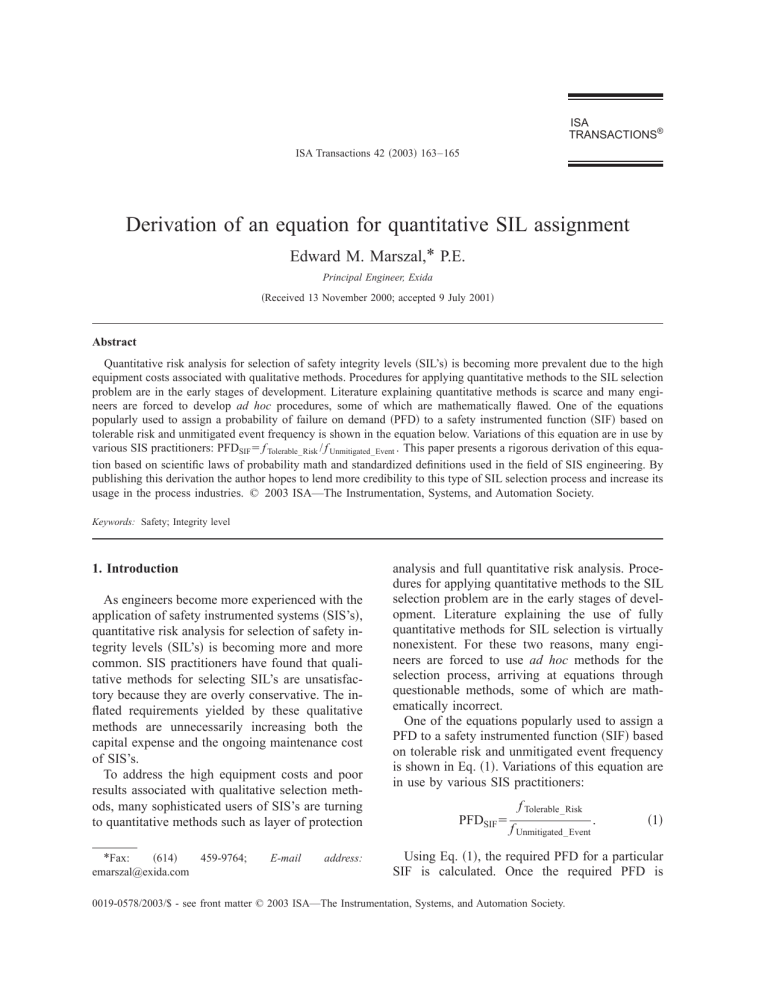

ISA TRANSACTIONS® ISA Transactions 42 共2003兲 163–165 Derivation of an equation for quantitative SIL assignment Edward M. Marszal,* P.E. Principal Engineer, Exida 共Received 13 November 2000; accepted 9 July 2001兲 Abstract Quantitative risk analysis for selection of safety integrity levels 共SIL’s兲 is becoming more prevalent due to the high equipment costs associated with qualitative methods. Procedures for applying quantitative methods to the SIL selection problem are in the early stages of development. Literature explaining quantitative methods is scarce and many engineers are forced to develop ad hoc procedures, some of which are mathematically flawed. One of the equations popularly used to assign a probability of failure on demand 共PFD兲 to a safety instrumented function 共SIF兲 based on tolerable risk and unmitigated event frequency is shown in the equation below. Variations of this equation are in use by various SIS practitioners: PFDSIF⫽ f Tolerable Risk / f Unmitigated Event . This paper presents a rigorous derivation of this equa– – tion based on scientific laws of probability math and standardized definitions used in the field of SIS engineering. By publishing this derivation the author hopes to lend more credibility to this type of SIL selection process and increase its usage in the process industries. © 2003 ISA—The Instrumentation, Systems, and Automation Society. Keywords: Safety; Integrity level 1. Introduction As engineers become more experienced with the application of safety instrumented systems 共SIS’s兲, quantitative risk analysis for selection of safety integrity levels 共SIL’s兲 is becoming more and more common. SIS practitioners have found that qualitative methods for selecting SIL’s are unsatisfactory because they are overly conservative. The inflated requirements yielded by these qualitative methods are unnecessarily increasing both the capital expense and the ongoing maintenance cost of SIS’s. To address the high equipment costs and poor results associated with qualitative selection methods, many sophisticated users of SIS’s are turning to quantitative methods such as layer of protection *Fax: 共614兲 emarszal@exida.com 459-9764; E-mail address: analysis and full quantitative risk analysis. Procedures for applying quantitative methods to the SIL selection problem are in the early stages of development. Literature explaining the use of fully quantitative methods for SIL selection is virtually nonexistent. For these two reasons, many engineers are forced to use ad hoc methods for the selection process, arriving at equations through questionable methods, some of which are mathematically incorrect. One of the equations popularly used to assign a PFD to a safety instrumented function 共SIF兲 based on tolerable risk and unmitigated event frequency is shown in Eq. 共1兲. Variations of this equation are in use by various SIS practitioners: PFDSIF⫽ f Tolerable – Risk f Unmitigated – Event . 共1兲 Using Eq. 共1兲, the required PFD for a particular SIF is calculated. Once the required PFD is 0019-0578/2003/$ - see front matter © 2003 ISA—The Instrumentation, Systems, and Automation Society. 164 Edward M. Marszal / ISA Transactions 42 (2003) 163–165 known, the required SIL is selected using the tables provided in standards ISA 84.01 and IEC 61508/61511 which equate SIL categories to ranges of PFD’s. P Tolerable⫽ P UnmitigatedEventPFDSIF . Solving the equation for probability of failure on demand of the safety instrumented function yields Eq. 共5兲: 2. Derivation PFDSIF⫽ The derivation of the SIL assignment equation begins with the law of probability multiplication, as shown in Eq. 共2兲, which is a fundamental scientific law: P (AandB) ⫽ P A P B . 共2兲 The probability of an unwanted event is the probability that an event occurs that will result in the accident if not prevented by the safety instrumented function 共SIF兲, and the SIF that is protecting against the unwanted event fails to operate on demand. Using the probability multiplication law, this situation can be mathematically stated as shown in Eq. 共2兲. The probability that an event occurs, which if not prevented by the SIF will lead to an unwanted event, is referred to as the unmitigated event: P Unwanted – Event ⫽ P Unmitigated – EventP SIF – Failure – on – Demand . 共3兲 For the purposes of the SIL selection problem, the terms whose probabilities are being discussed should be clarified. In order to make this problem useful, the probability at which an unwanted event is allowed to occur must be limited to a tolerable level. As such, the term P UnwantedEvent should be redefined as P Tolerable – Risk . It is important to note that the tolerable probability discussed here refers to the probability at which the specific event that a SIF is preventing is tolerable, as opposed to more general tolerable risk goals such as individual risk of fatality. As defined in ISA 84.01 and IEC 615108/61511, the probability that a SIF will fail is defined as the probability of failure on demand 共PFD兲. It is also important to note that PFD applies to a individual loops, called SIF, as opposed to the entire system that includes all of the safety functions performed by a particular logic solver. A more accurate description for P SIF Failure would thus be PFDSIF . After making these substitutions, the equation is as shown in Eq. 共4兲: 共4兲 P Tolerable P UnmitigatedEvent 共5兲 . The probability at which an event will occur is a function of the frequency at which that event has historically occurred and the time interval over which the probability is calculated. The fundamental equation relating probability and frequency is shown in Eq. 共6兲. Constant frequency is consistent with general assumptions used in reliability engineering and is consistent with empirical evidence: P⫽1⫺e ⫺ f t , 共6兲 where f is the frequency of the event, t is the time interval over which the probability is calculated. Using Eq. 共6兲 to describe both the probability of a tolerable event and the probability of the occurrence of an unmitigated event in Eq. 共5兲 yields Eq. 共7兲: PFDSIF⫽ 1⫺e ⫺ f tolerablet Tolerable 1⫺e ⫺ f UnmitigatedEventt UnmitigatedEvent 共7兲 . Taking the first two terms of a Taylor series expansion for each of the exponents yields Eqs. 共8兲 and 共9兲. It is important to note that this is only valid for relatively small values of the f -t products in the exponentials. e ⫺ f tolerable•t Tolerable⫽1⫹ 共 ⫺ f tolerable•t Tolerable兲 , 共8兲 e ⫺ f UnmitigatedEvent•t UnmitigatedEvent ⫽1⫹ 共 ⫺ f UnmitigatedEvent•t UnmitigatedEvent兲 , 共9兲 PFDSIF ⫽ 1⫺ 共 1⫺ f tolerable•t Tolerable兲 1⫺ 共 1⫺ f UnmitigatedEvent•t UnmitigatedEvent兲 ⫽ f tolerable•t Tolerable . f UnmitigatedEvent•t UnmitigatedEvent 共10兲 Edward M. Marszal / ISA Transactions 42 (2003) 163–165 The variable ‘‘t’’ represents the amount of time over which a probability is calculated. In all cases, solution of the problem requires that the probability for the tolerable event occurrence and the probability of unmitigated event occurrence be evaluated over the same reference time interval. Therefore t Tolerable is equal to t UnmitigatedEvent. Since the two terms are divided in Eq. 共10兲, they will both drop out of the equation, yielding the final result in Eq. 共11兲: PFDSIF⫽ f Tolerable f UnmitigatedEvent . 共11兲 Therefore PFDSIF⫽ f Tolerable – Risk f Unmitigated – Event . 共1兲 165 process control and release of gas and determined that the event would occur once in 1000 years if no SIF were fitted on the process. In the scenario presented, the tolerable risk frequency is set at 1/100 000 per year and the unmitigated event frequency is set at 1/1000 per year. The effectiveness of the SIF required to make the risk of the process is then calculated using Eq. 共1兲 as shown below: PFDSIF⫽ 1/100 000 ⫽0.01. 1/1000 共12兲 A SIF that has a PFD of 0.01 will reduce the risk from its current level to the tolerable region. Table 4.1 of the ISA 84.01 standard correlates a PFD of 0.01 to safety integrity level 2. Thus the SIL that should be selected as the integrity target for this SIF is SIL 2. Quod Erat Demonstratum. 4. Summary 3. Example of use Consider the following example of use of Eq. 共1兲 for a SIL assignment in the process industries. A chemical plant includes a process that handles a flammable gas. There is a possibility that the flammable gas might be released when control of the process is lost. The release of the flammable gas could result in ignition and an explosion. The loss prevention group reviewed the magnitude of the consequence and the corporate risk tolerance policy and determined that the tolerable frequency of the event is once in 100 000 years. The loss prevention group also performed a fault tree analysis of the events surrounding the loss of This paper presents a derivation of an equation used for quantitatively calculating the PFD required for a SIF. The purpose for presenting this derivation is to elevate the state of quantitative risk analysis for the purpose of SIL selection by providing background on the equations and methods that are used. Publishing a derivation of the equation used by SIS practitioners to calculate required PFD will lend more credibility to this type of SIL selection process. To that end, this paper provided a derivation that demonstrated the evolution of the final equation from the scientific laws of probability math and standardized definitions used in the field of SIS engineering.