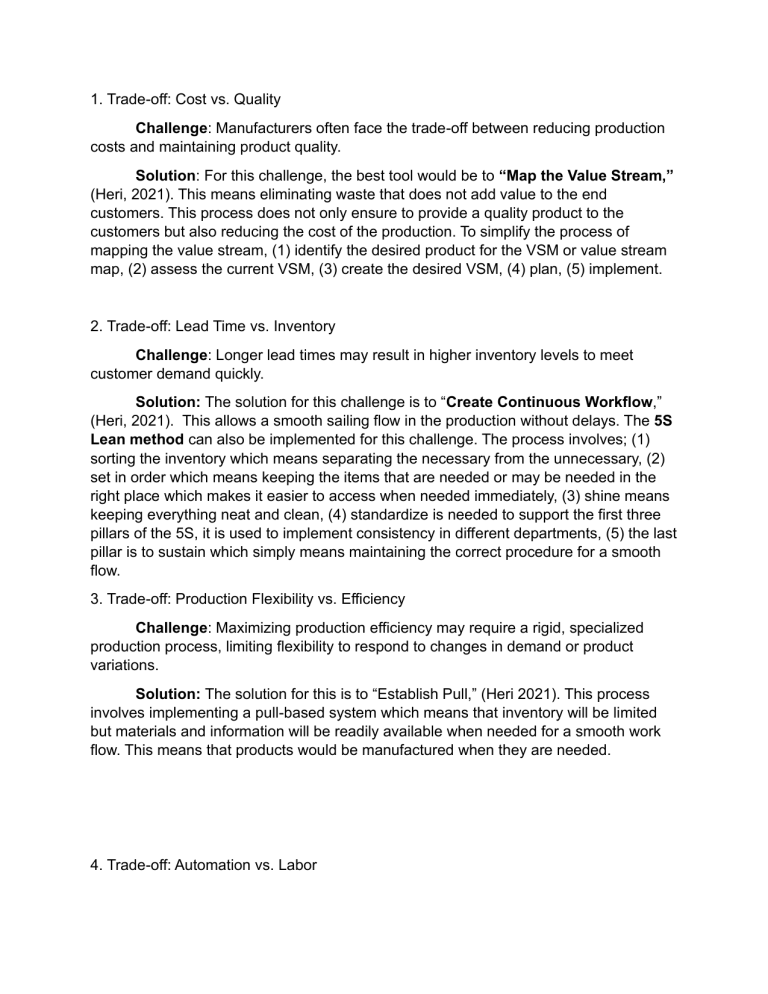

1. Trade-off: Cost vs. Quality Challenge: Manufacturers often face the trade-off between reducing production costs and maintaining product quality. Solution: For this challenge, the best tool would be to “Map the Value Stream,” (Heri, 2021). This means eliminating waste that does not add value to the end customers. This process does not only ensure to provide a quality product to the customers but also reducing the cost of the production. To simplify the process of mapping the value stream, (1) identify the desired product for the VSM or value stream map, (2) assess the current VSM, (3) create the desired VSM, (4) plan, (5) implement. 2. Trade-off: Lead Time vs. Inventory Challenge: Longer lead times may result in higher inventory levels to meet customer demand quickly. Solution: The solution for this challenge is to “Create Continuous Workflow,” (Heri, 2021). This allows a smooth sailing flow in the production without delays. The 5S Lean method can also be implemented for this challenge. The process involves; (1) sorting the inventory which means separating the necessary from the unnecessary, (2) set in order which means keeping the items that are needed or may be needed in the right place which makes it easier to access when needed immediately, (3) shine means keeping everything neat and clean, (4) standardize is needed to support the first three pillars of the 5S, it is used to implement consistency in different departments, (5) the last pillar is to sustain which simply means maintaining the correct procedure for a smooth flow. 3. Trade-off: Production Flexibility vs. Efficiency Challenge: Maximizing production efficiency may require a rigid, specialized production process, limiting flexibility to respond to changes in demand or product variations. Solution: The solution for this is to “Establish Pull,” (Heri 2021). This process involves implementing a pull-based system which means that inventory will be limited but materials and information will be readily available when needed for a smooth work flow. This means that products would be manufactured when they are needed. 4. Trade-off: Automation vs. Labor Challenge: Automating processes can reduce labor costs but may not be costeffective for small batch production or highly variable product lines. Solution: Heijunka or Level Scheduling would be best fit for this challenge. Which basically means planning the quantity or volume of the products to be produce in a day without compromising the inventory. This process involves planning the production based on the average order in a given time period. 5. Trade-off: Standardization vs. Customization Challenge: Balancing the need for standardized processes with customer demands for customized products can be challenging. Solution: Define the value or the customer value which means understanding what the customers could be wiling to pay for. Many of the customers are not aware of what they want which is why tools such as interviews, survery, etc., should be utilized in gathering information. 6. Trade-off: Workforce Efficiency vs. Employee Well-being Challenge: Striking a balance between optimizing workforce efficiency and ensuring employee well-being can be complex. Solution: The Gemba method aims to oversee the production while observing the employees and their day-to-day tasks. This technique allows the top management to gain insight of what is happening in the “real place” which are often overlooked. This process involves getting information through observation and engaging a conversation with the employees. This allows them to identify the problem or struggles that employees are experiencing that may affect their work efficiency. 7. Challenge: Overproduction Challenge: Overproduction can lead to high inventory levels, increased storage costs, and the risk of producing defective or outdated products. Solution: The method of “Just in Time” could be used in this challenge. This means only producing products when customers need it. This process involves understanding customers and making production schedules. 8. Challenge: Inefficient Processes Challenge: Inefficient processes lead to bottlenecks, increased lead times, and wasted resources Solution: The method Poka-Yoke or mistake-proofing would be best fit for this problem. This helps with preventing mistakes which causes waste and increases lead time. To simplify the process, the problem must be identified first in order to determine the necessary method and solution. The poka-yoke method could be implemented and taught to the employees to prevent future problems. 9. Trade-off: Employee Workload vs. Efficiency Challenge: Managing employee workloads while optimizing production efficiency. Solution: The “Gemba” can also be used in this scenario. If this process is implemented, the overload work of the employees can be manage which will result to more productive and efficient work. 10. Challenge: Variability in Demand Challenge: Dealing with fluctuating demand, seasonal variations, or unexpected spikes in orders. Solution: The “Heijunka” method could be used for this scenario which means that production will start according to the demand of the customers which lessen the burden of the demand and keeping up with order spikes. This also eliminates the overflowing of inventory. This process involves calculating the “takt time”, knowing the production amount and establishing the time for producing each product.