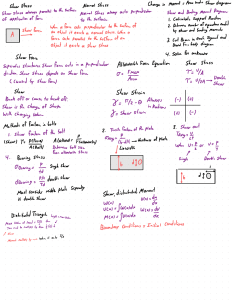

Limitations of Maximum Shear Stress Theory The maximum shear stress theory does not give accurate results for the state of pure shear stresses developed by the Torsion test. The Tresca theory provides conservative results leading to an increase in component cost. This theory is not applicable to brittle materials. Steps for using the Maximum Shear Stress Theory • To use the maximum shear stress theory in problem solving the following steps are necessary to be followed: • Step 1: Determine the three principal stresses (σ1,σ2, and σ3) from the triaxial stress system using principal stress equations or Mohr’s circle method. • Step 2: Find out the maximum (σ1) and the minimum (σ3) principal stresses. • Step 3: Determine the value of the maximum shear stress τmax=(σ1 -σ3 )/2. • Step 4: Find out the allowable stress value of the material; allowable stress= σsy /N or σy /2N as mentioned above (N=Factor of safety) • Step 5: Compare the value calculated at step 3 with the allowable value found at step 4. If the Value at step 3 is less than the allowable value at step 4, then the design is safe as per the maximum shear stress theory.