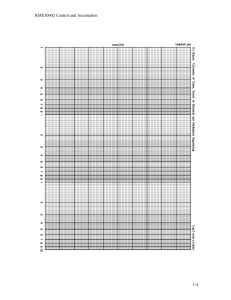

INNOVA - Via F. Baracca 15/B - 20010 Bareggio (MI) - Italy P.IVA 11863530157 - Tel. 02-90361802/02-90364635 - Fax 02-90361803 E-mail: innovait@tin.it – Internet: www.innovaitaly.com AUTOMATION At present there is a big confusion in the market about reverse osmosis automation so we need to clarify with the following information. Our plants can be equipped by PLC and LCD display with 2 different simple automation levels. Simple automation Models in this version have a system which allows to make easily the following steps: • Start • Stop • Flushing – Rinsing • Periodical membrane cleaning • Others modules connected to our plant (such as sand filter, EDI module, etc.) Simple automation: electric panel (internal and external view) Plants of such type require the frequent presence of a medium – high level technician who has to be trained on the RO technology and that must have enough time and capability. When this is not possible the RO plant can suffer damages and high running cost. In this case it is much more convenient our complete automation hereafter described. Exemple of plant with simple automation The system includes the following components: - Simple PLC of small dimensions - Frontal LCD panel with 2 lines The type of automation over described is the one proposed by the most part of our competitors, excluding the very few ones who offer plants with total automation. a b c (a) High pressure group with manual valves - Pressure safety switch and pressure gauge - (b) Flow meter with cartridge filter - (c) Flow meter with solenoid valves for water discharge out specification Full automation Models with full automatic PLC, beyond having the same functions over cited, can control in an automatic way the demineralized or desalted water production, and in particular: • regulate pressure valve VP on concentrate line in order to obtain the wished permeate water flow (value settable on LCD panel) • regulate recycling valve VR to recovery a part of discarder water and so reduce the inlet water flow. • obtain the correct recovery rate, given by produced water/inlet water, VP and VR valves setting. Exemple of plant with full automation INNOVA - Via F. Baracca 15/B - 20010 Bareggio (MI) - Italy P.IVA 11863530157 - Tel. 02-90361802/02-90364635 - Fax 02-90361803 E-mail: innovait@tin.it – Internet: www.innovaitaly.com The system includes: • High capacity PLC • Frontal LCD panel 5.7"available in several colours "touch screen" type • Pressure transducers instead of traditional pressostats • Electronic flow metes instead of sight flow meters • Inverter or soft start (on request) • Automatic modulating valves LCD Display allows to see and to execute the following functions: • see and choose operation mode (Production, Cleaning, etc.); • change of main functioning parameters • visualization of alarms/advices • graphical visualization of main process parameters Flow sheet - production Main menu a b c (a) Electronic flow meter on inlet water - (b) Electronic flow meter on outlet water - (c) Pressure trasducer and pressure gauge Our technology allows to run the plant all time at the best and without any operator. The only thing needed is a pe ri o di ca l i n fre que n t inspection. On request we can also supply: • Modem, for remote High pressure group with control of the main automatic modulanting functioning parameters valves of the plant, and the possibility to modify them if needed • Inverter, for complete control of high pressure pump – it alloy to reduce plant energy consumption and to optimize working conditions and flow-pressure Our exclusive software has been made by INNOVA technical engineers Our PLC is very easy to use, also for a generic operator and it is pre-programmed with factory values before being delivered. Production - Operation values Alarms Automatic flushing Full automation: electric panel (internal and external view) Cleaning phase – chemicals dosage and valves setting N.B.: Models for sea water desalination have not the recycling circuit because sea water inside membrane should be too much concentrated. So VR valve is not installed but remaining parts are the same. INNOVA - Via F. Baracca 15/B - 20010 Bareggio (MI) - Italy P.IVA 11863530157 - Tel. 02-90361802/02-90364635 - Fax 02-90361803 E-mail: innovait@tin.it – Internet: www.innovaitaly.com Recovery rate control The conversion rate, said also recovery rate, is the relation between the quantity of permeate flow produced by the RO plant and water inlet flow to the reverse osmosis plant. The remaining quantity is discarded or recirculated. It is commonly said concentrate (because of more concentrated in salts than inlet flow). Recovery rate is depending on several factors which are mainly raw water quality and its temperature, the selected operating pressure, the desired permeate quality and quantity. In most cases recovery rate varies from 60% to 70% in case of deionised water production and residual permeate salinity is normally 2 – 5 mg/l starting from raw water having less than 500 ppm. The remaining 30% - 40% can be sent to a softener and reused or, as said in another section, it can be reused for other purposes or drained off considering the low raw water cost. In case of sea water reject is 60% and it can be normally drained into sea. In traditional reverse osmosis plants recovery rate is normally set by hand closing or opening the pressure regulating valve on membrane outlet and on recycling circuit, but not all times the last one is installed by our competitors even if it is very useful for water saving. Manual set-up is quite easy and it is made during the initial start–up when our engineer explains the plant to the customers. But it normally happens that during production the permeate quantity changes due to several factors, like membrane fouling, variable feed pressure, variable raw water feed temperature and other factors. It is consequently necessary to inspect at least once a day the plant performances and operate manually on the 2 valves over said in order to adjust the recovery rate at the required level (on fully automatic plants this operation is not required because of automatically do). When this is not done, there is more raw water consumption, more electric energy cost, the membrane life is reduced even considerably, more consumption of filtering cartridges and chemicals for raw water pre-treatment. From an intensive and accurate survey made by our experts, we found that more than 50% of the customers using an RO plant have not enough technical background for properly operating the plant or men involved have not enough time to do it, being engaged in many other sectors. Due to this, produced water costs are normally 2 – 3 times higher and even more. This is the main reason why reverse osmosis plants are still seen with doubts and reserves. In the following prospect we make an estimation of the cost of produced water with RO system (correct run and incorrect run): Tabel with running cost estimation of produced water with RO system (correct run and incorrect run). . INNOVA - Via F. Baracca 15/B - 20010 Bareggio (MI) - Italy P.IVA 11863530157 - Tel. 02-90361802/02-90364635 - Fax 02-90361803 E-mail: innovait@tin.it – Internet: www.innovaitaly.com From figures over reported it appears that major cost for incorrect running is very high, especially for large models and / or 6.000 working hours/ years. If you consider that a reverse osmosis plant can work for 5-10 years before changing, the major cost is very remarkable. In order to avoid this waste of money, on request we can supply our plant with powerful PLC, automatic valves for recovery rate total control and/or inverter. Constant production of permeated water With same components used for automatic conversion rate operating it is possible to maintain constant flow of deionised or desalted water. This is obtained by means of electronic flow meters which send a signal to PLC on the base of l/h of produced water measured. On the base of value of produced water settled by display (litres per hours), the PLC program moves automatic pressure regulating valve an recirculating valve in order to obtain desired permeate flow and contemporarily the recovery rate at the pre-set point so as to keep it constant (recovery rate is set by display too). The pressure cannot overpass a pre-set maximum limit. When this is reached, the plant stop. Usually it becomes when membranes are almost clogged and, so, must be cleaned. Our software reportS on display when pressure vessels is too high and so is advisable to proceed with membranes cleaning1. Remote support and remote control We can supply in our full automatic plants different configuration: • remote control • supervisory control • remote assistance Further specific request will be valued case by case. With this advanced technology we can check from our main office at any time your plant running and modify, if request, the operating parameters to optimize production. High pressure pump with energy saving inverter Normal high pressure multistage centrifugal pumps operate at constant rpm (rotations per minute) but output flow is variable in relation to the selected operating pressure. So at low pressure flow is much higher than at high pressure and this is not good for a reverse osmosis plant for the following reasons. In order to have the required permeate quantity, at the beginning with new membranes one must operate at a lower pressure than later on, when membranes will be clogged. But at low pressure the pump gives a water flow higher than required, with consequent electric energy consumption much higher than necessary. Similarly, as said in another chapter, water temperature makes the permeate flow to change 3% more or less for any °C than 25°C reference temperature. So if during cold season water temperature decreases, a much higher operating pressure is required in comparison to hot season. In both cases (membranes fouling and 1 2 temperature lower or higher) one has to change the operating pressure but not the inlet flow or pump outlet because the recovery or conversion ra te must re ma i n constant. In order to obtain this, we make the centrifugal pump run at more or less rpm by means of a suitable inverter2 controlled by our PLC. With this technology the c e ntr i fuga l pump operates at constant flow like as a volumetric pump even changing operating pressure, as required by a reverse osmosis plant. This system allows to save electric energy and to optimize RO production. Inverter normally reduces 20%-30% electric consumption and purchase cast for such accessory is widely payback during plant-life. For models with full automation PLC and transducer In case of inverter failure the high pressure pump can be operated in normal version simply.