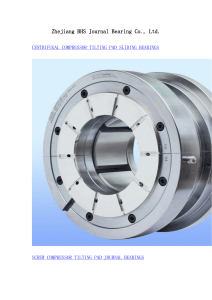

Translated from Vietnamese to English - www.onlinedoctranslator.com NSG Vietnam Glass Industries Ltd. INSTRUCTIONS-WORK INSTRUCTION REPLACE EVAPORATOR BEARINGS Code -Code Last modified -Rev PM-2-WI-004 01 Page -Page Approval date -Date Page 1 of 6 December 11, 2019 REPLACE EVAPORATOR BEARINGS Issued by Confirmed by Confirmed by CHECKED BY APPROVED BY Nguyen Minh Tuan Ono Yasuo ISSUED BY Nguyen Phuoc Dai Loc NSG CONFIDENTIAL – NOT TO BE USED OUT OF CONTEXT NOT TO BE DISCLOSED TO OUTSIDE PARTIES WITHOUT THE PERMISSION OF THE VIETNAM GLASS INDUSTRIES DOCUMENT CONTROLLER January 3, 2020 Setting history–LIST OF CHANGES TO DOCUMENTS Detail Times modified Approval date REVISION APPROVED DATE DEFINITION OF CHANGE 00 July 8, 2013 New establishment – New establishment 01 December 11, 2019 Additional safety and environmental information section – Update safety and environmental information Promulgate by ISSUED BY Confirmed by APPROVED BY NL Dai TN Huy NPD Loc Y. Ono Paper Copies are not Controlled unless stamped in RED “Internal control” by document controller. NSG Vietnam Glass Industries Ltd. INSTRUCTIONS-WORK INSTRUCTION REPLACE EVAPORATOR BEARINGS Code -Code Last modified -Rev PM-2-WI-004 01 Page -Page Approval date -Date Page 2 of 6 December 11, 2019 January 3, 2020 Table of contents–Contents Cover– Covers first Table of contents– Contents 2 1. Purpose– Purpose 3 2. Scope of application– Scope 3 3. Responsibility– Responsibility 3 4. Terminology– Terminology 3 5. Safety and environmental requirements– Safety & environmental requirements 3 6. Require equipment and tools– Equipment requirements 4 7. Procedures and instructions– Procedures and guidelines 4~6 Appendix– Appendix 6 Paper Copies are not Controlled unless stamped in RED “Internal control” by document controller. NSG Vietnam Glass Industries Ltd. INSTRUCTIONS-WORK INSTRUCTION REPLACE EVAPORATOR BEARINGS Code -Code Last modified -Rev PM-2-WI-004 01 Page -Page Approval date -Date Page 3 of 6 December 11, 2019 1. Purpose–Purpose:To keep the evaporator operating properly and without interruption means maintaining stable production and high quality output. We must periodically replace bearings. Or during operation, if we detect that the bearing is operating abnormally, we must replace it. To ensure the device operates in the best condition. 2. Scope of application–Scope:Applies to the pipeline group, belonging to the Maintenance department. Use when replacing evaporator bearings. 3. Responsibility–Responsibility:Workers in charge, Team Leaders in charge, Foreman and engineers in charge. 4. Terminology–Terminology:Do not apply. 5. Safety and environmental requirements–Safety & environmental requirements: (Details on protection and notes on safety and environment– Detail PPEs and safety & environmental attentions) Specific instructions– Detail instructions • Illustration– Pictures (Necessary-if necessary) Note– Notes Fully equipped with labor protection: uniforms, glasses, hats, protective shoes, wrist bandages, ankle bandages, chemical resistant gloves, masks. • There must be 2 or more people to do this job. • Hazard identification sheet. • Get a work permit. • Isolate the power supply to the evaporator. • Isolate the nitrogen source supplied to the evaporator. • Isolate the steam source supplied to the evaporator. • Isolate the DMT source conducted through the evaporator. • Release gas sources such as DMT, Nitrogen, Steam. • Clean the work area after completing work. • Classify waste and waste and put them in the correct places of 03 01 the factory. Note : In addition, if any previous related accidents have occurred, they must be mentioned in this section Notes : Besides, if any previous relevant accident happened, please mention them here Paper Copies are not Controlled unless stamped in RED “Internal control” by document controller. 2020 NSG Vietnam Glass Industries Ltd. INSTRUCTIONS-WORK INSTRUCTION REPLACE EVAPORATOR BEARINGS Code -Code Last modified -Rev PM-2-WI-004 01 Page -Page Approval date -Date Page 4 of 6 December 11, 2019 6. Require equipment and tools–Equipment requirements Specific instructions–- Detail instructions Illustration– Pictures (Necessary-if necessary) 1/2kg rubber hammer, 1/2kg steel hammer, 7mm~34mm wrench set, 1.5mm~10mm hexagon set, 150mm leaf ruler, 200mm caliper, RP7, bearing closing tool, bearing pulley. 03 01 Note– Notes 2020 7. Procedures and instructions–Procedures and guidelines Specific instructions– Detail instructions Illustration– Pictures (Necessary-if necessary) I. PREPARATION - Bring all necessary tools to the working area. - Notify the operations team to isolate all gas and power sources related to the evaporator that needs bearing replacement. - Notify the electrical team to assist in isolating the power source. II. OPERATION - After completing the iterative steps, release energy and chemicals. Then proceed with the following steps: - Remove the motor base bolts. Separate motor part 16 from housing 3.Be sure to mark the position and elevation of the bolts before removing. Because the space is tight, avoid colliding and damaging other equipment while operating. - Remove bolt 30 and remove the magnet. Paper Copies are not Controlled unless stamped in RED “Internal control” by document controller. Note– Notes NSG Vietnam Glass Industries Ltd. INSTRUCTIONS-WORK INSTRUCTION REPLACE EVAPORATOR BEARINGS Code -Code Last modified -Rev PM-2-WI-004 01 - Take out key 14 and remove part 6. - Remove flange bolts 17, 18, 19. - Disassemble cover 3 with detail number 2. - Disassemble bearings 15a and 15b.Note that bearing 15a uses hex head screws to position the bearing with the shaft. - Page -Page Approval date -Date Page 5 of 6 December 11, 2019 03 01 Remove shaft 5 from the housing.Pay attention to the position of gaskets (Oring) 4e and 13. The material of the shaft is soft and easily deformed, warped and dented, so manipulation must be gentle. - Install according to the following steps: - Install shaft 5 into housing 2. - Install bearing 15a in the correct position on the shaft.Note the position determined by the hexagonal screw. - Install cover 3 and tighten bolts 17, 18, 19. - Install bearing 15b and secure with key 14. - Install part number 6. - Install the magnet part and install bolt 30 and tighten it. * * * Note: all bolts and nuts are made of stainless steel, so be careful during disassembly to avoid damaging the threads. - Install the motor into position and align it according to the markings before removing.Be sure to ensure the device is installed in its original position and is level. - Install the air hoses in place of the device.Pay close attention to the process. Avoid thread damage and air leakage. - Notify the electrical side and the operating side to remove isolation and test run to check the condition of the equipment after installation. Paper Copies are not Controlled unless stamped in RED “Internal control” by document controller. 2020 NSG Vietnam Glass Industries Ltd. INSTRUCTIONS-WORK INSTRUCTION REPLACE EVAPORATOR BEARINGS Code -Code Last modified -Rev PM-2-WI-004 01 Page -Page Approval date -Date Page 6 of 6 December 11, 2019 - After confirming that the device is in good working condition, stop. - Making a handover record to the operator about the condition of the equipment after reassembly is normal operation. - Clean up tools and clean the workplace. - Take notes of points to note while performing work or update the OP if necessary. Appendix–Appendix January 3, 2020 1. Related records/documents–Relevant records/ documents Name of file/document Record/document Name Code Code Retention period Keeping period Storage room Keeping department Paper Copies are not Controlled unless stamped in RED “Internal control” by document controller.