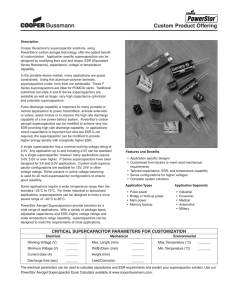

Journal of Science: Advanced Materials and Devices 8 (2023) 100586 Contents lists available at ScienceDirect Journal of Science: Advanced Materials and Devices journal homepage: www.elsevier.com/locate/jsamd Original Article Chitosan-derived carbon aerogel nanocomposite as an active electrode material for high-performance supercapacitors Le Hong Quan a, b, Ung Thi Dieu Thuy c, Pham Viet Nam d, Nguyen Van Chi a, Tang Xuan Duong a, Nguyen Van Hoa e, * a Coastal Branch of the Joint Vietnam - Russia Tropical Science and Technology Research Center, 30 Nguyen Thien Thuat, Nha Trang, Vietnam Graduate University of Science and Technology, Vietnam Academy of Science and Technology, 18 Hoang Quoc Viet, Cau Giay, Ha Noi, Vietnam Institute of Materials Science, Vietnam Academy of Science and Technology, 18 Hoang Quoc Viet, Cau Giay, Ha Noi, Vietnam d Faculty of Food Science and Technology, Ho Chi Minh City University of Food Industry, 140 Le Trong Tan, Tan Phu, Ho Chi Minh City, Vietnam e Department of Chemical Engineering, Nha Trang University, 2 Nguyen Dinh Chieu, Nha Trang, Vietnam b c a r t i c l e i n f o a b s t r a c t Article history: Received 15 December 2022 Received in revised form 24 April 2023 Accepted 23 May 2023 Available online 25 May 2023 The valorization of shrimp wastes to develop advanced materials brings economic and environmental advantages. This paper presents a facile and eco-friendly synthesis of shrimp chitosan-derived carbon (CCS) and CCS/NiO@Ni(OH)2 (CSSN) aerogel nanocomposite for supercapacitor application, in which NiO and Ni(OH)2 nanoparticles were tightly attached to the porous surface of CCS aerogel. As a result, CCSN300 aerogel carbonized at 300 C has high porosity and electrical conductivity and demonstrates its potential as an active electrode material for supercapacitors. The CCSN-300 aerogel material electrode exhibits a high capacitance of 316 mAh g1 at 1.0 A g1. Furthermore, the CCS//CCSN-300 device had a capacitance of 209 F g1 at 1.0 A g1 and over 84% remaining after the 10,000 cycles. Moreover, it has a high energy density of 65 Wh kg1 at a power density of 1500 W kg1. The results demonstrate that chitosan-derived carbon composites hold great promise in high application efficiency for energy storage. © 2023 Vietnam National University, Hanoi. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). Keywords: Chitosan Chitosan-derived carbon Aerogel nanocomposites Supercapacitor 1. Introduction Currently, the demand for energy around the world is increasing. With constant efforts, researchers are finding ways to replace fossil fuels with renewable energy sources such as solar and wind power to fulfill sustainability. However, one of the significant issues with this renewable energy is the continuous storing of energy while passively dependent on factors like the sun and wind. Therefore, the demand for energy storage systems is exploding, and energy storage devices are creating a strong attraction in the research world today. Among them, the role of supercapacitors is considered the golden key to sustainable energy [1e4]. The ideal material for supercapacitor electrodes should have the following properties: large capacitance, high conductivity, large surface area, low density, and large porosity with suitable pore size. Generally, three primary materials commonly used for electrode coating for supercapacitors are metal oxides/hydroxides/sulfides * Corresponding author. E-mail address: hoanv@ntu.edu.vn (N. Van Hoa). Peer review under responsibility of Vietnam National University, Hanoi. (MOHS), conductive polymers, and carbon materials [5e9]. However, each of those materials has its advantages and drawbacks. For example, MOHS materials have high electrical potential due to redox reactions but have low conductivity and are less stable when charged/discharged repeatedly [9]. Meanwhile, carbonaceous materials with high electrical conductivity and large porosity but low capacitance [10]. Finally, conductive polymers have high strength but low porosity [9]. So far, composite materials of two or three components above are mentioned to overcome the above problem because they have the following advantages: (i) enhance the surface area and porosity of the material; (ii) improve the conductivity of the electrode; (iii) decrease the size of nanoparticles or polymers due to the uniform distribution of components in the assembly. Therefore, the properties of composite materials have outstanding features and greatly enhance supercapacitors' performance by increasing capacity and energy density. In addition, it is worth noting that the electrochemical performance of the electrodes is improved when carbon is combined with pseudo-capacitive materials due to carbon's electrical conductivity and the metal compounds' redox activity [11e13]. https://doi.org/10.1016/j.jsamd.2023.100586 2468-2179/© 2023 Vietnam National University, Hanoi. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/ licenses/by-nc-nd/4.0/). L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 2.3. Characterization Metal oxides, hydroxides, and sulfides such as RuO2, NiO, MnO2, Ni(OH)2, MoS2, and conductive polymers such as polypyrrole and polyaniline are common materials for supercapacitors [14e17]. For example, among various transition metal oxides, NiO and Ni(OH)2 are widely studied as active electrode materials for supercapacitors due to their high capacitance, easy preparation, high chemical stability, and low cost. However, they have poor electrical conductivity and a low electron transport rate. Carbon aerogel is a potential material for supercapacitor fabrication due to its high conductivity, large surface area, and good flexibility [18e20]. Carbon aerogel is often studied and prepared from graphene by chemical reduction and freeze-drying. However, due to the relatively high cost of graphene raw materials, its practical application and commercial production trade still face many difficulties [21e24]. Chitosan (CS) is a biopolymer, commercially produced mainly from shrimp shells, which is discharged from seafood factories in massive amounts [25]. The molecular structure of chitosan contains many amino groups (-NH2). In addition, in the chitosan molecule, there are functional groups in which the oxygen and nitrogen atoms of the functional group have unused electron pairs, so they can create complexes and coordinate with most transition metals. After forming the aerogel and being carbonized, the resulting product is an N-doped carbon aerogel with good electrical conductivity and electrochemical properties. Based on those considerations, this work aimed to prepare carbon/NiO@Ni(OH)2 (CCSN) aerogel nanocomposite for energy storage application, in which carbon was derived from chitosan. The as-prepared materials were characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD), X-ray spectroscopy (EDX), and BET surface measurement. In addition, the electrochemical performance of the CCSN nanocomposites was investigated in both three- and two-electrode systems. The morphology and elemental mapping of samples were characterized using scanning electron microscopy (SEM, Hitachi, S4800). The phase composition of CCSN aerogels was analyzed using X-ray diffraction analysis (XRD, PANalytical, X'Pert-PRO MPD) under Cu Ka radiation. The chemical structure of samples was determined by a Fourier transform infrared spectrometer (FTIR, Nicolet iS10, Thermo Scientific) from 500 to 4000 cm1 at a resolution of 16 cm1 for 32 scans. BrunauereEmmetteTeller (BET) and BarretteJoynereHalenda (BJH) methods were applied to determine the specific surface area and pore size, respectively. 2.4. Electrochemical measurements Chitosan (CS, deacetylation of 95%, viscosity of ca. 200 mPa s) was prepared from shrimp shells in our laboratory. Acetic acid (CH3COOH, 99%), sodium hydroxide (NaOH, 99%), Glutaraldehyde (GA, 50%), nickel (II) nitrate hexahydrate (Ni(NO3)2$6H2O, 99%) were purchased from SigmaeAldrich and used as received. An electrochemical workstation Autolab PGSTAT204N (Metrohm, Netherlands) was employed to investigate the electrochemical performances. In a three-electrode configuration, the Platinum foil and an Ag/AgCl electrode were used as counter and reference electrodes, respectively. The working electrode was fabricated by pressing a paste of 80 wt.% aerogel, 10 wt.% carbon black, and 10 wt.% chitosan solution binder on a nickel foam collector (1.0 cm 1.0 cm). All electrochemical tests were conducted at room temperature using a 6 M KOH electrolyte solution. On the other hand, the electrochemical performance of the CCSN aerogels was investigated in an asymmetrical two-electrode configuration in a 6 M KOH electrolyte solution. The setup is built into a stainless cell with filter paper as the separator. The electrode is cut into circular films approximately 15 mm in diameter. Cyclic voltammetry (CV) was measured at different scan rates from 2 to 200 mV s1 and within a potential range of 0.0 0.4 V (for the three-electrode system) and 0.0 1.5 V (for the two-electrode system). The capacitance and rate capability were evaluated based on galvanostatic charge/discharge (GCD), measured at various current densities from 1.0 to 7.5 A g1 at a potential window of 0.0 0.4 V (for the three-electrode system) and 0.0 1.5 V (for the two-electrode system). A chargeedischarge test of 10,000 cycles was implemented at a constant current density of 5.0 A g1. Electrochemical impedance spectroscopy (EIS) was performed in a frequency range of 102 105 Hz with an AC amplitude of 5.0 mV. The specific capacitance (Q, mAh g1) was calculated from the GCD through a three-electrode system using the following equation (1) [1,2]: 2.2. Preparation of CCSN aerogels Q¼ Fig. 1 shows a schematic process regarding preparing chitosanderived carbon aerogel nanocomposite for supercapacitors. Firstly, CS was dissolved in a 2.0 wt.% acetic acid aqueous solution to form a 2.0 wt.% CS solution. Then, 1.75 g (6 mmol) of Ni(NO3)2$6H2O was added to the 100 ml CS solution and stirred for 30 min to homogenize the mixture. Next, 1.0 wt.% GA was injected into the CS solution containing Ni2þ and stirred for 30 min. Next, soak the resulting solution in a container containing 10 wt.% NaOH solution till the gelation was completed. The CS-Ni(OH)2 hydrogels were washed with deionized water repeatedly to be neutral. Next, the hydrogel samples were frozen at 40 C for 24 h and dried by lyophilization to get CS-Ni(OH)2 aerogels. Finally, the CS-Ni(OH)2 aerogels were converted into CCS-NiO@Ni(OH)2 (CCSN) nanocomposites in a tube furnace at different temperatures under a nitrogen atmosphere. The heating rate is 5 C min1. The activation temperatures were 300, 400, and 500 C, and the obtained samples were denoted as CCSN-300, CCSN-400, and CCSN-500, respectively. where I is the discharge current (A), t is the discharge time (s), and m is the mass of the active material (g). For the asymmetrical device, the capacitance was calculated from GCD curves according to the following equation (2) [26]: 2. Experimental 2.1. Materials C¼ It m 2It mDV (1) (2) where C is the capacitance (F g1), t is the discharge time (s), m is the total mass of the active material at the two electrodes (g), and DV is the working voltage window (V). The energy density (E, Wh kg1) and power density (P, kW kg1) were calculated from GCD tests in the following equations (3) and (4), respectively [4,26]: E¼ 2 1 C DV 2 2 3:6 (3) L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 Fig. 1. Schematic diagram of the preparation of CCSN aerogel nanocomposite for supercapacitor application. E P ¼ 3600 t 52.2 correspond to the (100) and (110) crystal planes of Ni(OH)2. Therefore, it can be concluded that the formation of CCSN composites is doped with a small amount of Ni(OH)2. The obtained XRD is also consistent with other studies [27e31]. The FTIR spectra of CS and various CCSN aerogels are shown in Fig. 3. The characteristic absorption peaks of CS are at 3500 cm1 (OeH and NeH), 1645 cm1 (C¼O stretching vibration), 1545 cm1 (NeH bending vibration), 1135 and 1224 cm1 (-CH2 and CeO distinct groups) [32]. The CCSN samples have peaks at 3500, 1645, and 1545 cm1 attenuated in descending order at 300, 400, and 500 C, which may be caused by the reduction of OeH, C¼O, and NeH groups after heating at high temperatures. For the CCSN300 sample, the absorption band is around 500e600 cm1, corresponding to the NieO vibration band [26], and is significantly weakened for the CCSN-400 and CCSN-500 samples. Fig. 4 presents SEM images of bare CCS, pristine NiO@Ni(OH)2, and CCSN samples. It can be seen that the surface of CCSN-400 and CCSN-500 aerogels is relatively smooth with few visible/neutral pores (Fig. 4aed). Meanwhile, the surface of the CCSN-300 sample (4) where C is the capacitance from the two-electrode tests (F g1), t is the discharge time (s), and DV is the working voltage window (V). 3. Results and discussion The phase structures of CS and CCSN composites were analyzed by XRD. Fig. 2 shows the XRD patterns of bare CS and various CCSN nanocomposites. The XRD pattern of the CS sample shows a broad weak band at 2q of 11 and 25 corresponding to the (020) and (110) planes in typical carbons. For the CCSN-300, CCSN-400, and CCSN-500 samples, the XRD pattern spectra exhibit diffraction peaks at 2q of 43.2 and 76 , corresponding to the (200) and (222) crystal planes of NiO nanoparticles, respectively. However, no diffraction peaks relating to CS were observed, indicating the formation of an amorphous carbonaceous structure in the prepared CCSN nanocomposites. The diffraction peaks at 2q of 39.2 and Fig. 2. XRD patterns of (a) bare CCS, (b) CCSN-300, (c) CCSN-400, and (d) CCSN-500 samples. Fig. 3. FTIR spectra of (a) bare CCS, (b) CCSN-300, (c) CCSN-400, and (d) CCSN-500 samples. 3 L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 Fig. 4. SEM images of (a) bare CCS, (b) pristine NiO@Ni(OH)2, (c) CCSN-500, (d) CCSN-400, (e) CCSN-300, and (f) TEM image of CCSN-300. CCSN-400 and CCSN-500 is of type IV, characteristic of adsorbents mesoporous. The hysteresis loop of CCSN-300 is of type H3 [33], showing that the sample contains many slit holes. The CCSN-300 delay loop is not closed. This phenomenon is common in materials with well-developed pore structures and may be related to the expansion effect of the microporous adsorbent gas [34,35] and pressure-dependent elastic deformation behavior [36]. The desorption curves of CCSN-300 changed relatively modestly, corresponding to the pore shape of the primarily cylindrical CCSN-300 sample. The pore size distribution graph according to Barrett e Joyner e Halenda (BJH) of the CCSN samples is shown in Fig. 6b. The pore distribution was mainly mesoporous and ranged from 3 to 8 nm without any macroporous features. The calculated maximum surface area for the CCSN-300, CCSN-400, CCSN-500 samples is approximately 38, 25, 22 m2 g1, respectively. The average pore diameter for the CCSN-300, CCSN-400, and CCSN-500 samples was around 3.5, 3.4, and 3.6 nm, respectively (Table 1). As an active material for supercapacitors, this porous nanolayer is helpful with high porosity and more active sites, resulting in a fast discharge rate for the redox reaction. The specific surface area and the pore volume of CCS are 817 m2 g1 and 0.083 cm3 g1, respectively, which is a good negative material when assembled with the CCSN in an ACS is high porosity, and pores can be observed clearly (Fig. 4e). At higher magnification, the porous surfaces and walls of the 3D porous lattice were filled with interconnected and open pores (Fig. 4f). Therefore, the high specific surface area and hierarchical porous structure in CCSN-300 aerogel are better than CCSN-400 and CCSN-500 samples. It indicated the high potential of CCSN300 aerogel for electrode materials. Fig. 4f shows the TEM image of the CCSN-300 sample with a hierarchical porous structure, which presents a well-distribution of the NiO and Ni(OH)2 nanoparticles on the porous CCS matrix. Fig. 5 shows the K-edge signals of C, Ni, and O and the EDX spectrum of the CCSN-300 sample. Once again, a uniform distribution of C, Ni, and O was observed, confirming the even deposition of NiO and Ni(OH)2 nanoparticles on the CCS sheets. A survey of the surface properties of CCS and different CCSN samples was carried out by BET measurement. Fig. 6a shows the nitrogen adsorptionedesorption isotherms. The isotherms of CCSN show a hysteresis ring with relatively high pressure (P/P0) between 0.0 and 1.0. The slope increases from 0.3 to 0.9, corresponding to a relatively high pressure indicating pore size mesopores [7]. The shape of the adsorption hysteresis loop is related to the pore shape. According to the IUPAC classification [33], the hysteresis loop of 4 L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 Fig. 5. (a) SEM images of CCSN-300, EDX mappings of (b) carbon, (c) nickel, (d) oxygen, and (e) EDX spectrum of the CCSN-300 sample. Fig. 6. (a) The BET nitrogen adsorption isotherm plot, and (b) the pore size distribution of the CCSN-300, CCSN-400, and CCSN-500 samples. curves of NiO@Ni(OH)2 and CCSN active materials at a scan rate of 50 mV s1 in the potential range from 0.0 to 0.4 V in a 6 M KOH electrolyte. The CV curve of the NiO@Ni(OH)2 and all CCSN samples show a pair of separate redox peaks on the CV curves, indicating that they both have characteristics of typical pseudo-capacitance device. The reduced specific surface area of CCSN compared to CCS may be the doping blocks of metal oxide and hydroxide particles into the pores of the carbon material. The working electrode's electrochemical performance was studied using a three-electrode system. Fig. 7a shows the typical CV 5 L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 There are two reasons for this phenomenon: (i) CS acts to prevent agglomeration of NiO and Ni(OH)2 nanoparticles and provides a high surface area, resulting in a more extensive electrical activity range for the redox reactions; (ii) CCSN-300 with a superior specific surface area is superior to other samples, making ion diffusion easier throughout the surface of the material. Fig. 7b presents the Nyquist plots of the CCSN-300, CCSN-400, and CCSN-500 electrodes. The inset shows the Nyquist plot at the high-frequency region. All three electrodes exhibited small charge transfer resistance (Rct), and no obvious semicircle appeared in the high-frequency region. In addition, the total resistance of the CCSN300 electrode is lower than the other two types. Fig. 7c shows the Table 1 Parameters on the pore structure of various chitosan-derived carbon aerogels. Sample SBET (m2 g1) Vpore (cm3 g1) dBJH (nm) CCS CCSN-300 CCSN-400 CCSN-500 817 38 25 22 0.083 0.046 0.084 0.094 3.5 3.5 3.4 3.6 caused by the reversible Farada transition between Ni2þ and Ni3þ. Among them, the CV curve of CCSN-300 has the largest area, indicating excellent electrochemical efficiency among electrodes. Fig. 7. (a) CV curves of the different electrodes at a scan rate of 50 mV s1 in 6M KOH, (b) Nyquist plots of the various electrodes, (c) Capacities of the various electrodes at different current densities, (d) CV curves of the CCSN-300 electrodes at different scan rates, (e) Galvanostatic discharge plots of the CCSN-300 electrode at different current densities, (f) The capacitance stability and coulombic efficiency of the CCSN-300 at 5 A g1. 6 L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 active mass. From the above data, the CCSN-300 electrode was chosen as the positive electrode to investigate the further electrochemical performance in supercapacitor devices. The electrochemical properties of CCS//CCSN-300 asymmetric supercapacitors were studied, and the results are shown in Fig. 8. For a supercapacitor to achieve good performance, it is necessary to ensure a charge balance qþ ¼ q. Therefore, the mass of electrode materials was optimized, and the mass ratio mþ/m was found to be about 0.24. The CV curve of the CCS electrode at a scan rate of 50 mV s1 with of the potential window 1.1 0.0 V as shown inset in Fig. 8a. The CV curves of the CCS electrode presented a nearly regular rectangular shape without obvious redox peaks, representing an electrical double-layer capacitive behavior [38]. In addition, the overall enhanced electrochemical performance of the CCS electrode due to the pseudo-capacitive contribution made by functional groups (N) alongside electric double capacitance originating from the physical interactions of electrode/electrolyte ions on the high surface area interface. The CV curves of asymmetric supercapacitors at different scan rates in the potential range of 0.0e1.5 V are presented in Fig. 8a. As can be seen, the shape of the CV curves does not change much as the scan rate increases from 2 to 200 mV s1, which indicates a good capacitance state of the asymmetric supercapacitor. Fig. 8b presents the discharge curves of asymmetric supercapacitors at current densities from 1.0 to 7.5 A g1 over a potential window of 1.5 V. The CCS//CCSN-300 device exhibits good capacitance retention even at high current densities, 209 F g1 at 1.0 A g1 and about 55% retention at a high current density of 7.5 A g1 as illustrated in Fig. 8c. Fig. 8d demonstrates the cyclic stability of the CCS//CCSN-300 supercapacitor after 10,000 cycles at a current density of 5.0 A g1. It shows good capacitance retention (84.3%) and coulombic efficiency (89.0%) over 10,000 cycles, opening up the potential application of CCS//CCSN-300 in supercapacitor technology. Fig. 8e shows the energy (E, Wh kg1) and power densities (P, W kg1) of the asymmetric device. It revealed a change in energy density values from 65 to 35 Wh kg1 and an increased power density value from 1500 to 11,250 W kg1 at different current densities. Besides, the energy density and power density of the CCS//CCSN-300 device are higher than those of some chitosanderived carbon and graphene-based supercapacitors in the literature (Table 3). LEDs have confirmed the practical application of the fabricated asymmetric supercapacitor. A 1.5 V LED is individually lit using two CCS//CCSN-300 devices connected in series (Fig. 8f). After charging the supercapacitor for 30 s, the LED bulb can be effectively illuminated for 2 min. This result opens a new direction for sustainable energy related to seafood waste as a valuable energy source for developing supercapacitors. capacities of the electrodes at different current densities. The capacities of the CCSN-300, CCSN-400, and CCSN-500 electrodes were calculated as 316, 102, and 28 mAh g1, respectively, at 1 A g1 current density. They indicated that the CCSN-300 electrode has the highest capacities, consistent with the CV curve survey results above. The redox peak current of the CCSN-300 electrode has increased significantly with an increasing scan rate (Fig. 7d). Furthermore, the anodic peak current densities and the cathode peak current densities increase linearly with the scan rate, indicating that the prepared carbon aerogel has abundant redox reaction during charge storage. Furthermore, clear redox peaks were observed at a high scanning rate (200 mV s1), which suggests the rapid transport of electrons and ions and the possibility of rate good of the prepared electrode. Galvanostatic discharge time was executed to inspect the stability of the CCSN electrode. The galvanostatic discharge plots of the CCSN-300 electrode at different current densities are presented in Fig. 7e. It can be observed that at low current densities, the discharge plots display a broader plateau. The related reactions can occur during the charging/discharging process as follows. NiO þ OH 4 NiOOH þ e (5) NiðOHÞ2 þ OH 4NiOOH þ H2 O þ e (6) Based on the galvanostatic discharge plots, the capacities of the CCSN-300 electrode were calculated as 316, 299, 265, 240, 238, 205, and 168 mAh g1, respectively, at a current density of 1.0, 1.5, 2.5, 3.0, 4.0, 5.0, 7.5 A g1. The degradation of capacitance at high current densities can be attributed to the large mesopores of the composite with diameters of 5e40 nm [37] and the destruction of the NiO and Ni(OH)2 nanoparticles. Table 2 compares the electrochemical performance of the CCSN-300 electrode with other related works. It indicates that the CCSN nanocomposite is comparable with reported chitosan-based electrode materials in the literature. To evaluate the capacitance stability of the CCSN-300 electrode, we evaluated the electrode capacitance after 10,000 charge/ discharge cycles at a current density of 5.0 A g1; the result is shown in Fig. 7f. The specific capacitance was reduced by about 24% from the original value after 10,000 cycles. In addition, the coulombic efficiency of the CCSN-300 electrode retention to 85e100% over the entire 10,000 cycles. The main reason may be the NiO or Ni(OH)2 in the composites decaying during the charge/ discharge processes. Besides, the contraction and volume expansion of NiO or Ni(OH)2 due to redox reactions during the charge/ discharge may lead to electron permeability errors and loss of Table 2 Comparison of the electrochemical performance between the CCSN-300 electrode and other previously reported related materials. Electrode materials Specific capacitance (F g1) Current density (A g1) Electrolyte Ref. Chitosan-based carbon Chitosan-based carbon Chitosan-based carbon Chitosan-based carbon Chitosan-based carbon Bagasse-based carbon Chitosan-Mxene Graphene-NiO Graphene-NiO Graphene-NiO CCSN-300 210 958.33 110 197 41 142.1 257 240 632 243 790 F g1 1 5 5 mV s1 0.2 1 0.5 5 3 mV s1 2 3 mV s1 1 6M 6M 6M 6M 1M 6M 3M 6M 6M 6M 6M [37] [39] [40] [23] [41] [42] [43] [44] [45] [46] This work 7 KOH KOH KOH KOH Na2SO4 KOH KOH KOH KOH KOH KOH L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 Fig. 8. (a) CV curves of the CCS//CCSN-300 device at different scan rates in 6M KOH, (b) Galvanostatic discharge plots at different current densities, (c) The capacitance retentions at different current densities, (d) The capacitance retention and coulombic efficiency at 5 A g1; e) Ragone plots at different current densities, and (f) two ASC devices connected in series. Table 3 Comparison of the energy density and power density between this study and previously reported devices. Positive materials Negative materials Energy density (Wh kg1) Power density (W kg1) Ref. Chitosan-based carbon Chitosan-based carbon Chitosan-based carbon Chitosan-based carbon Chitosan-based carbon Bagasse-based carbon Chitosan-Mxene Graphene-NiO Graphene-NiO Graphene-NiO CCSN-300 Chitosan-based Chitosan-based Chitosan-based Chitosan-based Chitosan-based AC AC AC AC AC Chitosan-based 5.62 43.75 5.8 27.4 28.74 19.74 19.31 47.3 30.56 47.5 65 120 516.25 1900 400 400 500 3906 140 2800 145 1500 [37] [39] [40] [23] [41] [42] [43] [44] [45] [46] This work carbon carbon carbon carbon carbon carbon 8 L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 4. Conclusion [13] Z. Zhihao, J. Kun, Z. Zitong, Y. Hao, C. Wei, H. Yongqing, F. Min, The yolk-shell nanorod structure of Ni3Se2@C electrodes boosting charge transfer and cyclability in high-performance supercapacitors, J. Colloid Interface Sci. 615 (2022) 133e140. [14] L. Huang, D. Chen, Y. Ding, S. Feng, Z. Wang, M. Liu, Nickel-cobalt hydroxide nanosheets coated on NiCo2O4 nanowires grown on carbon fiber paper for high-performance pseudocapacitors, Nano Lett. 13 (2013) 3135e3139. [15] C. Lamiel, N.V. Hoa, D. Tuma, J.J. Shim, Non-aqueous synthesis of ultrasmall NiO nanoparticle-intercalated graphene composite as active electrode material for supercapacitors, Mater. Res. Bull. 83 (2016) 275e283. [16] N.V. Hoa, J.J. Shim, Three-dimensional nickel foam/graphene/NiCo2O4 as highperformance electrodes for supercapacitors, J. Power Sources 273 (2016) 110e117. [17] N.V. Hoa, J.J. Shim, In situ growth of hierarchical mesoporous NiCo2S4@MnO2 arrays on nickel foam for high-performance supercapacitors, Electrochim. Acta 166 (2015) 302e309. [18] C. Xionga, B. Li, X. Lin, H. Liu, Y. Xu, J. Mao, C. Duan, T. Li, Y. Ni, The recent progress on three-dimensional porous graphene-based hybrid structure for supercapacitor, Compos. B Eng. 165 (2019) 10e46. [19] J. Shen, P. Dong, R. Baines, X. Xu, Z. Zhang, P.M. Ajayan, M. Ye, Controlled synthesis and comparison of NiCo2S4/graphene/2D TMD ternary nanocomposites for high-performance supercapacitors, Chem. Commun. 52 (2016) 9251e9254. [20] T.Y. Wei, C.H. Chen, H.C. Chien, S.Y. Lu, C.C. Hu, A cost-effective supercapacitor material of ultrahigh specific capacitances: spinel nickel cobaltite aerogels from an epoxide-driven sol-gel process, Adv. Mater. 22 (2010) 347e351. [21] P. Chen, T. Xiao, H. Li, J. Yang, Z. Wang, H. Yao, S. Yu, Nitrogen-doped graphene/ZnSe nanocomposites: hydrothermal synthesis and their enhanced electrochemical and photocatalytic activities, ACS Nano 6 (2012) 712e719. [22] P. Hao, Z. Zhao, Y. Leng, J. Tian, Y. Sang, R. Boughton, C.P. Wong, H. Liu, B. Yang, Graphene-based nitrogen self-doped hierarchical porous carbon aerogels derived from chitosan for high performance supercapacitors, Nano Energy 15 (2015) 9e23. [23] X.L. Li, H.L. Wang, J.T. Robinson, H. Sanchez, G. Diankov, H.J. Dai, Simultaneous nitrogen doping and reduction of graphene oxide, J. Am. Chem. Soc. 131 (2009) 15939e15944. [24] C. Wang, G. Zhong, W. Zhao, S. Wu, W. Su, Z. Zei, K. Xu, Chitosan-derived three-dimensional porous graphene for advanced supercapacitors, Front. Energy Res. 8 (2020) 61. [25] T.S. Trung, N.C. Minh, H.N. Cuong, P.T.D. Phuong, P.A. Dat, P.V. Nam, N.V. Hoa Nv, Valorization of fish and shrimp wastes to nano-hydroxyapatite/chitosan biocomposite for wastewater treatment, J. Sci. Adv. Mater. Dev. 7 (2022) 100485. [26] R. Vinodh, R.S. Babu, R. Atchudan, H.J. Kim, M. Yi, L.M. Samyn, Fabrication of high-performance asymmetric supercapacitor consists of nickel oxide and activated carbon (NiO//AC), Catalysts 12 (2022) 375. [27] S. Govindan, E.A.K. Nivetha, R. Saravanan, V. Narayanan, A. Stephen, Synthesis and characterization of chitosanesilver nanocomposite, Appl. Nanosci. 2 (2012) 299e303. [28] H. Abdolmohammad-Zadeh, Z. Ayazi, Z. Naghdi, Nickel oxide/chitosan nanocomposite as a magnetic adsorbent for preconcentration of Zn(II) ions, J. Magn. Mater. 488 (2019) 165311e165329. [29] Y. Zhang, Y. Shen, X. Xie, W. Du, L. Kang, Y. Wang, X. Sun, Z. Li, B. Wang, Onestep synthesis of the reduced graphene oxide@NiO composites for supercapacitor electrodes by electrode-assisted plasma electrolysis, Mater. Des. 196 (2020) 109111. [30] F. Davar, Z. Fereshteh, M. Salavati-Niasari, Nanoparticles Ni and NiO: synthesis, characterization and magnetic properties, J. Alloys Compd. 476 (2009) 797e801. [31] Y. Chen, D.L. Peng, D. Lin, X. Luo, Preparation and magnetic properties of nickel nanoparticles via the thermal decomposition of nickel organometallic precursor in alkylamines, Nanotechnology 18 (2007) 505703. [32] A. Drabczyk, S. Kudłacik-Kramarczyk, M. Gła˛ b, M. Ke˛ dzierska, A. Jaromin, ski, B. Tyliszczak, Physicochemical investigations of chitosanD. Mierzwin based hydrogels containing aloe vera designed for biomedical use, Materials 13 (2020) 3073. [33] Z.A. Lothman, A Review: fundamental aspects of silicate mesoporous materials, Materials 5 (2012) 2874e2902. [34] P. Chu, Q. Liu, L. Wang, E. Chen, X. Liao, Y. Liu, W. Huang, Y. Chen, Effects of pore morphology and moisture on CBMrelated sorption-induced coal deformation: an experimental investigation, Energy Sci. Eng. 9 (2021) 1180e1201. [35] J. Wang, X. Yang, D. Wua, R. Fu, M.S. Dresselhaus, G. Dresselhaus, The porous structures of activated carbon aerogels and their effects on electrochemical performance, J. Power Sources 185 (2008) 589e594. [36] T. Jia, M. Yang, F. Yu, X. Chen, L. Tan, G. Wang, 1-Octadecanol@hierarchical porous polymer composite as a novel shape-stability phase change material for latent heat thermal energy storage, Appl. Energy 187 (2017) 514e522. [37] L. Min, W. Xin, M. Taotao, Y. Pei, Z. Ziqi, M. Huihua, C. Minzhi, C. Weimin, Z. Xiaoyan, Rapid one-step preparation of hierarchical porous carbon from chitosanbased hydrogel for high-rate supercapacitors: the effect of gelling agent concentration, Int. J. Biol. Macromol. 146 (2019) 453e461. [38] J.H. Lee, S.Y. Lee, S.J. Park, Highly porous carbon aerogels for high-performance supercapacitor electrodes, Nanomaterials 13 (2023) 817. [39] S.A. Dida, N.A. Ameen, A. Jahangeer, M.A. Abdullah, N. Mu, U. Mohd, M.A. Saad, Ruksana, A. Tansir, Fabrication of hybrid nanocomposite derived from We have successfully synthesized a chitosan-derived carbon aerogel nanocomposite for supercapacitor application. The resulting composite material has a high capacity of 316 mAh g1 at a current density of 1.0 A g1. Besides, the assembled asymmetric device (CCS//CCSN) has a capacitance of 209 F g1 at 1.0 A g1. Furthermore, this ASC device has a high energy density of 65 Wh kg1 at a power density of 1500 W kg1 with cyclic stability of 84.3% after 10,000 cycles. The exemplary capacitive behavior is attributed to the unique features of chitosan-based carbon aerogels embedded with NiO@Ni(OH)2 nanoparticles with high specific surface area, pore volume, proper pore size, reasonable pore size distribution, and even distribution of nanoparticles. In practical testing, a series connection of two CCS//CCSN supercapacitors can illuminate LED bulbs (3 V) for 2 min with the 30s of charging time. The research suggests an excellent potential fabrication of low-cost and high-electrochemical performance nanomaterials for energy storage. Declaration of competing interests The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgments Le Hong Quan was funded by the Master, Ph.D. Scholarship Programme of Vingroup Innovation Foundation (VINIF), Code VINIF.2022. TS098. Coastal Branch of the Joint Vietnam - Russia Tropical Science and Technology Research Center, Vietnam support to carry out experiments. References [1] F. Min, Z. Zitong, C. Wei, Y. Hao, L. Ruitao, Carbon cloth supported flower-like porous nickel-based electrodes boosting ion/charge transfer characteristics of flexible supercapacitors, Carbon 199 (2022) 520. [2] Z. Zitong, Z. Zhihao, Z. Qingru, G. Fan, L. Qingyun, Z. Xixi, F. Min, Growth of MnCo2O4 hollow nano-spheres on activated carbon cloth for flexible asymmetric supercapacitors, J. Power Sources 492 (2021) 229669. [3] Z. Qingru, L. Wenzheng, Z. Zitong, Y. Hao, C. Wei, Y. Jing, F. Min, Facile growth of hierarchical SnO2@PPy composites on carbon cloth as all-solid-state flexible supercapacitors, J. Alloys Compd. 906 (2022) 164275. [4] Z. Zitong, G. Fan, Z. Zhihao, Z. Qingru, L. Qingyun, Y. Hao, F. Min, In-situ growth of MnCo2O4 hollow spheres on nickel foam as pseudocapacitive electrodes for supercapacitors, J. Colloid Interface Sci. 587 (2021) 56e63. [5] A. Trunov, Analysis of oxygen reduction reaction pathways on Co3O4, NiCo2O4, Co3O4-Li2O, NiO, NiO-Li2O, Pt, and Au electrodes in alkaline medium, Electrochim. Acta 105 (2013) 506e513. [6] J. Bejar, L. Alvarez-Contreras, J. Ledesma-Garcia, N. Arjona, L.A. Gerardo, An advanced three-dimensionally ordered macroporous NiCo2O4 spinel as a bifunctional electrocatalyst for rechargeable Zn-air batteries, J. Mater. Chem. 8 (2020) 8554e8565. [7] N.V. Hoa, P.A. Dat, N.V. Chi, L.H. Quan, A hierarchical porous aerogel nanocomposite of graphene/NiCo2S4 as an active electrode material for supercapacitors, J. Sci. Adv. Mater. Dev. 6 (2021) 569e577. [8] H.M. Jeong, J.W. Lee, W.H. Shin, Y.J. Choi, H.J. Shin, J.K. Kang, J.W. Choi, Nitrogen-doped graphene for highperformance ultracapacitors and the importance of nitrogen-doped sites at basal planes, Nano Lett. 11 (2011) 2472e2477. [9] P. Simon, Y. Gogotsi, Materials for electrochemical capacitors, Nat. Mater. 7 (2008) 845e854. [10] H. Jiang, P.S. Lee, C. Li, 3D carbon based nanostructures for advanced supercapacitors, Energy Environ. Sci. 6 (2013) 41e53. [11] F. Min, Z. Zhihao, C. Wei, H. Yongqing, Y. Hao, Honeycomb nickel-cobalt layered double hydroxides supported on carbon skeleton as highperformance electrodes in supercapacitors, J. Alloys Compd. 938 (2023) 168527. [12] F. Min, Z. Zitong, Z. Zhihao, Z. Qingru, C. Wei, L. Qingyun, Microwave deposition synthesis of Ni(OH)2/sorghum stalk biomass carbon electrode materials for supercapacitors, J. Alloys Compd. 846 (2020) 156376. 9 L.H. Quan, U.T. Dieu Thuy, P.V. Nam et al. Journal of Science: Advanced Materials and Devices 8 (2023) 100586 [43] L. Pu, J. Zhang, Y. Gao, H. Zhou, N. Naik, P. Gao, Z. Guo, N-doped MXene derived from chitosan for the highly effective electrochemical properties as supercapacitor, Adv. Compos. Hybrid Mater. 5 (2022) 356e369. [44] E.S. Agudosi, E.C. Abdullah, A. Numan, N.M. Mubarak, S.R. Aid, G.R. Pedro, M. Khalid, N. Omar, Fabrication of 3D binder-free graphene NiO electrode for highly stable supercapattery, Nat. Resour. 10 (2020) 11214. [45] A. Sankara, S.V. Chitra, M. Jayashree, M. Parthibavarman, T. Amirthavarshinid, NiO nanoparticles/graphene nanocomposite as high-performance pseudocapacitor electrodes: design and implementation, Diam. Relat. Mater. 122 (2022) 108804. [46] E.S. Agudosi, E.C. Abdullah, A. Numan, N.M. Mubarak, S.R. Aid, B.V. Raúl, G.R. Pedro, M. Khalid, N. Omar, Fabrication of 3D binder-free graphene NiO electrode for highly stable supercapattery, Sci. Rep. 10 (2020) 11214. chitosan as efficient electrode materials for supercapacitor, Int. J. Biol. Macromol. 120 (2018) 2271e2278. [40] D. Bo, G. Xiang, Y. Xu, F. Yan, H. Liang, Z. Jun, Z. Lina, Unique elastic N-doped carbon nanofibrous microspheres with hierarchical porosity derived from renewable chitin for high rate supercapacitors, Nano Energy 27 (2016) 482e491. [41] X.L. Zhang, C.N. Feng, H.P. Li, X.C. Zheng, N, O self-codoped hierarchical porous carbon from chitosan for supercapacitor electrode active materials, Cellulose 28 (2020) 437e451. [42] P. Hao, Z. Zhao, Y. Leng, J. Tian, Y. Sang, R. Boughton, C.P. Wong, H. Liu, B. Yang, U. Ahmad, Hierarchical porous carbon aerogel derived from bagasse for high performance supercapacitor electrode, Nanoscale 6 (2014) 12120. 10