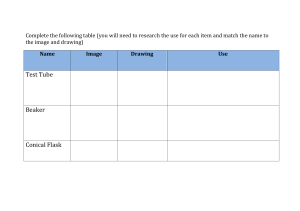

Research Training Report on DESIGNING AND STRESS ANALYSIS OF VARIABLE PITCH CONICAL SPRING Submitted By HARSH PANDEY B. Tech (IV Year), Mechanical Engineering, Sardar Vallabhbhai National Institute of Technology, Surat Training Period (14 June 2021 to 06 August 2021) Under the Guidance of Mr. AK Kashyap, Scientist `F` Aerial Delivery Research & Development Establishment(ADRDE) Defense Research & Development Organization Ministry of Defense, Government of India Agra Cantt – 282 001 1 CERTIFICATE This is to certify that the project report compiled by Mr. Harsh Pandey which is entitled ''Designing And Stress Analysis of Variable Pitch Conical Spring " is an authentic record of the effort carried out by him during the period of his summer training from 14 June 2021 to 06 August 2021. The report is aimed towards the partial fulfillment of the requirement of the training certificate duly accredited by Aerial Delivery Research & Delivery Establishment (ADRDE), Agra under the guidance of Mr. AK Kashyap, Scientist `F`. Training In-charge Mr. AK Kashyap, Scientist `F` Parachute Group ADRDE Agra, Uttar Pradesh 2 ACKNOWLEDGEMENT Aerial Delivery Research & Development Establishment (ADRDE) is one of the premier establishments of the Defense Research and Development organization (DRDO). This establishment is committed to provide the users state-of-the-art product & services to its customers in areas of the aerodynamic decelerators, pneumatic structures, aircraft arrester barriers and allied systems through research and development, innovation, team work and following up the same by continual improvement based on user's perception. I am highly obliged to Shri Arun Kumar Saxena, Director ADRDE, Agra for allowing me to associate with this esteemed establishment as a summer trainee in 'Parachute Group’ for one month period from 14 June 2021 to 06 August 2021. Further, I extend my heartfelt gratitude to the Scientist Mr. Gayasuddin Qureshi, for entrusting me with such a substantial project on "Designing and Stress Analysis of Variable Pitch Conical Springs'', and teaching the valuable Technical knowledge. Working in this project has certainly been a good learning experience and has reinforced my knowledge of Designing and Mechanical Finite Element Analysis to a great deal. Most importantly, I express my sincere thanks to Mr. AK Kashyap, Scientist `F`, for his unflagging guidance throughout the progress of this project as well as valuable contribution in the preparation and compilation of the text. I am thankful to all those who have helped me for the successful completion of my training at ADRDE. Agra. Harsh Pandey B. Tech (IV Year) Mechanical Engineering Sardar Vallabhbhai National Institute of Technology, Surat 3 ABOUT ADRDE Aerial Delivery Research & Development Establishment (ADRDE) is one of the premier establishments of the Defense Research and Development organization (DRDO). ADRDE deals with high-level research in defense related technologies. Various projects are under progress like parachutes for different applications, aerostats for surveillance, platforms for heavy drop, floatation for Space Recovery Experiment (SRE), aircraft arrester barrier system for air force, etc. Defense Research and Development organization (DRDO) is a premier organization of the Government of India, responsible for development of technology for use by the three services of defense in India. It was formed in 1958 by the merger of the Technical Development Establishment and the directorate of Technical Development and Production with the Defense Science Organization. My training area for around 8 weeks was in the Department of Parachute Group, Sub Division ABS, ADRDE Agra. 4 TABLE OF CONTENT S NO. 1. 2. 3. 4. i) ii) iii) iv) v) vi) vii) viii) 5. I. i) ii) iv) v) II. i) ii) iv) v) 6. 7. TOPIC Certificate Acknowledgment About ADRDE Literature Review Introduction Advantages of Variable pitch over Constant pitch Application of Variable Pitch Conical Spring Nomenclature Elementary Calculation Conical Spring With Constant Helix Angle. Conical Spring With Constant Stress at Solid. Conical Spring With Linear Behavior Case Study For Constant Spring With Constant Helix Angle Theoretical Calculation Modelling in SOLIDWORKS 2021 Stress Analysis in ANSYS R1 2021 Results For Constant Spring With Constant Stress at Solid. Theoretical Calculation Modelling in Solidworks 2021 Stress Analysis in ANSYS R1 2021 Results Conclusion References PAGE NO. 2 3 4 6 7 8 9 11 12 14 15 17 19 21 23 29 31 34 34 35 36 37 5 INTRODUCTION Springs are often used in mechanical devices for their ability to store and return energy. The range of applications is very wide. In some applications, conical springs can be preferred to cylindrical springs for their ability to have a smaller solid length. Depending on their geometry, they may be able to fully telescope, inducing a solid length equal to the wire diameter. Conical springs with constant pitch are quite well known but many other types of conical springs can be manufactured. For a given conical shape and a given number of turns, the properties of the spring can evolve significantly depending on the way the coils are distributed along the conical profile. In fact, cylindrical springs can simultaneously possess a constant pitch, a constant angle, a constant stress at solid and a linear behavior whereas, for a conical spring, only one property can be achieved at a time. Following properties of conical springs has Variable Pitch● Conical spring with a constant angle. ● Conical spring that leads to a constant stress when fully telescoped. ● Conical spring with a fully linear load-length behavior. 6 ADVANTAGES OF VARIABLE PITCH SPRINGS OVER CONSTANT PITCH SPRINGS Following are the advantages of variable pitch springs over constant pitch springs. ● Manufacturers find a number of advantages in the ability to vary spring pitch For example, conical springs (and other types of variable diameter spring) can be made to deflect at a linear rate. ● Variable pitch can also be used to prevent coils from fully closing in “soft” springs, or springs with a low spring rate. ● Both extension and compression springs can sometimes benefit from the inclusion of several rows of closed coils, which still allows flexibility but prevents tangling. ● A more technical advantage is the prevention of spring surge. Spring surge occurs when a spring’s natural frequency corresponds to the frequency of applied force, causing the spring to oscillate back and forth (similar to the way a slinky moves when held on both ends). ● Spring surge shortens the life of springs, and in some cases can cause immediate failure. ● By varying the spring pitch, manufacturers can prevent spring surge in high-frequency applications like valves and automatic weapons. 7 APPLICATION OF VARIABLE PITCH CONICAL SPRING IN ADRDE These Spring are used in various parachute system like ● ● ● ● ● ● Ram Air 9 Cell Parachute. Aircrew Parachute.. Controlled Aerial Delivery System (CADS). Space Payload Recovery Parachute. AN-32 Heavy Drop System Brake Parachute. Conical springs are also found in● ● ● ● ● ● High-Performance Vehicle Suspension Commercial Vehicle Suspension High-End Mattresses Gravity equilibrators Laser light applications Non-linear joints of robots. 8 NOMENCLATURE → α - current helix angle → θ - angle that defines the position on the conical helix → δ - deflection → δ1- deflection of the part of the spring that is freely deflect (from D1 to DL) → δ2 - deflection of the part that is at solid (from DL to D2) → τ - uncorrected stress → τi - constant uncorrected stress at solid. → d - wire diameter → dn - elementary coil → dr - elementary radial displacement on the conical shape → dl - elementary orthoradial displacement on the conical shape → dz - elementary axial displacement on the conical shape → D1 - minimum mean diameter → D2 - maximum mean diameter → DL - diameter that defines the limit between coils that are free to deflect and coils at solid for a given load P → F - initial spring flexibility → Fe - elementary flexibility → G - torsional modulus → La - active length → Lf - free length → Na - number of active coils → NL - number of active coils that defines the limit between coils that are free to deflect and coils at solid for a given load P → pe - elementary axial pitch → P - axial load → PM - load when all the coils come to solid (when DL=D1). → PT - load from which the spring starts to come to solid (when DL=D2) → r - running helix radius (varies from D1/2 to R) → R - current helix radius (varies between D1/2 and D2/2) 9 ⮚ The geometry of the conical helix can be defined as follows: ⮚ Global equation of the conical spring: ....................(1) In this equation, the helix angle α is a function of the current radius r and depends on the type of conical spring considered. ⮚ If the spring can telescope fully, the next equation must be satisfied for any value of θ : .........................(2) 10 ELEMENTARY CALCULATIONS ✔ The stress in an elementary coil defined by its radius r and subjected to a load P can be calculated using the formula proposed by Wahl (uncorrected stress of a coil that is free to deflect): ........................(3) ✔ The elementary flexibility is: ….....................(4) ✔ The elementary axial pitch is: ........................(5) Now analyzing following properties of conical springs that has Variable Pitch one by one● Conical spring with a constant angle. ● Conical spring that leads to a constant stress when fully telescoped. ● Conical spring with a fully linear load-length behavior. 11 CONICAL SPRING WITH A CONSTANT HELIX ANGLE With a constant helix angle (and a variable axial pitch) which induces a logarithmic spiral (the radial pitch increases with the radius)It can be noted that a conical spring can't have a constant pitch and a constant helix angle at the same time (only cylindrical springs have this property): ...................(i) Also, we know that So, we get ..........................(ii) Reversing the equation, we get - ...........................(iii) LOAD CALCULATION For a given load P, the limit between the coils that are free to deflect and the coils that are at solid is obtained for Pe = Fe*P. Thus, combining Eq. (4) and (5), the associated diameter can be defined: 12 The load from which the spring starts to come to solid (when DL=D2). The load when all the coils come to solid (when DL=D1 … Full Compression For a load lower than PT, the deflection curve is linear For a load between PT and PM, the deflection of the spring can be expressed as the addition of two deflections: the deflection of the part of the spring that is free to deflect (from D1 to DL) and the deflection of the part that is at solid (from DL to D2). 13 CONICAL SPRING WITH CONSTANT STRESS AT SOLID An elementary coil situated at a radius r and subjected to a load P induces an elementary deflection (when it is free to deflect) of: .............(I) When the elementary coil comes to solid, the following equation is obtained: .............(II) Combining Eqs. (I), (II) and (3), the value of the helix angle Eq (1) becomes- ...............(III) But we know that , ...............(IV) Eq. (III) and (IV) can be combined: 14 And Above Equation can be reversed: LOAD CALCULATION For a given load P, the diameter that separates the part of the spring that is free to deflect from the part that is already at solid: The load from which the spring starts to come to solid (when DL=D2). The load when all the coils come to solid (when DL=D1). CONICAL SPRING WITH LINEAR BEHAVIOR To obtain fully linear behavior, any elementary coil situated at a radius r should come to solid for the same load PM. The elementary deflection thus has to be equal to the elementary axial pitch. Thus Equations (4) and (5) give: 15 Eq. (1) then becomes: ..............(a) LOAD CALCULATION But we still know that Thus, the constant value of PM can be calculated: ..............(b) There is no transition load for this kind of conical spring. Eq. (a) can be simplified by exploiting Eq. (b): Above equation can be reversed: Being fully linear, this kind of spring is the only one to offer a conical shape at any compression state. The other kinds of springs have a conical shape only when uncompressed and their shape is non-conical when they are compressed, even for conical springs with constant pitch. 16 CASE STUDY- Given thatTotal Number of Coil = 6 Total Number of Active Coil, N a = 4 Free length, Lf =368 mm Diameter of wire, d= 5 mm Active Length, La = 368-6*5 = 338 mm Minimum mean diameter, D1= 56 mm Maximum mean diameter, D2 = 128 mm Conical Spring with a Constant Helix Angle, and calculating theoretically, ➢ Putting above values, we get tanα = 0.30 17 → Calculating the diameter of each coil of Spring R(π/2) = 29.48; D(π/2) = 58.97; R(5π/2) = 36.25; D(5π/2) = 72.50; R(9π/2) = 44.57; D(9π/2) = 89.15; R(13π/2) = 54.81; D(13π/2) = 109.62; → PT = 346.04 N = 35.28 kgf → PM = 1807.9 N = 184.35 kgf 18 19 20 MODELLING In the present work Conical spring with constant helix angle is taken for modeling and analysis, to compute and compare results. The dimensions for the same are obtained theoretically as calculated above. The 3D modeling of Conical spring is carried out using SOLIDWORKS 2021 and it is shown in Figure. The dimensions of the Variable Pitch Conical spring are shown below: 21 MATERIAL SELECTION Structural steel is the conventional material used for Conical spring. The properties of the materials used in the present work are as mentioned in Table Material Property Density ρ Unit weight γ Modulus of elasticity E (Young's modulus) Value ≈ 7850 kg/m3 ≈ 78.5 kN/m3 Shear modulus G G = E / [2 ⋅ (1 + ν)] ≈ 76923 MPa Poisson's ratio in elastic range ν Coefficient of linear thermal expansion α 0.30 12 ×10-6 °K-1 210000 MPa 22 FINITE ELEMENT ANALYSIS OF A CONICAL SPRING Finite Element Method (FEM) in ANSYS 2021 R1 software. ● Capable of solving large, complex problems with general geometry, loading, and boundary conditions. ● Increasingly becoming the primary analysis tool for designers and analysts. ● The Finite Element Method is also known as the Matrix Method of Structural Analysis in the literature because it uses matrix algebra to solve the system of simultaneous equations MESHING 23 DETAILS OF MESHING- 24 LOADS AND BOUNDARY CONDITIONS For this static structural analysis, the following boundary conditions are applied Applying Fixed Support at Coil of Diameter 128mm as shown below- Applying Load along Y axis in smaller coil of diameter 5 mm as shown below- 25 STATIC STRUCTURAL ANALYSIS 1. Applied load = 100 N Static structural analysis was carried out on Conical springs with constant helix angle and their corresponding deflections and von mises' stresses were determined. Total deflection and Von misses stress results are shown in, respectively. 26 2. Applied load = 500 N Static structural analysis was carried out on Conical spring with constant helix angle and their corresponding deflections and von misses' stresses were determined. Total deflection and Von mises stress results are shown in, respectively. 27 2. Applied load = 1500 N Static structural analysis was carried out on Conical spring with constant helix angle and their corresponding deflections and von misses' stresses were determined. Total deflection and Von misses stress results are shown in, respectively. 28 RESULTS OBSERVATION TABLE ● FOR CONICAL SPRING WITH CONSTANT HELIX ANGLE APPLIE D LOAD FEM ANALYSIS EQUIVALENT STRESS (In MPa) 100N 200N 500N 1000N 1500N 157.26 314.51 786.28 1572.6 2358.8 THEORETICAL ANALYSIS TOTAL EQUIVALENT DEFORMATIO STRESS N (In MPa) (In mm) 30.56 144 61.13 288 152.83 720 305.67 1440 386.85 2160 TOTAL DEFLECTION (In mm) 51.51 103.03 239.31 314.75 335.09 29 30 Conical Spring with a Constant Stress at Solid, and calculating theoretically R(π/2) = 29.02; D(π/2) = 58.04; R(5π/2) = 33.97; D(5π/2) = 67.94; R(9π/2) = 40.96; D(9π/2) = 81.92; R(13π/2) = 51.56; D(13π/2) = 103.13; = 554.02 N = 56.49 kg-f = 1266.34 N = 129.13 kg-f = 1444.67 N 31 32 33 MODELLING Modelling Conical Spring considering above calculated information in SOLIDWORK 2021 Software, we get- Analysis done in ANSYS 2021 R, same as done earlier. 34 RESULTS OBSERVATION TABLE ● FOR CONICAL SPRING WITH CONSTANT STRESS AT SOLID APPLIED LOAD FEM ANALYSIS THEORETICAL ANALYSIS TOTAL DEFORMATION TOTAL DEFLECTION 100 N 26.728 43.84 200 N 53.456 87.69 500 N 133.64 219.24 1000 N 267.28 330.83 1500 N 323.64 338 35 CONCLUSION ● Most research papers that exploit conical springs focus only on conical springs with a constant pitch. In order to increase the range of possibilities, this paper has studied conical springs with Constant helix angle and Conical Spring with Constant stress at Solid. ● The analytical study enabled us to define the theoretical geometry of the spiral in order to obtain a conical spring with a constant angle and with a constant maximum stress, load -length relation for fully telescoping springs. Based on the spirals proposed, the corresponding compression load has been calculated using the common assumptions for springs. ● The formulae can be used for any kind of conical shape (whether the spring is able to telescope or not). Tests on conical springs made using Fused Deposition Modeling showed that all the analytical formulae proposed enable the initial rates to be determined with accuracy. ● On the other hand, the theoretical formulae tend to under-estimate the load required to reach a given length. It would be of great interest to increase the accuracy of the predictions. Thus advanced finite element studies could be used to evaluate the effect of end coils, which is suspected to be the main cause of the gap. ● To reach the required accuracy, the studies would have to manage large displacements, contact between coils and contact between coils and the ground. Such finite element studies would be able to test several options for the end coil geometry and may help to find the most suitable ones. ● Another source of improvement could be to precisely identify the loads (forces and moments) induced by the end coils as they are, and to perform another analytical study to determine the associated load -length relations. 36 REFERENCES Analytical and Experimental Study of Conical Telescoping Springs With Nonconstant Pitch. By Manuel Paredes ,Université de Toulouse; INSA, UPS, Mines Albi, ISAE; ICA (Institut Clément Ader) 135, avenue de Rangueil, 31077 Toulouse, France Available from: https://www.researchgate.net/publication/330410037_Analytical_and_Experimenta l_Study_of_Conical_Telescoping_Springs_With_Nonconstant_Pitch. Constraint Analysis and Optimization of NES System Based on Variable Pitch Spring Zhenhang Wu, Manuel Paredes (B), and Sébastien Seguy, Institut Clément Ader UMR CNRS 5312, Université de Toulouse, UPS, INSA, ISAE-SUPAERO, MINES-ALBI, CNRS, 3 rue Caroline Aigle, Toulouse, France Available from: https://www.researchgate.net/publication/351040236_Constraint_Analysis_and_O ptimization_of_NES_System_Based_on_Variable_Pitch_Spring Optimal design of conical springs MANUEL PAREDES, EMMANUEL RODRIGUEZ, Université de Toulouse; INSA, UPS; LGMT (Laboratoire de Génie Mécanique de Toulouse); 135,avenue de Rangueil, F-31077 Toulouse, France Available from: https://www.researchgate.net/publication/220677684_Optimal_design_of_conical_ Springs 37