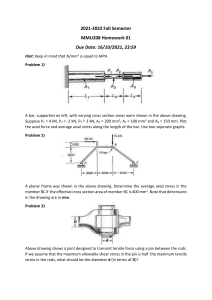

Dr B R AMBEDKAR NATIONAL INSTITUTE OF TECHNOLOGY JALANDHAR DEPARTMENT OF MECHANICAL ENGINEERING Design of Machine Element (ME 301) ASSIGNMENT-3 1. Design the longitudinal joint for a 1.25 m steam boiler, that is to carry a steam pressure of 5.25 N/mm2.you may assume the ultimate tensile strength of the plate as 420.0 N/mm2, crushing strength 650.0 N/mm2 and shearing strength 398.0 N/mm2. The joint efficiency may be assumed as 85%. Sketch the designed joint with all dimensions. 2. Design the circumferential and longitudinal joints of a 1.2 m diameter horizontal return tabular boiler which must carry a working pressure 1.15 N/mm2 gauze. The design will be based on a triple riveted, double strap but joint (unequal straps) for the longitudinal seam, with an assumed efficiency of 85 percent. This assumed efficiency will be checked later on by the calculations on the joint. Plates are to be made of mild steel having an ultimate strength in tension and shear of 430.0 N/mm2 and 330.0 N/mm2 respectively. Factor of safety may be taken as recommended by I.B.R. Assume the rivets to be 87.5% more stronger in double shear than in single shear. Prepare the working drawings of the design joint. 3. A triple riveted butt joint with double cover plates is used for the longitudinal joint of a Lancashire boiler having internal diameter 2.5 m. Working steam pressure 1.1 N/mm 2. The efficiency of the joint may be assumed as 85%. Calculate the plate thickness for mild steel of 459.0 N/mm2 ultimate tensile strength. The diameter of the rivet hole may be fixed by Unwin’s formula. Assume the ratio of tensile to shear stress as 1.23. Design a suitable circumferential joint also. Show the designed joined by a complete drawing, giving at least three rivets in the outer row. Calculate the actual efficiencies of your designed joints. 4. Draw two views of the end of a flat link for suspension bar, taking body of the bar to be 150 mm wide. The allowable stresses are, ft = 100 N/mm2, fs = 75 N/mm2, fc + 150 N/mm2. 5. A mild steel rod is hinged to a cast iron bracket by a steel pin as shown in figure. The rod carries a tensile load of 45 kN. Design the tie rod, eye end of the rod, fork end and pin. Allowable stress in the rod material is 80 N/mm2 in tension. Allowable shear and crushing stresses of the pin material are 45 N/mm2. Allowable tensile stress for cast iron is 28 N/mm2. 6. A sluice valve, used in a water-pipeline, consists of a gate raised by the spindle, which is rotated by the hand wheel. The spindle has single-start square threads. The nominal diameter is 36 mm and the pitch is 6 mm. The inner and outer diameters of the friction collar are 30 mm and 50 mm respectively. The coeffi cients of friction at the threads and the collar are 0.15 and 0.20 respectively. The weight of the gate is 7.5 kN and the frictional resistance to open the valve due to water pressure is 2.5 kN. Using the uniform wear theory for collar friction, calculate: (i) the torque required to raise the gate; and (ii) the overall effi ciency of the mechanism. 7. A double-threaded power screw, used for lifting a load, has a nominal diameter of 30 mm and a pitch of 6 mm. The coefficient of friction at the screw threads is 0.1. Neglecting collar friction, calculate: (i) efficiency of the screw with square threads; and (ii) efficiency with Acme threads (2q = 29°). 8. A bracket for supporting the travelling crane is shown in Fig. 1. The bracket is fixed to the steel column by means of four identical bolts, two at A and two at B. The maximum load that comes on the bracket is 5 kN acting vertically downward at a distance of 250 mm from the face of the column. The bolts are made of steel 40C8 (Syt = 380 N/mm2) and the factor of safety is 5. Determine the major diameter of the bolts on the basis of maximum principal stress. Assume (dc = 0.8d) 9. A welded connection of steel plates is shown in Fig. 2. It is subjected to an eccentric force of 50 kN. Determine the size of the weld, if the permissible shear stress in the weld is not to exceed 70 N/mm2. Fig. 1` Fig. 2