should be

rinsed.

INGESTION

If necessary, patient should be kept under medical

observation whereas patient’s mouth must be rinsed.

Vomiting should not be induced.

INHALATION

If the patient is unconscious, artificial respiration may be

administered.

MEASURES TO FIGHT THE FIRE

ADVISABLE

Alcohol resistant foam, dry chemical, carbon dioxide, or

water spray

INADVISABLE

Water jet is not suitable

References

[1] Iskender H. Risk assessment for an acetone storage tank in a chemical plant in

Istanbul, Turkey: Simulation of dangerous scenarios. Proc Safety Prog. 2021

[2] Canadian Centre for Occupational Health and Safety, www.ccohs.ca/ [Accessed:

01.05.2022]

[3]

Fedyaeva

OA,

Poshelyuzhnaya

EG.

Concentration

dependences

of

the

physicochemical properties of a water-acetone system. Russ J Phys Chem A.

2017;91:63-66

[4] “Material Safety Data Sheet,” Air Liquid company, 04.09.2018 [Accessed: 03.05.2022]

[5] Barrettine “Safety Data Sheet”, Acetone, [Accessed: 03.05.2022]

Individual section 1.

Banovsha Mammadova, CE 19’2

The following topics will be covered:

Flow diagram explanation

Mass balance

Energy balance

Pipeline and pump design

Heat exchanger design

HSE (Health, safety, and environment)

References

Process description

This section is going to examine the equipment and streams outlined within a blue frame.

As it has already be stated the process is

executed for obtaining world’s one of the

most important chemicals-acetone from the

dehydrogenation of isopropyl alcohol which

is the sole and only raw material in acetone

manufacturing

process

that

requires

catalyst. First of all the water and

Picture 1. Process flow diagram

isopropanol mixture is taken from the T-101 feed tank with the initial temperature of 298K

and transferred to HE-101, whose operation pressure is 1atm, in order to be heated up

to 320 K before mixed with recycle stream. After recycle stream and S-2 streams are

mixed, the new mixture is subsequently pumped by P-101, which will increase the

pressure from 1.5atm to 2.6atm, to next heat exchanger for being heated more while

further heating will be done within the vaporizer (V-101) by molten salt as well.

Mass and energy balance

As it has already been depicted in previous sections, material and energy balances

should be done in a correct way since further design stages have direct dependence from

them. While the balances have already been provided, now streams around the P-101

pump and HE-101 will be given.S-1 and S-2 streams are the inlet and outlet of HE-101

respectively, whereas S-3 and S-5.1 are input and output of P-101. In all of these streams

there are no hydrogen gas, and other 3components namely isopropanol, water and

acetone are in liquid phase.

Table 1. Mass balance of S1 and S2 streams

isopropanol

water

hydrogen

MW(kg/kmol)

60

18

2

S1/S2

Mole

(kmol/h)

Comp.

435.165

0.67

214.335

0.33

0

0

Mass

(kg/h)

26109.9

3858.03

0

58

-

acetone

TOTAL

0

129.9

0

1

0

29967.93

Table 2.Mass balance of S3 and S5.1 streams

S3/S5.1

isopropanol

water

hydrogen

acetone

TOTAL

Mole

Mass

(kmol/h)

Comp.

(kg/h)

482.94 0.667966805

28976.4

240.00855 0.331962033 4320.1539

0

0

0

0.05145 7.11618E-05

2.9841

723

1

33299.5

Additionally, by means of molar heat capacity constants taken from data book, heat

capacities and molar enthalpies are defined:

Table 3. Molar heat capacities and enthalpies of required streams

Number of

the stream

Molar

heat

capacity

(J/mol*K)

S-1

S-2

S-3

S-5.1

152.78

0

157.12 3401.0546

157.59 3411.499

157.59 3411.499

Molar

enthalpy(J/mol)

Determination of properties in streams

Before commencing on any kind of design calculation, the initial step is to figure out the

crucial and required physical fluid properties through the whole system including density

values, viscosities, and conductivities. The ways how to find out the properties of S-1

stream will be detailed in subsequent paragraphs and, as the calculations are similar for

other streams as well, for putting a stop to repetition they will not ne depicted and can be

observed from the correlating excel spreadsheet. It is undeniably true that there are

several types of methods for computations of those properties each of which has

individual and different precision and accuracy. The masses and moles for S-1 stream is

given below which will be actually very important and considered in further calculation

stages.

Table 4. Material balance for P-101 pump

Name of the

Mass flow Mass fraction Mole

Mole

corresponding

(kg/hr)

flow(kmol/hr) fraction

component

isopropanol

40566.96 0.8701742

676.116 0.668

water

6048.21546 0.1297362

336.012 0.332

hydrogen

0

0

0

0

7Eacetone

4.17774 8.961E-05

0.07203

05

Total result

46619.3532

1

1012.2

1

Viscosity ascertainment

Viscosity is one of the most important physical properties whose actual meaning is

resisting ability of fluid to shear stressing deformation or tensile stress which contributed

by layer motions’ intermolecular friction.

Based on the book called Coulson and

Richardson, the ways for finding viscosities for gases and liquids are different, and as in

S-1 stream, there is no hydrogen-no gas, all components are in the liquid phase, only

subsequent equations will be applied, and constants have been taken from Appendix.

log(𝜇) = 𝐴 +

𝐵

+𝐶𝑇 + 𝐷𝑇 2

𝑇

Where constants of A,B,C and D are for each component as well as unitless, whereas

the temperature is represented as T with Kelvin as its unit. After finding each chemical’s

viscosity, these formulae beneath should be used for ascertainment of that of mixture:

1

𝜇(𝑚𝑖𝑥𝑡𝑢𝑟𝑒)

=

𝑋(1) 𝑋(2) 𝑋(3)

𝑋(𝑛)

+

+

+ ⋯+

𝜇(1) 𝜇(2) 𝜇(3)

𝜇(𝑛)

𝜇 indicates the value of dynamic viscosity with Pa*s as its unit and X indicates mass

fraction.

By applying those expressions and given mass fraction values within the Table 5. all

results are given within next Table:

Table 5. Viscosity determination table of P-101

The name of

the

A

component

isopropanol

B

-0.7009

C

841.5 0.008607

D

T

8E06

Log (𝜇)

320 0.02416286

10^

log

(centipoise)

(𝜇 )

1.057214

-1Ewater

-10.2158 1792.5 0.01773

05

320 -0.2340519

0.583375

-2Eacetone

-7.2126 903.05 0.018385

05

320 0.59151595

0.256144

As in the constant providing book, the unit of viscosity was given in centipoise, it is needed

to

convert in to Pa×s by dividing 1000 :

Table 6. Viscosity values of each component in P-101

Name of the

component

Viscosity

(in Pa*s)

isopropanol

water

acetone

0.001057214

0.000583375

0.000256144

Turning to mixture viscosity determination, by inserting Equations….. , the required values

are obtained:

1

𝜇(𝑚𝑖𝑥𝑡𝑢𝑟𝑒)

0.8701742

0.1297362

8.961 × 10−5

=

+

+

= 1045.821

0.001057214 0.000583375 0.000256144

𝜇(𝑚𝑖𝑥𝑡𝑢𝑟𝑒) =

1

1045.821

= 0.000956 Pa×s

Density ascertainment

Density is another physical feature of chemicals which shows the mass amount of

component per volume and has significantly important applications in industrial fields. As

the S-1 stream only consists of liquid phase components, the formulae taken from

Coulson and Richardson which is considered for liquid phase components must be

applied:

𝜌(𝑙𝑖𝑞𝑢𝑖𝑑_𝑝ℎ𝑎𝑠𝑒) =𝐴𝐵

−(1−𝑇

𝑇

𝑐𝑟𝑖𝑡𝑖𝑐𝑎𝑙

)𝑛

For the mixture containing different components:

𝜌(𝑚𝑖𝑥𝑡𝑢𝑟𝑒) = 𝑋(1) × 𝜌(1) + 𝑋(2) × 𝜌(2) +…+ 𝑋(𝑛) × 𝜌(𝑛)

A, B and n are substances’ regression constants

𝑇(𝑐𝑟𝑖𝑡𝑖𝑐𝑎𝑙) and T are critical and actual stream temperatures respectively in Kelvin

X shows mass fraction of each component

𝜌 is density value in kg/𝑚3

Table 8. Density table of P-101

Component

A

n

B

isopropanol

water

acetone

T

0.26785 0.26475

0.243

0.3471

0.274 0.28571

0.27728

0.2576 0.29903

𝜌(𝑚𝑖𝑥𝑡𝑢𝑟𝑒) = 0.8701742 × 760.8785869 +

Tc

320

320

320

Density (kg/m^3)

508.31 760.8785869

647.13 1007.245479

508.2 759.610499

0.1297362 × 1007.245479 +

8.961 ×

10−5 ×759.610499=792.8412 kg/𝒎𝟑

Thermal conductivity ascertainment

Thermal conductivity is a property which is defined as heat rate of conduction per unit

area whenever area and temperature are perpendicular to each other. To find out the

thermal conductivities of components and mixture, subsequent expressions should be

applied orderly:

𝑇 2

log10 𝑘𝑙𝑖𝑞𝑢𝑖𝑑 =A+B× (1 − )7

(for organic liquids-isopropanol,

𝐶

acetone)

k = A+BT+C𝑇 2

(for inorganic liquid-water)

𝑘(𝑚𝑖𝑥𝑡𝑢𝑟𝑒) = 𝑋(1) × 𝑘(1) + 𝑋(2) × 𝑘(2) +…+ 𝑋(𝑛) × 𝑘(𝑛)

Where X is mass fraction, k is thermal conductivity, actual stream temperature is indicated

as T with its unit as Kelvin, and A,B,C are constants. Thermal conductivity values

separately for each chemical is systemized within the table here:

Table 9. Thermal conductivity table of P-101

The name

of

the A

component

isopropanol

water

1.372

1

0.275

8

Temperatur

e

(K)

C

B

0.658

508.31

0.00461

2

-5.5391E06

log10(k)

320

320 -

0.8766

4

k(W/m*K)

0.13285

0.63283

6

acetone

1.385

7

0.7643

508.2

320

0.8102

6

0.15479

𝑘(𝑚𝑖𝑥𝑡𝑢𝑟𝑒) =0.197718 W/m× 𝑲

Pipeline and Pump design

P-101 pump design along with the design of pipeline will be provided in a detailed way in

this part of the report. Firstly, that in many of plants and platforms, approximately 25-50%

of general energy consumption is accounted by pumps is noteworthy; therefore, a correct

and proper design of pump systems is essential process. In real applications, pumps are

provided to the plants individually, but their operations become feasible when they are

started to operate as a part of system. Consequently, different considerations including

economic aspects, hydraulic and service issues must be taken into consideration

carefully. Energy and material expenses are estimated based on the pump design and

overall installation. Being able to design pumps and pipelines properly has utmost

essence in terms of guaranteeing maintenance for long period of time, to have possible

lowest amount of energy and cost of service.

In mechanical engineering fields, there is a term called Schedule number which is used

for description of wall thickness of pipes. When the Schedule numbers for pipes are

different but their nominal pipe diameters are the same, in that case wall thickness values

will be varies because of the changes of outside diameter respecting

to

inside diameter.

In industrial applications, there a lot of types of the Schedule numbers each of which has

their individual characteristic features, however the most common and preferrable one is

Schedule number 40. In this process, austenitic stainless- stell pipe with 40 schedule

number is chosen to be used in order to decrease the possibility of risky situations to

minimum and as the desirable pressures are not too much. Moreover, the austenitic

stainless- stell material can deal with higher possess and flow rates , and corrosion

process which is anticipated as in the process water in high amount is present. This type

of pipeline does not require extra maintaining processes and expense, as well as their

lifetime can be till fifty years. Additionally, this material can be recycled, so eco-friendly

and cost-effective. Taking all these advantages into account, it was decided that

austenitic stainless- steel pipe with 40 schedule number is the best option for the process,

and for calculating optimum diameter of pipe, subsequent equation must be used:

Optimum diameter =260× 𝑚𝑎𝑠𝑠 𝑓𝑙𝑜𝑤 0.52 × 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 −0.37 =260× 12.950.52 × 792.84−0.37 =

83.301mm

In the equation above, mass flow rate should be expressed in kg/s whereas density

should be with the unit of kg/𝑚3 . The value for optimum diameter was calculated and

found out as 83.301mm which is actually does not exist in standard values table. So, in

order to choose the value from the table, the closest value of internal diameter to optimum

diameter must be opted to; however as the values in table is provided with inches, (

1in=2,54cm) , the optimum diameter should be converted to inch which is 3.28 inch and

taken from table like below:

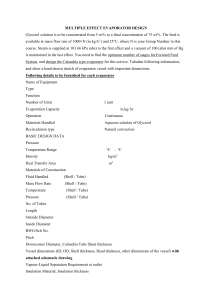

Picture 2. Standard pipe values of 40schedule number

As it is seen, the standard internal diameter of pipe which is relevant to optimum value,

is chosen as 3.548inch.

Picture 3. Inner appearance of cross of pipe

For finding other diameter, inner one should be summed with 2times thickness as it is

evident from provided illustration about diameters and thickness. All needed figures are

put in the next table:

Table 10. Length and diameter values for pipeline

Pipeline

Density

(kg/m^3)

mass

flow

rate

(kg/s)

Optimum

diameter,

mm

optimum

diameter,

inch

OD(inch)

OD(m)

ID

(inch)

ID

(m)

Thickness

of

wall(inch)

Thickness

of wall

(m)

Pipe

nominal

,

inch

Wt

per ft

3.5

9.2

0.09

792.8

12.9

83.30

3.280

4 0.102 3.55

0.226

0.0057

Now, the design procedures can be started as diameters have already been estimated.

Initially, it is required to figure out cross sectional area:

Pipe cross sectional area=

2

𝜋𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

𝜋∗0.092

4

=

4

=0.00638 𝒎𝟐

If the S-1 stream’s mass flow rate is divided by its density , the volume flow is obtained

which stands at the value of 0.01633 𝑚3 /s and, the previously found value of cross section

and volume flow rate should be inserted in linear velocity equation like that:

𝑄

0.01633

𝐴

0.00638

𝑢𝑙𝑖𝑛𝑒𝑎𝑟= =

=2.56m/s

Subsequent that by using already determined density, inner diameter and viscosity

values, as well as linear velocity, Re (Reynolds number) must be defined which will give

information about regime of the flow:

𝑢𝑙𝑖𝑛𝑒𝑎𝑟× 𝜌(𝑚𝑖𝑥𝑡𝑢𝑟𝑒) ×𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙 2.56×792.8412×0.09

Reynolds number=

𝜇(𝑚𝑖𝑥𝑡𝑢𝑟𝑒)

=

0.000956

=191344

The obtained value is greater than the critical value which is 2300 and indicates that the

flow of inside pipe is turbulent.

The next stage is relative roughness calculation which is equal to the division of absolute

roughness to internal diameter. To explain roughness, it actually shows any unevenness

of inner surface of pipe, and it directly related to the pressure drop of pipe section.

Actually, the values of absolute roughness depend on the material from which the pipe is

constructed, and those values are obtained experimentally; as it has already been stated

the material for this process case is austenitic stainless steel and its epsilon (absolute

roughness value) is 0,015mm. Now, relative roughness should be calculated:

𝑟𝑜𝑢𝑔ℎ𝑛𝑒𝑠𝑠𝑟𝑒𝑙𝑎𝑡𝑖𝑣𝑒 =

𝜀

𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

= 0.000166446

There are actually several techniques for finding friction factor, and one of them is using

friction factor calculators from which gives the result of 0.017, however for the sake of

being more exact and providing comparison of the conclusions obtained from calculator

and equation, the following Colebrook formulae ( can be used for the cases of turbulent

regime) has also been applied which gives the result as 0.0167 that is very close to

previously obtained result.

1

√𝑓

=-2*log(

𝜀

3.7∗𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

+

2.51

𝑅𝑒∗√𝑓

The next is the determination of pipe sections’ pressure losses stem from friction based

on the famous equation named as Darcy-Weisback equation (for the cases of mixture

transportation) :

𝐿

Δ𝑃_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_ =f× (

𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

)×

2

𝜌𝑚𝑖𝑥𝑡𝑢𝑟𝑒 ×𝑢𝑙𝑖𝑛𝑒𝑎𝑟

2

In general, there are 2 possibilities for pressure losses; one of them is caused by friction

and is considered as major loss, whereas the second can be contributed by elbows,

bends ,fittings , valves and so on. The equation above is only take major losses into

account, however there are two methods which also consider minor losses namelyequivalent length and velocity head loss. The equivalent length methods will be used, and

now equation above is expressed as below:

𝐿

Δ𝑃_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_ =f× (

𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

+

∑𝐿(𝑒𝑞)

2

𝜌𝑚𝑖𝑥𝑡𝑢𝑟𝑒 ×𝑢𝑙𝑖𝑛𝑒𝑎𝑟

𝑑

2

)×

Before using this method, there is one important requirement here which is the indication

of fittings, entries, valves, exits and their dimensionless pipe diameters in suction and

discharge sections. The given below tables depict minor losses for suction and discharge

sections in turn:

Table11. Side fittings of the suction side

Table12. Side fittings of the discharge side

Type of the

fitting

Fitting’s

number

Pipe

diameter_

number

Pipe

diameters’

total

number

Sudden

reduction

(Outlet of the

tank)

1

25

Ball

valve

(100%open)

1

Type of the

fitting

Fitting’s

number

Pipe

diameter

number

Pipe

diameters’

total

number

25

Check valve

(100%open)

100

1

100

18

18

90

elbow

standard

radius

40

1

40

1

19.5

Total L equivalent/d, m

19.5

62.5

Temperature

control valve

Total L equivalent /d, m

140

After the determination fittings’ diameters for both inlet and outlet sides, pressure drops

for both sides can now be estimated . Before turning to that stage, it is needed to define

length of pipe on both parts. The assumption was made related to approximate length

value of pipe section and scale; it is assumed that the value of 1cm in process flow

diagram is the same as it was in ten meter in real applications. ( the ratio is 1:1000). It

has assumed that suction pipe is 12m long and discharge is 30m long. Now,

corresponding equations must be inserted and calculations should be done:

𝐿

Δ𝑃_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_𝑠𝑢𝑐𝑡𝑖𝑜𝑛 =f× (

𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

+

∑𝐿(𝑒𝑞)

2

𝜌𝑚𝑖𝑥𝑡𝑢𝑟𝑒 ×𝑢𝑙𝑖𝑛𝑒𝑎𝑟

𝑑

2

792.8412×2.562

2

)×

= 8493.25Pa

12

=0.0167× (

0.09

+ 62.5) ×

𝐿

Δ𝑃_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒 =f× (

𝑑𝑖𝑛𝑡𝑒𝑟𝑛𝑎𝑙

+

792.8412×2.562

2

∑𝐿(𝑒𝑞)

𝑑

)×

2

𝜌𝑚𝑖𝑥𝑡𝑢𝑟𝑒 ×𝑢𝑙𝑖𝑛𝑒𝑎𝑟

2

=0.0167× (

30

0.09

+ 140) ×

= 20527.7Pa

One more possible pressure loss is left which is needed to be expressed ; when larger

amount of fluid transports into the pipe , in that case liquid’s acceleration process can

cause certain pressure losses in entrance which must be defined.

2

𝜌𝑚𝑖𝑥𝑡𝑢𝑟𝑒 ×𝑢𝑙𝑖𝑛𝑒𝑎𝑟

792.8412×2.562

Δ𝑃_𝑒𝑛𝑡𝑟𝑦 =

2

=

2

=2599.33Pa

Exit losses are neglected during the calculations, and as there is not any sudden

compression or expansion on inlet and outlet section which would have effect on pressure

losses, possible drops because of sudden (

as well as gradual) compression and

expansion are also ignored.

Ascertainment of total head of suction side

The total head of pump ( this term can also be named as total dynamic head) has very

important place in pumping processes which is equal to the difference of discharge and

suction heads. Total pump head indicates the head which is needed to handle the

pressure drops and any variations which can be both vertical and horizontal through the

overall system. Firstly, for total suction head value calculation, it is important to know total

suction pressure equation as head is the distance which can be reached by applying the

pressure.

𝑃__𝑠𝑢𝑐𝑡𝑖𝑜𝑛__𝑡𝑜𝑡𝑎𝑙 =𝑃𝑠𝑡𝑎𝑡𝑖𝑐__𝑠𝑢𝑐𝑡𝑖𝑜𝑛_ + 𝜌*g*𝑍𝑠 - Δ𝑃_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_𝑠𝑢𝑐𝑡𝑖𝑜𝑛 - Δ𝑃_𝑒𝑛𝑡𝑟𝑦

And if all the terms above are divided by 𝜌*g , corresponding heads of pressures and as

a consequence corresponding total suction head will be obtained:

ℎ__𝑠𝑢𝑐𝑡𝑖𝑜𝑛__𝑡𝑜𝑡𝑎𝑙 =ℎ𝑠𝑡𝑎𝑡𝑖𝑐_𝑠𝑢𝑐𝑡𝑖𝑜𝑛_ + 𝑍𝑠 - Δℎ_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_𝑠𝑢𝑐𝑡𝑖𝑜𝑛 - Δℎ_𝑒𝑛𝑡𝑟𝑦

Where ℎ𝑠𝑡𝑎𝑡𝑖𝑐_𝑠𝑢𝑐𝑡𝑖𝑜𝑛_ is the inlet pressure of pump (static pressure), 𝑍𝑠 is total suction side

head which is 18m .After inserting values, the result is obtained:

ℎ__𝑠𝑢𝑐𝑡𝑖𝑜𝑛__𝑡𝑜𝑡𝑎𝑙 =19.4513+18-1.09199- 0.3342=36.12m

Ascertainment of total head of discharge side and total pump head

For doing calculations for discharge side, the subsequent equation must be known and

used:

ℎ__𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒__𝑡𝑜𝑡𝑎𝑙 =ℎ𝑠𝑡𝑎𝑡𝑖𝑐_𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒_ +

𝑍𝑑 +

Δℎ_𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛_𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒 =

33.8728+18+2.64=54.51m

It must be kept in mind that the proper operation of centrifugal pump is only possible when

there is an intersection between system and pump curves, and for showing this

intersection, pump selector app will be utilized for this purpose. Before that overall head

of pump should be stated:

ℎ__𝑝𝑢𝑚𝑝__𝑡𝑜𝑡𝑎𝑙 =ℎ__𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒__𝑡𝑜𝑡𝑎𝑙 -ℎ__𝑠𝑢𝑐𝑡𝑖𝑜𝑛__𝑡𝑜𝑡𝑎𝑙 = 54.51𝑚 − 36.12𝑚=18.39m

Ascertainment of NPSH (Net Positive Suction Head)

There is a famous issue related to the pumps called cavitation which happens because

of the reduction of static pressure to vapor pressure contributing small vapor bubbles’

creation and can create shock waves which is undesirable for the safety of the process

and equipment. In order to control that whether there is a cavitation risk or not, net positive

suction head term is used whose unit is meter. There are 2 types of NPSH one of which

is called NPSH available and characterizes fluid proximity at given point to cavitation and

flashing. To be more exact, it depicts the head of absolute pressure which is able to be

obtained from application to suction part in which first cavitation is expected to happen.

There are different ways for NPSH available determination such as experimental testing

on actual hydraulic system or monitoring during the period of process and using analytical

equation. Now, analytical way is going to be given:

NPSH available=

𝑃𝑠 −𝑃𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒𝑑

𝜌∗𝑔

=ℎ__𝑠𝑢𝑐𝑡𝑖𝑜𝑛__𝑡𝑜𝑡𝑎𝑙 -

𝑃𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒𝑑

𝜌∗𝑔

𝑃𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒𝑑 term here ( is known as vapor or saturation pressure) indicates the pressure

under which the system has its max amount of water in vapor phase. One of the wellknown equations called Antoine equation is used for the determination of that term and

as the units for pressures obtained from Antonius are given in mmHg and should be

converted to kPa after calculation:

𝐵

log10 𝑃 𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑖𝑜𝑛 =A+ +C*log10 𝑇+D*T+E*T2

𝑇

In the equation the constants A,B,C,D, and E are specific for each component whereas

the system’s temperature is indicated as T. As it is clear, there are not just 1 pure and

single component in the system, however Antonius equation above is only needed for

pure components. Thus, for solving this issue and calculate the mixture saturation

pressure another famous law- Raoult’s law can be applied:

𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑖𝑜𝑛

∑𝑖=1 𝑥𝑖 ∗ 𝑃𝑖𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑖𝑜𝑛

𝑃𝑚𝑖𝑥𝑡𝑢𝑟𝑒

Where, 𝑃𝑖𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑖𝑜𝑛 is the vapor pressure of each component (mmHg) and 𝑥𝑖 is the mole

fraction of each of them. All of the important computations are tabulated within the

subsequent table of pressures:

Table 13. Saturation pressure ascertainment table.

Component

mole fraction

A

C

B

D

isopropanol 0.667967 38.2363 3551.3 10.031

water

0.331962 29.8605 3152.2 7.3037

acetone

Total

7.12E-05 28.5884

-2469

-7.351

E

T

-3.474E10

1.7367E-06 320

2.4247E09 0.000001809 320

2.8025E10

2.7361E-06 320

log10(P)

P(mm Hg)

2.187 153.874

1.898

79.114

2.738 546.505

1

After doing the calculations, the figure for saturated pressure is gotten as 17.21kPa and

now this value is going to be used for NPSH available estimation:

NPSH available= ℎ__𝑠𝑢𝑐𝑡𝑖𝑜𝑛__𝑡𝑜𝑡𝑎𝑙 -

𝑃𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒𝑑

𝜌∗𝑔

= 36.12 -

17.21∗1000

= 33.9m

792.84∗9.81

As it was mentioned, cavitation happens whenever the suction heat decreases below of

vapor pressure and it generally takes place around the sections on impeller as the

minimum pressure is observed here as a result of which voids are rushed and shock

waves are generated by liquid which has very adverse influence on equipment and its

parts, especially impeller. The second type of NPSH is used for preventing that happened

which is called net positive suction head required. And in all processes of pumps, it is

demanded to have greater NPSH available than NPSH required. While NPSH available

can be calculated via equation, NPSH required should be provided by pump producer

companies’ characteristic curves.

Selection of Pump

There is a software called “Wilo Pump Selector” (results are depicted in below picture)

and it has been utilizing for the determination of required NPSH value which was shown

as 3.8m and as from calculations NPSH available was obtained as 33.9m , no cavitation

will occur since 33.9>3.8. And this selector app also found the value of efficiency which

stand for 82.8% and is considered very desirable value as 70-85% efficient pumps are

very common in industrial applications. Hence, it means that P-101 pump will do its duty

safely and the mixture will be expected to be successfully transported to next heat

exchanger.

Pump type was opted as centrifugal since this kind can easily be handle with higher

values of flow rates and high heads. Additionally, these pumps have simple design and

maintenance is also easy as there is not any moving components’ array.

As a final stage, the input pump power which is needed to be computed should be defined

by knowing efficiency and other certain physical properties:

𝑉

0.016

𝜂

0.828

Input power= 𝜌 ∗ 𝑔 ∗ ℎ𝑡𝑜𝑡𝑎𝑙𝑝𝑢𝑚𝑝 * =792.84*9.81*18.39*

=2822.59W

Table 14. Pump datasheet table (P-101)

Pump Data Sheet

Equipment

Function

equipment

Centrifugal pump

of

Transportation of fluid

Process Operation Conditions

Water

,acetone

Fluid type

,isopropanol mixture Phase

liquid

Minimum

Flow best efficiency

flow(m/s)

0.016 point

0.02

Suction side

Discharge side

Temperature,

K

320 Temperature, K

320

Density ,kg/m3

792.84 Density ,kg/m3

792.84

Viscosity, Pa*s

0.000956186 Viscosity, Pa*s

0.000956186

Vapour

pressure ,Pa

17210

Pipeline data

Diameter

of

pipe, m

0.10160 Diameter of pipe, m

0.10160

Length of pipe,

m

12 Length of pipe ,m

30

Roughness,

mm

0.015 Roughness ,mm

0.015

Technical Design Data

Suction

Discharge pressure

pressure, kPa

280.895 ,kPa

423.982

Total

pump

head, m

18.397 NPSH available ,m

33.90

Number

of

Impeller Pat 07 002

stages

1 Impeller type

115

Pipeline

material

Stainless steel

NPSH required ,m

3.8

Motor

Type

IEC standard

Size, kW

Enclosure

Sizing

requirement

TEFC

Speed ,rpm

3

3749

Maximum power

Frame ,L

Specifications of pump

Actual power,

Theoretical

power

kW

2.337107625 ,kW

Efficiency,%

82.8 Size

100

2.82259375

2*37H

Heat transfer equipment -HE design

In the subsequent section, the design report will be continued with the description of

design procedures related to heat exchanger, namely HE-101 whose purpose is to heat

up the mixture temperature from 298K to 320 K before mixing of the stream with recycle

stream. After investigation of types of heat transfer equipment in industrial fields, their

advantages, disadvantages and applications , it has been decided that the most proper

and relevant one to current process requirements is shell and tube heat exchanger, and

some of the preference reasons are outlined as follows:

It is more comfortable and easier to handle with the cleaning issues of this type.

STHEs occupy less space and give more efficiency.

The design is not very complicated and that is why maintenance is not hard and

does not require additional effort and cost.

Tube numbers can be higher.

Handling with leaked tubes is not tremendously hard.

There are also some more benefits of STHEs, however it is enough to mention the main

ones. As it was noted down, HE-101 will increase liquid mixture temperature and the

reason for that is related to the increment of viscosity value which makes transportation

process more comfortable by making mobility to be higher. The brackish water (in other

words sea water) will be used as heating agent whose temperature will decrease from

353K to 338K and put in the shell side. This heating agent was preferred due to its

availability and heat capacity’s higher value. The sea water is in the shell side due to its

corrosive nature while the mixture of organic and inorganic fluids is in the tube side. To

prevent any feasible wear or corrosion of tubes, austenitic stainless steel construction

material was chosen.

The famous method called Kern’s method is used for design procedures of HE-101.

Before starting certain benefits and drawbacks of Kern’s method must be explained in

order to have better understanding. Whereas in standard design stages this method

gives satisfactory and reasonable heat prediction transferring coefficient, easy to be

applied, preliminary precise design computations, pressure loss predictions are not that

much satisfying as within this method leakage and bypass streams are not taken into

account ( they are essential on pressure drops for heat transfer equipment).

In order to get highest possible heat transferring rate, keep comparatively stable

difference of temperatures, prevent higher temperature deviations, counter-current flow

arrangement was opted. Turning to the pitch selection, whereas there is a possibility to

have more pressure drop, as it is the best option for higher heating rate, triangular pitch

was selected , and it was set that the difference between centers of the tubes is 1.25

times greater than outer diameter whereas the number of passes is chosen as 6.

Ascertainment of physical properties of heat exchanger

Since the calculation ways of density, viscosity and thermal conductivity and specific heat

capacity have already been elucidated in previous sections, there is no need to show

them again , and for that reason tube and shell sides’ physical properties are tabulated

within table provided below:

Table 15. Tube and shell side properties of HE-101

TUBE Cold stream (water and

isopropanol mixture)

Physical

properties

Inlet part

Temperature,

Celsius

Temperature, Kelvin

Mean temperature

(Kelvin)

Density at T mean,

kg/m^3

Viscosity at T mean

,Pa*s

Molecular

weight(kg/kmol)

Heat capacity at T

mean ,J/mol*K

Heat capacity

Tmean,kJ/kg*K

at

Conductivity at

mean , W/m*K

T

Outlet part

25

298

47

320

SHELL Hot stream (water)

Outlet

part

Inlet part

80

353

309

345.5

803.5990128

976.3

0.000126851

0.000389298

46.2067265

18

155.1571276

75.438

3.357890492

4.191

0.197801557

0.663355

65

338

Ascertainment of Duty of HE and LMTD

The mass flow rate value for liquid mixture which contains water and isopropanol is equal

to 11.65kg/s. By applying the values of specific heat capacities, temperature of both tube

and shell sides, and tube side’s mass, firstly duty of heat transfer equipment and secondly

mass flow of shell side liquid can easily be found out.

Q=mtube*cp,tube*(Tout,tube- T,in,tube)= 11.65*3357.89*(320-298)=860.915kW

After some additional research papers review ( Couper 1964), it was found that for having

more stable temperature difference in both sides, it would be better to have inlet and

outlet temperatures of water side as 353 and 338K in turn, then mass of sea water is

calculated and heat exchanger’s temperature profile is shown subsequent to that:

𝑄

mshell=

860915

=

=13.69kg/s

cp,shell∗(Tout,shell− T,in,shell) 4191∗(353−338)

Graph 1. Temperature diagram of HE-101

Temperature profile of HE-101

360

Temperature values in Kelvin

350

340

330

320

310

300

290

1

1.2

1.4

Hot shell side

1.6

1.8

2

Cold tube side

By means of the temperature plots above, LMTD which mean logarithmic mean

temperature difference between two sides can be determined , and it is noteworthy to

write that having greater LMTD is desirable, since in that case heat transfer rate will also

be higher.

∆𝑇𝐿_𝑀 =

∆𝑇1 −∆𝑇2 33−40

∆𝑇

ln(∆𝑇1 )

2

=

33

ln(40)

=36.39 Celsius

However, the value of LMTD is not always as the same as true value of temperature

difference , especially in the cases of multi-passing and cross flows; thus correction factor

is used for compensation of calculated LMTD value to mean temperature difference. This

factor is mostly used when the arrangement is counter current , and if the input and output

temperature values are available, in that case it is easier to size heat exchanger by using

true difference of temperatures. Actually, the value of correction factor has dependency

from both tube and shell sides, as well as tube numbers and shell passes, but for

determination of its value from chart or equation, 2 unitless ratios are used :

𝑅=

𝑆=

𝑇1_𝑠ℎ𝑒𝑙𝑙 −𝑇2_𝑠ℎ𝑒𝑙𝑙

𝑡2_𝑡𝑢𝑏𝑒 −𝑡1_𝑡𝑢𝑏𝑒

𝑡2_𝑡𝑢𝑏𝑒 −𝑡1_𝑡𝑢𝑏𝑒

𝑇1_𝑠ℎ𝑒𝑙𝑙 −𝑡1_𝑡𝑢𝑏𝑒

=0.68

=0.4

By using those coefficients and correction factor chart the correction factor value can be

found out if the R curves and S values on x axis are intersected with corresponding y

value which stands for 𝐹𝑡 and is found out as 0.96.

Chart 1. Correction factor determination

Moreover, there is one more way of finding correction factor which is analytical and

following equation should be applied:

𝐹𝑡 =

1−𝑆

1−𝑅𝑆

√𝑅2 ln

2−𝑆∗(𝑅+1−√𝑅2 +1)

(R−1)∗ln

2−𝑆∗(𝑅+1+√𝑅2 +1)

This equation gives the value for 𝐹𝑡 as 0.957 and this is very close to graphically obtained

one, thus:

Mean temperature difference=𝐹𝑡 * LMTD=0.96*36.39=34.82 Celsius

Assuming of heat transfer coefficient

The main and necessary stage in Kern method is having correct assumption of heat

transferring coefficient for successfully completing the design as it is needed. Since the

mixture within the tube side consists of water and 2 organic liquids, and shell side only

has sea water, the U value is assumed to be 400W/m2 °C.

Ascertainment of number of tubes and diameter of shell

Now, it is time for surface area determination of heat exchange equipment:

𝑄̇ = 𝑈𝐴∆𝑇

A=

𝑄

=

860915

=61.8m2

𝑈∆𝑇 400∗34.82

It must be said here that the area for shell and tube heat exchanger selection should be

greater that 50 m2 and it is evident that this requirement is met by this value. Outer tube

diameter is taken as 45mm whereas the inner one is 36.6mm and tube length is 2.4 m

which can be varied between 2m and 10m. Following to that area for just 1 tube is to be

commenced:

𝐴𝑓𝑜𝑟_𝑜𝑛𝑒_𝑡𝑢𝑏𝑒 = 𝜋𝑑_𝑜𝑢𝑡𝑒𝑟_ 𝐿 = 𝜋 ∙ 0.045𝑚 ∙ 2.4𝑚 = 𝟎. 𝟑𝟑𝟗𝟑 𝒎𝟐

Since total equipment area and area of 1 tube are known, by dividing the first one to the

second it has been found that there are totally 183 tubes of HE and , by considering the

fact that STHEs are able to accommodate approximately 10000 tubes, this figure is

sufficient and normal.

Bundle diameter is estimated by means of an experimental formulae which is based on

standard tube layouts where K1 and n1 are constant figures for pattern -triangle and are

taken from below:

Table 16. Triangular pitch values for K1 and n1

1

𝐷_𝑏𝑢𝑛𝑑𝑙𝑒_ = 𝑑_𝑜𝑢𝑡𝑒𝑟_ ∙

𝑁_

𝑛

( 𝑡𝑢𝑏𝑒𝑠_) ! =1024.1mm

𝐾1

Triangular pitch with p=1.25 was preferred as fluid of shell side is relatively clean without

having impure components. When it comes to the selection reasons of split floating head,

having differential expansion (thermal expansion) among shell and tube sides, simple

cleaning and rational cost can be given as instances. Since shell diameter is the

summation of bundle diameter and space between shell inside and tube bundle, which is

considered as clearance, clearance value is needed to be known from the below chart:

Chart 2. Bundle diameter and clearance chart

So, clearance was taken as 74mm and shell diameter is calculated as 1098.1mm and

according to TEMA standards, this value is allowed to be till 1520mm.

Ascertainment of tube side HTC (Heat transfer coefficient)

First of all heat area must be defined:

𝐴𝑡𝑢𝑏𝑒 = 𝐴𝑡𝑢𝑏𝑒_𝑖𝑛 ∙

𝑁_𝑡𝑢𝑏𝑒

𝑁_𝑝𝑎𝑠𝑠𝑒𝑠

=

𝜋∙0.03862 𝑚2

4

∙

183

6

=0.03569 𝑚2

Subsequent to that linear velocity of tube side mixture can be found:

𝑉

𝑢𝑙𝑖𝑛𝑒𝑎𝑟= = 0.4m/s

𝐴

There is one more term named as Colburn coefficient which is essential to be introduced

before going on with next stages of calculations. In general , transfer principles of mass

and heat, also momentum principles are the same in most of the cases and they can be

intercorrelated in certain circumstances. In this section of the design , the analogy called

Colburn-Chilton will be used based on what tube side HTC will be estimated:

1

ℎ𝑡𝑢𝑏𝑒_𝑠𝑖𝑑𝑒

𝑘𝑡𝑢𝑏𝑒 ∙ 𝑗ℎ ∙ 𝑅𝑒 ∙ (Pr)3

=

𝑑𝑖𝑛𝑛𝑒𝑟

Where k shows thermal conductivity of mixture, Re is Reynolds number for fluid regime

determination, Prandtl number is indicated as PR and Colburn factor is indicated as j.

Calculation of the value of Reynolds number is the next step:

𝑅𝑒 =

𝜌∗𝑢𝑙𝑖𝑛𝑒𝑎𝑟= ∗𝑑𝑖𝑛𝑛𝑒𝑟 803.59∗0.4∗0.0386

𝜇(𝑡𝑢𝑏𝑒)

=

0.000126851

=99357

The flow regime is turbulent since obtained value is greater than critical value.

Then, Pr number calculation is performed:

Pr_ 𝑛𝑢𝑚𝑏𝑒𝑟 =

𝑐𝑝∗𝜇(𝑡𝑢𝑏𝑒)

𝑘(𝑡𝑢𝑏𝑒)

=2.15

Now, there is just one unknown parameter -Colburn factor which must be taken from

corresponding chart:

Chart 3. Tube side heat transfer factor Colburn chart

At given value of Re number, heat transfer factor is nearly equal to 0.029 and, by inserting

all given in the equation for tube side HTC , following result will be obtained:

1

ℎ𝑡𝑢𝑏𝑒_𝑠𝑖𝑑𝑒 =

1

𝑘𝑡𝑢𝑏𝑒 ∙𝑗ℎ ∙𝑅𝑒∙(Pr)3 0.198∙0.029∙99357∙(2.15)3

𝑑𝑖𝑛𝑛𝑒𝑟

=

0.0386

=1901.83 W/k*m2

Ascertainment of shell side HTC (Heat transfer coefficient)

The primary step for shell HTC estimation is the determination of baffle spacing, and

baffles are very important parts of the heat exchangers as their duty is keeping the tubes

all together. The most preferred baffle spacings vary between 0.2 and 1 times of diameter

of shell. It must also be kept in mind that when the baffles are put closer to each other,

higher rate will be observed but at expense of greater pressure loss. In this design, baffle

spacing is accepted to be 0.5 times of shell diameter which gives the figure as 549mm.

𝐴_𝑠ℎ𝑒𝑙𝑙_ =

(𝑝𝑝𝑖𝑡𝑐ℎ −𝑑𝑜𝑢𝑡𝑒𝑟 )∙𝐷𝑠ℎ𝑒𝑙𝑙 𝐿𝑏

𝑝𝑝𝑖𝑡𝑐ℎ

Then, linear velocity should be defined:

𝑢𝑙𝑖𝑛𝑒𝑎𝑟=

𝑉

𝐴_𝑠ℎ𝑒𝑙𝑙_

= 0.116m/s

=0.12 m2

And as it has done for tube side, the same calculations for Re and Pr numbers should be

executed:

𝑅𝑒 =

𝜌∗𝑢𝑙𝑖𝑛𝑒𝑎𝑟 ∗𝑑𝑒𝑞𝑢𝑖𝑣𝑎𝑙𝑒𝑛𝑡 803.59∗0.4∗0.0386

𝜇(𝑡𝑢𝑏𝑒)

Pr_ 𝑛𝑢𝑚𝑏𝑒𝑟 =

=

𝑐𝑝∗𝜇(𝑡𝑢𝑏𝑒)

𝑘(𝑡𝑢𝑏𝑒)

0.000126851

=99357

=2.459

Once again the factor proposed by Colburn must be used, however in comparison to tube

side, in shell side baffle cut must be chosen for intersecting with corresponding Re

number, and 25% baffle cut was chosen which is considered the most common and

optimum cut:

Chart 4. Shell side heat transfer factor Colburn chart

Here it is also necessary to calculate equivalent diameter since in shell side calculations

it

will

𝑑𝑒𝑞𝑢𝑖𝑣𝑎𝑙𝑒𝑛𝑡 =

be

1.27

𝑑𝑜𝑢𝑡𝑒𝑟

needed:

2

(𝑝𝑡2 − 0.785𝑑𝑜𝑢𝑡𝑒𝑟

)=0.032m

Now by inserting all values in required places , shell side HTC is obtained:

1

ℎ𝑠ℎ𝑒𝑙𝑙𝑠𝑖𝑑𝑒 =

𝑘𝑠ℎ𝑒𝑙𝑙 ∙𝑗ℎ ∙𝑅𝑒∙(Pr)3

𝑑𝑒𝑞𝑢𝑖𝑣𝑎𝑙𝑒𝑛𝑡

𝑊

=

1

0.066 2 ∙0.006∙9321∙2.463

𝑚 𝐾

0.032

=1562.672

1

ℎ𝑠ℎ𝑒𝑙𝑙_𝑠𝑖𝑑𝑒 =

𝑘𝑠ℎ𝑒𝑒𝑙 ∙𝑗ℎ ∙𝑅𝑒∙(Pr)3

𝑑𝑒𝑞𝑢𝑖𝑣𝑎𝑙𝑒𝑛𝑡

=1562.6733 W/k*m2

Tube and shell sides’ pressure drops’ ascertainment

Pressure losses are other crucial properties that must be calculated, since they are

greater than allowable pressure drops, it would not be desirable. In this case, friction

factor charts will be applied for both sides, whereas the finding ways will be similar as in

Colburn charts. From the charts below, shell side friction factor coefficient is obtained as

0.05 while that for tube side is equal to 0.0029.

Chart 5. Shell side friction factor determining chart

Chart 6. Tube side friction factor determining chart

𝑙

∆𝑃𝑠ℎ𝑒𝑙𝑙_𝑠𝑖𝑑𝑒 = 8𝑗𝑓 ( 𝑡𝑢𝑏𝑒) (

𝐿𝑏

𝐷𝑠ℎ𝑒𝑙𝑙

𝑑𝑒𝑞𝑢𝑖𝑣𝑎𝑙𝑒𝑛𝑡

∆𝑃𝑡𝑢𝑏𝑒_𝑠𝑖𝑑𝑒 = 𝑁𝑜𝑓_𝑝𝑎𝑠𝑠𝑒𝑠 ∗ (8𝑗𝑓 ∗

2

𝜌𝑢𝑡𝑢𝑏𝑒

2

)

2

𝜌𝑢𝑠ℎ𝑒𝑙𝑙

𝑙𝑡𝑢𝑏𝑒

𝑑𝑖𝑛𝑛𝑒𝑟

2

=8*0.05*4.37*34.37*6.6=396.944Pa

+ 2.5) ∗

=6*(8*0.029*(2.4/0.0286+2.5)*(803.6*0.42)/2=1569.155Pa

Overall heat transfer coefficient’s ascertainment

Finally, Kern method’s most important part is reached which is dedicated to the

determination of overall HTC and comparison of it with initially assumed value. Taking

into account the constriction material which is stainless steel and deposits layers that are

also resistant to transferring of heat known as fouling factor, they all must be considered

during calculation. The fouling factors, thermal conductivity and shell and tube side HTCs

are tabulated below:

Table 17. Required figures for overall HTC calculation

Tube side HTC

Tube side fouling coefficient

Material conductivity (stainless

steel)

Shell side HTC

Shell side fouling coefficient

1

𝑈𝑜𝑣𝑒𝑟𝑎𝑙𝑙_

1901.834711

4000

16

1562.67329

1000

𝑑

𝑑𝑜𝑢𝑡𝑒𝑟 ln ( 𝑜𝑢𝑡𝑒𝑟 )

𝑑𝑜𝑢𝑡𝑒𝑟

𝑑𝑜

𝑑𝑖𝑛𝑛𝑒𝑟

=

+

+

+

+

ℎ𝑠ℎ𝑒𝑙𝑙 ℎ𝑠ℎ𝑒𝑙𝑙𝑓𝑜𝑢𝑙𝑖𝑛𝑔

2 ∙ 𝑘𝑠𝑡𝑎𝑖𝑛𝑙𝑒𝑠_𝑠𝑡𝑒𝑒𝑙

𝑑𝑖𝑛𝑛𝑒𝑟 ℎ𝑡𝑢𝑏𝑒 𝑑𝑖 ℎ𝑡𝑢𝑏𝑒_𝑓𝑜𝑢𝑙𝑖𝑛𝑔

𝑈𝑜𝑣𝑒𝑟𝑎𝑙𝑙_ =

1

1

1

0.045

0.045 ln(0.386)

1

1

0.045

0.045

+

+

+0.0386∗1901.83+0.0386∗4000

1562.67 1000

2∙16

= 362.306 𝑾/𝒎𝟐 ℃

This is very close to the assumed value which was 400 𝑊/𝑚2 ℃ and there is just 9.42%

error which is allowable.

Table 18. HE-101 construction table

Type

Purpose

Number of passes

Properties

Construction sheet of HE-101

Shell and Tube

Heating gas mixture

Tube

Shell

6

1

Shell side

Inlet

Outlet

353

338

1

1

13.69

Utility

Heat transfer area

Tube material

Number of tubes

Tube side

Inlet

293

3

11.65

Sea water

61.8 m2

Stainless

steel

183

Outlet

370

1

Temperature (K)

Pressure (bar)

Mass flow rate (kg/s)

Allowable pressure drop

0,2

0,2

(bar)

75.438

155.157

Average Cp (J/mol K)

Average

conductivity

0.66

0,197

(W/m K)

976.3

803.599

Average density (kg/m3)

0.000389

0.0001268

Viscosity (Pa*s)

Tube parameters

Shell parameters

2.4

Shell diameter (mm)

1098

Length (m)

45

Bundle diameter (mm)

1024

Outer diameter (mm)

38.6

Clearance (mm)

74

Inner diameter (mm)

67.5

Equivalent d (m)

0.032

Tube pitch (mm)

3.2

Baffle space (mm)

549

Thickness (mm)

0.4

Baffle cut (%)

25

Velocity (m/s)

Heat transfer specifications

Overall coefficient (W/m2

C)

362.306

Driving force (K)

34.82

CounterHeat load (kW)

860.915kW

Flow Regime

current

Equipment safety

While very detailed information has already been provided in safety section, safety issues

related to pumps and heat exchangers are going to be explained individually in this part

as well.

Pumps:

As it is obvious, there are several kinds of centrifugal pumps which would operate properly

if the selection is true, however there are certain possibilities which must be considered

in order to prevent possible failures contributing to cost, ecological and mechanical