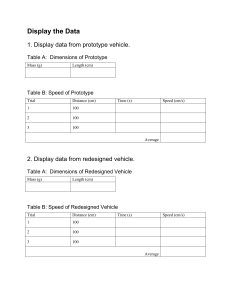

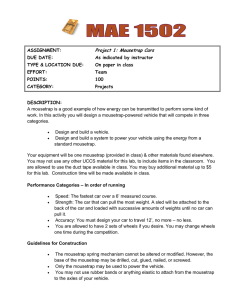

2.4 Case Study in Conceptual Design: Mousetrap-Powered Vehicles 57 For instance, an electron beam melts metal powder in a vacuum chamber, creating very strong parts that can withstand high temperatures. Customized production is giving engineers the ability to manufacture a product as soon as someone orders it to one-of-a-kind specifications by taking advantage of rapid manufacturing technologies. 2.4 CASE STUDY IN CONCEPTUAL DESIGN: MOUSETRAP-POWERED VEHICLES Requirements development In this case study, we trace the progress of a hypothetical team of engineering students as they generate concepts for designing a mousetrap-powered vehicle. Readily visualized and built, these vehicles are a useful means for experiencing part of a design process and for gaining an appreciation of the trade-offs that must be made for a design to satisfy all its requirements. As described in Section 2.2, the first stage in a design process is developing a set of comprehensive requirements. In our illustrative case study of designing and building the vehicle, the system requirements are essentially provided to the teams of engineering students by the instructor, as follows: • Vehicles must travel 10 m as quickly as possible • The vehicle must be powered by only a standard household mousetrap. Energy that is incidentally stored by other elastic elements or obtained from a change in elevation of the vehicle’s center of mass must be negligible • Each vehicle is to be designed, built, refined, and operated by a team of three students • Teams will compete against one another in head-to-head races during a tournament; so the vehicles must be both durable and reusable • The mass of the vehicle cannot exceed 500 g. The vehicle must fit completely within a 0.1-m3 box at the start of each race. Each vehicle will race in a lane that is 10 m long but only 1 m wide. The vehicle must remain in contact with the surface of the lane during the entire race • Tape cannot be used as a fastener in the vehicle’s construction Each of these requirements constrains, in different ways, the hardware that the teams will ultimately produce. If any single requirement is not met, the entire design will be inadequate, regardless of how well the vehicle might perform relative to the other requirements. For instance, because the racing lane is ten times longer than it is wide, the vehicle must be capable of traveling in a reasonably straight line. If a particular vehicle is fast, but it sometimes veers outside the lane, then it could be defeated by a slower vehicle in a headto-head race. The design teams recognize that the vehicles should not be optimized with respect to only one specification, but rather balanced to meet all of the requirements. 58 Chapter 2 Conceptual design Mechanical Design We next follow the thought process of a hypothetical team as it begins to create several design concepts. The students document their ideas in a bound design notebook, and they use written comments and hand drawings to describe each concept. Subsequently, the team will record progress as prototypes are constructed and tested in order to document the outcome of their iteration efforts. In short, the notebook serves as a log to chronicle the team’s entire design experience. As described in Section 2.2, such notebooks are often dated, signed, and even witnessed to formally document a product’s development. With an eye toward your own professional career, you should also begin the practice of systematically recording your original ideas. First Concept: String and Lever Arm An idea that emerges from the team’s first brainstorming session is based on using the mousetrap’s snap arm to pull and unwrap string from a drive axle. Together, the team members sketch the concept shown in Figure 2.19. As the trap snaps closed, string is unwound from a spool that is attached to the rear axle, and the vehicle is propelled forward. The concept vehicle incorporates a lever arm that lengthens the snap arm supplied with the mousetrap, pulls more string from the axle, and changes the velocity ratio between the mousetrap and the drive wheels. Although this concept has the positive attribute of being simple and straightforward to construct, the team raises a number of questions and lists them in their notebook: • What should be the length of the lever arm’s extension and the radius of the spool that is attached to the drive axle? With a long-enough string, the vehicle would be powered steadily by the mousetrap over the entire course. On the other hand, if the string is shorter, the mousetrap will close sooner, and the vehicle would coast after being powered only along the first part of the course. The team’s discussion of this issue prompts the idea for a tapered spool, as sketched in Figure 2.19(c), which would enable the velocity ratio between the mousetrap and the drive axle to change as the mousetrap closes. • Should the mousetrap be positioned behind, above, or in front of the drive axle? In their concept sketch, the students drew the mousetrap directly between the front and rear wheels. At this stage, however, that placement is arbitrary, and the team has no reason to expect that choice to be better than any other. This question could be resolved in the future by building a prototype and conducting some tests. • What should be the radius of the wheels? Like the length of the lever arm’s extension and the radius of the spool, the radius of the drive wheels influences the vehicle’s velocity. The team noted on its sketch that computer compact discs could be used as the wheels, but the vehicle might post a better race time with wheels having a smaller or larger diameter. Another question is how to place the two mouse traps, whether to put them next to eachother or one behind the other one. 2.4 Case Study in Conceptual Design: Mousetrap-Powered Vehicles Lever arm's extension Figure 2.19 First design concept that is based on a lever arm for pulling and unwrapping string from the drive axle. (a) Side view with two wheels removed for clarity. (b) Top view of the vehicle. (c) Concepts for straight and tapered unwinding spools. 59 Compact disc wheels Rotation String Unwinding spool (a) Mousetrap Spring Snap arm (b) String's tension (c) The team records these questions and discussion topics in their notebook, but they leave them for future consideration. At this early point in the conceptual design stage, no decisions need to be made on dimensions or materials. However, if this concept eventually emerges as a promising candidate, the team will need to resolve these issues before constructing a viable prototype. Second Concept: Compound Geartrain As the discussions continue, the team next devises the option shown in Figure 2.20 (see on page 60), in which a compound geartrain transfers power from the mousetrap to the drive axle. This vehicle has only three wheels, and a portion of the body has been removed to reduce weight. The concept 60 Chapter 2 Figure 2.20 Mechanical Design Rear axle Compound geartrain Second concept that is based on a compound geartrain between the mousetrap’s snap arm (which rotates through one-half turn) and the drive axle (which is powered over the race course’s full distance). (a) Top view of the vehicle. (b) Layout of the two-stage geartrain. Cut out body to reduce weight Spring Snap arm (a) Gears #2 and #3 on same shaft Gear #4 attached to rear axle N2 N3 Snap arm attached to gear #1 N1 Mousetrap N4 (b) incorporates a two-stage geartrain, and its velocity ratio is set by the numbers of teeth on the four gears. The team’s illustration of a two-stage geartrain is arbitrary; a system with only one stage or more than two stages might be preferable. However, the students accept such ambiguity, and they realize that a decision for the geartrain’s velocity ratio is not yet necessary. During the give-and-take of the meetings, the team identifies additional constraints that are common to their first and second concepts. For instance, the students agree that the vehicle should be designed so that the drive wheels do not spin and slip as the vehicle accelerates. Otherwise, some portion of the limited energy that is available from the mousetrap’s spring would be wasted. To prevent slippage, weight could be added to the vehicle to improve contact between the drive wheels and the ground. On the other hand, a heavier vehicle would be slower because the potential energy of the mousetrap spring is converted into the vehicle’s kinetic energy. As they investigate the project in more detail, the students see that the technical issues at hand are interrelated. Even in the context of this seemingly straightforward exercise, the designers must grapple with competing constraints and requirements. 2.4 Case Study in Conceptual Design: Mousetrap-Powered Vehicles 61 Third Concept: Sector-Shaped Gear The team’s third concept combines and extends certain ideas that arose during the earlier discussions. The design of the concept in Figure 2.21 incorporates a geartrain between the mousetrap and the drive wheels, but it enables the vehicle to coast once the trap closes. The students envision such a vehicle as accelerating quickly over the first few meters of the race course, reaching peak velocity, and then coasting at that speed over the remaining distance. In their concept, a sector-shaped gear, instead of a full circular one, is attached to the snap arm of the mousetrap. A small notch at one end of the gear enables the mousetrap to disengage from the simple geartrain once the snap arm has closed, as shown in the Figure 2.21(c). The sector-shaped gear serves as the input to the geartrain, and the output gear is directly attached to the front drive axle. The idler gear (Section 8.5) is included to increase the offset between the mousetrap and the front axle. With several concepts in mind, the students can now begin making trade-offs, considering various materials, narrowing down their options, and experimenting with prototypes. Although selecting specific components would be premature, the students use their imaginations to list some materials that could be used: foamcore poster board, balsa and poplar wood, aluminum and brass tubing, threaded rods, plexiglass, ball bearings, oil and graphite lubricants, wire, and epoxy. After addressing some of the technical issues that have been raised and performing some order-of-magnitude calculations, the team might decide to build and test a few prototypes before selecting the one concept to be refined in detail. Sector-shaped gear Figure 2.21 Third concept that is based on a simple geartrain and a sector-shaped gear. The vehicle is powered over the first portion of the race course and then coasts at top speed over the remaining distance. Side views of the geartrain (a) as the mousetrap begins to close, (b) during the powered phase, and (c) during the coasting phase where the notch disengages the sector-shaped gear from the drive wheels. Front drive wheel Cut out notch for coasting phase Gear attached to wheel Idler gear Body (a) Mousetrap N2 N3 No meshing while vehicle is coasting N1 (b) (c)