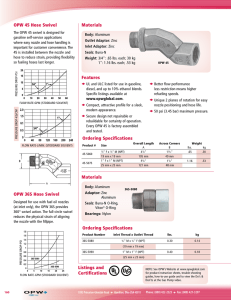

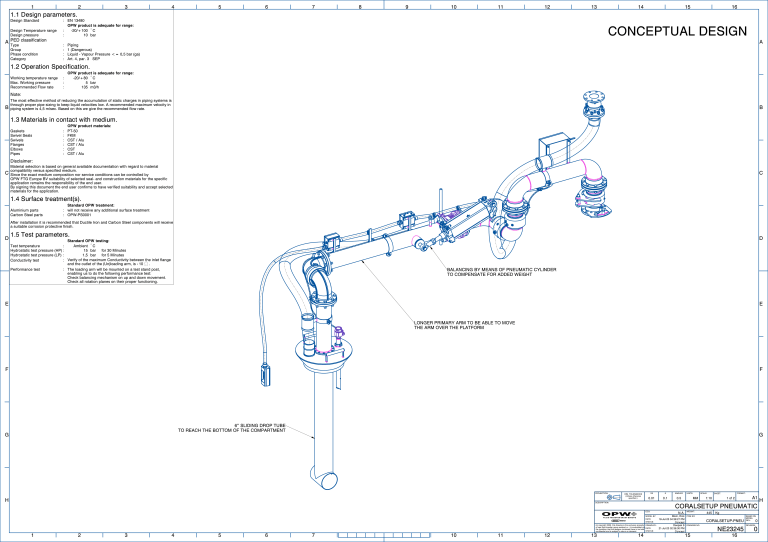

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1.1 Design parameters. Design Standard Design Temperature range Design pressure : EN 13480 OPW product is adequate for range: : -20/+100 C : 10 bar Type Group Phase condition Category : : : : A PED classification CONCEPTUAL DESIGN A Piping 1 (Dangerous) Liquid - Vapour Pressure <= 0,5 bar (ga) Art. 4, par. 3 SEP 1.2 Operation Specification. Working temperature range Max. Working pressure Recommended Flow rate OPW product is adequate for range: : -20/+80 C : 5 bar : 135 m3/h Note: B The most effective method of reducing the accumulation of static charges in piping systems is through proper pipe sizing to keep liquid velocities low. A recommended maximum velocity in piping system is 4,5 m/sec. Based on this we give the recommended flow rate. B 1.3 Materials in contact with medium. Gaskets Swivel Seals Swivels Flanges Elbows Pipes : : : : : : OPW product materials: PT-50 FKM CST / Alu CST / Alu CST CST / Alu Disclaimer: C Material selection is based on general available documentation with regard to material compatibility versus specified medium. Since the exact medium composition nor service conditions can be controlled by OPW FTG Europe BV suitability of selected seal- and construction materials for the specific application remains the responsibility of the end user. By signing this document the end user confirms to have verified suitability and accept selected materials for the application. C 1.4 Surface treatment(s). Aluminium parts Carbon Steel parts Standard OPW treatment: : will not receive any additional surface treatment : OPW-PS0001 After installation it is recommended that Ductile Iron and Carbon Steel components will receive a suitable corrosion protective finish. D 1.5 Test parameters. Test temperature : Hydrostatic test pressure (HP) : Hydrostatic test pressure (LP) : Conductivity test : Performance test : D Standard OPW testing: Ambient C 15 bar for 30 Minutes 1,5 bar for 5 Minutes Verify of the maximum Conductivity between the inlet flange and the outlet of the (Un)loading arm, is ‹ 10 . The loading arm will be mounted on a test stand post, enabling us to do the following performance test: Check balancing mechanism on up and down movement. Check all rotation planes on their proper functioning. BALANCING BY MEANS OF PNEUMATIC CYLINDER TO COMPENSATE FOR ADDED WEIGHT E E LONGER PRIMARY ARM TO BE ABLE TO MOVE THE ARM OVER THE PLATFORM F F 6" SLIDING DROP TUBE TO REACH THE BOTTOM OF THE COMPARTMENT G G PROJECTION: H DIM. TOLERANCES (Unless otherwise specified.) .XX .X ANGLES 0.01 0.1 0.5 DESCRIPTION: MODEL BY: DATE: STATUS: 2 3 4 5 6 7 10 11 12 (c) copyright 2009. this drawing is the exclusive property DRAWN BY: of opw fluid transfer group europe b.v.. it is submitted on DATE: the condition that the designs contained there in be held STATUS: confidential and is subject to return on demand. 13 MM SCALE: FORMAT: SHEET: 1:10 1 of 2 A1 CORALSETUP PNEUMATIC ECO: 1 UNITS: 14 N.A. Blom, Rick 18-Jul-23 04:39:27 PM Concept Deepak S 21-Jul-23 02:36:30 PM Concept WEIGHT: 445 Kg ITEM NO: CORALSETUP-PNEU DRAWING NO: 15 NE23245 16 BASED ON MODEL REV: 0 REVISION: 0 H 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 (3750) 2300±10 1000±10 A 571±5 367±5 A B B C D D 652±5 589±5 C E (4064) 851 E F 2556 F G G PROJECTION: H DIM. TOLERANCES (Unless otherwise specified.) .XX .X ANGLES 0.01 0.1 0.5 DESCRIPTION: MODEL BY: DATE: STATUS: 2 3 4 5 6 7 10 11 12 (c) copyright 2009. this drawing is the exclusive property DRAWN BY: of opw fluid transfer group europe b.v.. it is submitted on DATE: the condition that the designs contained there in be held STATUS: confidential and is subject to return on demand. 13 MM SCALE: FORMAT: SHEET: 1:10 2 of 2 A1 CORALSETUP PNEUMATIC ECO: 1 UNITS: 14 N.A. Blom, Rick 18-Jul-23 04:39:27 PM Concept Deepak S 21-Jul-23 02:36:30 PM Concept WEIGHT: 445 Kg ITEM NO: CORALSETUP-PNEU DRAWING NO: 15 NE23245 16 BASED ON MODEL REV: 0 REVISION: 0 H