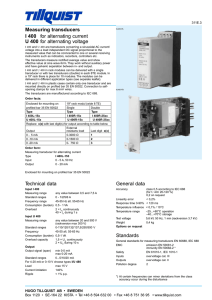

A Technical Seminar on VLSI-based Intelligent Transducers Submitted by NAME: Nellutla Vishnu Vamshi ROLL NO: 20B81A1051 BACHELOR OF TECHNOLOGY IN ELECTRONICS AND INSTRUMENTATION ENGINEERING Department of Electronics and Instrumentation Engineering CVR COLLEGE OF ENGINEERING (An Autonomous Institution) Approved by AICTE & Affiliated to JNTU, Hyderabad, Vastunagar, Mangalpalli (V), Ibrahimpatnam (M), RR District, Telangana 2023-2024 CVR COLLEGE OF ENGINEERING (An Autonomous Institution) Vastunagar, Mangalpalli (V), Ibrahimpatnam (M), R.R. District, Telangana 501510 Department of Electronics and Instrumentation Engineering CERTIFICATE This is to certify that the dissertation work entitled “VLSI Based Intelligent Transducers” is the work presented by Nellutla Vishnu Vamshi, Roll No. 20B81A1051. This Technical Seminar report is submitted in the partial fulfillment for the award of the degree of ‘BACHELOR OF TECHNOLOGY’ in “Electronics and Instrumentation Engineering” from CVR College of Engineering affiliated to JNTUH, during the academic year 2023-2024. The seminar report has been approved as it satisfies the academic requirements with respect to technical seminar work presented for the Bachelor of Engineering degree during the academic year 20232024. Coordinators 1. Ms. V. Sreelatha Reddy Sr. Assistant Professor 2. Dr. G. Ramesh Sr. Assistant Professor Head of the Department ACKNOWLEDGEMENT The satisfaction and euphoria that accompany the successful completion of any task would be incomplete without the mentioning of the people whose constant guidance and encouragement made it possible. I express my gratitude to Dr. Ramamohan Reddy Kasa, principal of our college, for constant encouragement and motivation throughout the progress of the project. I derive great pleasure in expressing our sincere gratitude to the Head of the Department Dr. S. Harivardhagini for her timely suggestions which helped me to complete this work successfully. I express my sincere thanks to the Technical Seminar Coordinators, Ms. V. Sreelatha Reddy, Sr. Assistant Professor and Dr. G. Ramesh, Sr. Assistant Professor, for giving me support, attention and valuable guidance throughout this technical seminar. I would also like to thank our staff for supporting me during the presentation. Finally, I would like to add few heartfelt words for the people who were the part of seminar in various ways, especially my friends and classmates who gave me unending support right from the beginning. My family has been the most significant in my life so far and this part of my life has no exception. Without their support, persistence and love I would not be where I am today. I ABSTRACT In the realm of modern electronics, VLSI (Very Large Scale Integration) technology has revolutionized the design and functionality of intelligent transducers. These transducers, which are key components in various sensor applications, have undergone a remarkable transformation thanks to the integration of VLSI. This abstract explores the significant advancements and implications of VLSI-based intelligent transducers, emphasizing their capabilities in sensor integration, signal processing, low power consumption, and miniaturization. One of the most notable achievements of VLSI-based intelligent transducers is their ability to seamlessly integrate multiple sensors onto a single chip. This integration enhances the versatility of transducers, allowing them to measure various physical parameters simultaneously. Furthermore, VLSI technology enables the implementation of sophisticated signal processing algorithms directly on the transducer chip. This on-chip processing capability empowers these transducers to provide accurate and real-time data analysis, reducing the burden on external processing units and enhancing the overall system efficiency. Another significant advantage of VLSI-based intelligent transducers is their low power consumption. Moreover, their compact form factor opens up new possibilities for embedding transducers into smaller devices, such as wearables and IoT devices, enabling the creation of more advanced and integrated systems. In conclusion, VLSI-based intelligent transducers represent a promising frontier in sensor technology, offering enhanced functionality, reduced power consumption, and greater integration capabilities, with applications spanning across various industries. Keywords: VLSI, Intelligent Transducers, Sensor Integration, Signal Processing, Low Power II TABLE OF CONTENTS ACKNOWLEDGEMENT ............................................................................................ i ABSTRACT................................................................................................................. ii CONTENTS ................................................................................................................ iii LIST OF FIGURES .....................................................................................................iv LIST OF TABLES ....................................................................................................... v CHAPTER 1: INTRODUCTION ............................................................................... 1 CHAPTER 2: FABRICATION OF TRANSDUCER................................................. 4 CHAPTER 3: OBJECTIVES ....................................................................................... 6 CHAPTER 4: HISTORY ..............................................................................................8 CHAPTER 5: LITERATURE REVIEW ....................................................................10 CHAPTER 6: JUSTIFICATION ................................................................................12 CHAPTER 7: INTERNAL BLOCK DIAGRAM.......................................................14 CHAPTER 8: DETAILS OF EACH BLOCK ............................................................15 CHAPTER 9: TECHNOLOGY .................................................................................17 CHAPTER 10: ADVANTAGES ................................................................................19 CHAPTER 11: DISADVANTAGES .........................................................................21 CHAPTER 12: APPLICATIONS ...............................................................................23 CHAPTER 13: FUTURE SCOPE ..............................................................................26 QUESTIONS & ANSWERS -------------------------------------------------------------29 REFERENCES---------------------------------------------------------------------------------31 III LIST OF FIGURES PAGE No. Figure 1.1 Different types of transducers 1 Figure 6.1 VLSI Chip 14 Figure 7.1 Block Diagram of VLSI-Based Intelligent Transducers 15 Figure 8.1: Different types of Sensors 16 Figure 8.2: Preprocessing Amplifiers 17 Figure 9.1: VLSI EDA Tools 20 Figure 9.1: VLSI Technology Applications 27 Figure 13.1: Future Scope of VLSI Technology 30 IV LIST OF TABLES PAGE No. Table 1.1 Difference Between General Transducer and VLSI Based Intelligent Transducers v 3 CHAPTER 1 INTRODUCTION The field of transducer technology has undergone a remarkable evolution, driven in large part by the integration of Very Large Scale Integration (VLSI) technology. Intelligent transducers, which are critical components in a wide range of applications, have benefited immensely from this convergence of VLSI and sensor technology. This introduction sets the stage for a comprehensive exploration of the topic "VLSI-Based Intelligent Transducers," delving into the transformative impact of VLSI on sensor integration, signal processing, low power operation, and miniaturization, and highlighting the potential applications and implications of this innovative approach. Figure 1.1 Different types of transducers Transducers, often referred to as sensors or detectors, are devices that convert various physical parameters, such as temperature, pressure, or light, into electrical signals. They serve as the interface between the physical world and digital systems, providing essential data for numerous applications, from environmental monitoring to medical diagnostics. Traditionally, transducers have been stand-alone components that require external circuitry for signal processing 1 and amplification. However, the advent of VLSI technology has reshaped the landscape of transducer design and functionality. One of the most significant advancements facilitated by VLSI technology in the realm of intelligent transducers is the integration of multiple sensors onto a single chip. This integration represents a paradigm shift in sensor design, enabling transducers to measure multiple physical parameters simultaneously. This multifunctionality is particularly valuable in applications where comprehensive data acquisition is essential, such as in automotive sensors, environmental monitoring systems, and industrial automation. By incorporating diverse sensors on a single chip, VLSI-based intelligent transducers streamline the process of data acquisition and reduce the complexity of sensor networks, ultimately leading to more efficient and cost-effective solutions. Moreover, VLSI technology empowers intelligent transducers with on-chip signal processing capabilities. Traditionally, signal processing was performed externally, necessitating additional components and energy consumption. With VLSI integration, intelligent transducers can execute complex signal processing algorithms directly on the chip. This means that the raw sensor data can be processed in real-time, enabling more sophisticated data analysis and decisionmaking at the sensor level. Applications ranging from medical devices that require precise data interpretation to autonomous vehicles that demand rapid sensor fusion and decision-making can greatly benefit from this enhanced onchip processing capability. In addition to sensor integration and signal processing, VLSI-based intelligent transducers offer a compelling advantage in terms of power efficiency. As VLSI technology allows for the miniaturization of transducer components, these devices can operate with reduced power consumption. This aspect is particularly crucial for battery-powered applications, where extending the operational life of the device is a primary concern. 2 In conclusion, the convergence of VLSI technology and intelligent transducers represents a pivotal moment in the evolution of sensor technology. The integration of multiple sensors, on-chip signal processing, low power operation, and miniaturization capabilities significantly enhance the functionality and versatility of intelligent transducers. This transformative approach holds immense promise across a wide spectrum of applications, from healthcare and automotive industries to environmental monitoring and beyond. By harnessing the power of VLSI, intelligent transducers are poised to drive innovation, efficiency, and convenience in our increasingly interconnected and data-driven world. Aspect Transducers VLSI Based Intelligent Transducers Basic Convert one form of Same as traditional transducers Functionality energy or signal into but with advanced processing another capabilities. (eg., temperature to voltage). Integration Standalone devices Integrated sensors, signal processing, microcontrollers, and more on a single chip. Signal Primarily provide Processing raw data Perform on-chip signal processing, data analysis, and decision-making. Power Typically energy- Consumption efficient Power Consumption is very low Table 1.1 Difference Between Transducers and VLSI Based Intelligent Transducers 3 CHAPTER 2 FABRICATION OF VLSI BASED INTELLIGENT TRANSDUCERS The fabrication of VLSI (Very Large Scale Integration) based intelligent transducers involves a multi-step process that combines semiconductor fabrication techniques with specialized sensor integration and signal processing components. Here is an overview of the key steps in the fabrication of VLSIbased intelligent transducers: 1. Design and Specification: The process begins with the design and specification of the intelligent transducer. This phase involves defining the sensor type(s), the signal processing algorithms, and the overall functionality of the transducer. Engineers create a detailed blueprint that outlines the architecture and layout of the VLSI chip. 2. Semiconductor Fabrication: The heart of the fabrication process is the semiconductor fabrication facility, commonly known as a "fab." In the fab, a silicon wafer is used as the substrate. Thin layers of various materials, such as silicon dioxide (SiO2) for insulation and different dopants for creating transistors, are deposited onto the wafer through processes like chemical vapor deposition (CVD) and ion implantation. Photolithography techniques are used to define patterns on the wafer. 3. Transistor and Component Fabrication: VLSI chips consist of millions or even billions of transistors. These transistors are created using photolithography and etching processes to define the transistor gates and interconnections. Various components like amplifiers, analog-to-digital converters, and digital logic circuits are also fabricated on the same chip. 4 4. Sensor Integration: Depending on the application, various sensors are integrated onto the same VLSI chip. These sensors can include photodetectors, accelerometers, temperature sensors, pressure sensors, and more. Integration often involves the creation of specialized structures or layers to interface the sensors with the VLSI circuitry. 5. Signal Processing Circuitry: Signal processing components, which may include digital signal processors (DSPs), analog-to-digital converters (ADCs), and microcontrollers, are integrated into the chip. These components allow for the processing and conditioning of the raw sensor data. 6. Interconnections and Wiring: Metal interconnects and wiring layers are added to establish electrical connections between different components on the chip. These interconnections are carefully designed to minimize signal interference and ensure efficient data transfer. 7. Testing and Quality Control: Extensive testing is performed at various stages of fabrication to ensure the functionality and reliability of the VLSI-based intelligent transducer. This includes testing individual components, sensor calibration, and overall system testing. 8. Packaging: After successful testing, the VLSI chip is packaged in a protective casing. The choice of packaging depends on the specific application requirements, such as environmental conditions and size constraints. 9. Integration into Systems: The packaged VLSI-based intelligent transducer is integrated into the target system or application. This may involve connecting 5 the transducer to other electronic components, microcontrollers, or communication interfaces, depending on the intended use. 10. Application-Specific Programming: In some cases, the transducer may require specific programming or firmware to customize its behavior for a particular application. This programming is typically done during system integration. 11. Calibration and Validation: The final step involves calibration and validation of the intelligent transducer in the real-world environment where it will be deployed. This ensures accurate and reliable performance according to the specified parameters. The fabrication of VLSI-based intelligent transducers is a complex and highly specialized process that requires expertise in semiconductor manufacturing, sensor technology, and signal processing. It plays a crucial role in enabling advanced sensing capabilities and intelligent decision-making in a wide range of applications, from consumer electronics to industrial automation and healthcare devices. 6 CHAPTER 3 OBJECTIVES The The objective of the topic "Fabrication of VLSI-Based Intelligent Transducers" is to provide an understanding of the key steps and processes involved in the creation of intelligent transducers that incorporate Very Large Scale Integration (VLSI) technology. The topic aims to: 1. Educate on Transducer Integration: To inform readers about how various sensors, signal processing components, and VLSI circuitry can be seamlessly integrated onto a single chip. This objective involves explaining the importance of sensor integration and the benefits it offers, such as reduced complexity and improved data acquisition in various applications. 2. Describe Semiconductor Fabrication Techniques: To introduce the fundamental semiconductor fabrication techniques used in creating VLSI-based intelligent transducers. This includes processes like photolithography, chemical vapor deposition, and ion implantation, which are essential for building the transistor-based components of the chip. 3. Highlight Sensor Types and Integration: To shed light on the diversity of sensors that can be integrated into intelligent transducers, ranging from photodetectors to pressure sensors. The objective is to emphasize the versatility and customization potential of these transducers to suit specific application needs. 4. Explain Signal Processing and Circuitry: To clarify how signal processing components, such as digital signal processors (DSPs) and analog-to-digital 7 converters (ADCs), are incorporated into the VLSI chip. This includes illustrating how these components enhance data processing and accuracy. 5. Discuss Quality Control and Testing: To emphasize the importance of rigorous quality control and testing procedures throughout the fabrication process. This objective underscores the need for ensuring the reliability and functionality of intelligent transducers in real-world scenarios. 6. Illustrate Real-World Application: To demonstrate how VLSI-based intelligent transducers are applied in real-world systems and devices across various industries, such as healthcare, automotive, consumer electronics, and industrial automation. This showcases the practical implications and significance of this technology. 7. Highlight Integration and Calibration: To explain the integration process of these transducers into larger systems or devices and emphasize the calibration and validation steps to ensure accurate and dependable performance. In essence, the objective is to provide a comprehensive overview of the fabrication process of VLSI-based intelligent transducers, offering insights into the technologies and methodologies that underpin these innovative devices. This knowledge is valuable for engineers, researchers, and enthusiasts interested in understanding the core principles behind the development of intelligent sensors and transducers that play a crucial role in modern electronics and data-driven applications. 8 CHAPTER 4 HISTORY The history of VLSI (Very Large Scale Integration) technology and its application in intelligent transducers has evolved over several decades. Here is a brief overview of its history year by year: 1950s: - 1958: The invention of the integrated circuit (IC) by Jack Kilby and Robert Noyce marked the beginning of modern microelectronics. The first ICs contained a small number of transistors. 1960s: - 1960: Metal-oxide-semiconductor (MOS) transistors gained attention for their potential in digital applications. - 1961: The first commercial MOS ICs were introduced. - 1965: Gordon Moore formulated "Moore's Law," predicting that the number of transistors on an integrated circuit would double approximately every two years. 1970s: - 1971: Intel released the 4004 microprocessor, one of the earliest microprocessors, incorporating thousands of transistors on a single chip. - 1970s: The concept of Application-Specific Integrated Circuits (ASICs) emerged, allowing for the custom design of integrated circuits for specific applications, including sensors. 9 - 1970s-1980s: Research into microelectromechanical systems (MEMS) technology began, leading to the development of miniaturized sensors and actuators. 1990s: - 1990s: Advancements in complementary metal-oxide-semiconductor (CMOS) technology made it a dominant choice for VLSI design due to its low power consumption and high integration capabilities. 2000s: - 2000s: VLSI-based intelligent transducers became more prevalent in applications such as smartphones, where sensor fusion and on-chip processing enhanced user experiences. - 2000s: The Internet of Things (IoT) gained momentum, driving the demand for small, low-power intelligent sensors with wireless connectivity. 2010s: - 2010s: VLSI technology continued to follow Moore's Law, with semiconductor manufacturers producing chips with billions of transistors. - 2010s: Advances in MEMS technology led to the development of tiny, lowpower sensors used in wearable devices, medical implants, and environmental monitoring systems. - 2010s: AI and machine learning capabilities were increasingly integrated into intelligent transducers for more sophisticated data analysis and decisionmaking. 10 CHAPTER 5 LITERATURE REVIEW Maclean, Robert Bart., "A VLSI implementation of an intelligent sensor." (1998). Electronic Theses and Dissertations. The implementation of the intelligent sensor presented in this thesis improves on a previous design. The improvements are a result of design practices used and the benefits of the BiCMOS technology chosen. A VLSI implementation of an artificial neural network described in this thesis is designed for the use in process control applications requiring image capture or non-contact measurement. The VLSI implementation discussed in this thesis offers increased photo- sensor performance. [1] VLSI Design for Multi-Sensor Smart Systems on a Chip Louiza Sellami1 and Robert W. Newcomb(2012) Developed a general framework for the design and fabrication of a multi-sensor system on a chip, which includes intelligent signal processing, as well as a built-in self test and parameter adjustment units. Further, outlined its architecture, and examined various types of sensors (fluid biosensors for measuring resistivity and dielectric constant, spectral sensors, MEMS based photo-sensors, and optical microchemical and biochemical sensors. [2] Smart Transducers - Principles, Communications, and Configuration Wilfried Elmenreich1 and Stefan Pitzek(2003) Described the basic design principles for smart transducers and compare two smart transducer interface standards. This paper presented basic principles of smart transducers and shortly examined multiple solutions for communication in transducer networks.[3] 11 VLSI design of intelligent, Self-monitored and managed, Strip-free, Noninvasive device for Diabetes mellitus patients to improve Glycemic control using IoT To overcome the problems of existing invasive blood glucose monitoring, like pain while pricking, uncomfortable test strips, possibilities of infections, a real-time display and 24 hours non-invasive intelligent blood glucose level monitoring system is proposed. The proposed system is realized using FPGA and produces maximum efficiency and high throughput with low energy consumption. [4] Proc. Eurosensors XXIV, September 5-8, 2010, Linz, Austria Smart temperature sensors in standard CMOS K.A.A. Makinwa S-Based Inertial Navigation Systems by Y. Sun, X. Liu, and J. Li (2012). In this paper the basic operating principles of CMOS smart temperature sensors are explained and the stateof-the-art is reviewed. Two new figures of merit for smart temperature sensors are defined, which express the tradeoff between their energy/conversion and their resolution and inaccuracy, respectively. In the case of SoC thermal management, the emphasis is on achieving moderate inaccuracy, but without trimming and with low chip area [10][22]. In nanometer CMOS, vertical PNPs have very low current gains. [5] 12 CHAPTER 6 JUSTIFICATION The topic "History of VLSI-Based Intelligent Transducers" is highly relevant and justifiable for several reasons. First and foremost, it provides valuable insights into the evolution of microelectronics and semiconductor technology, showcasing the remarkable journey from the early integrated circuits of the 1950s to the highly sophisticated VLSI-based intelligent transducers of today. Understanding this history is essential for engineers, researchers, and students in the fields of electronics, materials science, and sensor technology, as it offers a historical context for the current state of the industry and the challenges faced by innovators in the past. Secondly, the topic highlights the crucial role that VLSI technology plays in modern society. It underscores how VLSI integration has enabled the miniaturization of sensors and the integration of complex signal processing capabilities into these devices. This miniaturization has paved the way for the proliferation of intelligent transducers in various applications, ranging from consumer electronics to healthcare and industrial automation. The historical perspective helps us appreciate the impact of VLSI-based intelligent transducers on our daily lives, from the smartphones we use to the advancements in medical diagnostics and the growth of the Internet of Things (IoT). Lastly, the topic serves as a foundation for forecasting future trends in VLSIbased intelligent transducers. By tracing the historical trajectory, we can make informed predictions about the direction of the field. It allows us to anticipate further advancements in sensor technology, signal processing, and integration techniques, as well as the potential applications in emerging technologies such as autonomous vehicles, artificial intelligence, and smart infrastructure. Understanding the history of VLSI-based intelligent transducers is crucial for 13 Figure 6.1 VLSI Chip In conclusion, the topic of "VLSI-Based Intelligent Transducers" is thoroughly justified in our contemporary world. It encapsulates the convergence of VLSI technology, sensors, and signal processing, offering solutions to the everincreasing demand for more capable and efficient sensors. Moreover, these intelligent transducers are catalysts for technological advancements, enhancing autonomy, miniaturization, and addressing global challenges across various industries. Therefore, exploring and advancing this topic is crucial for driving innovation and progress in the fields of electronics, automation, healthcare, and beyond. 14 CHAPTER 7 INTERNAL BLOCK DIAGRAM Figure 7.1 Block Diagram of VLSI-Based Intelligent Transducers 15 CHAPTER 8 DETAILS OF EACH BLOCK 1. Sensors: Sensors play a pivotal role in the block diagram of VLSI-based intelligent transducers, as they serve as the bridge between the physical world and the digital processing capabilities of integrated circuits. These sensors are responsible for detecting, measuring, and converting real-world physical phenomena into electrical signals that can be processed, analyzed, and utilized by the transducer system. For instance, in an environmental monitoring application, a temperature sensor could be employed to measure ambient temperature, a humidity sensor to gauge moisture levels, and a light sensor to detect illumination levels. These sensors generate analog signals that must be conditioned and converted to digital form for further processing within the VLSI components Figure 8.1: Different types of Sensors 16 2. Intelligent Preprocessor Amplifiers: Intelligent preprocessor amplifiers play a critical role in VLSI-based intelligent transducers by enhancing the quality and reliability of sensor signals before further processing. These amplifiers are equipped with smart features and algorithms that enable them to adapt to varying input conditions and optimize signal quality. Their role is pivotal in ensuring accurate measurements and robust performance in diverse applications.One example of the role of intelligent preprocessor amplifiers can be found in environmental monitoring systems, where sensors measure temperature, humidity, and air quality. These sensors often produce weak and noisy signals, which can be susceptible to interference or variations due to environmental factors. Intelligent preprocessor amplifiers can apply adaptive filtering techniques to remove noise and compensate for sensor drift. For instance, if a temperature sensor's output tends to drift over time, the intelligent amplifier can continuously monitor and correct this drift to maintain accuracy. . Figure 8.2: Preprocessing Amplifiers 17 3. ADC (Analog-to-Digital Converter): ADCs are essential in converting analog sensor measurements into digital data, enabling processing by digital systems. They provide accuracy and precision in quantifying real-world phenomena, such as voltage, temperature, or light intensity, for further analysis and decision-making in applications like IoT, data acquisition, and instrumentation. 4. Microprocessor: Microprocessors serve as the brain of intelligent systems, executing algorithms, managing data, and controlling hardware components. They process sensor data, perform computations, and facilitate communication, making them fundamental in various applications, including smartphones, embedded systems, and general-purpose computing. 5. Neural Networks: Neural networks are advanced machine learning models inspired by the human brain. They excel in tasks like pattern recognition, image classification, and natural language processing. In VLSI-based systems, neural networks enable complex data analysis, allowing intelligent transducers to make decisions, recognize patterns, and adapt to changing environments in applications like autonomous vehicles, voice assistants, and image processing. tors play a crucial role in MEMS by enabling the controlled movement or manipulation of micro-scale components. MEMS devices are integrated systems that combine microelectronics with miniaturized mechanical components. Micro actuators are a subset of these mechanical components, and they are responsible for converting electrical energy into mechanical motion at the micro-scale. 18 CHAPTER 9 TECHNOLOGY VLSI-based intelligent transducers require a combination of technologies and tools across various domains. Here is a list of key technologies and tools required for the successful realization of VLSI-based intelligent transducers: 1. Semiconductor Fabrication Tools: These tools are essential for the manufacturing of integrated circuits (ICs) and include photolithography equipment, chemical vapor deposition (CVD) machines, ion implanters, and etching systems. Semiconductor fabrication tools are used to create the silicon wafers and the intricate patterns that define the transducer's components. 2. VLSI Design and Simulation Software: VLSI design tools like Cadence, Synopsys, and Mentor Graphics provide a platform for designing the transducer's digital and analog components. These tools enable the creation of custom IC layouts, circuit simulations, and verification. 3. MEMS Design and Simulation Tools: When MEMS (Microelectromechanical Systems) sensors are integrated, specialized MEMS design software like CoventorWare and MEMS Pro is used for modeling and simulating the behavior of micro-scale mechanical structures. 4. Analog and Digital Circuit Design Tools: Software tools like SPICE (Simulation Program with Integrated Circuit Emphasis) are used for simulating analog circuits, while digital design tools like Verilog and VHDL are employed for designing and simulating digital logic. 5. Signal Processing Algorithms: Various programming languages and software environments like MATLAB, Python, or specialized DSP (Digital Signal Processing) software are used to develop and test signal processing algorithms that operate on the sensor data. 19 6. Electronic Design Automation (EDA) Tools: EDA tools are crucial for automating the design and verification processes. They assist in layout design, schematic capture, and netlist generation. 7. Testing and Validation Equipment: Specialized testing equipment, including probe stations, oscilloscopes, spectrum analyzers, and environmental chambers, is required for validating the performance and reliability of VLSI-based intelligent transducers. 8. Nanotechnology Tools: In cases where nanoscale sensors or components are used, specialized tools for nanofabrication and characterization are essential. 9. Materials Science and Sensing Materials: Understanding of materials science and the selection of appropriate sensing materials (e.g., silicon, polymers, piezoelectric materials) based on the application's sensing requirements are crucial for successful sensor integration. These technologies and tools collectively enable the design, fabrication, testing, and deployment of VLSI-based intelligent transducers across a wide range of applications, from consumer electronics to industrial and healthcare systems. Figure 9.1: VLSI EDA Tools 20 CHPATER 10 ADVANTAGES "VLSI-Based Intelligent Transducers" offers several significant advantages, making it a pivotal field of research and development. Here are some of the key advantages of this topic: 1. Enhanced Functionality: VLSI-based intelligent transducers provide enhanced functionality by integrating multiple sensors and signal processing capabilities onto a single chip. This integration allows for the measurement of multiple physical parameters simultaneously, enabling more comprehensive data acquisition and analysis. 2. Miniaturization: These transducers leverage VLSI technology to create compact and miniaturized devices. This miniaturization is especially valuable in applications with space constraints, such as wearable devices, medical implants, and IoT sensors, where small form factors are crucial. 3. Low Power Consumption: VLSI-based intelligent transducers are designed with a focus on low-power operation. This energy efficiency is vital for batterypowered applications, as it extends the operational life of the device and reduces the need for frequent battery replacement or recharging. 4. Real-Time Data Processing: On-chip signal processing capabilities enable these transducers to process and analyze data in real-time. This real-time processing is critical in applications that require rapid decision-making, such as autonomous vehicles, robotics, and industrial automation. 21 5. Integration and Simplification: Integration of sensors and signal processing on a single chip simplifies the overall system design. It reduces the complexity of external circuitry, lowers the bill of materials, and streamlines the development process, resulting in cost-effective solutions. 6. Accuracy and Precision: VLSI-based intelligent transducers offer high accuracy and precision in data measurement and processing. This accuracy is essential in applications such as medical diagnostics, where precise measurements are critical for patient care and treatment. 7. Versatility: These transducers are versatile and adaptable to various applications and industries. Whether in healthcare, automotive, environmental monitoring, or consumer electronics, they can be customized to meet specific needs. 8. Real-World Applications: VLSI-based intelligent transducers are integral to a wide range of real-world applications. They play a vital role in the development of advanced technologies like autonomous vehicles, IoT devices, smart wearables, and healthcare devices, contributing to improved quality of life and safety. In conclusion, the advantages of VLSI-based intelligent transducers extend across multiple domains, from improved data collection and processing to energy efficiency and versatility. Their impact is felt in diverse industries and applications, fostering innovation and addressing complex challenges in today's technology-driven world. 22 CHAPTER 11 DISADVANTAGES While VLSI-based intelligent transducers offer numerous advantages, they also come with certain disadvantages and challenges. Here are some of the disadvantages associated with this topic: 1. Complex Design and Development: The design and development of VLSIbased intelligent transducers can be highly complex and time-consuming. Integrating multiple sensors, signal processing components, and communication interfaces on a single chip requires significant expertise and resources. 2. Cost: The fabrication and development of VLSI-based intelligent transducers can be costly, particularly for small-scale or specialized applications. High initial costs for semiconductor fabrication facilities and specialized equipment may pose barriers to entry. 3. Limited Customization: While VLSI-based transducers offer versatility, there are limits to how much customization can be achieved on a single chip. Designing transducers for highly specialized or unique applications may be challenging. 4. Sensitivity to Environmental Factors: Miniaturized sensors and components can be sensitive to environmental factors such as temperature, humidity, and radiation. Specialized packaging and shielding may be required to mitigate these effects. 23 5. Reliability Concerns: Ensuring the reliability and long-term stability of VLSI-based transducers can be a challenge, especially in applications where devices are exposed to harsh conditions or undergo continuous operation. 6. Integration Complexity: Integrating VLSI-based transducers into existing systems may require compatibility with different communication protocols and interfaces. Ensuring seamless integration can be complex and time-consuming. 7. Power Consumption Trade-Offs: While these transducers are designed for low power consumption, achieving a balance between energy efficiency and performance can be challenging. In some cases, optimizing power usage without compromising functionality may be difficult. 8. Data Security and Privacy: Transducers that communicate wirelessly may be vulnerable to data security breaches and privacy concerns. Ensuring the security of data transmission and storage is a critical consideration. In summary, while VLSI-based intelligent transducers offer numerous advantages, addressing the associated disadvantages and challenges requires careful planning, expertise, and consideration of application-specific requirements. Researchers and engineers must weigh these factors when designing and implementing VLSI-based transducer solutions. 24 CHAPTER 12 APPLICATIONS MEMS VLSI-based intelligent transducers find applications across various industries and fields due to their advanced signal processing capabilities and versatility. Here are some common applications of VLSI-based intelligent transducers: 1. Automotive Systems: - Advanced Driver Assistance Systems (ADAS): VLSI-based transducers are used in ADAS to collect data from various sensors like cameras, lidar, radar, and ultrasonic sensors, enabling features like adaptive cruise control and lanekeeping assistance. 2. Healthcare and Medical Devices: - Wearable Health Monitors: Intelligent transducers are used in wearable devices to monitor vital signs such as heart rate, blood pressure, and oxygen levels, providing real-time health data to users. - Medical Imaging: In medical imaging equipment like MRI and CT scanners, these transducers help in acquiring and processing high-resolution images. 3. IoT (Internet of Things): - Smart Home Devices: VLSI-based transducers are integrated into smart thermostats, lighting systems, and security cameras to enable automation and remote control. - Environmental Monitoring: IoT sensors equipped with intelligent transducers are used to monitor air quality, water quality, and weather conditions. 25 4. Industrial Automation: - Robotic Systems: Intelligent transducers play a key role in robotic arms and automated machinery by providing precise position and feedback data. - Quality Control: They are used in quality control systems to monitor production processes and detect defects in real-time. 5. Aerospace and Aviation: - Flight Control Systems: In aircraft and drones, these transducers are essential for navigation, altitude control, and autopilot systems. - Aircraft Health Monitoring: They enable real-time monitoring of aircraft health, contributing to safety and maintenance. 6. Environmental Monitoring: - Weather Stations: VLSI-based transducers are used in weather stations to measure temperature, humidity, wind speed, and other meteorological parameters. - Natural Disaster Early Warning: They help in monitoring seismic activity, providing early warning in case of earthquakes and tsunamis. 7. Consumer Electronics: - Smartphones and Tablets: These devices incorporate intelligent transducers for functions like touchscreen operation, motion sensing (accelerometers and gyroscopes), and ambient light sensing. - Gaming Consoles: VLSI-based transducers are used in gaming controllers to provide responsive feedback and motion sensing. 26 8. Energy Management: - Smart Grids: Intelligent transducers contribute to efficient energy distribution and management in smart grid systems. - Solar Energy Systems: They monitor and optimize the performance of solar panels and inverters. 9. Defense and Security: - Surveillance Systems: VLSI-based transducers are used in surveillance cameras and systems for image processing and object recognition. - Military Sensors: In military applications, these transducers support surveillance, reconnaissance, and target tracking. These applications showcase the versatility and significance of VLSI-based intelligent transducers across various sectors, contributing to improved efficiency, safety, and automation in a wide range of industries and technologies. Figure 9.1: VLSI Technology Applications 27 CHAPTER 13 FUTURE SCOPE The future scope of VLSI-based intelligent transducers is promising and will continue to expand as technology advances and new applications emerge. Here are some key areas of future development and growth for this topic: 1. IoT and Edge Computing: With the proliferation of IoT devices and the increasing need for real-time data analysis at the edge, VLSI-based intelligent transducers will play a crucial role in providing efficient and intelligent data processing capabilities. This includes applications in smart cities, industrial IoT, and environmental monitoring. 2. Healthcare and Telemedicine: In healthcare, VLSI-based intelligent transducers will continue to enable wearable devices for continuous health monitoring. Additionally, they will contribute to the development of telemedicine solutions by providing reliable data collection and processing for remote patient monitoring. 3. Autonomous Systems: The future of autonomous vehicles, drones, and robotics relies heavily on VLSI-based intelligent transducers. These devices will help enhance the perception, decision-making, and navigation capabilities of autonomous systems, making them safer and more efficient. 4. Artificial Intelligence (AI) Integration: VLSI-based transducers will increasingly incorporate AI and machine learning capabilities. This integration will enable advanced pattern recognition, predictive maintenance, and autonomous decision-making in various applications. 28 5. Environmental Sustainability: VLSI-based intelligent transducers will continue to contribute to environmental sustainability efforts by providing accurate and real-time data for environmental monitoring, resource management, and energy optimization. 6. 5G and Beyond: As 5G and future communication technologies evolve, VLSI-based transducers will benefit from improved connectivity and reduced latency, enabling more responsive and data-intensive applications, such as augmented reality and remote robotics. 7. Security and Privacy: With the growing importance of data security and privacy, VLSI-based intelligent transducers will incorporate advanced encryption and security measures to protect sensitive data collected and transmitted by these devices. 8. Biomedical and Biotechnology Advancements: In biomedical fields, VLSIbased transducers will continue to be instrumental in areas such as personalized medicine, genetic analysis, and bioinformatics, driving advancements in healthcare and life sciences. 9. Space Exploration: As space exploration efforts expand, VLSI-based intelligent transducers will be used in spacecraft and rovers for tasks such as navigation, communication, and data analysis in challenging extraterrestrial environments. 10. Customization and Specialization: Future developments will allow for greater customization and specialization of VLSI-based transducers to meet the unique requirements of specific industries and applications, leading to innovation in niche areas. 29 11. Energy Efficiency: Continued research into energy-efficient design and power management will be essential, ensuring that VLSI-based transducers can operate for extended periods on battery power or in energy-constrained environments. 12. Global Challenges: VLSI-based intelligent transducers will play a crucial role in addressing global challenges such as climate change, resource conservation, and disaster management by providing data-driven insights and monitoring capabilities. In summary, the future of VLSI-based intelligent transducers is characterized by continued innovation, integration with emerging technologies, and a broadening range of applications. These devices will be at the forefront of advancements in automation, connectivity, healthcare, and environmental sustainability, making them central to the development of smarter and more efficient systems and technologies. Figure 13.1: Future Scope of VLSI Technology 30 QUESTION & ANSWER Question 1: What are Intelligent Transducers? Answer: Intelligent transducers are sensor devices equipped with embedded processing capabilities, typically implemented using VLSI technology. They can collect, process, and analyze data on-chip, providing real-time insights and decision-making, making them ideal for applications requiring advanced data processing and automation. Question 2: What is the primary application of VLSI technology? Answer: VLSI technology is widely used in the design and manufacturing of microprocessors, enabling the development of powerful and energy-efficient computing devices. Question 3: How are VLSI Based Intelligent Transducers devices manufactured? Answer: VLSI-based intelligent transducers are manufactured using semiconductor fabrication techniques. This involves creating intricate circuit patterns on silicon wafers through processes like photolithography, chemical deposition, and etching. The integration of sensors, signal processing components, and communication interfaces onto a single chip is achieved during the manufacturing process. Question 4: What types of sensors can be made using VLSI technology? Answer: VLSI technology is commonly used to create a wide range of sensors, including pressure sensors, temperature sensors, humidity sensors, motion sensors (e.g., accelerometers and gyroscopes), light sensors (photodetectors), and environmental sensors. Question 5: What are some advantages of VLSI Based Intelligent Transducers? Answer: VLSI-based intelligent transducers offer several advantages, including enhanced functionality with integrated signal processing, reduced power 31 consumption for energy-efficient operation, and miniaturization for spaceconstrained applications. Question 6: What is difference between general Transducer and VLSI Based Intelligent Transducer Answer: The key difference between a general transducer and a VLSI-based intelligent transducer lies in their functionality and processing capabilities. General transducers primarily convert one form of energy or signal into another without sophisticated data analysis. In contrast, VLSI-based intelligent transducers integrate advanced signal processing and decision-making capabilities, enabling real-time data analysis and enhancing their suitability for complex applications like autonomous systems and IoT devices. Question 7: What are the steps of VLSI design Answer: VLSI design involves three key steps: 1. Specification, 2. Design, 3. Verification Question 8: What are some emerging applications for VLSI technology? Answer: Emerging applications for VLSI technology include Quantum Computing, Neuromorphic Computing, Edge AI Devices. Question 9: What is the difference between FPGA and ASIC? Answer: FPGAs (Field-Programmable Gate Arrays) are reconfigurable hardware devices that can be programmed and reprogrammed to perform a variety of tasks. ASICs (Application-Specific Integrated Circuits), on the other hand, are custom-designed, fixed-function chips optimized for specific tasks. FPGAs offer flexibility but may have lower performance and higher power consumption, while ASICs provide higher performance and lower power consumption but lack flexibility. Question 10: Are there any challenges associated with VLSI Based Intelligent Transducers? Answer: Challenges with VLSI-based intelligent transducers include Complex Design, Power Efficiency, Miniaturization. 32 REFERENCES [1] Maclean, Robert Bart., "A VLSI implementation of an intelligent sensor." (1998). Electronic Theses and Dissertations. 872. [2] VLSI Design for Multi-Sensor Smart Systems on a Chip Louiza Sellami1 and Robert W. Newcomb(2012) [3] Smart Transducers - Principles, Communications, and Configuration Wilfried Elmenreich1 and Stefan Pitzek(2003) [4] VLSI design of intelligent, Self-monitored and managed, Strip-free, Noninvasive device for Diabetes mellitus patients to improve Glycemic control using IoT (16th International Learning & Technology Conference 2019) [5] Proc. Eurosensors XXIV, September 5-8, 2010, Linz, Austria Smart temperature sensors in standard CMOS K.A.A. Makinwa 33