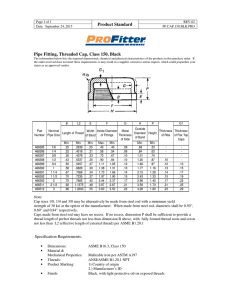

ASME - ASME BPVC 2010 - Section III, Division 1, Subsection ND Class 3 Components

advertisement