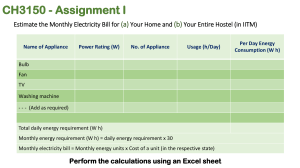

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BRITISH STANDARD

Installation and

maintenance of flues

and ventilation for gas

appliances of rated

input not exceeding

70 kW net (1st, 2nd and

3rd family gases) —

Part 2: Specification for installation and

maintenance of ventilation for gas

appliances

ICS 91.060.40

12&23<,1*:,7+287%6,3(50,66,21(;&(37$63(50,77('%<&23<5,*+7/$:

BS 5440-2:2000

Incorporating

Amendments Nos. 1

and 2

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

Committees responsible for this

British Standard

The preparation of this British Standard was entrusted to Technical

Committee GSE/30, Gas installations (1st, 2nd and 3rd family gases), upon

which the following bodies were represented:

BCEMA – British Combustion Equipment Manufacturers Association

Boiler and Radiator Manufacturers’ Association Ltd

British Flue and Chimney Manufacturers’ Association

Centrica

Consumer Policy Committee of BSI

CORGI – Council for Registered Gas Installers

DTI – Consumer Safety Unit

HSE – Health and Safety Executive

Heating and Ventilating Contractors’ Association

Institute of Domestic Heating and Environmental Engineers

Institution of Gas Engineers

Liquified Petroleum Gas Industry Technical Association

Society of British Gas Industries

Co-opted member

This British Standard was

published under the authority

of the Standards Committee

and comes into effect

on 15 January 2000

© BSI 6 July 2004

Amendments issued since publication

The following BSI references

relate to the work on this British

Standard:

Committee reference GSE/30

Draft for comment 98/712227 DC

ISBN 0 580 33098 2

Amd. No.

Date

13368

1 November 2001

14912

6 July 2004

Comments

Commentary and recommendations on

5.1.1 amended

BS 5440-2:2000

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

Contents

Committees responsible

Foreword

1

2

3

4

5

6

7

Page

Inside front cover

ii

Scope

Normative references

Definitions

Design and materials for air vents and ducts

Size and position of air vents

Other aspects of ventilation

Maintenance

Bibliography

21

Figure 1 — Typical air vent arrangements

Figure 2 — Free-areas

Figure 3 — Air vents in series

Figure 4 — Air vent positions for an open-flued appliance in a room or

internal space

Figure 5 — Air vent positions for an open-flued appliance in an appliance

compartment

Figure 6 — Air vent positions for a room-sealed appliance in an appliance

compartment, room and internal space

14

15

16

Table 1 — Minimum separation distances between air vents and appliance

flue terminals (mm)

Table 2 — Minimum air vent free-area for appliance compartments:

open-flued appliances

Table 3 — Minimum air vent free-area for appliance compartments:

room-sealed appliances

Table 4 — Minimum permanent opening free-area for flueless appliances

© BSI 6 July 2004

1

2

2

3

5

12

13

17

18

19

6

8

9

11

i

BS 5440-2:2000

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

Foreword

This part of BS 5440 has been prepared by Technical Committee GSE/30. It is a

revision of the specification BS 5440-2:1989, which is withdrawn.

The title has been modified to incorporate actions required when maintaining

appliances and the provisions for ventilation. A new Clause 7 has been introduced

to cover this aspect.

This standard recognizes investigative work carried out by British Gas plc and

other bodies into the magnitude of adventitious openings, which are always

present in rooms to some degree. The lower limit of 35 cm2 remains valid and this

figure is used in this revision for open-flued appliances.

This standard allows manufacturers’ instructions to specify a method of

installation, testing, commissioning or maintenance which differs in points of

detail from this standard. This reference to manufacturers’ instructions is

allowed only where it will result in at least an equivalent level of safety. In such

circumstances, it is important that the manufacturer’s instructions are followed.

This publication does not purport to include all the necessary provisions of a

contract. Users are responsible for its correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Attention is drawn to the following statutory regulations. The regulations may be

amended from time to time and whichever regulations are currently in force at

the time an installation is carried out are to be complied with. The advice in this

British Standard reflects the state of the regulations in 1999.

a) The Gas Safety (Installation and Use) Regulations [1]. These control all

aspects of the ways in which gas-fired systems are installed, maintained and

used, in premises where they apply, and the classes of persons who may

undertake gas work.

b) The building regulations for the appropriate legislative region. These control

works carried out in the construction of new or extension of existing buildings.

Detailed advice for England and Wales [2] is given in approved documents and

for Northern Ireland [3] in technical booklets. The Building Standards

(Scotland) [4] are accompanied by methods that are deemed to satisfy these

standards.

Summary of pages

This document comprises a front cover, an inside front cover, pages i and ii,

pages 1 to 21 and a back cover.

The BSI copyright notice displayed in this document indicates when the

document was last issued.

ii

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

1 Scope

1.1 Equipment

This part of BS 5440 specifies the ventilation requirements for new or replacement gas appliances for

domestic or non-domestic purposes utilizing 1st, 2nd or 3rd family gases which carry the CE mark and with

a rated heat input not exceeding 70 kW based on net CV (net calorific value). It may also be used for

installations of appliances which are not required under the Gas Appliances (Safety) Regulations:1995 [5]

to carry the CE mark, e.g. used appliances. This standard does not cover:

a) LPG installations covered by the requirements of BS 5482-2 and installations with all gases covered

by BS 5482-3;

b) any gas installations in caravans, holiday homes or residential park homes constructed to conform

to BS EN 721 or BS 3632 as appropriate, which were installed at the time of construction;

c) decorative fuel effect gas appliances of the type covered by BS 5871-3.

NOTE 1 Standards that should be consulted are listed in normative references Clause 2 and the bibliography at the end of the

standard.

NOTE 2

Maintenance requirements relating to existing vents are given in Clause 7.

NOTE 3 The installer should check the data given with an appliance to establish the basis on which the heat input is given. The

data in this standard refers to heat input expressed in terms of net calorific values (CV) with conversion given for natural gas gross CV

quoted in brackets where appropriate.

The ratio of gross:net heat input is approximately 1.11:1 for natural gas, 1.09:1 for propane and 1.08:1 for

butane. For example, convert 9 kW input based on gross CV for natural gas to the equivalent net CV input

as follows.

Net input = 9.0/1.11 = 8.1 kW.

The change to the method of quoting input rating is not intended to have any significant effect on the sizes

of vents required for gas appliances as compared with the previous version of this standard

(BS 5440-2:1989).

The differences in gross:net input ratio between natural gas, propane and butane are marginal and this

factor has been taken into account when specifying the method of calculating vent requirements in 5.2.1.

1.2 Competence

It is essential that persons carrying out the installation of any gas appliance be competent to do so, and, in

the case of any work that is subject to the current Gas Safety (Installation and Use) Regulations, it is

essential to comply with these regulations.

It is essential that persons who design the ventilation system or installation have a knowledge and

understanding of the standards and regulations that apply to ensure that the completed plans will produce

a safe and satisfactory installation.

COMMENTARY AND RECOMMENDATIONS ON 1.2

At the time of publication, the body with HSE approval to operate and maintain a register of businesses who

are “members of a class of persons” is the Council for Registered Gas Installers (CORGI). Thus it is essential

that all business or self employed gas fitters should be registered with CORGI.

Guidance on the individual competency required for gas work is given in the Health and Safety

Commission’s Approved Code Of Practice (ACOP) — Standards of training in safe gas installation. [6]

Persons deemed competent to carry out gas work are those who hold a current certificate of competence in

the type of activity to be conducted issued under the ACOP arrangements, or by a certification body

accredited by the United Kingdom Accreditation Service (UKAS).

© BSI 6 July 2004

1

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute

provisions of this part of this British Standard. For dated references, subsequent amendments to, or

revisions of, any of these publications do not apply. For undated references, the latest edition of the

publication referred to applies.

BS 1179-6, Glossary of terms used in the gas industry — Combustion and utilization including installation

at consumer’s premises.

BS 7624, Specification for the installation of domestic direct gas-fired tumble dryers up to 3 kW heat input

(2nd and 3rd family gases).

BS EN 449:1997, Specification for dedicated LPG appliances. Domestic flueless space heaters (including

catalytic combustion heaters).

3 Definitions

For the purpose of this part of BS 5440 the definitions given in BS 1179-6 apply, together with the

following.

3.1

adapter

a device to facilitate smooth and unrestricted air flow through transitional changes in section, where the

cross-sectional shape of an air duct differs to that of the associated air vent

3.2

air vent

a non-adjustable purpose provided unit/assembly designed to allow permanent ventilation (see Figure 1)

3.3

appliance compartment

an enclosure (not being a habitable space) specifically designed or adapted to house one or more gas

appliances. (See 5.2.2 and 5.3.2 for further details.)

3.4

equivalent area

the air vent free-area which is aerodynamically equivalent to a single sharp edged circular hole. For a

simple air vent (e.g. a grille on both ends of a smooth uninterrupted duct), the equivalent area can be

regarded as the “free-area”

3.5

free-area

the unobstructed cross-sectional area of a grille, louvre or duct calculated as the sum of the cross-sectional

areas of all unobstructed apertures measured through the plane of minimum area and at right angles to

the air flow within the apertures (see Figure 2)

3.6

grille

a simple fixed mesh or lattice arrangement designed and constructed to preclude vermin but to allow the

passage of air at all times. It may be employed independently as an air vent, set in a dedicated housing, or

used with an adapter or duct. (See commentary and recommendations to 4.1.2 for further details.)

3.7

internal space

an interior space such as a hall, passageway, stairway or landing, which is not a room

3.8

intumescent air vent

an assembly specified for preventing the spread of fire, consisting of a metal louvre/grille with an

intumescent block secured behind it which incorporates a latticework of holes to provide continuous

ventilation but will expand and close in the event of extreme heat build up such as in a fire. When fitted to

doors, the assembly usually has a louvre/grille on both sides

2

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

3.9

louvre

an assembly of fixed sloping blades or vanes contained within a framework designed and constructed to

resist light and rain penetration but allow the unrestricted passage of air at all times. It may be employed

independently as an air vent, set in a dedicated housing or used with an adapter or duct

3.10

protected area

an area (e.g. hall, landing, lobby, corridor, stairway, shaft) other than an appliance compartment, which is

enclosed with fire resisting materials

3.11

ventilation

the process of supplying air to, and removing air from a room, internal space, appliance compartment or

garage. The air may be used or intended to be used for purposes of combustion, cooling and/or the operation

of a flue

4 Design and materials for air vents and ducts

4.1 Design

4.1.1 Free-area

A proprietary unit/assembly which is marked with the free-area shall be used wherever possible.

COMMENTARY AND RECOMMENDATIONS ON 4.1.1

The development of materials, technology and manufacturing techniques has led to a wide diversity of

ventilation products, including complex multiple assemblies dedicated to specific applications such as

minimizing draughts or sound transmission, or providing air warming. The free-area of such products, by

virtue of their internal aerodynamic characteristics, may not be calculated reliably from physical

measurement. There is currently no formally agreed standard for the design or production of air vents for

use with gas appliances and thus manufacturers are not obliged to mark their products with an area

calculated in a uniform manner. However, in order to encourage consistency between claims of vent

characteristics, a procedure has been developed which is contained in the BG Technology publication.

“A dynamic test procedure for characterizing ventilator free-area” [7]. The equivalent area measured by this

procedure and stated in the vent manufacturer’s literature and/or marked on the air vent, should be used

where it is available, as this may differ considerably from the free-area measured at one end of the air vent.

In the absence of any such marking on a grille, louvre or duct, the sum of the free cross-sectional areas of the

apertures should be used (see Figure 2). For a louvre, the areas should be measured at right angles to the

blades or vanes. For an air vent assembly, the free cross-sectional area of the most restrictive component in

an assembly should be used to calculate the free-area.

Where two or more components are employed to construct a non-proprietary assembly, changes in section

and cross-sectional area should be avoided where possible. Where such changes do occur, adapters should

be used to facilitate a smooth and efficient transition which minimizes any restriction at any of the

components. The free-area should be determined from the free-area of the component with minimum

free-area.

In Figure 1a), for example, if the air brick has 60 holes of 9 mm × 9 mm, i.e. area = 48 cm2, the duct

is 150 mm in diameter, i.e. area = 176 cm2, the louvre has 6 slots each of which is 156 mm long and 9 mm

wide, i.e. area = 84 cm2, the free-area for the whole vent should be taken as that of the component with the

minimum area i.e. 48 cm2. If the areas are similar then caution should be used since components with

similar aerodynamic resistances placed in series will be more restrictive than the individuals. If the

free-area cannot be established, an alternative vent should be used.

Although a non-preferred practice, where grilles/louvres and ducts of dissimilar shape or proportion are

used together, [see Figure 2b)], e.g. 225 mm × 150 mm rectangular louvre and a 125 mm diameter duct,

sufficient space should be allowed between the rear face of the louvre and the end of the duct to prevent an

obstruction to the free-area. (20 mm is typically a satisfactory clearance.)

All grilles, louvres or louvered doors required by this standard to be used internally, should be marked or

labelled “IMPORTANT — Do not block this vent”.

© BSI 6 July 2004

3

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

4.1.2 Air vents communicating directly with outside air

A ventilation opening across an external wall directly to outside air, shall be continuous, unobstructed and

fitted with a terminal device such as a grille or louvre at each end. Where a ventilation opening passes

through a cavity wall, it shall include a continuous duct across the cavity, conforming to 4.1.4 and shall be

fitted so that it does not impair the water resistance of the cavity.

COMMENTARY AND RECOMMENDATIONS ON 4.1.2

Where an air vent incorporates a draught reducing device or other restriction, experience has shown that this

imposes a 25 % to 50 % reduction in equivalent area over that of an unrestricted air duct. The manufacturer

should state the equivalent area.

The apertures of an air vent should prevent the entry of a 10 mm diameter ball but allow entry of a 5 mm

diameter ball. Experience has shown that vermin can thrive in ducts fitted with vents of little over 10 mm

and conversely that domestic debris can block vents of little less than 5mm. No gauze or fly screen (i.e. mesh

having apertures of less than 5 mm) should be incorporated or subsequently fitted to an air vent. Such

practices may compromise the free-area and in certain circumstances provide habitat for vermin.

4.1.3 Air vents not communicating directly with outside air

Where an opening is made through any internal wall, door, partition or panel for the purpose of providing

ventilation, the opening so formed shall be completely cleared of debris prior to fitting of the air vent. Where

the wall, door, partition or panel contains any material, e.g., insulation, that may slip and cause an

obstruction, a duct shall be used between each end of the air vent.

COMMENTARY AND RECOMMENDATIONS ON 4.1.3

Where air is taken from a roof space or underfloor space, refer to the commentary and recommendations

on 5.1.2.2.

4.1.4 Ducts

Any duct used for the purpose of providing ventilation shall be of such a size to allow the full ventilation

requirement of this standard to be met. The cross-sectional free-area of a duct shall be not less than that

of any grilles or louvres fitted at either end of the duct. The design and construction of a duct shall be such

that there are no gaps which permit the ingress of water, vermin, cavity insulation material etc. It shall

facilitate inspection of the entire air passage for integrity and blockage at any time, e.g. on initial

installation or after cavity foam insulation has been installed.

COMMENTARY AND RECOMMENDATIONS ON 4.1.4

Where the cross-sectional shape of a duct differs from that of the associated grille/louvre, the cross-section of

the duct should be modified, or adapters employed to facilitate smooth transition and ensure that neither

the air duct nor the grilles/louvres are restricted. Where an adapter is employed, the air vent free-area may

be reduced, or even determined by the adapter. Every effort should be made to keep the ducts proportional

and of similar cross-sectional shape to that of the associated grilles/louvres.

It may be necessary to inspect a duct on installation of the air vent and/or the gas appliance, or after the

cavity has been filled with insulation, e.g. foam or granules.

Long horizontal ducts and ducts intended to convey air downwards should be avoided. Where horizontal

ducts are necessary, e.g. for internal rooms or basements, they should be as short as practicable, not more

than 3 m long and incorporate not more than 2 right angled bends, unless a special allowance is made for

the restriction that they impose. This may be achieved by increasing the cross-sectional area by 50 % for each

successive 3 m or part thereof in excess of the initial 3 m run and/or incorporating an upwards slope.

Ducts intended to convey air downwards are unlikely to be effective as buoyancy forces of indoor air tend to

counteract the flow of incoming air. Attention is drawn to BS 5440-1 for advice on balanced compartments.

The use of flexible ducting should be avoided wherever possible. Where there is no practicable alternative,

flexible ducting should be firmly fixed in a taut manner.

4.2 Materials

4.2.1 Air vents and ducts shall be such that they are dimensionally stable (except in the case of an

intumescent air vent, see 4.3) and corrosion resistant and suitable for their intended use. When selecting

an air vent or duct, due consideration shall be given to its free-area, siting and environment.

4.2.2 Components containing asbestos shall not be used. Further advice is given in BS 5440-1.

4

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

4.3 Intumescent air vents in fire rated compartments

Where intumescent air vents are used in accordance with the building regulations, they shall be acceptable

provided that the manufacturer of the air vent, in calculating the free area, has accounted for a space

between the intumescent block and metal louvre/grille as explained in the commentary and

recommendations on 4.1.1.

The air vent shall have no means of manually closing and the use of any device other than an intumescent

block is not acceptable.

When an intumescent air vent has been triggered by a high temperature such as a fire, it shall be replaced

before any appliance is operated.

5 Size and position of air vents

5.1 General

NOTE Where the air supply requirements for a particular installation are not covered by this standard, reference should be made

to the appliance manufacturer. (See foreword.)

5.1.1 Air vents communicating directly with outside air

An air vent shall be sited in accordance with Table 1 so that there is a minimum separation between the

air vent and any part of an appliance flue terminal serving any combustion appliance in order to minimize

the risk of re-entry of the products of combustion.

COMMENTARY AND RECOMMENDATIONS ON 5.1.1

Where ventilation is provided via a roof space, see 5.1.2.2.

Table 1 gives the minimum requirements for the separation distances necessary between an air vent and an

appliance flue terminal for the following:

a) the heat input of the appliance; and

b) the type of flue to which the terminal is connected. The specified separation distances should be achieved

upon completion of the appliance and/or the air vent installation. In some cases, this may necessitate the

re-siting of an existing air vent.

These separation distances also apply to general room-extract fan outlets with, or without, a non-return flap,

mechanical ventilation openings, or any opening into a roof space. They do not apply to extract duct

terminals fitted with non-return flaps that are connected via ducts to an appliance, e.g. cooker hoods and

tumble dryers.

In addition, the air vent should not be located in a position where it is likely to be easily blocked, e.g. by

leaves or snow or other debris, become flooded, or where contaminated air might be present at any time,

e.g. car ports. Location should be such that the air currents produced will not pass through normally

occupied areas of a room and may be achieved by one or more of the following:

a) siting the appliance in an appliance compartment having air vents communicating directly with

outside air;

b) siting the air vent at a point adjacent to the appliance;

c) siting the air vent at or near ceiling height and orienting the internal louvres to direct incoming air away

from the living or general accommodation area.

5.1.2 Air vents not communicating directly with outside air

5.1.2.1 An air vent in an internal wall, other than an appliance compartment wall, shall be located not more

than 450 mm above floor level in order to reduce spread of smoke in the event of fire.

5.1.2.2 An air vent shall not communicate with a ventilated roof space or underfloor space if that space

communicates with other premises. Where an air vent is drawing air from a ventilated roof space or

ventilated underfloor space, the total effective free-area of the vents into that space shall be at least equal

to the total effective free-area of any vent or vents drawing ventilation from that space.

© BSI 6 July 2004

5

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

COMMENTARY AND RECOMMENDATIONS ON 5.1.2.2

Ventilation may be taken from an adequately ventilated roof space where this is isolated from the habited

area and as such is generally considered to be effectively outside air. Roofs built to the 1985 (or subsequent)

Building Regulations for England and Wales [2] should have adequate ventilation but this should be

confirmed. For other applications, an individual assessment may be necessary to ascertain that the

ventilation of the roof space exceeds that required by the gas appliance. In addition, due consideration

should be given to potential blockage by insulation materials, fly screens in roof space vents and the

avoidance of condensation and associated problems that may result from seasonal low ambient

temperatures in the roof space. Air vents supplying air to the appliance from the roof space should be sited

not less than 300 mm above joists so as to avoid blockage by insulation material etc., and preferably should

be fitted with a terminal device or bird guard to prevent blockage.

For advice on Radon gas and underfloor spaces, see 6.3.

Table 1 — Minimum separation distances between air vents and appliance flue terminals (mm)

Air vent position

Appliance input

(kW)

Balanced flue

Natural draught

Open-flue

Fanned draught

Natural draught

Fanned draught

Separation (mm)

A

Above a

terminal

B

Below a

terminal

C

Horizontally to

a terminal

0 to 7

>7 to 14

>14 to 32

>32

0 to 7

>7 to 14

>14 to 32

>32

0 to 7

>7 to 14

>14 to 32

>32

300

600

1 500

2 000

300

300

300

600

300

400

600

600

300

300

300

300

300

300

300

300

300

300

300

300

300

600

1 500

2 000

300

300

300

600

300

400

600

600

300

300

300

300

300

300

300

300

300

300

300

300

Key to Table 1 — Minimum separation of air vent from terminal

5.1.2.3 No air vent shall penetrate a protected area (3.10).

6

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

5.1.3 Air vents in series

See Figure 3. Where outside air is conveyed to an open-flued appliance through an external air vent

(vent number 1) into a room and thereafter through one internal wall/partition air vent (vent number 2) in

series, both vents shall be sized in accordance with 5.2.1.

Where there is more than one internal vent, the free-area of each internal vent (2, 3, 4 etc.) shall be

increased by at least 50 % over that required for vent 1.

Where an appliance is in an appliance compartment, the free-area of the high and low compartment vents

shall be determined from Table 2.

COMMENTARY AND RECOMMENDATIONS ON 5.1.3

Where only two air vents are in series, experience has shown that the additional flow resistance is acceptable

without any increase in the area of each over that required for the external air vent communicating directly

with the outside air. The imposition of vents in series will theoretically increase the resistance of air flow to

an appliance, hence the 50 % increase in area of all internal wall/partition vents, excluding compartment

vents, as a readily achievable simplification. Experience has shown that it is not necessary to increase the

size of vent 1 in this case and this may be partly due to the increased adventitious ventilation that occurs

with each extra room that the ventilation path passes through.

5.2 Open-flued appliances

5.2.1 Open-flued appliance installed in a room or internal space

Where an open-flued appliance with a rated input exceeding 7 kW is installed in a room or internal space

or garage, that room or internal space shall be provided with an air vent having a minimum free-area

of 5 cm2 for every kW of appliance maximum rated input in excess of 7 kW. Ventilated underfloor space

shall be considered as outside air for the purpose of sizing ventilator free air, providing the ventilators

supplying air to the underfloor space remain adequate, i.e. vents have not been removed, blocked or sealed.

Underfloor vents to gas space heaters shall not be positioned directly under the appliance and shall be in

accordance with BS 5871-1, BS 5871-2 and BS 5871-3 as appropriate.

When determining the net input for existing appliances whose instructions or labelling do not make any

specific reference to net or gross input, and for those appliances whose instructions or labelling quote their

input rating in gross terms, the quoted input rating shall be divided by the factor 1.1.

The permanent opening shall be either direct to outside air in accordance with 4.1.2, or to an adjacent room

or internal space via vents in accordance with 5.1.3, or to a roof space which itself has an opening of at least

the same free-area direct to outside air.

In domestic premises, the permanent opening shall be an air vent.

COMMENTARY AND RECOMMENDATIONS ON 5.2.1

The purpose of the permanent opening is to provide air for combustion and the correct operation of the flue.

Suitable air vent positions are illustrated in Figure 4 (also see 5.1.3).

It is assumed that a room or internal space can provide adequate ventilation for an appliance up to 7 kW.

Due to tolerances, it is practical for this to apply to heat inputs of 7 kW on both gross and net CV. Appliances

above this rating require purpose-designed vents. Ventilation is normally present due to natural or

adventitious ventilation through floorboards, cracks in window frames and doors, etc. However, the

availability of such ventilation should never be taken for granted as it can be affected by double glazing,

cavity insulation, draught proofing, the method of construction, the installation of extraction fans and so on.

Whilst the conversion of rated input between gross and net values strictly depends on the CV of gas used, in

practical terms a common factor 1.1 should be used. For example, an appliance with a gross heat input

of 16.5 kW has a net heat input of 15 kW (i.e. 16.5 gross/1.1 = 15 net) and to be installed in a room, it requires

a vent of (15 p 7) × 5 cm2 = 40 cm2.

If spillage from an appliance is detected, then the whole installation, including the flue, and the ventilation

should be checked and rectified. If spillage occurs and no flue fault is found, increase the ventilation

provided by progressively opening a door or window. If the flue then clears the combustion products,

measure the area of the opening and make provision for the equivalent amount of additional permanent

ventilation.

Where underfloor ventilation is used reference should also be made to 6.3.

© BSI 6 July 2004

7

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

5.2.2 Open-flued appliance installed in an appliance compartment

5.2.2.1 Where an open-flued appliance is installed in an appliance compartment, air vents in the appliance

compartment shall be sized in accordance with the appliance manufacturer’s instructions, or, in the

absence of any such instructions, in accordance with Table 2.

Vents shall be provided at both the lowest and highest practicable levels in the appliance compartment.

Both high and low level vents shall communicate either with the same room or internal space, or with the

outside air through the same wall.

Clearance around the sides, front, above and below the appliance shall be provided in accordance with the

appliance manufacturer’s instructions, or, in the absence of any such instructions, these clearances shall

be a minimum of 75 mm to the sides, above, below and in front of the appliance.

An appliance compartment shall not be used for storage. (See 5.2.2.5.)

Where an enclosure contains an appliance compartment and a storage space, e.g. an airing cupboard, the

appliance compartment shall be separated from the storage space by a non-combustible partition which

may be perforated, if required, by apertures which shall have the major dimension no greater than 13 mm.

The vents required by this standard shall be located in the appliance compartment part of the enclosure

although further vents may be located elsewhere in the enclosure for other purposes such as clothes airing.

Table 2 — Minimum air vent free-area for appliance compartments: open-flued appliances

Vent position

Appliance compartment ventilated:

to room or internal spacea

direct to outside air

cm per kW (net) of appliance maximum

rated input

cm per kW (net) of appliance maximum

rated input

2

High level

Low level

a

10

20

2

5

10

A room containing an appliance compartment for an open-flued appliance will also require ventilation, calculated in accordance

with 5.2.1.

COMMENTARY AND RECOMMENDATIONS ON 5.2.2.1

An appliance compartment, from the definition, is an enclosure which is not a habitable space. The purpose

of the vents in an appliance compartment is to provide air for combustion, correct operation of the flue and

appliance compartment cooling. However, small compartments are susceptible to vitiation caused by down

draught and great care should be taken to ensure that the ventilation is in strict accordance with this

standard or the manufacturer’s instructions.

Small rooms, such as individual WC’s, cloakrooms, understairs spaces etc., are not normally compartments.

However, because of the above susceptibility to malfunction and/or where the heat loss from the appliance

could lead to high ambient temperatures, appliance compartment ventilation should be considered.

The vertical distance between the high and low level vents should be as great as is possible to encourage a

convective air flow. Positioning air vents so that they communicate with the same room or internal space, or

with the outside air on the same wall, ensures that they are subject to a common air source and pressure.

For new (as opposed to replacement) installations, both air vents should communicate with outside wherever

practicable. Suitable air vent positions are illustrated in Figure 5.

An exception to the general requirement of both high and low vents in an appliance compartment

communicating with the same room or internal space may be defined in the appliance manufacturer’s

instructions.

A CO alarm to BS 7860 may be used to provide additional assurance.

Where an open-flued appliance is installed in a balanced appliance compartment specific installation

requirements, including those for ventilation, apply. These are given in BS 5440-1. Specialist advice should

also be obtained.

Where louvred doors provide ventilation to the appliance compartment, the total area, measured across the

minimum dimension of the slots, should not be less than the sum of the high and the low level requirements.

5.2.2.2 Where two or more appliances are installed in the same appliance compartment, whether or not

they are supplied as a combined unit, the aggregate maximum rated input shall be used to determine the

air vent free-area from Table 2.

8

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

5.2.2.3 Where the low level ventilation is via a duct from a higher level, the duct shall be independent from

any duct used for supplying the high level ventilation. No high level ventilation shall be via a duct from a

lower level. Ducts shall be sized in accordance with 4.1.4.

COMMENTARY AND RECOMMENDATIONS ON 5.2.2.3

Where practicable, both high and low level vents should communicate either with the same room or internal

space, or with the outside air at the same wall. The vertical distance between the high and low level vents

should be as great as possible.

Where low level ventilation is to be provided via a duct fed from a space above the appliance compartment,

the duct should be insulated to reduce the possibility of flow reversal and the lower end should be below the

level of the burner in the appliance.

WARNING NOTE. This is a non-preferred method for new installations since there is a possibility of

reversed air flow up the duct and products of combustion passing up this duct.

5.2.2.4 Where the appliance compartment air vents communicate with a room or internal space that room

or internal space shall itself be provided with a permanent opening in accordance with 5.2.1.

5.2.2.5 An appliance compartment containing an open-flued appliance shall be labelled to warn against

blockage of the vents and use for storage.

COMMENTARY AND RECOMMENDATIONS ON 5.2.2.5

Suitable wording for the label is as follows:

“IMPORTANT — DO NOT BLOCK THIS VENT

Do not use for storage”

5.2.3 Air vent communication

A vent supplying air to an open-flued appliance shall not communicate with a room or internal space

containing a bath or shower.

5.3 Room-sealed appliances

5.3.1 Room-sealed appliance installed in a room or internal space

A room-sealed appliance installed in a room shall not require purpose provided ventilation.

5.3.2 Room-sealed appliance installed in an appliance compartment

5.3.2.1 Unless the appliance manufacturer’s installation instructions state otherwise, air vents shall be

provided in an appliance compartment containing a room-sealed appliance and shall be sized in accordance

with Table 3, at both high and low levels.

Table 3 — Minimum air vent free-area for appliance compartments: room-sealed appliances

Vent position

Appliance compartment ventilated:

to room or internal space

direct to outside air

cm per kW (net) of appliance maximum

rated input

cm per kW (net) of appliance maximum

rated input

2

High level

Low level

10

10

2

5

5

COMMENTARY AND RECOMMENDATIONS ON 5.3.2.1

The purpose of the air vents is to supply air for cooling. Both high and low level vents in an appliance

compartment should communicate either with the same room or internal space, or with the outside air at the

same wall. The vertical distance between the high and low level vents should be as great as is possible to

encourage a convective air flow. Suitable air vent positions are illustrated in Figure 6.

5.3.2.2 Where two or more appliances are installed in the same appliance compartment, whether or not

they are supplied as a combined unit, the aggregate maximum rated input shall be used to determine the

air vent free-area from Table 3 or the appliance manufacturer’s instructions.

© BSI 6 July 2004

9

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

5.3.2.3 Where the low level ventilation is via a duct from a higher level, the duct shall be independent from

any duct used for supplying the high level ventilation. No high level ventilation shall be via a duct from a

lower level. Ducts shall be sized in accordance with 4.1.4.

COMMENTARY AND RECOMMENDATIONS ON 5.3.2.3

Where practical, both high and low level vents should communicate either with the same room or internal

space, or with the outside air at the same wall. The vertical distance between the high and low level vents

should be as great as is possible.

Where low level ventilation is to be provided via a duct fed from a space above the appliance compartment,

the duct should be insulated and the lower end should be below the level of the burner in the appliance.

5.3.2.4 An appliance compartment containing a room-sealed appliance shall be labelled to warn against

blockage of the vents and use for storage.

COMMENTARY AND RECOMMENDATIONS ON 5.3.2.4

Suitable wording for the label is as follows:

“IMPORTANT — DO NOT BLOCK THIS VENT

Do not use for storage”

5.4 Flueless appliances

Where a flueless appliance is installed/operated in a room or internal space, that room or internal space

shall be provided with vents which communicate directly with outside air and are sized in accordance

with Table 4. For further information on cooker installations in kitchens see 6.4.

Ventilation for tumble dryers shall be in accordance with BS 7624:1993.

Where no openable window is available, an alternative means of ventilation shall be provided.

Any manufacturer’s instructions which specify room volumes or vent sizes which are less than the values

given in Table 4 will not comply with this standard and the manufacturer would not be able to claim

compliance with this standard.

COMMENTARY AND RECOMMENDATIONS ON 5.4

Where an appliance is not rigidly fixed, i.e. it is portable, a vent should be provided in every room in which

the appliance may be connected to the fixed pipework. This does not include moveable cabinet heaters which

carry their own gas bottles.

Example

For a space heater in a typical room (4 m × 4 m × 2.4 m = 38.4 m3), the maximum heat input allowed

at 45 W/m3of heated space would permit a maximum heater size of 1.73 kW.

10

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

Table 4 — Minimum permanent opening free-area for flueless appliances

Type of appliance

Maximum

appliance rated

input limit (net)

Domestic oven,

None

hotplate, grill or any

combination thereofd

Instantaneous water 11 kW

heater

Space heater in a

room

45 W/m3 of

heated space

Space heater in an

internal space

90 W/m3 of

heated space

Space heaters

conforming

to BS EN 449:1997

in a room

Space heaters

conforming

to BS EN 449:1997

in an internal space

Refrigerator

Single burner

hotplate/boiling ring

(2 or more to be

treated as a hotplate)

45 W/m3 of

heated space

a

b

c

d

Room volume

Permanent vent size

(m3)

(cm2)

<5

5 to 10

>10

<5

5 to 10

>10 to 20

>20

100

50a

Nil

Installation not permitted

100

50

Nil

100 plus 55 for every kW (net)

by which the appliance rated

input exceeds 2.7 kW (net)

100 plus 27.5 for every kW (net)

by which the appliance rated

input exceeds 5.4 kW (net)

50 plus 27.5 for every kW (net)

by which the appliance rated

input exceeds 1.8 kW (net)

Openable window

or equivalent also

requiredb c

Yes

Yes

Yes

Yes

Yes

90 W/m3 of

heated space

50 plus 13.7 for every kW (net) Yes

by which the appliance rated

input exceeds 3.6 kW (net)

None

None

Nil

Nil

No

No

If the room or internal space containing these appliances has a door which opens directly outside, no permanent opening is

required.

Alternative acceptable forms of opening include any adjustable lourve, hinged panel or other means of ventilation that opens

directly to outside air. This is additional to the permanent vent requirement.

Where no openable window direct to outside is available, other products shall be sought or the appropriate building regulations

advice should be followed, see 6.4.

The appliance, unless a single burner hotplate/boiling ring, is not to be installed in a bed sitting room of less than 20 m3 volume.

5.5 Multi-appliance installations

5.5.1 Where a room or internal space contains more than one gas appliance, the air vent free-area

requirement shall be calculated from the greatest of the following:

a) the aggregate maximum rated input of flueless space heating appliances; or

b) the aggregate maximum rated input of open-flued space heating appliances except where the

interconnecting wall between two rooms has been removed and the resultant room contains only two

similar chimneys, each fitted with a similar gas fire with rated input each less than 7 kW, an air vent

may not be required; or

c) the greatest individual rated input of any other type of appliance.

COMMENTARY AND RECOMMENDATIONS 5.5.1a) AND b)

The term space heating appliance is taken to mean central heating appliance, air heater, gas fire or

convector.

If permanent ventilation is required for a multi-appliance installation, this should, wherever practicable, be

sited between the appliances.

© BSI 6 July 2004

11

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

Where, for whatever reasons, two or more chimneys serve a common space, the draught of the stronger

chimney can influence the pull of the weaker and cause spillage. This can happen with gas-fired appliances

of different types and even more so if one of the chimneys serves a solid fuel appliance, (see 5.5.2). Where an

interconnecting wall has been removed between two rooms and the resultant room contains two similar

chimneys, each fitted with a gas fire or inset live fuel effect fire, an air vent is not normally required if the

rated heat input of each of the appliances does not exceed 7 kW and the installation instructions do not

specify additional ventilation. For further information see BS 5871-1, -2 and -3.

5.5.2 Where a room or internal space also contains oil or solid fuel burning appliances, the air vent for the

gas appliance shall be sized with due consideration being given to the rating of other appliances and their

usage pattern at the same time as the gas appliance.

COMMENTARY AND RECOMMENDATIONS ON 5.5.2

Where two or more chimneys serve a common space, the draught of the stronger chimney can influence the

pull of the weaker and cause spillage. The provision for ventilation for each appliance shall be made

separately. e.g. if a gas appliance and a solid fuel appliance are located in the same room, one ventilation

provision is required for the gas appliance and another for the solid fuel appliance.

Further advice is given in Appendices 1 and 2 of the HSC publication “Safety in the installation and use of

gas appliances”. [8]

The ventilation provision for oil and solid fuel appliances is given in BS 5410 and BS 8303 respectively and

in relevant building regulations. If the rated output rather than the rated input is shown on an oil or solid

fuel burning appliance, the rated input should be calculated using the following formula:

Output × 10

Input = ---------------------------------6

Example

For a space heater in a typical room (4 m × 4 m × 2.4 m = 38.4 m3), the maximum heat input allowed

at 45 W/m3 of heated space would permit a maximum heater size of 1.73 kW.

6 Other aspects of ventilation

6.1 Effect of extract fans

Where there is a depressurizing extract or other fan in any room or internal space of a premises that

contains any type of open-flued appliance and the operation of the fan has the effect of reducing the

pressure ambient to the appliance, and thus adversely affects the operation of the flue, i.e. spillage,

additional air vents shall be provided and a spillage test be confirmed as satisfactory before the appliance

is used.

COMMENTARY AND RECOMMENDATIONS ON 6.1

Examples of fans which may affect the performance of the flue by reducing the pressure ambient to the

appliance are:

— room-extract fans;

— fans in the flues of open-flued appliances;

— externally ducted tumble dryers;

— fans in cooker hoods;

— circulating fans of warm air heating systems (whether or not gas-fired);

— fans used for removing undesirable gases, e.g. radon (see 6.3) or land fill gases;

— ceiling (paddle) fans.

As a general guide an extra 50 cm2 of air vent free-area will be sufficient for most situations, however, the

spillage test should be repeated after extra vents have been fitted. Further advice on spillage testing is given

in part 1 of this standard.

12

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

6.2 Passive stack ventilation

Passive stack ventilation (PSV) shall be considered independently from the provision of ventilation for gas

appliances.

COMMENTARY AND RECOMMENDATIONS ON 6.2

For advice on the effects on flueing of appliances see part 1 of this standard.

PSV is a ventilation system using ducts from the ceiling of a room to terminals on the roof, which operate by

a combination of the natural stack effect, i.e. the movement of air due to difference in temperature between

inside and outside, and the effect of the wind passing over the roof of the dwelling.

6.3 Radon gas

In areas where radon gas has been identified as a problem, ventilation shall not be taken from the space

below ground floor level (e.g. using a floor vent) or interfere in any way with remedial measures which may

already be in place to prevent radon gas entering the habitable part of the dwelling.

COMMENTARY AND RECOMMENDATIONS ON 6.3

One option to overcome this difficulty would be to use uncontaminated air drawn from outside through ducts

which may pass through the underfloor space, so that the ducted air is isolated from the underfloor space.

Areas identified as requiring action for radon gas will be known due to local publicity but in case of doubt,

further advice can be obtained from the local authority building control office. (Also see BS 5440-1.)

6.4 Internal kitchens

Open-flued appliances in internal kitchens shall be provided with ventilation in accordance with 5.2 of this

standard. Flueless appliances in internal kitchens shall be ventilated in accordance with the Building

Regulations in England and Wales, and the Building Standards (Scotland) Regulations in Scotland.

COMMENTARY AND RECOMMENDATIONS ON 6.4

For further information on how to provide ventilation in these circumstances, in England and Wales see

Approved Document F to the Building Regulations and in Scotland, Technical Standard K for compliance

with the Building Standards (Scotland) Regulations.

7 Maintenance

When attending an installation for maintenance, the provisions for air supply shall be checked. Existing

air vents shall be checked to ensure that they are unobstructed, externally and internally. Any fly screens

shall be removed and any adjustable control shall be removed or fixed in the open position. The size and

position shall be checked for compliance with this standard.

COMMENTARY AND RECOMMENDATIONS ON CLAUSE 7

Attention is drawn to the requirements in 5.2.1 for sizing air vents for existing installations.

When checking an existing air vent, the grilles and/or air bricks should be checked visually for signs of

obstruction. Where practicable, the openings should be poked with a screwdriver or similar tool to ensure

that no blockage is present, e.g. clear plastic sheet or fly screen. Any mortar extrusions into air bricks should

be cleared where practicable. Where the internal parts of a vent or ducting are inaccessible, the best

practicable endeavours should be used to ensure that they are unobstructed.

All these checks will be in addition to the formal checks for correct operation of the appliance. Where any

defects are identified with an existing installation or appliance in respect of any part of this standard,

reference should be made to the appropriate guidance notes in the Health and Safety Commission Approved

Code of Practice document “Safety in the installation and use of gas systems and appliances”,

reference L56 [8]. If the appliance is operating correctly, with any substandard air supply, it may not be

necessary to update the provisions for air supply. The term “substandard” in this context, refers to

installations or appliances which are not in accordance with current Regulations, Codes of Practice or

Standards and Specifications.

If the installation has a history of satisfactory operation, and the ventilation is within 10 % of the current

requirements, then it may not be necessary to inform the customer.

© BSI 6 July 2004

13

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

Figure 1 — Typical air vent arrangements

14

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

Figure 2 — Free-areas

© BSI 6 July 2004

15

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

NOTE

16

Compartment vents (1 and 2) as per 5.2.2.

Figure 3 — Air vents in series

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

NOTE Ducting runs, where unavoidable, should be kept to a minimum, not more than 3 meters long. Low level vent in internal

wall to be not more than 450 mm above floor level.

Figure 4 — Air vent positions for an open-flued appliance in a room or internal space

© BSI 6 July 2004

17

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

b) High and low level vents communicating with another room or internal space and subsequently to outside air or ventilated floor/roof space

NOTE All compartment installations should have both high and low level vents (see 5.2.2). Observe manufacturer’s

recommendations for clearance around appliance casing. Ducting runs, where unavoidable, should be kept to a minimum of not

more than 3 metres long and the vertical distance between high and low vents should be as great as possible.

Figure 5 — Air vent positions for an open-flued appliance in an appliance compartment

18

© BSI 6 July 2004

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

NOTE

Where vents and terminals are located on the same wall, take note of minimum separation in Table 1. All compartment

installations should have both high and low level vents (see 5.3.2.1). Observe manufacturer’s recommendations for clearance

around appliance casing. Ducting runs where unavoidable should be kept to a minimum of with not more than 3 metres and the

vertical distance between high and low vents should be as great as possible.

Figure 6 — Air vent positions for a room-sealed appliance in an appliance compartment,

room and internal space

© BSI 6 July 2004

19

20

blank

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BS 5440-2:2000

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

Bibliography

Standards publications

BS 3632:1995, Specification for residential park homes.

BS 5258-10:1980, Safety of domestic gas appliances — Part 10: Flueless space heaters (excluding catalytic

combustion heaters) (3rd family gases).

BS 5258-11:1980, Safety of domestic gas appliances — Part 11: Flueless catalytic combustion heaters

(3rd family gases).

BS 5410-1:1997, Code of practice for oil firing — Part 1: Installations up to 45 kW output capacity for space

heating and hot water supply purposes.

BS 5410-2:1978, Code of practice for oil firing — Part 2: Installations of 44 kW and above output capacity

for space heating, hot water and steam supply purposes.

BS 5410-3:1976, Code of practice for oil firing — Part 3: Installations for furnaces, kilns, ovens and other

industrial purposes.

BS 5440-1:1990, Installation of flues and ventilation for gas appliances of rated input not exceeding 60 kW

(1st, 2nd and 3rd family gases) — Part 1: Specification for installation of flues.

BS 5482-2:1997, Domestic butane- and propane-gas-burning installations — Part 2: Installations in

caravans and non-permanent dwellings.

BS 5482-3:1979, Domestic butane- and propane-gas-burning installations — Part 3: Installations in boats,

yachts and other vessels.

BS 5871-1:1991, Specification for installation of gas fires, convector heaters, fire/back boilers and decorative

fuel effect gas appliances —Part 1: Gas fires, convector heaters and fire/back boilers (1st, 2nd and 3rd family

gases).

BS 5871-2:1991Specification for installation of gas fires, convector heaters, fire/back boilers and decorative

fuel effect gas appliances — Part 2: Inset live fuel effect gas fires of heat input not exceeding 15 kW (2nd and

3rd family gases).

BS 5871-3:1991, Specification for installation of gas fires, convector heaters, fire/back boilers and decorative

fuel effect gas appliances — Part 3: Decorative fuel effect gas appliances of heat input not exceeding 15 kW

(2nd and 3rd family gases).

BS 7860:1996, Specification for carbon monoxide detectors (electrical) for domestic use.

BS 8303-1:1994, Installation of domestic heating and cooking appliances burning solid mineral fuels —

Part 1: Specification for the design of installations.

BS 8303-2:1994, Installation of domestic heating and cooking appliances burning solid mineral fuels —

Part 2: Specification for installing and commissioning on site.

BS 8303-3:1994, Installation of domestic heating and cooking appliances burning solid mineral fuels —

Part 3: Recommendations for design and on site installation.

BS EN 721, Leisure accommodation vehicles — Safety ventilation requirements.

Other publications

[1] Gas Safety (Installation and Use) Regulations: 1998.

[2] Building Regulations for England and Wales Approved documents F and J.

[3] Building Regulations (Northern Ireland) (Statutory Rules of Northern Ireland 1994. No. 243) Technical

Booklet Part L.

[4] Building Standards (Scotland) — Parts F and K.

[5] Gas appliance (Safety) Regulations:1995.

[6] HSE Approved Code of Practice — Standards of training in safe gas installation.

[7] A dynamic test procedure for characterizing ventilator free-area — BG Technology

publication (GRTC/R2941).

[8] HSC Safety in the installation and use of gas systems and appliances, L56, available from HSE Books.

[9] BRE Information paper 13/94 — Building Research Establishment, Garston.

[10] BRE Information paper 21/92 — Building Research Establishment, Garston.

© BSI 6 July 2004

21

BS 5440-2:2000

Licensed Copy: na na, University of the West of England JISC, Thu May 11 23:19:33 BST 2006, Uncontrolled Copy, (c) BSI

BSI — British Standards Institution

BSI is the independent national body responsible for preparing

British Standards. It presents the UK view on standards in Europe and at the

international level. It is incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of

British Standards should make sure that they possess the latest amendments or

editions.

It is the constant aim of BSI to improve the quality of our products and services.

We would be grateful if anyone finding an inaccuracy or ambiguity while using

this British Standard would inform the Secretary of the technical committee

responsible, the identity of which can be found on the inside front cover.

Tel: +44 (0)20 8996 9000. Fax: +44 (0)20 8996 7400.

BSI offers members an individual updating service called PLUS which ensures

that subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: +44 (0)20 8996 9001.

Fax: +44 (0)20 8996 7001. Email: orders@bsi-global.com. Standards are also

available from the BSI website at http://www.bsi-global.com.

In response to orders for international standards, it is BSI policy to supply the

BSI implementation of those that have been published as British Standards,

unless otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library and its Technical Help to Exporters

Service. Various BSI electronic information services are also available which give

details on all its products and services. Contact the Information Centre.

Tel: +44 (0)20 8996 7111. Fax: +44 (0)20 8996 7048. Email: info@bsi-global.com.

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For details

of these and other benefits contact Membership Administration.

Tel: +44 (0)20 8996 7002. Fax: +44 (0)20 8996 7001.

Email: membership@bsi-global.com.

Information regarding online access to British Standards via British Standards

Online can be found at http://www.bsi-global.com/bsonline.

Further information about BSI is available on the BSI website at

http://www.bsi-global.com.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the

UK, of the publications of the international standardization bodies. Except as

permitted under the Copyright, Designs and Patents Act 1988 no extract may be

reproduced, stored in a retrieval system or transmitted in any form or by any

means – electronic, photocopying, recording or otherwise – without prior written

permission from BSI.

BSI

389 Chiswick High Road

London

W4 4AL

This does not preclude the free use, in the course of implementing the standard,

of necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

Details and advice can be obtained from the Copyright & Licensing Manager.

Tel: +44 (0)20 8996 7070. Fax: +44 (0)20 8996 7553.

Email: copyright@bsi-global.com.