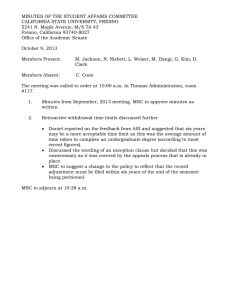

Inspection - - Manufacturing Inspections Report factory [date] Inspection - - Manufacturing Inspections 202306- Workplace safety (HVM) Report for: factory - Inspector: Inspection Type: Manufacturing Inspections Inspection Checklist: Manufacturing Safety Checklist Inspection Completed Date: Monday, July 17, 2023 Frequency: Action Owner: Contractor: Equipment: Project Code: Project Manager: Type of Work: Quality Cluster Manager: Work Center: Work Permit: NEN 3140 / IEC 60204-1 (guidelines) compliant: Next Inspection before: Confidential Inspection - - Manufacturing Inspections Report factory [date] Executive Summary At Monday, July 17, 2023 an inspection has been performed at factory -. The inspection was performed by (8). Detailed results have been included in as well in this document. Summary of the inspection: - - Type of inspection: Manufacturing Inspections All findings and actions have been included; this report contains the detailed findings and actions The findings are sorted by: - Deviations - Observations - Best Practices During the inspection a site tour has been made at sector This inspection resulted in the following findings: - 2 Deviations have been found - 0 Observations have been found - 0 Best Practices have been found Confidential Inspection - - Manufacturing Inspections Report factory [date] Contents 1 Introduction ......................................................................................................................................... 4 1.1 Background and objectives ........................................................................................................... 4 1.2 Methodology................................................................................................................................. 4 2 Inspection Findings .............................................................................................................................. 5 3 Inspection Actions ................................................................................................................................ 6 4 Checklist + Answers.............................................................................................................................. 7 5 Private Document Attachments......................................................................................................... 12 Confidential Inspection - - Manufacturing Inspections Report factory [date] 1 Introduction 1.1 Background and objectives An inspection has been performed based on the Manufacturing Safety Checklist checklist. The goal of this inspection was to evaluate the compliance to the requirements based on this checklist. 1.2 Methodology A site tour including interviews has been conducted in order to check compliance with the Manufacturing Safety Checklist checklist. The results are documented in the Inspection Management module of MyEHS. Findings are categorized as followed: 1. Deviations 2. Observations 3. Best Practices Confidential Inspection - - Manufacturing Inspections Report factory [date] 2 Inspection Findings In the table underneath, an overview of all inspections findings is shown. Finding Category Deviation Safety Risk Low Description Missing evacuation route map in front of cabin YS WIP2. Team/Supplier Status Picture Closed S__ 18087944.j pg Deviation Low No ground label for two fire extinguishers in Cabin YSWIP2. Closed S__ 18087945.j pg S__ 18087946.j pg Confidential Inspection - - Manufacturing Inspections Report factory [date] 3 Inspection Actions In the table underneath, an overview of all action plans is shown. Action No. Related Finding Action Type Action Required Person Responsible Due Date Status 57391 No ground label for two fire extinguishers in Cabin YSWIP2. Containment Need to stick the ground red line for two fire extinguishers in Cabin YSWIP2 based on the evacuation map. Jimmy Chang (636002) Sunday, July 30, 2023 Completed Missing evacuation route map in front of cabin YS WIP2. Containment Need to post the evacuation route map for cabin YS WIP2. Mack Tsai (649666) Picture MicrosoftT eams-i mage (72).png MicrosoftT eams-i mage (73).png 57392 Monday, July 31, 2023 Completed Confidential Inspection - - Manufacturing Inspections Report factory [date] 4 Checklist + Answers Question Code Question MSC.1 Locks/Tags available, correct use (Apply and Remove), certified operator, according to procedure, overhead crane Enough space around electrical panels? (36 inch / ~1m) MSC.10 MSC.11 MSC.12 MSC.13 MSC.14 Answer Comments Picture Cords and Cables good condition, insulated/guarded, approved kind, right location, no strain/pull, no taps/splice, located away from walking areas to prevent tripping hazards? Powerstrip and extension cords approved, single use, grounded, not attached to structures, not used permanent No open wiring / electrical tooling / clean and good state Flammables & Combustables stored in cabinets (marked, labeled, organized, no waste, trash, paper, cardboard) within reach sprinkler Confidential Inspection - - Manufacturing Inspections Report factory [date] MSC.15 Fire Extinguishers available, unblocked, inspected, charged, good condition & clearly marked, serviced/tagged annually, Unblocked NOK YS WIP2 area Fire Extinguishers and evacuation route inspection Doors All Fire Doors Self-closing - Tested, All Cabinet doors working properly MSC.16 MSC.17 EXIT all EXIT signs illuminated, all EXIT paths free Equipment, Tools and PPE available, used and stored correctly (Scaffold, Harness,lanyard, fence, guardrail, Anchor Points, Ladders*) - 3-points of contact while ascending or descending ladders, pre-checked (frequently & before use) all in good and clean condition working zone is controlled access zone, all trained/certified / radiation badge visible MSC.18 Path and steps in good shape, clearly marked, free of tripping hazard MSC.19 Adequate Light / no noise / PPE Signs MSC.2 Other Safety Hazard MSC.20 Other Physical Hazard MSC.21 Physical Ergonomics (body) Lifting Tools / reaching / kneeling / bending / sitting position overstretching / lying / manual lifting above shoulder height too many repetitions / heavy items stored on lower shelves carts available (Mach. Covers) / cushions available OK Confidential Inspection - - Manufacturing Inspections Report factory [date] MSC.22 MSC.23 MSC.24 MSC.25 MSC.26 Workplace Ergonomics (surroundings) Extreme Temperature / Magnetics / Tripping hazards falling objects / obstructions Other Ergonomic Hazard (Power)Tools blades sharp, good shape, no alterations, secured, guarded, clean, no missing parts, no visible defects, handles/grips are ok, wiring in good shape, grounded, insulated, Right tooling for job, calibrated, certificate, Trained for use tool? Correct approved transport tooling available, (pre)checked and used (e.g. Forklift, Pallet Truck, Powered Industrial Trucks) Route is free from obstruction (power cords, SISO plates, metal/plastic plates, machine covers, loose parts) Load secured and stabilized (e.g. Forklift fixed with lashing belt) Apply PtW to excute the work without AWI or Coach Procedure? Other Tooling & Equipment MSC.27 Aware of all Safety Alarms, Escape routes and Emergency number MSC.28 Trained, qualified and competent wrt. Tooling IEQ / QEW / Confined Space / Internal Course Special Operation / Local Requirements / completed legal re-qualification Other Competence & Training MSC.29 MSC.3 Tooling used (Gas Monitors) / visibility cabin clear / PtW filled in / H2 status machine correct Confidential Inspection - - Manufacturing Inspections Report factory [date] MSC.30 MSC.31 MSC.32 MSC.33 PPE available and correctly used (Clean Eye WashShower, Head, Eye, Ears, Respiratory, Arms, Hands, Legs, Feet, Arc Flash Gear, 1st Aid Supply available ) Procedures / Work instructions are Available, Clear, Accessible, Adhered to All signs visible and clear in (sub)Fab (Warning, exit, Remote Access Devices, PPE advise) (e.g. which way a door opens, Storage Rack labels, platform load limit weight, Exit) When working alone, communicated before start, no high risk MSC.34 Certified operator / tooling, controlled access zone, PPE MSC.35 When manually lifting heavy objects sufficient help (2 or more employees) MSC.36 Other Safety WoW MSC.37 Other Biological Hazard MSC.38 Other Psychological Hazard MSC.4 WF specific: Compressed Gas Cylinders | secured, capped, upright, separated, labelled MSC.5 Do you smell, taste, hear of feel anything that would point out a gas issue or leak? Confidential Inspection - - Manufacturing Inspections Report factory [date] MSC.6 Safety Data Sheet (SDS) meets local legal requirement / Employee knows where to find SDS MSC.7 Hazardous Waste Containers/Cabinets Location, Closed, Labeled correct (GHS), no leaks MSC.8 Chemicals stored correct (in chemicalflam cabinet) / PPE used / Satellite areas labelled / inspected frequently MSC.9 Other Chemical Hazard Confidential Inspection - - Manufacturing Inspections Report factory [date] 5 Private Document Attachments Pictures Confidential Inspection - - Manufacturing Inspections Report factory [date] Confidential